Abstract

It is of critical importance to improve toughness, strength and wear-resistance together for the development of advanced structural materials. Herein, we report on the synthesis of unoxidized graphene/alumina composite materials having enhanced toughness, strength and wear-resistance by a low-cost and environmentally benign pressure-less-sintering process. The wear resistance of the composites was increased by one order of magnitude even under high normal load condition (25 N) as a result of a tribological effect of graphene along with enhanced fracture toughness (KIC) and flexural strength (σf) of the composites by ~75% (5.60 MPa·m1/2) and ~25% (430 MPa), respectively, compared with those of pure Al2O3. Furthermore, we found that only a small fraction of ultra-thin graphene (0.25–0.5 vol%, platelet thickness of 2–5 nm) was enough to reinforce the composite. In contrast to unoxidized graphene, graphene oxide (G-O) and reduced graphene oxide (rG-O) showed little or less enhancement of fracture toughness due to the degraded mechanical strength of rG-O and the structural defects of the G-O composites.

Similar content being viewed by others

Introduction

Atomically thin graphene is one of the strongest materials; therefore, it is promising as a toughening/strengthening agent in ceramic-based structural materials1. Smaller nano-scale graphene, compared to conventional whisker/fiber reinforcement, would induce smaller flaws, potentially resulting in higher strength/toughness2. Considering the enormous surface area of graphene (e.g. single-layer graphene ~2630 m2/g), surprisingly small amounts of graphene would be enough to satisfy complete coverage of precursor nanoparticles (less than 1.0 vol%). In the case of carbon nanotube (CNT), it has been reported that higher reinforcement concentration (1 ~ 10 vol%) was generally required for the toughening and strengthening of CNT/ceramic composites2,3,4,5,6,7,8.

Moreover, graphene is a good candidate for solid lubrication that reduces the friction force between contact surfaces at micro- and nano-scale while protecting the coated surface9,10. A nanometer-thick surface layer of hard, strong and lubricating graphene on ceramic grains can lead to a significant improvement in contact-damage resistance, such as wear resistance due to a tribological effect of 2-dimensional (2D) graphene. However, previous studies on graphene tribology have focused on nano-scale friction and wear behavior (normal load <250 μN)9,10,11. On the other hand, micro-/macro-scale tribological studies of graphene have remained relatively unexplored, but there is an increasing need to utilize graphene's full potential for diverse tribological applications. There has been no report on the friction and wear behavior of ceramic-based graphene composites in micro- and macro-scale under high normal load (>20 N), which is important for contact-mechanical applications (e.g. bearing, valves, nozzles, armour, prostheses) and protective coating applications.

Structural materials for extreme environments (e.g. high temperature/pressure, nuclear radiation, chemicals) are required to be both strong and tough. However, strength and toughness (fracture-resistance) are mutually exclusive. High-strength materials are well-known to be associated with strong directional bonding and limited plasticity (e.g. dislocation mobility); hence, these in turn lead to lower toughness by minimizing the local relief of high stress12,13,14. Wear-resistant (contact-mechanical) applications, which are successfully commercialized to a greater extent than structural ceramics, still have a problem due to their brittleness when wear conditions are severe. In order to overcome those problems, a variety of ceramic composites that are reinforced with fibres15, carbon nanotubes (CNTs)2,3,4,5,6,7,8, or whiskers16,17,18, have been considered to date. Still, a large amount of reinforcement material (e.g., for SiC ~ 20 vol%) and high-pressure-sintering have been required to obtain sufficient density to achieve a ‘high’ fracture toughness (>5.5 MPa·m1/2) in such CMCs (e.g. SiC whisker/Al2O3 composite). Those CMCs have only been made by high-pressure-sintering methods such as Spark-plasma-sintering (SPS) or Hot pressing (HP), which requires special tools and thus incur high cost.

Recently, attempts have been made to develop advanced structural materials with improved toughness through the incorporation of graphene in the matrix because the high Young's modulus of mechanically exfoliated graphene (~1.0 TPa) makes it promising for the reinforcement of CMC1,19,20. However, to the best of our knowledge, there has been no report so far on the use of unoxidized graphene as an additive to improve the mechanical properties of bulk ceramics. It seems quite reasonable to use graphene oxide (G-O) or reduced graphene oxide (rG-O) for the mechanical property enhancement because, unlike graphene, they have dangling atoms and functional groups, which improve bonding with other matrix materials21,22. However, the Young's modulus of the rG-O was reported to be significantly smaller (~0.25 TPa) than that of unoxidized graphene (~1.0 TPa) reported by Gomez-Navarro et al.23 and Paci et al.24 In this respect, it appears that consistent, significant improvement in the fracture toughness of graphene-reinforced ceramics has yet to be demonstrated since the mechanical strength of the ‘graphene’ filler exhibits remarkable variation depending on the method of its synthesis25,26,27,28.

In this work, we report on the development of ceramic-based composite materials reinforced with unoxidized graphene, which did not go through any oxidation or reduction process. Remarkably, the addition of only 0.25–0.5 vol% of unoxidized graphene was observed to increase the fracture toughness by ~75% and the strength by ~25%. Furthermore, the wear rate for the composite was drastically reduced by a factor of ~1/11 under high normal load condition (25 N), benefitting from a tribological effect of the graphene layer along with enhanced fracture-resistance. These improvements were achieved by pressure-less sintering without the use of high-pressure-sintering. We believe that this is a new, cost-effective and environmentally benign synthesis of ceramic-based composites that are strong, tough and wear-resistant, created by the hybridization of mechanically strong graphene with brittle ceramic materials. Direct fracture toughness measurement by the SEVNB method revealed that unoxidized graphene shows a greater toughening effect than reduced graphene oxide due to fewer structural defects.

