Abstract

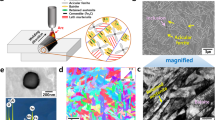

Many traditional approaches for strengthening steels typically come at the expense of useful ductility, a dilemma known as strength–ductility trade-off. New metallurgical processing might offer the possibility of overcoming this. Here we report that austenitic 316L stainless steels additively manufactured via a laser powder-bed-fusion technique exhibit a combination of yield strength and tensile ductility that surpasses that of conventional 316L steels. High strength is attributed to solidification-enabled cellular structures, low-angle grain boundaries, and dislocations formed during manufacturing, while high uniform elongation correlates to a steady and progressive work-hardening mechanism regulated by a hierarchically heterogeneous microstructure, with length scales spanning nearly six orders of magnitude. In addition, solute segregation along cellular walls and low-angle grain boundaries can enhance dislocation pinning and promote twinning. This work demonstrates the potential of additive manufacturing to create alloys with unique microstructures and high performance for structural applications.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$29.99 / 30 days

cancel any time

Subscribe to this journal

Receive 12 print issues and online access

$259.00 per year

only $21.58 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

References

Li, Z., Pradeep, K. G., Deng, Y., Raabe, D. & Tasan, C. C. Metastable high-entropy dual-phase alloys overcome the strength–ductility trade-off. Nature 534, 227–230 (2016).

Kimura, Y., Inoue, T., Yin, F. & Tsuzaki, K. Inverse temperature dependence of toughness in an ultrafine grain-structure steel. Science 320, 1057–1060 (2008).

Yamamoto, Y. et al. Creep-resistant, Al2O3-forming austenitic stainless steels. Science 316, 433–436 (2007).

Eoyama, M. et al. Bone-like crack resistance in hierarchical metastable nanolaminate steels. Science 355, 1055–1057 (2017).

Gludovatz, B. et al. A fracture-resistant high-entropy alloy for cryogenic applications. Science 345, 1153–1158 (2014).

Hofmann, D. C. et al. Designing metallic glass matrix composites with high toughness and tensile ductility. Nature 451, 1085–1089 (2008).

Kim, S.-H., Kim, H. & Kim, N. J. Brittle intermetallic compound makes ultrastrong low-density steel with large ductility. Nature 518, 77–79 (2015).

Jiang, S. et al. Ultrastrong steel via minimal lattice misfit and high-density nanoprecipitation. Nature 544, 460–464 (2017).

Wang, Y. M., Chen, M. W., Zhou, F. H. & Ma, E. High tensile ductility in a nanostructured metal. Nature 419, 912–915 (2002).

Fang, T. H., Li, W. L., Tao, N. R. & Lu, K. Revealing extraordinary intrinsic tensile plasticity in gradient nano-grained copper. Science 331, 1587–1590 (2011).

Yan, F. K., Liu, G. Z., Tao, N. R. & Lu, K. Strength and ductility of 316L austenitic stainless steel strengthened by nano-scale twin bundles. Acta Mater. 60, 1059–1071 (2012).

Wei, Y. et al. Evading the strength- ductility trade-off dilemma in steel through gradient hierarchical nanotwins. Nat. Commun. 5, 3580 (2014).

Wu, X. L. et al. Heterogeneous lamella structure unites ultrafine-grain strength with coarse-grain ductility. Proc. Natl Acad. Sci. USA 112, 14501–14505 (2015).

Herzog, D., Seyda, V., Wycisk, E. & Emmelmann, C. Additive manufacturing of metals. Acta Mater. 117, 371–392 (2016).

MacDonald, E. & Wicker, R. Multiprocess 3D printing for increasing component functionality. Science 353, 1512 (2016).

Khairallah, S. A., Anderson, A. T., Rubenchik, A. & King, W. E. Laser powder-bed fusion additive manufacturing: physics of complex melt flow and formation mechanisms of pores, spatter, and denudation zones. Acta Mater. 108, 36–45 (2016).

Kamath, C., El-dasher, B., Gallegos, G. F., King, W. E. & Sisto, A. Density of additively-manufactured, 316L SS parts using laser powder-bed fusion at powers up to 400 W. Int. J. Adv. Manuf. Technol. 74, 65–78 (2014).

