Abstract

Polyurethane (PU)-acrylic hybrid composites were prepared by emulsion polymerization of acrylic monomers in the presence of preformed PU chains containing polymerizable terminal vinyl groups. To study the effect of the nature of diisocyanate on the film's morphology and properties, composites were prepared from two different diisocyanates: tetramethylxylene diisocyanate and 4,4′-dicyclohexylmethane diisocyanate. The samples were then characterized using size exclusion chromatography, dynamic light scattering, transmission electron microscopy, Fourier-transformed infrared spectroscopy (FTIR) and small-angle X-ray scattering (SAXS), and the gel fraction content and mechanical properties of the films were also determined. The hybrid composites were found to be cross-linked systems that underwent changes in their particle and film morphologies with increasing acrylic content. The FTIR results revealed a good interaction between the PU and acrylic moieties, and SAXS experiments showed that systems with up to a 50 wt% acrylic component were homogeneous. An attempt to incorporate a higher amount of acrylic component resulted in phase-separated materials. The composition at which phase separation was observed was found to be strongly dependent on the diisocyanate structure. Although the properties of hybrid samples with lower acrylic contents were dependent on the diisocyanate used, samples with higher acrylic contents behaved similarly to those of pure acrylic regardless of the diisocyanate used for preparation.

Similar content being viewed by others

Introduction

Waterborne polyurethanes (PUs) have been studied for over 50 years and their performance has continuously improved. These polymers are very interesting materials that have gained substantial importance in recent years because of their wide range of applications and because their properties can be readily tailored by varying their components.1, 2

Increased demands for improved technical performance have motivated research on the development of new systems by both industrial and academic organizations. One approach to improve the performance of PU resins is to introduce different polymer chemistries within each of the emulsion particles in an interest to combine, in the same material, incompatible components at the nanoscale level because these materials offer prospects for new and synergistic properties.3

In this manner, hybrid emulsions based on acrylic polymers (ACs) and PUs are being studied. Several approaches to prepare waterborne PU-acrylic hybrid emulsions (PU-ACs) have been proposed.4, 5, 6, 7, 8 The most representative approach is to polymerize acrylic monomers in the presence of a PU dispersion to obtain a hybrid emulsion. These hybrid emulsions are expected to provide the advantages of ACs such as hardness, gloss weatherability and chemical resistance coupled with the beneficial properties of PUs, such as excellent adhesion and toughness. In addition, it is expected that the preparation of such hybrid materials should lead to improved properties when compared with blends of acrylic latexes and emulsified PUs.9, 10, 11

It is accepted that the morphology of multi-component polymer systems (phase domain size and shape, interfacial bonding and phase connectivity) and the factors influencing them both determine the physical and mechanical properties of such materials. PU typically consists of semi-crystalline hard and soft segments. Owing to the distinct chemical incompatibility of the soft and hard segments, phase separation occurs in segmented urethanes, and as a consequence, a specific domain structure is formed. These segments are thermodynamically incompatible, with the result that the materials are strongly microphase separated under normal conditions.2, 12, 13, 14 A very large number of chemical and structural factors have an important role in microphase separation or phase mixing. As the chemical structure and symmetry of the diisocyanate used has an important role in the properties of the ensuing PU,15, 16 it is expected that the diisocyanate structure would also affect the morphology and phase behavior, as well as the resulting properties of the hybrid composites prepared from these PUs.

There have been few reports regarding the morphology of hybrid emulsion particles and the properties of the films prepared from these hybrid emulsions. The existing studies are mainly focused on the preparation and performance of PU-acrylic hybrids as coating materials based on PUs prepared from isophorone diisocyanate. To our knowledge, preparation of such dispersions from any other diisocyanates has not been reported. In this study, the morphology and properties of PU-AC hybrid systems prepared from PUs based on tetramethylxylene diisocyanate (TMXDI) and 4,4′-dicyclohexylmethane diisocyanate (H12MDI) were investigated. Here, the emphasis is placed on the comparative properties of hybrid polymers with varying acrylic content according to the nature of the diisocyanate used.