Results

Microstructure and Raman Analysis

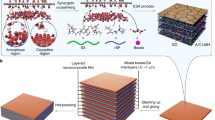

Figure 1 shows a schematic diagram of composite synthesis, indicating that graphene nanoplatelets (EG, rG-O, G-O) encapsulate precursory alumina particles (~300 nm) in colloidal suspension and the nanometer-thick graphene layers are embedded in micron-sized alumina grains after sintering. We compared mechanical properties of the sintered graphene(EG, G-O, rG-O)/alumina composite, which was related to the nature of the embedded graphenes. The EG (electrochemically expanded, chemically exfoliated graphene) has a nature of unoxidized graphene with much smaller defects and functional groups than reduced graphene oxide (rG-O) or graphene oxide (G-O), since the EG did not go through any oxidation process29.

Figure 2a shows a bright-field TEM image of the Al2O3/EG composite. The Al2O3 grains were well sintered even though the composite was prepared by a pressure-less sintering method. All the Al2O3 in this work have alpha-type structure. We observed a thin layer (~5 nm) which can be distinguished by relatively bright contrast at the grain boundary in Figure S1. Such a feature implies that carbonaceous matter exists at the grain boundary, so the elemental distribution across the grain boundary (red line) was characterized using EELS. The EELS line scan profile in Fig. 2b reveals that there is a carbon layer sandwiched between the Al2O3 grains at the grain boundary. The thickness of the carbon layer, which was determined by full-width at half-maximum of the carbon profile, was ~5 nm, indicating that the carbonaceous matter is a thin layer of EG. The microstructure in Fig. 2c implies the existence of graphene embedded in the grains, which can interfere with a crack propagation. As shown in Figure S1a, a thin layer (~2 nm) of few-layered graphene (FLG) was also observed at the grain boundary in the EG/LPS-Al2O3 composite. Here, the composites from glass-phase-coated Al2O3 are denoted as the liquid-phase-sintered alumina (LPS-Al2O3) composite. The comparison of carbonaceous matter in the composite was carried out by using EELS spectrum as shown in Fig. 2d. The σ* and π* peaks of graphene were sharply observed both in raw EG powder and in EG/Al2O3 and it could be clearly distinguished from the broad σ* peaks in G-O/Al2O3 and rG-O/Al2O3. This result demonstrates that the structure of EG was not significantly modified during the sintering process for the EG/Al2O3 composite.

TEM images and analysis of graphene/alumina composites.

(a) TEM images for 0.5 vol% EG/Al2O3 composite, showing a triple point in the sintered composite. The enlarged image of (a), showing a thin layer of EG (~5 nm) present between grains 1 and 2, is presented in Figure S1b. (b) Line scan measurement of EELS spectra across the grain boundary (red line in Fig. 2a), which shows that a thin carbon layer is present in the grain boundary. (c) The embedded EG in grains, which is exposed in the micro-crack of the EG/Al2O3 composite. (d) EELS spectra of the EG sheets and graphene (EG,G-O,rG-O)/Al2O3 composites are shown. This indicates that unoxidized nature and much smaller defect sites of EG were maintained during sintering process.

Figure 3 shows the typical Raman spectra of raw graphite, G-O, rG-O, EG and the G-O/Al2O3, rG-O/Al2O3, EG/Al2O3, G-O/LPS-Al2O3, rG-O/LPS-Al2O3 and EG/LPS-Al2O3 composites. For the G-O and rG-O, the D band becomes stronger and broader because of the higher level of disorder of the graphene layers, as shown in Fig. 3a. The defects also seem to have increased during the oxidation process30. On the other hand, EG showed a reduced D band compared to the G band (ID/IG ≅ 1/6), indicating that far fewer defects and functional groups were present in EG because of the absence of the oxidation process as shown in Fig. 3a29. (Note that the lateral dimensions of the EG platelets (roughly 1–5 μm) would mean that the Raman laser beam frequently intersects the edges of the EG platelets, so the D band may primarily be due to edge atoms.) The unoxidized nature of EG was also confirmed by X-ray Photoelectron Spectroscopy (XPS) analysis (Figure S2 in supporting information). The surface elemental compositions of the EG mainly consist of carbon (95.9%) and oxygen (4.1%). Therefore, the EG is expected to have a greater mechanical strength due to the fewer defect sites compared to the rG-O and G-O, which could contribute to enhancement of mechanical properties of the composite.

Raman spectra of graphite, graphene oxide (G-O), reduced graphene oxide (rG-O), exfoliated graphite (EG) and their various composites.

(a) Raman spectra with D, G and 2D peaks, (b) fitting of 2D peak. The reduced D peak intensity of EG compared to the rG-O and G-O indicates fewer structural defect sites of EG. The 2D band around 2700 cm−1 was numerically fitted by two peaks (2D1, 2D2) seen in the right plot. The fitted parameters are listed in Table S1. The 2D peaks for the EG-composites exhibit well-resolved features (2D1/2D2) compared to those of the G-O-composites.

The Raman spectra of the sintered composites (G-O/Al2O3, rG-O/Al2O3 and EG/Al2O3) confirm that the graphene is well-dispersed in the ceramic matrix and there was little or no damage to the graphene during the ball milling and sintering process in an inert atmosphere. The 2D band of the G-O/Al2O3, EG/Al2O3, G-O/LPS-Al2O3 and EG/LPS-Al2O3 composites consisting of two peaks, D1 and D2, was numerically fitted by two Lorentzian line shapes as shown in Fig. 3b and Table S1. The present EG/Al2O3 and EG/LPS-Al2O3 composites show a discernible splitting of the 2D band as seen in Fig. 3b, which means few-layer graphene or a thin nanolayer of EG was dispersed in the alumina matrix31,32. When graphene has less than 5 layers, a doublet or multiplet 2D band can be distinguished as revealed in previous results31,32. The present Raman results show that a few layer of EG was well dispersed in the alumina matrix, which is consistent with the TEM result (2–5 nm). On the other hand, G-O/Al2O3 and G-O/LPS-Al2O3 showed a smaller splitting of the 2D band, possibly implying that multiple layered G-O could have been dispersed in the matrix.

