Abstract

A SAXS study of the crystallization process in PHB and PHB/DGEBA (poly(3-hydroxybutyrate/ diglycidyl ether of bisphenol A) blends with PHB/DGEBA weight ratios of 100/0, 90/10, 70/30 and 50/50 crystallized at 60 and 100 °C was performed. The measurements were performed at different stabilized temperatures between 30 and 140 °C. The relaxation of the rigid amorphous fraction influences the crystallization process at crystallization temperatures higher than 70 °C, and the same rigid amorphous fraction constrains the development of crystals at temperatures <70 °C. Evidence for interlamellar segregation without influence from the crystallization temperature for DGEBA contents <30% and indications of interfibrillar or interspherulitic segregation for DGEBA contents >30% were observed. The results are discussed based on the segregation of DGEBA affecting the recrystallization process of PHB. At high temperatures, the co-existence of lamellae with different dimensions was observed. The results also indicate that DGEBA reduces the possibility of secondary crystallization in the blends.

Similar content being viewed by others

Introduction

A deep understanding of the physical processes that govern the blending of polymers is an important goal of research in the field of novel materials with the aim of technological applications. Poly(3-hydroxybutyrate) (PHB), which is a component of polymer blends, has been studied because its biodegradability suggests its potential use for replacing traditional polymers to improve the environmental sustainability of the produced blends.

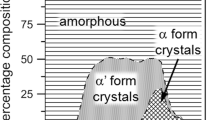

PHB crystallizes by forming banded spherulites with an orthorhombic crystalline structure.1 PHB blended with different polymers, such as poly(p-vinylphenol),2 poly(lactic acid),3 atactic PHB4 and poly(vinylidene fluoride),5 has been studied. In most of these studies, the SAXS technique enabled the determination of the type of segregation during crystallization. PHB samples that crystallize from solution have been studied by X-ray scattering and exhibit discontinuous growth in the lamellar thickness during heating and a temperature range over which two lamellar structures coexist.6 Recent studies7, 8 have indicated that the crystallization of PHB can be successfully analyzed using a model of crystallization that takes into account the intermediate states of mesomorphic granular crystals and crystals.9 The thermal history of PHB is relevant to the final structures of the crystalline and amorphous regions.10 Therefore, the image of PHB as a semicrystalline polymer composed of two separate phases (that is, one amorphous phase and one crystalline phase) has been modified to account for an intermediate nanophase that is present at the interphase between the crystals and the surroundings. This interphase is typically referred to as the ‘rigid amorphous fraction’ (RAF), and its mobility is less than that of the unconstrained amorphous phase, which is typically referred to as the ‘mobile amorphous fraction’.11, 12 The influence of the RAF on the crystallization and crystalline structures has been recognized in previous studies. Schick et al.13 reported that the RAF vitrifies owing to morphological changes and not temperature changes, avoiding the existence of a second glass transition temperature in PHB. Righetti et al.12 demonstrated that complete mobilization of the RAF in PHB occurs at a temperature of ~70 °C, which is a critical temperature for the formation and disappearance of the RAF.

However, when crystallization occurs in a blend containing a noncrystallizable component, this component is rejected from the lamellae. This rejection can be produced toward the interlamellar region (that is, near the crystalline region) or the interfibrillar or interspherulitic regions. The location of the noncrystallizable component depends on the interplay between the forces that tend to pull the molecules out of the interlamellar regions and the forces that attempt to keep the molecules joined.14 The first force is a product of the lower conformational entropy owing to the lower dimensionality of the interlamellar region, and the second force is owing to favorable interactions between the noncrystallizable component and the amorphous phase.

The previous discussion demonstrates the complexity and richness of the process of crystallization in PHB and PHB blends as a polymer model that is important from both the academic and applications perspectives for the development of sustainability.

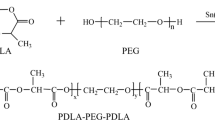

In this study, crystallization in PHB/DGEBA (diglycidyl ether of bisphenol A) blends was analyzed using SAXS results obtained at different temperatures in samples crystallized at 60 or 100 °C. The crystallization temperatures were selected because they are lower and higher than the temperature of RAF mobilization. However, the measurement temperature was varied from 30 to 140 °C to study the changes in the crystallite parameters. The results from this study provide new insight into the miscibility and crystallization in the previously developed PHB/DGEBA blends.15, 16 In addition, the development of the crystallization process at the selected temperatures, as well as the influence of the segregation process and the RAF on the stability of crystals, are discussed.