Experimental procedure

Materials

Methyl methacrylate and n-butyl acrylate were of technical grade and distilled before use. Methacrylic acid (Fluka, Buenos Aires, Argentina), (TMXDI, Cytec, Buenos Aires, Argentina), H12MDI (Bayer, Buenos Aires, Argentina), HEMA (2-hydroxyethyl methacrylate) (Aldrich, Buenos Aires, Argentina), potassium persulfate (Anedra, Buenos Aires, Argentina), hydrazine monohydrate (Aldrich), dibutyltin dilaurate (Aldrich), triethylamine (Dorwil S.A U.V.E., Buenos Aires, Argentina), dimethylol propionic acid (Aldrich) and SDS (Anedra) were of analytical grade and used as received. Polypropylene glycol 1000 (Voranol 2110, Dow Química Argentina S.A, Buenos Aires, Argentina) was dried and degassed at 80 °C at 1–2 mm Hg before use.

Preparation of polymer dispersion

Synthesis of aqueous PU dispersion

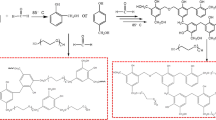

PU dispersion (PUx) was synthesized after a prepolymer mixing process that involved the polyaddition of the corresponding diisocyanate, polypropylene glycol, 2-hydroxyethyl methacrylate and dimethylol propionic acid. The PU anionomer with 2-ethoxymethacrylate terminal groups was dispersed in water containing a chain extender (hydrazine) with previous neutralization of the carboxylic acid groups with triethylamine. A typical base formulation of the PUs used in this paper is given in Table 1.

Synthesis of PU-acrylate dispersions

An emulsion polymerization of methyl methacrylate/n-butyl acrylate/acrylic acid mixture (45/53/2 wt%) in the presence of PUx dispersion was performed with SDS as the emulsifier (2 wt% in the acrylic monomer base). The polymerization led to formation of colloidal dispersions of PU-acrylic hybrids. More experimental details on the preparation of these polymers are described in a previous study.17 A shorthand notation is used in this paper to describe the hybrid systems: ‘X90:10’ denotes a hybrid system prepared using 90 wt% of PU and an acrylic feed of 10 wt%, where X is H or T for hybrid systems based on the use of H12MDI or TMXDI, respectively.

Synthesis of acrylic dispersion and PU-polymerized dispersion

Pure acrylic dispersion (AC) was prepared by emulsion polymerization of the methyl methacrylate/n-butyl acrylate/methacrylic acid mixture using the same method as described for the PU-acrylic hybrids, with 2 wt% SDS in the monomer base serving as the emulsifier. PU-polymerized dispersion (PUX-pol) was prepared in the same manner as the hybrid systems without addition of acrylic monomers. Both polymers were used as reference materials for comparison with the hybrid systems (Table 2).

Polymer dispersion cleaning

Dispersions were cleaned before analysis using Spectra/Por Biotech polyvinylidene difluoride dialysis membranes of 15-mm diameter and a molecular weight cutoff of 1 000 000 Da to eliminate residual monomers, initiators and water-soluble compounds, as they may interfere with analytical techniques.

Film formation

Films were prepared by casting the dispersions onto a Teflon substrate by evaporating water at 30 °C. Samples were thermally treated at 60 °C for 48 h to allow for complete coalescence.

Characterization

Samples of the PU prepolymers PPx and PP-Hx (before and after HEMA addition, respectively), a PU polymer containing end double bonds (PUx) and an AC were all analyzed by size exclusion chromatography. Before sample injections, PU prepolymers (PPx and PP-Hx) were reacted with excess MeOH to remove the terminal –NCO groups. The chromatograph (Waters Corp, Milford, MA, USA, pump model 1525, automatic injector model 717 plus) was fitted with 7 fractionation columns (Waters Styragel, 7.8 × 300 mm2, 5 μm; HR 0.5, HR 1, HR 2, HR 3, HR 4, HR 5, HR 6), and a Waters Differential Refractive Index Detector (model 410). The mobile phase was tetrahydrofurane (1.0 ml/min, 30 °C). The chromatographic system was calibrated with a set of 9 narrow polystyrene standards (Shodex SM-105, Showa Denko America, Inc., New York, NY, USA) that covered the molar mass range of 1200–2 200 000 g per mol.