Figure 4a–d shows the SEM images of fracture surfaces for the specimens of (a) pure Al2O3, (b) 0.5 vol% G-O/Al2O3 composite, (c) 0.5 vol% EG/Al2O3 composite and (d) 0.5 vol% rG-O/Al2O3 composite. Note that microcracks were observed in the G-O composites with a lack of interfacial contact between the G-O and the alumina matrix, even though the G-O nanoplatelets are fairly homogeneously dispersed in the matrix of alumina.(Fig. 4b) This crack-like defects might be originated from open pores generated by gas evolution during G-O reduction at lower temperature. The presence of the nanoplatelets along grain boundaries was observed, which produced defects of several micrometers that could be potential origins of crack nucleation and propagation. This might become conspicuous in the present case of pressure-less sintering than high-pressure-sintering.

FE-SEM images for (a) Al2O3, (b) 0.5 vol% G-O/Al2O3 composite, (c) 0.5 vol% EG/Al2O3 composite, (d) 0.5 vol% rG-O/Al2O3 composite.

Figure 4c-d indicates that the α-Al2O3 grains were well sintered with interfacial bonding between the EG/rG-O and alumina grain. The black arrows in Fig. 4c–d indicate EG or rG-O nanosheets on the fracture surface.

On the other hand, intimate contact between the graphene and the alumina grain was observed in fully dense materials in Fig. 4c–d of 0.5 vol% EG/Al2O3 and 0.5 vol% rG-O/Al2O3 composites. The features are quite different from those of the G-O/Al2O3 nanocomposites, where the cohesion between the G-O nanoplatelets and the matrix was poor. The mechanical property of G-O/Al2O3 is inferior to those of the composites from EG and rG-O, which shows that the extent of interfacial bonding is a factor governing the toughness and strength of the composite.

Fracture Toughness and Strength

In our composites, the nature of graphene was found to significantly affect the fracture toughness of the resulting graphe/alumina composites. Grain boundary characteristics such as segregated phases or nanometers-thick films can affect the mechanical properties of the ceramic-based composites. However, any discernible changes in grain boundary structures due to graphene-embedding were found in TEM analysis of the present composites. Possible impurities such as lithium (from EG synthesis), oxidizing agent (from G-O/rG-O synthesis) and milling media were minimized by repeated washing and use of alumina media. Figure 5a shows that the EG (0.25 vol%)/Al2O3 composite showed the highest KIC value (4.72 MPa·m1/2) among the Al2O3 composites. The centrifuge rpm in the separation process of EG was 5000 rpm. The EG, which have the lowest defects, provided the greatest improvement in fracture toughness among the Al2O3 composites, ~48% increase at 0.25 vol% of graphene, compared to the pure alumina. The rG-O shows a moderate improvement of ~20% at 0.5 vol%, but the G-O has only marginal effects (<14%) on KIC. The G-O/Al2O3 composites showed only slightly increased KIC values (3.64 MPa·m1/2) at 1.0 vol% of G-O, which were listed in Table S2.

Comparision of mechanical properties between graphene composites and pure alumina.

(a) Fracture toughness (KIC) for Al2O3 and the composites. (b) Flexural strength values for Al2O3 and the composites. (c) Effect of unoxidized graphene (EG) on the wear rate of the EG/Al2O3 and EG/LPS-Al2O3 composites in severe wear environment (load: 25 N, sliding speed: 10 cm/s) and long sliding regime (27,700 cycle; 2,000 m). Inset shows optic images of wear tracks on sample surface. (d) a crack on the polished surface of 1.0 vol% EG/Al2O3 composite by indentation. The red arrows in Fig. 5d suggest crack bridging by embedded EG nanoplatelets.

The improvement of KIC due to the addition of graphene was also apparent at liquid-phase-sintered alumina (LPS-Al2O3). LPS-Al2O3 has plate-like grains as in Figure S3, which might contribute to the increase in fracture toughness (KIC: 4.04 MPa·m1/2) due to bridging of the grains. In this LPS-Al2O3, the addition of graphene resulted in further improvement of the fracture toughness. The EG(0.5 vol%)/LPS-Al2O3 composite showed the highest KIC value (5.60 MPa·m1/2) among the LPS-Al2O3 composites, which corresponds to ~75% increase, compared to pure alumina. The r-GO showed a moderate toughening effect of ~48% at 0.25 vol%. These results are possibly due to the degraded mechanical strength of the rG-O since more structural defects were present in the rG-O nanosheet compared to the EG. On the other hand, the G-O/LPS-Al2O3 composites showed lower KIC values (3.7-3.8 MPa·m1/2) than LPS-Al2O3, which were listed in Table S2. It seems that the volatilization of carbon oxide produces defects during the thermal reduction of G-O, which prevents toughening of the G-O/LPS-Al2O3 composites. (Fig. 4b).

Furthermore, our composites showed enhanced flexural strengths compared to pure Al2O3. (Fig. 5b) When compared to those of Al2O3 (330 ± 24 MPa), the strength of EG/Al2O3 and EG/LPS-Al2O3 increased by 28% (424 ± 34 MPa) and 29% (426 ± 59 MPa), respectively. The strength of rG-O/LPS-Al2O3 increased up to 468 ± 32 MPa (42%). The average grain sizes are approximately 1.0, 0.8, 1.2 and 0.8 μm for pure Al2O3, G-O/Al2O3, rG-O/Al2O3 and EG/Al2O3 composites, respectively, from SEM images. For pure LPS-Al2O3, G-O/LPS-Al2O3, rG-O/LPS-Al2O3 and EG/LPS-Al2O3 composites, the grain sizes are calculated to be 0.5, 0.38, 0.44 and 0.43 μm, respectively. Therefore, the increased strengths for the rG-O and EG composites were not consistently explained by Hall–Petch relationship, indicating the strengthening effect is not solely influenced by grain size. The degree of the strengthening for the composites is rather larger than that expected by Hall-Petch exponent, σ ∝ d−1/2, where d is average grain diameter. This cannot be explained by simple rule of mixture due to embedded graphenes as well. Therefore, we assume that high density of interfaces that block dislocation motion, which was introduced by embedded graphene, might enhance the strength of the composites. We believe that these results on the mechanical properties illustrate that the hybridization of mechanically strong graphene with a brittle ceramic material is potentially an important way to create a new composite with enhanced toughness and strength.