Trelewicz, J. R., Halada, G. P., Donaldson, O. K. & Manogharan, G. Microstructure and corrosion resistance of laser additively manufactured 316L stainless steel. J. Miner. Metals Mater. Soc. 68, 850–859 (2016).

Prashanth, K. G. & Eckert, J. Formation of metastable cellular microstructures in selective laser melted alloys. J. Alloys Compd 707, 27–34 (2017).

Ion, J. C., Shercliff, H. R. & Ashby, M. F. Diagrams for laser materials processing. Acta Metall. Mater. 40, 1539–1551 (1992).

Thomas, M., Baxter, G. J. & Todd, I. Normalised model-based processing diagrams for additive layer manufacture of engineering alloys. Acta Mater. 108, 26–35 (2016).

Rawers, J., Croydon, F., Krabbe, R. & Duttlinger, N. Tensile characteristics of nitrogen enhanced powder injection moulded 316L stainless steel. Powder Metall. 39, 125–129 (1996).

Zieliński, W., Abduluyahed, A. A. & Kurzydłowski, K. J. TEM studies of dislocation substructure in 316 austenitic stainless steel strained after annealing in various environments. Mater. Sci. Eng. A 249, 91–96 (1998).

Nakanishi, T., Tsuchiyama, T., Mitsuyasu, H., Iwamoto, Y. & Takaki, S. Effect of partial solution nitriding on mechanical properties and corrosion resistance in a type 316L austenitic stainless steel plate. Mater. Sci. Eng. A 460–461, 186–194 (2007).

Liu, G. Z., Tao, N. R. & Lu, K. 316L austenite stainless steels strengthened by means of nano-scale twins. J. Mater. Sci. Technol. 26, 289–292 (2010).

Ravi Kumar, B., Sharma, S. & Mahato, B. Formation of ultrafine grained microstructure in the austenitic stainless steel and its impact on tensile properties. Mater. Sci. Eng. A 528, 2209–2216 (2011).

Ueno, H., Kakihata, K., Kaneko, Y., Hashimoto, S. & Vinogradov, A. Enhanced fatigue properties of nanostructured austenitic SUS 316L stainless steel. Acta Mater. 59, 7060–7069 (2011).

Lu, K., Yan, F. K., Wang, H. T. & Tao, N. R. Strengthening austenitic steels by using nanotwinned austenitic grains. Scr. Mater. 66, 878–883 (2012).

Albertini, C., Cadoni, E. & Solomos, G. Advances in the Hopkinson bar testing of irradiated/non-irradiated nuclear materials and large specimens. Phil. Trans. R. Soc. A 372, 20130197 (2014).

Mower, T. M. & Long, M. J. Mechanical behavior of additive manufactured, powder-bed laser-fused materials. Mater. Sci. Eng. A 651, 198–213 (2016).

Chen, X. H., Lu, J., Lu, L. & Lu, K. Tensile properties of a nanocrystalline 316L austenitic stainless steel. Scr. Mater. 52, 1039–1044 (2005).

Kumar, B. R., Sharma, S. & Mahato, B. Formation of ultrafine grained microstructure in the austenitic stainless steel and its impact on tensile properties. Mater. Sci. Eng. A 528, 2209–2216 (2011).

Fernandes de Lima, M. S. & Sankare, S. Microstructure and mechanical behavior of laser additive manufactured AISI 316 stainless steel stringers. Mater. Des. 55, 526–532 (2014).

Saeidi, K., Gao, X., Zhong, Y. & Shen, Z. J. Hardened austenite steel with columnar sub-grain structure formed by laser melting. Mater. Sci. Eng. A 625, 221–229 (2015).

Wang, D., Song, C. H., Yang, Y. Q. & Bai, Y. C. Investigation of crystal growth mechanism during selective laser melting and mechanical property characterization of 316L stainless steel parts. Mater. Des. 100, 291–299 (2016).

Zhang, K., Wang, S., Liu, W. & Shang, X. Characterization of stainless steel parts by laser metal deposition shaping. Mater. Des. 55, 104–119 (2014).

Mertens, A. et al. Mechanical properties of alloy Ti–6Al–4V and of stainless steel 316L processed by selective laser melting: influence of out-of-equilibrium microstructures. Powder Metall. 57, 184–189 (2014).