Particle sizes of the dispersions were determined by dynamic light scattering using a Malvern 4700 instrument (Malvern Instruments Ltd, Worcestershire, UK). This technique gives an intensity-weighted average particle size, dint avg=∑(niIidi)/∑(niIi), where Ii is the intensity of light scattered from ni particles of diameter di, close to the z-average particle size (dz=∑(nidi7)/∑(nidi6)).

The gel content was determined by Soxhlet extraction during a 24-h period using tetrahydrofurane as a solvent. The cartridge (Whatman 1, weight W1, Whatman plc, Kent, UK) was loaded with ∼1 g of dry polymer (weight W2) before the extraction was carried out. The cartridge was dried in a ventilated oven at 60 °C and weighed again (weight W3). The amount of insoluble material (gel fraction) was calculated as follows: gel fraction=((W3−W1)/(W2−W1)) × 100.

Fourier-transformed infrared spectroscopy (FTIR) studies were performed in the transmission mode using a FTIR Nicolet 380 Spectrometer (Thermo Fisher Scientific, Waltham, MA, USA). Films of the polymers were prepared by spontaneous evaporation at room temperature of a diluted dispersion placed on a CaF2 window, and 64 scans were run for each experiment.

Transmission electron microscopy studies were performed using a JEM 1200 EX II Jeol instrument (Jeol, JEOL Ltd, Tokyo, Japan). Dilute dispersions were dried onto carbon-coated copper grids covered with Formvar, without a metal coating.

Small-angle X-ray scattering (SAXS) experiments were performed at the SAXS2 beamline at the National Laboratory of Synchrotron Radiation in Campinas, Brazil. A monochromatic beam with a wavelength of 1.608 Å and an exposure time of 300 s was used. Scattering intensity was registered using a two-dimensional detector with a sample detector distance of 728.32 mm. One-dimensional curves were obtained by integrating the two-dimensional data with the program FIT2D. The acquired data were corrected by subtracting the background contribution of the empty cell.

Tensile properties (such as tensile strength, elongation at brake and tension at brake) of the polymer films were measured at 25 °C using an EMIC DL-3000 (EMIC Ltda., San Pablo, Brazil) tensile-testing machine. Dog-bone-type specimens of 0.250 mm thickness, 6 mm width and 33 mm length were prepared according to the test procedure given in ASTM D-638 (type IV specimen), and a testing speed of 500 mm min−1 was used.

Results and Discussion

Molecular weight

Table 3 presents the molar mass of PU prepolymer samples before and after addition of HEMA and PU polymers. The values for both prepolymer PPX and PP-HX samples were similar; therefore, addition of a HEMA unit to the prepolymer chain had a negligible effect on its molecular weight. As expected, an important increase was observed after dispersion of PP-HX in water due to the chain extension reaction. The final molecular weight distribution of prepolymer samples was clearly bimodal, whereas a very broad distribution after chain extension was observed for PU samples as shown in Figure 1. The AC has a molecular weight in agreement with an emulsion polymerization technique. The PU/AC hybrids were cross-linked systems, which complicated their characterization and especially the determination of the molecular weight of the hybrid polymers by size exclusion chromatography (see below).

Particle sizes and gel content

Particle sizes of the dispersions and the final gel content of the hybrid polymers, PUX-pol and AC, are shown in Table 4. The PU based on TMXDI had a larger particle size than did the H12MDI-based PU.

Here, the increase in particle sizes associated with the use of TMXDI was attributed to its higher molecular stiffness compared with that of H12MDI. The higher stiffness produced an intimate phase mixing in the TMXDI-based PU compared with phase separation of the symmetrical H12MDI-based PU. Phase mixing of PUs made it difficult for anionic centers to move toward the surface during emulsification, leading to a larger particle size at this stage.18, 19

In the hybrid systems, the particle size decreased when increasing the acrylic content. Higher particle sizes were observed for TMXDI-based hybrid dispersions than for H12MDI-based hybrid dispersions when up to 50 wt% of acrylic content is considered. At higher acrylic contents, particle sizes tended to be similar, indicating that the AC content somewhat governs particle size. Transmission electron microscopy data (see below) indicated that for higher acrylic content, two different sizes of particles were observed, and therefore, the dynamic light scattering data represented an average of both types of particles.