Even if the validity of indentation fracture (IF) method for brittle materials is questionable21,33, the toughening effect was consistent with high fracture toughness of 6.37 MPa·m1/2 and 5.94 MPa·m1/2 for EG(1.0 vol%)/Al2O3 and EG(1.0 vol%)/LPS-Al2O3 composites, respectively, by the IF method. These values are much higher than obtained by the standardized SEVNB method in our work, according to ASTM C1421 (Standard Test Method for Determination of Fracture Toughness of Advanced Ceramics at Ambient Temperature). We judge that fracture toughness measured by the IF method is rather exaggerated compared to the results obtained using by the SEVNB method since the IF method not an indirect measurement method as mentioned above5,14. The IF method, which was used as an indirect measurement method of toughness in a previous study21, could give misleading results for ceramic matrix composites because the average crack length produced by the indentation is not related to toughness in the same way as for monolithic ceramics5,14,33.

Wear Resistance and Tribological Effect

The unoxidized graphene embedded in alumina matrix was found to significantly enhance not only the toughness and strength but also the wear resistance of the composites due to its triboloical effect. Figure 5c shows the wear rate of the composites, which shows the beneficial effect of the addition of unoxidized graphene in the alumina matrix. Even in the regime of long duration cycle under high normal load (load: 25 N, sliding speed: 100 mm/s, wear cycle: 27,700; 2,000 m), the use of EG as an additive (0.25 vol%) in the Al2O3 matrix resulted in a marked reduction of the wear rate from 2.12 × 10−4 mm3/N·m to 3.74 × 10−5 mm3/N·m by a factor of ~1/6. The EG/LPS-Al2O3 also showed a reduced wear rate of 3.98 × 10−5 mm3/N·m. The friction coefficients (COF) decreased from 0.637 to 0.448 and 0.454 for EG(0.25 vol%)/Al2O3 and EG(0.25 vol%)/LPS-Al2O3, respectively. (Figs. 5c and 6c) Furthermore, the EG/Al2O3 and EG/LPS-Al2O3 composites with higher loading of graphene (1.0 vol%) exhibited much lower wear rate values of 2.18 × 10−5 mm3/N·m and 1.87 × 10−5 mm3/N·m, respectively, which were reduced from that of pure Al2O3 by one order of magnitude. The friction coefficients (COF) were measured to be 0.449 and 0.365 for EG(1.0 v%)/Al2O3 and EG(1.0 v%)/LPS-Al2O3 composites, respectively.

Proposed toughening and wear resistance mechanism induced by graphene.

(a) A schematic diagram showing crack propagation interfered with by crack bridging and crack deflection is shown. A schematic representation of fracture toughness measurement by the Single-Edge V-Notch Beam (SEVNB) method using a parallelepiped specimen is also presented. (b) A schematic showing graphene-assisted lubrication at the sliding contact interface in wear test condition. (c) Friction coefficients of the Al2O3, EG/Al2O3 and EG/LPS-Al2O3. (d) Raman spectrum for worn surface of counter part (WC ball), which shows transfered graphene from the composites.

Discussion

Toughening and Wear-resistance Mechanism

The result that the increase in fracture toughness (KIC) is higher than the increase in flexural strength (σf), might come from the rising R-curve (or T-curve) in the graphene/alumina composite because, without rising R-curve, the improvement in fracture toughness must be proportional to the strength in the brittle fracture of ceramics34. Typically, in brittle ceramics, rising R-curve comes from phase transformation or bridging contributions behind the tip during crack propagation34. Toughening by crack-tip shielding due to dislocation and micro-crack cloud has been successful in metallurgical engineering and concrete mechanics. However, no evidence of these concepts was found in the microstructure of our composites. Instead, in our composite, the most probable mechanism is crack bridging due to the evidence of the bridging graphene in the microstructure. (Fig. 6a).

Figure 5d shows abundant bridges behind the crack tip, which was produced by Vickers indentation of 98N. Even though the observed bridging might not come from single layer graphene, it shows clearly the existence of bridging contribution from graphene nanoplatelets. Such a bridging mechanism has been widely reported in the ceramic composites containing at least a few vol% of whiskers or fibers15,16,17,18,35. However, in our graphene composites, the dimensions of the bridging elements are much smaller and their distribution is very homogenous throughout the microstructure. Specifically, the individual graphenes are so thin that they are believed to preside along most grain boundaries, impeding crack propagations in every single grain distance. Moreover, the homogeneous distribution of graphene nanoplatelets along the grain boundaries can overcome the drawback of the directional dependence of fracture toughness in the usual whisker or fiber reinforced composites.

Remarkable improvements in the wear resistance of the composites appear to be related to less grain pull-out during wear test. Cho et al. reported that the wear rate of alumina consists of two steps: deformation dominated- and grain pull-out dominated-wear36. The insets of Fig. 5c show that the EG addition to the alumina matrix reduced grain pull-out, which was shown as reduced black contrasts (scars, scratch marks) in the wear tracks. This reduced pull-out might be due to less tangential force applied to alumina grains and higher fracture toughness of the composites. In this stage, it is not easy to separate two effects exactly, but it is quite obvious that only small amount, 0.25–1.0 vol%, of unoxidized graphene was sufficient to such improvements in wear-resistance.