Amato, K. N. et al. Microstructures and mechanical behavior of Inconel 718 fabricated by selective laser melting. Acta Mater. 60, 2229–2239 (2012).

Gu, D. et al. Densification behavior, microstructure evolution, and wear performance of selective laser melting processed commercially pure titanium. Acta Mater. 60, 3849–3860 (2012).

Vrancken, B., Thijs, L., Kruth, J. P. & Van Humbeeck, J. Microstructure and mechanical properties of a novel beta titanium metallic composite by selective laser melting. Acta Mater. 68, 150–158 (2014).

Saeidi, K., Kvetkova, L., Lofajc, F. & Shen, Z. Austenitic stainless steel strengthened by the in situ formation of oxide nanoinclusions. Rsc Adv. 5, 20747–20750 (2015).

Tolosa, I., Garciandia, F., Zubiri, F., Zapirain, F. & Esnaola, A. Study of mechanical properties of AISI 316 stainless steel processed by ‘selective laser melting’, following different manufacturing strategies. Int. J. Adv. Manuf. Technol. 51, 639–647 (2010).

Sun, Z., Tan, X., Tor, S. B. & Yeong, W. Y. Selective laser melting of stainless steel 316L with low porosity and high build rates. Mater. Des. 104, 197–204 (2016).

Zhong, Y., Liu, L. F., Wikman, S., Cui, D. Q. & Shen, Z. J. Intragranular cellular segregation network structure strengthening 316L stainless steel prepared by selective laser melting. J. Nucl. Mater. 470, 170–178 (2016).

Murr, L. E. et al. Metal fabrication by additive manufacturing using laser and electron beam melting technologies. J. Mater. Sci. Technol. 28, 1–14 (2012).

Wu, J., Wang, X. Q., Wang, W., Attallah, M. M. & Loretto, M. H. Microstructure and strength of selectively laser melted AlSi10Mg. Acta Mater. 117, 311–320 (2016).

Tomota, Y., Lukas, P., Neov, D., Harjo, S. & Abe, Y. R. In situ neutron diffraction during tensile deformation of a ferrite-cementite steel. Acta Mater. 51, 805–817 (2003).

Clausen, B., Lorentzen, T. & Leffers, T. Self-consistent modelling of the plastic deformation of FCC polycrystals and its implications for diffraction measurements of internal stresses. Acta Mater. 46, 3087–3098 (1998).

Yan, K., Carr, D. G., Callaghan, M. D., Liss, K.-D. & Li, H. Deformation mechanisms of twinning-induced plasticity steels: in situ synchrotron characterization and modeling. Scr. Mater. 62, 246–249 (2010).

Mughrabi, H. Deformation-induced long-range internal stresses and lattice plane misorientations and the role of geometrically necessary dislocations. Philos. Mag. 86, 4037–4054 (2006).

Wang, Y. M. et al. Controlling factors in tensile deformation of nanocrystalline cobalt and nickel. Phys. Rev. B 85, 014101 (2012).

Wang, Y. M. et al. Defective twin boundaries in nanotwinned metals. Nat. Mater. 12, 697–702 (2013).

King, W. E. et al. Observation of keyhole-mode laser melting in laser powder-bed fusion additive manufacturing. J. Mater. Process. Technol. 214, 2915–2925 (2014).

Zeng, Z. et al. Gradient plasticity in graident nano-grained metals. Extreme Mech. Lett. 8, 213–219 (2016).

Rice, J. R. Inelastic constitutive relations for solids: an internal-variable theory and its application to metal plasticity. J. Mech. Phys. Solids 19, 433–455 (1971).

Asaro, R. J. & Rice, J. R. Strain localization in ductile single crystals. J. Mech. Phys. Solids 25, 309–338 (1977).

Kalidindi, S. R., Bronkhorst, C. A. & Anand, L. Crystallographic texture evolution in bulk deformation processing of FCC metals. J. Mech. Phys. Solids 40, 537–569 (1992).

Jang, D. & Atzmon, M. Grain-boundary relaxation and its effect on plasticity in nanocrystalline Fe. J. Appl. Phys. 99, 083504 (2006).