The gel fraction was 0% for pure PUX and increases in PUX-pol because of the reaction of the terminal double bonds, which increased the cross-linking density. The gel content for all the hybrid samples was ∼90 wt%, regardless of the acrylic content and the diisocyanate type. This fact indicates that the acrylic/PU hybrids are cross-linked systems, explaining their insolubility in the usual solvents (tetrahydrofurane, dimethylformamide, dimethyl sulfoxide).

FTIR spectroscopy results

Figure 2 shows the FTIR spectra of PUX-pol, AC and hybrid systems based on H12MDI (Figure 2a) and TMXDI (Figure 2b), respectively. The PUX-pol spectra show typical bands near 3330 and 3440 cm−1 arising from H-bonded N–H and free N–H stretching vibrations, respectively. Additional observations include the absorption at 1536 cm−1 in PUH-pol and 1517 cm−1 in PUT-pol (amide II band), a broad band centered at ∼1710 cm−1 (free C=O and H-bonded C=O stretching of the urethane group), a shoulder at 1630 cm−1 (free C=O and H-bonded C=O stretching of the urea group), a signal centered at 1240 cm−1 (amide IV band) and a band at 1110 cm−1 (C–O–C stretching vibration of polyetherdiol). The differences observed between PUH-pol and PUT-pol were attributed to the presence of the aromatic ring of TMXDI. The spectrum of the AC polymer (Figure 2, bottom) revealed a band at 1734 cm−1 assigned to the carbonyl (C=O) stretching vibration of the acrylic ester groups and a band at 1168 cm−1 corresponding to the C–O stretching vibration. A progressive change in the spectrum was observed in the hybrid samples with increasing acrylic content.

There were two regions of the FTIR spectra of particular interest in the investigation of the phase separation of segmented PUs. The first was the carbonyl stretching region. Although new bands and shifts in the C=O stretching region were observed in the hybrid samples, changes in the carbonyl peak seemed to simply follow the increase in acrylic content because both PU and AC contributed to the intensity between 1760 and 1620 cm−1.

The second area of interest was the N–H stretching region, shown in Figure 3. In the PU, the peak at ∼3330 cm−1 was assigned to the stretching mode of hydrogen-bonded N–H in both the urethane and the urea units. In model polyureas, this peak was found to sharpen as the urea groups became ordered. Disordered, hydrogen-bonded N–H groups are characterized by absorbance near 3370 cm−1, and the peak due to non-bonded N–H groups was located near 3445 cm−1.20 In this region, a broadening in the bands was observed as the acrylic content increased. Therefore, the presence of the acrylic component changes the hydrogen bonding interaction in the hybrid systems and shifts the maximum N–H absorption band to higher frequencies. This result implies an increase in the number of disordered H bonds of the N–H groups and is consistent with a less phase-separated system in the PU/AC hybrids (also see the SAXS results below). This observation is related to the interaction between the PU N–H groups and the C=O of the acrylic ester groups, indicating a good interaction between the PU and acrylic moieties, as well as a high degree of phase mixing in these materials.

Transmission electron microscopy results

Morphology of the colloidal particles was examined using transmission electron microscopy (Figure 4). For the X90:10 samples, particles with a core-shell morphology were clearly observed, wherein the acrylic component formed the core and the PU formed the shell.3, 21, 22 At 50 wt% of acrylic content (not shown), more than one kind of particle was observed, in which some were core-shell particles, whereas others did not show any contrast at all. The same trend was observed when the acrylic content increased, which is in agreement with hybrid systems based on isophorone diisocyanate that were prepared in a previous study.21 Therefore, on the basis of image analysis of the samples, increasing the acrylic content favored multiple nucleation loci in the reaction media. This resulted in the formation of core-shell particles composed of PU and AC and homogeneous particles.

SAXS measurements

Small-angle X-ray scattering experiments yielded information on the segregation of phases of different electron densities within a sample. Of primary importance are (1) the interdomain spacing (or d spacing), which may be correlated with domain size and (2) the interfacial thickness, which may be used to correlate the chemistry with the structure. Figure 5 shows the scattering intensity versus q for pure PUX-pol, the AC and the hybrids with different acrylic contents.