It appears that enhanced fracture toughness of EG(0.25 vol%)/Al2O3 and EG(0.25 vol%)/LPS-Al2O3 contributes to the reduction of the wear rate (~1/6), compared to pure Al2O3. On the other hand, further improvements in wear resistance of EG(1.0 vol%)/Al2O3 and EG(1.0 vol%)/LPS-Al2O3 reveal important contributions of reduced friction by higher loadings of EG because they show relatively lower KIC values than EG(0.25 vol%)/Al2O3 and EG(0.25 vol%)/LPS-Al2O3.(Fig. 7a–c) As shown in Fig. 6c, the friction coefficient decreased with an increasing EG concentration, which resulted in drastically reduced wear rate by ~1/11 for EG(1.0 vol%)/LPS-Al2O3. Furthermore, graphene or graphitic phases, transferred from the composites, were observed in the as-worn surface of counterparts, as shown in Raman spectra (Fig. 6d). This also supports that sliding wear mechanism took place in the contact zone rather than abrasion or pull-out. Another noticeable point is that, unlike thin graphene film on a substrate37,38, the embedded graphene in the matrix exhibits much longer duration time (up to >27,000 cycle under normal load of 25N) for the lubrication because new graphene surface is continuously exposed at the grain boundary during wear test. For the graphene coated steel37,38, the friction coefficient is fairly low (~0.2) for the first 500 cycles (under normal load of <5N), but it eventually reach the values of the pristine (0.7–0.8) due to worn-out of the graphene coating.

Dependence of fracture toughness on volume fraction of graphene and centrifugation speed.

(a) fracture toughness (KIC) values for the G-O/Al2O3, rG-O/Al2O3, EG/Al2O3, G-O/LPS-Al2O3, rG-O/LPS-Al2O3 and EG/LPS-Al2O3 nanocomposites as a function of graphene (G-O/rG-O/EG) concentration. (b) Evolution of KIC values for EG/Al2O3 composites with respect to the centrifuge rpm of EG. A schematic diagram, showing debonding and pull-out of graphene in the graphene-matrix interface, is shown in inset. (c) Evolution of KIC values for EG/LPS-Al2O3 with respect to the centrifuge rpm of EG, (d) Fracture toughness for EG (0.25/0.5 vol%)/Al2O3 and EG (0.25/0.5 vol%)/LPS-Al2O3 composites versus centrifuge rpm of EG. The EG obtained at 5000 rpm was found to be optimal to the fracture toughness enhancement.

Concentration and Size Effects of Graphene

In our synthesized composites, the toughening effect was the largest at small amounts of graphene (0.25–0.5 vol%) and decreased slowly with increasing graphene concentration, regardless of the nature of graphene (G-O, rG-O, EG).(Fig. 7a) Figure 7b shows the largest increase in toughness of the EG/Al2O3 composite with respect to the EG addition of 0.25 vol%, from 3.1 to 4.72 MPa·m1/2 (~48% increase). For the liquid-phase-sintered (LPS) samples, the fracture toughness of the composite from the EG precursor reached up to 5.60 MPa·m1/2 at an EG concentration of 0.25/0.5 vol%, an increase of ~75% compared to pure Al2O3. (Fig. 7c).

It should be noted that, in our composites, peak KIC values were obtained at 0.25–0.5 vol% of graphene, which is contrast to the previous works on carbon nanotube (CNT)/alumina composites3,4,5,6,7,8 or whisker-reinforced alumina16,17,18. The CNT/alumina composite usually showed the greatest improvement in fracuture toughness at 1 ~ 10 vol% CNT concentration and whisker-reinforced alumina at >10 vol%35. This high amount of CNTs or whisker for toughening impedes considerably sintering of ceramics, which requires high-pressure densification processes such as hot pressing and spark plasma sintering. Furthermore, in the case of CNT/ceramic composites3,4,5,6,7,8, in which the reinforcement concentration is high, the strength value was reported to be decreased as a result of relatively high structural flaw concentration9.

The result that the peak KIC values were observed at the reinforcement concentration of 0.25–0.5 vol%, is consistent with theoretical graphene concentration (~0.34 vol%) for the complete monolayer coverage of alumina precursor (~300 nm) considering the theoretical surface area of single-layer graphene (~2630 m2/g). The result implies that the EG is well-dispersed and then sintered with monolayer or bilayer (at least) coverage of precursory alumina particle and such ultra-thin graphene (~2 nm, Fig. S1a) has a more effective toughening effect than thicker multilayered platelets. The reinforcement concentration of graphene is much lower than that of carbon nanotubes (1 ~ 10 vol%)3,4,5,6,7,8. Furthermore, such a small amount of reinforcement is also beneficial to the suppression of flaw formation in pressure-less sintering under an inert atmosphere. As a result, sufficient relative densities (>95%) can be obtained only by sintering under ambient condition because of the relatively low reinforcement concentration, compared to previous results21.

The reinforcement (graphene)–matrix interface is usually characterized by the critical shear stress needed to debond the interface and the subsequent shear resistance for a relative sliding of the reinforcement and matrix. When the maximum shear stress reaches the interface shear strength, the debonding at the reinforcement–matrix interface occurs and then the reinforcement is pulled out, as shown in the schematic diagram of debonding/pull-out of the reinforcement in the interface (inset of Fig. 7b)34. In this work, in order to investigate the effect of debonding and pull-out on the toughness, we compared the KIC values according to the size of EG (lateral dimension and thickness). The lateral dimension and thickness of the graphene are determined by centrifuge rpm in the separation process, which was found to affect the fracture toughness of the composites. Figure 7d shows the evolution of fracture toughness in relation to centrifuge rpm in the separation process of EG, which reflects the vertical (thickness) and lateral dimensions of the EG in the Al2O3 and LPS-Al2O3 composites. As the centrifuge rpm in the separation process increased from 1,000 to 13,000 rpm, the vertical and lateral dimensions of the EG were expected to decrease. The average size of the EG aggregate observed by optical microscope was found to be ~100 μm, ~20 μm and ~10 μm (Figure S4). As seen in Fig. 7d, the composite from the EG obtained by 5,000 rpm showed the highest fracture toughness; the average size of the EG aggregate observed by optical microscope was ~20 μm. It seems that when a larger EG (~100 μm @ 1,000 rpm) is introduced as a reinforcing phase, it could produce a structural defect causing a fracture. This critical size has been known to be around 10 μm when an inflexible second phase such as ceramic is involved. As for the smaller EG separated at 13,000 rpm, the crack bridging effect seems to be weaker than that of EG separated at 5,000 rpm due to its smaller lateral dimension.