Rodrguez-Baracaldo, R., Benito, J. A., Caro, J., Cabrera, J. M. & Prado, J. M. Strain rate sensitivity of nanocrystalline and ultrafine-grained steel obtained by mechanical attrition. Mater. Sci. Eng. A 485, 325–333 (2008).

Kashyap, B. P. & Tangri, K. On the Hall–Petch relationship and substructural evolution in type 316L stainless steel. Acta Metall. Mater. 43, 3971–3981 (1995).

Quey, R., Dawson, P. R. & Barbe, F. Large-scale 3D random polycrystals for the finite element method: generation, meshing and remeshing. Comput. Methods Appl. Mech. Eng. 200, 1729–1745 (2011).

Plimpton, S. & Hendrickson, B. A new parallel method for molecular dynamics simulation of macromolecular systems. J. Comput. Chem. 17, 326–337 (1996).

Radjaï, F. & Dubois, F. Discrete-Element Modeling of Granular Materials (Wiley-ISTE, 2011).

Brilliantov, N. V., Spahn, F., Hertzsch, J.-M. & Pöschel, T. Model for collisions in granular gases. Phys. Rev. E 53, 5382–5392 (1996).

Silbert, L. E. et al. Granular flow down an inclined plane: Bagnold scaling and rheology. Phys. Rev. E 64, 051302 (2001).

Zhang, H. P. & Makse, H. A. Jamming transition in emulsions and granular materials. Phys. Rev. E 72, 011301 (2005).

Abaqus, Abaqus 6.13 Documentation (Dassault Systèmes, 2013).

Acknowledgements

The authors thank S. Khairallah, T. Haxhimali, G. Guss, S. Burke, P. Alexander, B. El-dasher, W. King and C. Kamash for their experimental assistance and/or inspiring discussion. J. Li is acknowledged for his initial contribution to the model set-up. R.T.O. acknowledges support from the US Department of Energy, Basic Energy Sciences, Materials Science and Engineering Division, under Contract No. DEAC02-07CH11358. This work was performed under the auspices of the US Department of Energy by Lawrence Livermore National Laboratory under contract No. DE-AC52-07NA27344. ChemiSTEM was performed at the OSU Electron Microscope Facility which is supported by NSF MRI grant number 1040588 and by the Murdock Charitable Trust and the Oregon Nanoscience and Micro-Technologies Institute. This research used resources of the Advanced Photon Source, a US Department of Energy (DOE) Office of Science User Facility operated for the DOE Office of Science by Argonne National Laboratory under Contract No. DE-AC02-06CH11357.

Author information

Authors and Affiliations

Contributions

Y.M.W., T.V., J.T.M., T.T.R. and M.K.S. characterized microstructures. T.V., J.Y., W.C. and Z.L. performed mechanical testing. Y.M.W., J.Y., N.P.C. and R.T.O. conducted in situ SXRD experiments and analysed the resultant data. P.J.D. and M.J.M. were involved with processing parameter development and sample print. Z.Z., Y.Z. and T.Z. constructed the models and conducted simulations. Y.M.W., T.V. and T.Z. drafted the initial manuscript. Y.M.W. conceived, designed, and led the project. All co-authors contributed to the data analysis and discussion.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Supplementary information

Supplementary Information

Supplementary Information (PDF 2428 kb)

Rights and permissions

About this article

Cite this article

Wang, Y., Voisin, T., McKeown, J. et al. Additively manufactured hierarchical stainless steels with high strength and ductility. Nature Mater 17, 63–71 (2018). https://doi.org/10.1038/nmat5021

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/nmat5021

This article is cited by

-

Additive manufacturing of defect-free TiZrNbTa refractory high-entropy alloy with enhanced elastic isotropy via in-situ alloying of elemental powders

Communications Materials (2024)

-

Critical role of slags in pitting corrosion of additively manufactured stainless steel in simulated seawater

Nature Communications (2024)

-

High fatigue resistance in a titanium alloy via near-void-free 3D printing

Nature (2024)

-

Multifunctional metallic nanocomposite for overcoming the strength–ductility trade-off

Scientific Reports (2024)

-

Manufacturing of high strength and high conductivity copper with laser powder bed fusion

Nature Communications (2024)