Small-angle X-ray scattering spectra for H12MDI and TMXDI-based PUs showed the typical broad band at q=0.1 Å−1. The incorporation of the acrylic component reduced the intensity of the maximum at 0.1 Å−1 observed in pure PUs polymers. Increasing the acrylic content reduced the intensity even more, and interestingly, a featureless spectrum was observed for 50 wt% acrylic content. This result indicated a high degree of phase mixing or a very homogeneous matrix at the nanoscale level. As observed in a previous study,21 the incorporation of the acrylic component in the PU had an influence on the microphase behavior of the final polymer material, possibly by altering the interaction between chains and, therefore, the shape and size of the PU domains. The SAXS results are in agreement with the conclusions derived from the FTIR observations above.

However, in the sample H30:70, a peak in q at ∼0.16 Å−1 appeared, and at 90 wt% acrylic content, both H12MDI- and TMXDI-based hybrids had peaks near 0.15 Å−1. This type of SAXS curve is attributed to a two-phase system with sharp boundaries and with electron density contrast, indicating a microphase separation at this particular composition. The q-values observed for these samples were similar to the position of the peak observed in the AC sample (0.138 Å−1).

The interdomain repeat distance (L), defined as the average distance between two hard domains, was obtained from SAXS intensity profiles by applying Bragg's equation: L=2π/q*, where q* is the observed peak position in the SAXS curve. Thus, the interdomain spacing in pure PUs was ∼6.3 nm. Incorporation of the AC seemed to modify this situation by decreasing the intensity of scattering and eliminating peaks in the hybrid systems with intermediate acrylic content. The observed peaks in H30:70 at 0.157 Å−1 corresponded to a smaller interdomain distance of 4.0 nm, and the peaks observed in H1090 and T1090 corresponded to a distance of 4.4 and 4.1 nm, respectively. With an increase in acrylic content, the interdomain spacing reached the value observed in the AC (4.5 nm). The interdomain spacing, specific for these compositions, may have resulted from the presence of acrylic segments and, therefore, formed a two-phase system.

In the hybrid samples prepared from the isophorone diisocyanate -based PU, the material with 70 wt% acrylic content showed phase separation with annealing at 60 °C. H12MDI- and TMXDI-based PUs seemed to behave differently. Phase separation before curing was clearly observed at 90 wt% acrylic content as in the isophorone diisocyanate -based PU; however, no change in the phase separation behavior was observed after thermal annealing in either the H30:70 or the T30:70 samples. This result implies that diisocyanates have an important role in the structure and phase separation behavior of hybrid materials.

Mechanical properties

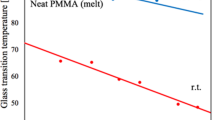

Figure 6 presents representative stress versus strain curves for the films of the systems prepared in this study. Figure 7 displays Young's modulus, stress at brake and elongation at break values of the films.

Two different behaviors were observed for PUX-pol. The elastic modulus and stress at brake were higher for PUH-pol than for PUT-pol, whereas the latter presented a higher elongation at brake. It seemed that the symmetrical structure of H12MDI produced the highest tensile properties. The largest tensile strength may be due to the higher hydrogen-bonding density and better phase separation. The pure AC sample showed a yield point at very low elongation with a stress peak and then a minimum in the curve, followed by the strain-hardening phenomenon. This behavior is typical of rigid and tough plastics with necking occurring across the width of the specimen. The maximum stress was near 12 MPa, and the elongation at break was ∼500%.

The deformation feature of the hybrid film greatly depends on the acrylic content and on the diisocyanate type. When the acrylic content was <50 wt%, the latex films exhibited characteristics typical of soft and tough polymers that show uniform extension, and their properties were related to the PU used in their preparation.

For the hybrid latex films prepared from PUH, both Young's modulus and tensile strengths significantly decreased as the acrylic content increased from 10 to 70 wt%. Incorporation of SSs in the HS domain would be expected to reduce HS domain cohesion. In this case, incorporation of 10–50 wt% acrylic content likely affected HS domain cohesion and reduced the mechanical properties. In the hybrids prepared from TMXDI-PU, stresses at brake initially increased with increasing acrylic content and reached a local maximum at 30 wt%. For these samples, Young's modulus did not change significantly. These improvements in the mechanical properties of the hybrid latex films with lower acrylic content can be attributed to extensive grafting and interpenetration between the PU and acrylics, resulting in highly miscible hybrid latexes.