In conclusion, we have shown that ultra-thin unoxidized graphene (2–5 nm) is remarkably effective in enhancing the fracture toughness, wear-resistance and flexural strength of the alumina ceramics at significantly lower graphene concentration (0.25–0.5 vol%) in comparison to carbon nanotubes (1 ~ 10 vol%). The fracture toughness (KIC) and strength of the composite increases by ~75% and ~25%, respectively, compared with those of pure Al2O3. Furthermore, we found that the wear-resistance remarkably increases by one order of magnitude due to the tribological effect of the embedded graphene along with enhanced mechanical property. It appears that a hard and lubricating graphene layer on the alumina grains shields the specimen surface from wear environments and prevents the cracking or falling out of alumina grains. It has been also found that unoxidized graphene, EG, shows a greater toughening effect compared to G-O and rG-O due to fewer defect sites as observed in the Raman spectra. This new cost-effective and environmentally benign route to graphene/ceramic composites with an enhanced mechanical property allows us to extend their application to many more fields in advanced structural materials, protective coating for micro-mechanical systems and contact-damage-resistant materials since pressure-less sintering is free of constraints regarding the shape and size of specimens.

Methods

Graphene Synthesis

Graphite flakes (~150 μm), phosphoric acid (~85.0%), sulfuric acid (~98.0%), potassium permanganate (>99.0%) and hydrochloric acid (~37%) were purchased from Sigma Aldrich and used as received. The G-O was prepared based on a modified Hummer's method39. The rG-O suspension was prepared according to the work by Park et al40. The EG dispersed in N,N-dimethylforamide (DMF) was prepared by ultrasonication of eletrochemically expanded graphite according to the study by Wang et al29.

Composite Synthesis

For the homogeneous dispersion of G-O, rG-O and EG in the ceramic matrices, the following steps were taken. First, stable colloidal suspensions of the exfoliated G-O, rG-O and EG were produced in water, a mixed solvent of DMF/H2O (99:1) and DMF, respectively. For rG-O, the mixed solvent of DMF and H2O was found to be most effective for homogeneous dispersion40. Second, alumina slurries were prepared by mixing AES-11 (~300 nm, Sumitomo Co. Ltd) or glass-phase (calcium silicate) coated Al2O3 for liquid-phase-sintering41 with a dispersant (Cerasperse, San Nopco Co. Ltd.) and then ball milling for 24 h to create homogeneous slurries. DMF was used as the solvent of the slurries for the rG-O and EG. The composites from the AES-11 and glass-phase coated Al2O3 are denoted as the Al2O3composite and the liquid-phase-sintered alumina (LPS-Al2O3) composite, respectively. Third, the slurries in water and DMF were added to the dispersed G-O and rG-O/EG suspensions, respectively and then ball-milled for 24 h using alumina ball media. The volume percentages of G-O, rG-O and EG were varied from 0.25 vol% to 1.5 vol% (estimated using the density of graphite, 2.25 g/cm3). Fourth, the resulting mixed slurry was dried, sieved (~45 μm) and then shaped into bar-type specimens (10 mm × 10 mm × 40 mm) by uniaxial press and subsequent cold isostatic press (200 MPa). Finally, the pressed compacts of the composites were sintered in an electrical furnace to form sintered composites for 3 h under flowing Ar gas (>5 N, 3 L/min). The heating rate was 10°C/min. The sintering temperatures for the Al2O3 and LPS-Al2O3 composites were 1700°C and 1450°C, respectively.

Mechanical Property Measurement

The fracture toughness (KIC) was measured according to standard methods for ceramics, ASTM C1421 (Standard Test Method for Determination of Fracture Toughness of Advanced Ceramics at Ambient Temperature). Measurements of the fracture toughness (KIC) were made using the single edge V-notch beam (SEVNB) method using a parallelepiped specimen (3 × 4 × 30 mm3), machined with a diamond blade, containing a notch. The notch was about 0.8–1.2 mm in depth (α ~ 0.25) and 200 μm in initial width. The root-radius of the notch was about 10 μm with a V-notch angle (β) of ~ 20°. No additional pre-crack was made for KIC measurement. The loading span distance for three-point bending was 16 mm. The flexure mode of 3-point or 4-point with a supporting span of 16, 30, or 40 mm does not affect the fracture toughness values42. A universal testing machine (Inspekt Table 250 KN, Hegewald & Peschke) was used and the loading velocity was about 0.5 mm/min. The flexural strength (σf) was measured using a parallelepiped specimen (2.5 × 3 × 30 mm3) with 1.0 inch loading span according to ASTM C1161-2C (Standard Test Method for Flexural Strength of Advanced Ceramics at Ambient Temperature). The number of specimens for toughness and strength measurements were >5 and >10, respectively. Tribological studies were performed at room temperature using a multi-purpose tribometer (MPW 110, Neoplus inc.) with a ball on disk contact geometry according to KS L 1606 (Determination of friction and wear characteristics of monolithic ceramics by ball-on-disc method). The surfaces were carefully prepared by polishing down to surface roughness below 0.04 μm. As a counterpart, the tungsten carbide ball of 9.5 mm diameter was used. The normal load during the tribotests was performed at 25 N load and a wear track of 11.5 mm radius was used in each flat. The sliding speeds for wear rate and friction coefficient measurements were 10 cm/s and 2.5 cm/s, respectively. The total wear cycles were 27,700 (2,000 m) and 1,250 (90 m), respectively.