Samples containing >50 wt% of acrylic behaved similarly, regardless of the PU used in their synthesis. In addition, they tended to behave like a pure AC, displaying a rubbery behavior under tested conditions. All these results were consistent with the morphology depicted in the SAXS results and indicated that, for high acrylic contents, the most likely morphology was of the two-phase type, with a continuous acrylic phase and the hybrid polymer as the second separated phase. This conclusion would explain the similar behavior between the H10:90 and T10:90 samples, as well as the tendency of these samples to behave like the AC.

It is important to note the non-linear behavior of the properties of the hybrid systems, which is likely related to the morphological changes that occur as the acrylic content varied; however, the mixtures did show a gradual change in their properties when ranging from PU to AC, as expected for an ideal mixture.

Conclusions

Water-based PU-acrylic composites have been synthesized from two different diisocyanates and characterized to investigate the effect of varying the acrylic content on the resulting morphology and mechanical properties. The effect of the diisocyanate nature was also evaluated. Incorporation of differing amounts of the acrylic component into the PU matrix when forming a hybrid material altered the morphology, and therefore, the resulting properties, generating a final polymer that was a cross-linked material. The acrylic monomers reacted with the PU prepolymer double bonds, altering the hard segment distribution and inhibiting the microphase separation typically found in pure PU. Colloidal dispersions of the hybrid systems were formed by particles with core-shell morphology of low acrylic content. Samples with high acrylic content were composed of more than one kind of particle, indicating that the increase in acrylic content favored different nucleation loci in the reaction media.

The diisocyanate structure has an important role in the phase separation behavior of hybrid materials, significantly affecting the properties of the final polymer. The molecular structure of the diisocyanate has a significant effect on the average particle size of the prepared PU, and therefore, affects the average particle size of hybrid dispersions. SAXS data suggested that, beyond the usual microphase separation between the soft and hard segments in PUs, phase separation might also be occurring within the soft domains, specifically for the AC, due to some degree of incompatibility between them. The acrylic content at which phase segregation is observed depends on the diisocyanate used and occurs at a lower acrylic content when a symmetrical diisocyanate is used. Tensile strength and Young’s modulus are higher for HMDI-based PU-acrylic hybrids, which may be due to better phase separation and likely a higher hydrogen-bonding density. The results indicate that the properties of the PU-acrylic hybrid systems do not follow a linear behavior with increasing acrylic content. Hybrid samples with acrylic content >70 wt% have similar properties regardless of the diisocyanate used for their preparation. This result indicates that acrylic is the component that controls the properties at these compositions, which is in good agreement with SAXS results. Physical blends do not have the same properties as the hybrid systems described in this article, and work is currently in progress to compare these two systems.

References

Chattopadhayay, D. K. & Raju, K.V.S.N. Structural engineering of polyurethane coatings for high performance applications. Prog. Polym. Sci. 32, 352–418 (2007).

Król, P. Synthesis methods, chemical structures and phase structures of linear polyurethanes. Properties and applications of linear polyurethanes in polyurethane elastomers, copolymers and ionomers. Prog. Mater. Sci. 52, 915–1015 (2007).

Guyot, A., Landfester, K., Schork, F. S. & Wang, C. Hybrid polymer latexes. Prog. Polym. Sci. 32, 1439–1461 (2007).

Kim, J. Y. & Suh, K. D. Preparation of PEG-modified urethane acrylate emulsion and its emulsion polymerization. Coll. Polym. Sci. 274, 920–927 (1996).

Kim, B. K. & Lee, J. C. Modification of waterborne polyurethanes by acrylate incorporations. J. Appl. Polym. Sci. 58, 1117–1129 (1995).

Hirose, M., Kadowaki, F. & Zhou, J. The structure and properties of core-shell type acrylic-polyurethane hybrid aqueous emulsion. Prog. Org. Coat. 31, 157–169 (1997).

Otts, D. B., Dutta, S., Zhang, P., Smith, O. W., Thames, S. F. & Urban, M. W. Synthesis and phase separation during film formation of novel methyl methacrylate/n-butyl acrylate/methacrylic acid (MMA/BA/MAA) hybrid urethane/acrylate colloidal dispersions. Polymer 45, 6235–6243 (2004).