Characterization

The final densities of the sintered compacts were determined by the Archimedes method with deionized water as the immersion medium. The microstructure of the sintered specimens was examined by field emission scanning electron microscopy (SEM). The Raman spectra of the sintered specimens were collected using an inVia Reflex System (Renishaw, UK). The radiation source was a laser of 514.5 nm wavelength. Microstructural characterizations were carried out by using a TEM/STEM system equipped with a probe Cs corrector (JEM-ARM 200F with Schottky type FEG operated at 200 kV, equipped with CEOS Cs-corrector). TEM samples were prepared using a focused ion beam system (FIB, Helios Nanolab 600, FEI). Electron energy loss spectroscopy (EELS) experiments were performed with an Enfina system from Gatan Inc.

References

Lee, C., Wei, X. D., Kysar, J. W. & Hone, J. Measurement of the Elastic Properties and Intrinsic Strength of Monolayer Graphene. Science 321, 385–388 (2008).

Padture, N. P. Multifunctional Composites of Ceramics and Single-Walled Carbon Nanotubes. Adv. Mater. 21, 1767–1770 (2009).

Zhan, G. D., Kuntz, J. D., Wan, J. & Mukherjee, A. K. Single-Wall Carbon Nanotubes as Attractive Toughening Agents in Alumina-based Nanocomposites. Nature Mater. 2, 38–42 (2002).

Fan, J. P. et al. Toughening and Reinforcing Alumina Matrix Composite with Single-wall Carbon Nanotubes. Appl. Phys. Lett. 89, 121910–93 (2006).

Wang, X., Padture, N. P. & Tanaka, H. Contact-Damage-Resistant Ceramic/Single-Wall Carbon Nanotubes and Ceramic/Graphite Composites. Nat. Mater. 3, 539–544 (2004).

Sun, J., Gao, L. & Jin, X. Reinforcement of Alumina Matrix with Multi-walled Carbon Nanotubes. Ceram. Intern. 31, 893–896 (2005).

Sun, J., Gao, L. & Li, W. Colloidal Processing of Carbon Nanotube/Alumina Composites. Chem. Mater. 14, 5169–5172 (2002).

Cha, S. I., Kim, K. T., Lee, K. H., Mo, C. B. & Hong, S. H. Strengthening and Toughening of Carbon Nanotube Reinforced Alumina Nanocomposite Fabricated by Molecular Level Mixing Process. Scrip. Mater. 53, 793–797 (2005).

Kim, K.-S. et al. Chemical Vapor Deposition-Grown Graphene: The Thinnest Solid Lubricant. ACS Nano 5, 5107–5114 (2011).

Lee, C. et al. Frictional Characteristics of Atomically Thin Sheets. Science 328, 76–80 (2010).

Lee, C. et al. Elastic and Frictional Properties of Graphene. Phys. Stat. Solidi. B 246, 2562–2567 (2009).

Ritchie, R. O. The Conflicts between Strength and Toughness. Nat. Mater. 10, 817–822 (2011).

Launey, M. E. & Ritchie, R. O. On the Fracture Toughness of Advanced Materials. Adv. Mater. 21, 2103–2110 (2009).

Sheldon, B. W. & Curtin, W. A. Tough to Test. Nat. Mater. 3, 505–506 (2004).

Hyuga, H., Jones, M. I., Hirao, K. & Yamauchi, Y. Fabrication and Mechanical Properties of Si3N4/Carbon Fiber Composites with Aligned Microstructure Produced by a Seeding and Extrusion Method. J. Amer. Ceram. Soc. 87, 894–899 (2004).

Zhang, P., Hu, P., Zhang, X., Han, J. & Meng, S. Processing and Characterization of ZrB2-SiCW Ultra-High Temperature Ceramics. J. Alloys Compd. 472, 358–362 (2009).

Zhang, X., Xu, L., Du, S., Han, W. & Han, J. Crack-healing Behavior of Zirconium Diboride Composite Reinforced with Silicon Carbide Whiskers. Scrip. Mater. 59, 1222–1225 (2008).

Niihara, K. New Design Concept of Structural Ceramics-Ceramic Nanocomposites. J. Ceram. Soc. Jpn. 99, 974–82 (1991). Zhao, J. et al. Mechanical behaviour of alumina–silicon carbide nanocomposites. J. Amer. Ceram. Soc. 76, 503–510 (1993).

Yu, M.-F., Files, B. S., Arepalli, S. & Ruoff, R. S. Tensile Loading of Ropes of Single Wall Carbon Nanotubes and Their Mechanical Properties. Phys. Rev. Lett. 84, 5552–5555 (2000).

Stankovich, S. et al. Graphene-based Composite Materials. Nature 442, 282–286 (2006).

Walker, L. S., Marotto, V. R., Rafiee, M. A., Koratkar, N. & Corral, E. L. Toughening in Graphene Ceramic Composites. ACS Nano 5, 3182–3190 (2011).

Wang, K., Wang, Y., Fan, Z., Yan, J. & Wei, T. Preparation of Graphene Nanosheet/Alumina Composites by Spark Plasma Sintering. Mater. Res. Bull. 46, 315–318 (2011).

Gomez-Navarro, C., Burghard, M. & Kern, K. Elastic Properties of Chemically Derived Single Graphene Sheets. Nano Lett. 8, 2045–2049 (2008).

Paci, J. T., Belytschko, T. & Schatz, G. C. Computational Studies of the Structure, Behavior upon Heating and Mechanical Properties of Graphite Oxide. J. Phys. Chem. C 111, 18099–18111 (2007).

Suk, J. W., Piner, R. D., An, J. H. & Ruoff, R. S. Mechanical Properties of Monolayer Graphene Oxide. ACS Nano 4, 6557–6564 (2010).

Liu, J., Yan, H. & Jiang, K. Mechanical properties of graphene platelet-reinforced alumina ceramic composites. Ceram. Intern. 39, 6215–6221 (2013).

Liu, J., Yan, H., Reece, M. J. & Jiang, K. Toughening of zirconia/alumina composites by the addition of graphene platelets. J. Europ. Ceram. Soc. 32, 4185–4193 (2012).

Porwal, H., Tatarko, P., Grasso, S., Khaliq, J., Dlouhý, I. & Reece, M. J. Toughening of zirconia/alumina composites by the addition of graphene platelets. Carbon 64, 359–369 (2013).

Wang, J., Manga, K. K., Bao, Q. & Loh, K. P. High-Yield Synthesis of Few-Layer Graphene Flakes through Electrochemical Expansion of Graphite in Propylene Carbonate Electrolyte. J. Amer. Chem. Soc. 133, 8888–8891 (2011).

Stankovich, S. et al. Synthesis of Graphene-based Nanosheets via Chemical Reduction of Exfoliated Graphite Oxide. Carbon 45, 1558–1565 (2007).

Gupta, A., Chen, G., Joshi, P., Tadigadapa, S. & Eklund, P. C. Raman Scattering from High-Frequency Phonons in Supported n-Graphene Layer Films. Nano Lett. 6, 2667–2673 (2006).

Ferrari, A. C. et al. Raman Spectrum of Graphene and Graphene Layers. Phys. Rev. Lett. 97, 187401–187404 (2006).

Quinn, G. D. & Bradt, R. C. On the Vickers Indentation Fracture Toughness Test. J. Amer. Cer. Soc. 90, 673–680 (2007).

Lawn, B. Fracture of Brittle Solids Ch.7, 194–248 (Cambridge Univ. Press, Cambridge, 1993).

Becher, P. F., Hsueh, C.-H., Angelini, P. & Tiegs, T. N. Toughening Behavior in Whisker-Reinforced Ceramic Matrix Composites. J. Amer. Cer. Soc. 71, 1050–1061 (1988).

Cho, S. J., Hockey, B. J., Lawn, B. R. & Bennison, S. J. Grain-size and R-curve Effects in the Abrasive wear of Alumina. J. Amer. Cer. Soc. 72, 1249–1252 (1989).

Berman, D., Erdemir, A. & Sumant, A. V. Reduced Wear and Friction enabled by Graphene Layers on Sliding Steel Surfaces in Dry Nitrogen. Carbon 59, 167–175 (2013).

Berman, D., Erdemir, A. & Sumant, A. V. Few Layer Graphene to Reduced Wear and Friction on Sliding Steel Surfaces. Carbon 54, 454–459 (2013).

Marcano, D. C. et al. Improved Synthesis of Graphene Oxide. ACS Nano 4, 4806–4814 (2010).

Park, S. J. et al. Colloidal Suspensions of Highly Reduced Graphene Oxide in a Wide Variety of Organic Solvents. Nano Lett. 9, 1593–1597 (2009).

Brydson, R., Chen, S.-C., Riley, F. L. & Milne, S. J. Microstructure and Chemistry of Intergranular Glassy Films in Liquid-Phase-Sintered Alumina. J. Amer. Cer. Soc. 81, 369–379 (1998).

Mizuno, M. & Kon, J.-I. VAMAS round robin on fracture toughness measurement of ceramic matrix composite, VAMAS technical report 32 (Japan Fine Ceramic Center, Nagoya,1997).

Acknowledgements

This research was supported through the program of Development of New Valued Ceramic Materials funded by the Ministry of Knowledge Economy and Basic Science Research Program (2011-0014209) through the National Research Foundation of Korea Grant funded by the Korean government Ministry of Science, ICT and Future Planning.

Author information

Authors and Affiliations

Contributions

H.J.K. synthesized the samples and performed mechanical testing. S.-M.L. and Y.-S.O. advised and discussed mechanical testing. Y.-H.Y. performed wear experiments. Y.S.L. performed TEM analysis. D.H.Y., C.L. and R.S.R. contributed to the discussion and writing the manuscript. J.-Y.K. conceived the idea and designed the project.

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Electronic supplementary material

Supplementary Information

Supplementary information

Rights and permissions

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivs 3.0 Unported License. The images in this article are included in the article's Creative Commons license, unless indicated otherwise in the image credit; if the image is not included under the Creative Commons license, users will need to obtain permission from the license holder in order to reproduce the image. To view a copy of this license, visit http://creativecommons.org/licenses/by-nc-nd/3.0/

About this article

Cite this article

Kim, H., Lee, SM., Oh, YS. et al. Unoxidized Graphene/Alumina Nanocomposite: Fracture- and Wear-Resistance Effects of Graphene on Alumina Matrix. Sci Rep 4, 5176 (2014). https://doi.org/10.1038/srep05176

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/srep05176

This article is cited by

-

Effect of Surface-Modified Graphene Addition on In Situ Synthesized Iron-Based Friction Materials

Journal of Materials Engineering and Performance (2024)

-

Significantly enhanced charge transport in polysilicon by alleviating grain boundary scattering through interface control using reduced graphene oxide

Journal of the Korean Ceramic Society (2022)

-

Applications of Spectroscopic Techniques for Characterization of Polymer Nanocomposite: A Review

Journal of Inorganic and Organometallic Polymers and Materials (2022)

-

Dispersion degree and sheet spacing control of graphene products via oxygen functionalities and its effect on electrical conductivities of P3HT-graphene composite coatings

Journal of Materials Science: Materials in Electronics (2020)

-

Mechanical and tribological properties of nanocomposites incorporated with two-dimensional materials

Friction (2020)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.