Mequianint, K., Sanderson, R. & Pasch, H. Phosphated plyurethane-acrilic dispersions: synthesis, rheological properties and wetting behavior. Polymer 43, 5341–5346 (2002).

Wang, C., Chu, F., Graillat, C., Guyot, A., Gauthier, C. & Chapel, J. P. Hybrid polymer latexes: acrylics–polyurethane from miniemulsion polymerization: properties of hybrid latexes versus blends. Polymer 46, 1113–1124 (2005).

Kukanja, D., Golob, J. & Krajnc, M. Kinetic investigations of acrylic–polyurethane composite latex. J. Appl. Polym. Sci. 84, 2639–2649 (2002).

Chai, S. H., Jin, M. M. & Tan, H. M. Comparative study between core-shell and interpenetrating network structure polyurethane/polyacrilate composite emulsions. Eur. Polym. J. 44, 3306–3313 (2008).

Lee, H. S. & Hsu, S. L. An analysis of phase separation kinetics of model polyurethanes. Macromolecules 22, 1100–1105 (1989).

Wang, C. B. & Cooper, S. L. Morphology and properties of segmented polyether polyurethaneureas. Macromolecules 16, 775–786 (1983).

Tawa, T. & Ito, S. The role of hard segments of aqueous polyurethane-urea dispersion in determining the colloidal characteristics and physical properties. Pol. J. 38, 686–693 (2006).

Okrasa, L., Czech, P., Boiteux, G., Méchin, F. & Ulanski, J. Molecular dynamics in polyester- or polyether-urethane networks based on different diisocyanates. Polymer 49, 2662–2668 (2008).

Yilgor, I., Yilgor, E., GulerI, I. G., Ward, T. C. & Wilkes, G. L. FTIR investigation of the influence of diisocyanate symmetry on the morphology development in model segmented polyurethanes. Polymer 47, 4105–4114 (2006).

Pardini, O. R. & Amalvy, J. I. FTIR, 1H-NMR spectra, and thermal characterization of water-based polyurethane/acrylic hybrids. J. Appl. Polym. Sci. 107, 1207–1214 (2008).

Durrieu, V., Gandini, A., Belgacem, M., Blayo, A., Eiselé, G. & Putaux, J- L. Preparation of aqueous aionic poly-(urethane-urea) dispersions: influence of the nature and proportion of the urethane groups on the dispersion and polymer properties. J. Appl. Pol. Sci. 94, 700–710 (2004).

Barikani, M., Valipour Ebrahimi, M. & Seyed Mohaghegh, S. M. Influence of diisocyanate structure on the synthesis and properties of ionic polyurethane dispersions. Polym Plast. Technol. 46, 1087–1092 (2007).

Garrett, J. T., Xu, R., Cho, J. & Runt, J. Phase separation of diamine chain-extended poly(urethane) copolymers: FTIR spectroscopy and phase transitions. Polymer 44, 2711–2719 (2003).

Peruzzo, P. J., Anbinder, P. S., Pardini, O. R., Costa, C. A., Leite, C. A., Galembeck, F. & Amalvy, J. I. Polyurethane/acrylate hybrids: effects of the acrylic content and thermal treatment on the polymer properties. J. Appl. Polym. Sci. 116, 2694–2705 (2010).

Hirose, M., Zhou, J. & Nagai, K. The structure and properties of acrylic-polyurethane hybrid emulsions. Prog. Org. Coat. 38, 27–34 (2000).

Acknowledgements

This research was partially supported by the LNLS—Brazilian Synchrotron Light Laboratory/MCT (proposal D11A-SAXS no. 5701/06). We thank CICPBA (Comisión de Investigaciones Científicas de la Provincia de Buenos Aires, Argentina) and ANPCyT (Agencia Nacional de Promoción Cientíca y Tecnológica) for their financial assistance. Christopher Young is thanked for his assistance in reviewing and correcting the paper. JIA and ORP are members of CICPBA. PJP and JV are members of CONICET (Consejo Nacional de Investigaciones Científicas y Técnicas, Argentina).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Peruzzo, P., Anbinder, P., Pardini, O. et al. Influence of diisocyanate structure on the morphology and properties of waterborne polyurethane-acrylates. Polym J 44, 232–239 (2012). https://doi.org/10.1038/pj.2011.111

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/pj.2011.111