The study of blends of PHB with DGEBA has two objectives. The first objective was to obtain information regarding this blend as a first step in the study of epoxy/PHB interpenetrating networks because the DGEBA monomer is one of the materials most often used to develop epoxy networks. In addition, epoxy is a thermoset polymer that is widely used either as a matrix in polymer composites or in the formation of interpenetrating networks. PHB/DGEBA blends also represent an intermediate case between polymer/diluent and polymer/polymer mixtures, which makes it relevant for the analysis of the segregation of DGEBA during the development of crystalline structures.

Experimental procedures

PHB powder with the trade name Biocycle was supplied by PHB Industrial S.A. (Sao Paulo, Brazil). The epoxy DGEBA monomer (diglycidyl ether of bisphenol A) was supplied by Huntsman (Araldite MY 790, Huntsman, Salt Lake City, UT, USA). For the SAXS measurements, blended samples with PHB/DGEBA weight ratios of 100/0, 90/10, 70/30 and 50/50 were melted at 180 °C and then quickly cooled using an oil bath at the selected crystallization temperatures (Tc; that is, 60 °C or 100 °C), and this Tc was maintained for 1 hour.

Small-angle X-ray scattering (SAXS) measurements were performed at the Brazilian Synchrotron Light Laboratory (LNLS) CNPEM/MCT, line SAXS 1, Campinas, Brazil. A wavelength (λ) of 1.55 Å was selected for the monochromatic beam used in the experiments. The low-angle scatter was recorded for scattering vector values q (q=(4π/λ) sinθ, where 2θ is the scattering angle) from qmin=0.008 Å−1 to qmax=0.300 Å−1 using a position-sensitive detector for the small-angle region located at a distance of 627 mm from the sample. The measurements were performed using a two-dimensional (2D) detector with a spatial resolution of 172 μm. The 2D scattering profiles were averaged at several radii and converted to 1D data using the FIT2D V12.077 program (A. Hammersley, ESRF http://www.esrf.eu/computing/scientific/FIT2D/). The experimental small-angle scattering curves were normalized by the integrated incident beam intensity. During the measurements, the samples were compressed and sealed in modified DSC pans with Kapton windows (Dupont Argentina, Berazategui, Argentina). A set of measurements was performed to observe possible changes in the sample due to radiation exposure. However, no variations were observed in the obtained spectra.

The SAXS measurements were performed at different temperatures ranging from 30 to 140 °C in successive steps at a heating rate of 20 °C min−1. The measurement time was 15 s. Prior to taking each measurement, the samples were maintained for 2 min at a constant temperature for thermostabilization after each temperature step.

The DSC measurements of pure PHB and PHB/DGEBA blends were carried out using a differential scanning calorimeter (Q20-TA Instruments, New Castle, DE, USA). The calorimeter was calibrated in temperature and heat flow using indium as a reference material. The measurements were performed under an argon atmosphere with a constant flux of 50 ml min−1. The isothermal crystallization was carried out by heating from room temperature to 190 °C at a rate of 10 °C min−1. The samples were maintained at 190 °C for 120 s to remove the thermal history, followed by rapid cooling to avoid crystallization to the Tc, which was maintained to sustain the crystallization process. Next, a second heating from Tc to 190 °C at 10 °C min−1 was performed. From previous DSC results,15 crosslinking between PHB and DGEBA does not occur during heating.

Results and discussion

SAXS measurements

For pure PHB at the chosen crystallization temperatures (that is, 60 and 100 °C), the plots of I.q2 as a function of q at different temperatures are shown in Figure 1 as typical examples of the obtained results (spectra). The SAXS measurements performed at room temperature exhibit maxima at qM values of 1.04 nm−1 for Tc=60 °C and 0.94 nm−1 for Tc=100 °C. As the measurement temperature increased, an increase in the height of the peaks and a decrease in the position of the maxima were observed. At temperatures higher than ≈110 °C, the SAXS spectra were deformed, and no evidence of a second peak located at a q value lower than that corresponding to the first peak observed at the qM position was observed. This second peak can be associated with the formation of new lamellar structures in the re-crystallization process. This result could indicate the coexistence of two types of lamellar structures. This assumption is based on the observations from previous studies of PHB single crystal growth from solution, where a model consisting of partial melting and recrystallization was used to explain the discontinuous lamellar increase with temperature.6 However, in the current study, the coexistence of two lamellar structures is not as clear because an amorphous phase between the crystal phases is present. This amorphous phase hampers the cooperative process between adjacent crystals, which results in smoothing of the two peaks in the SAXS curves.

Plots of I.q2 as a function of q for pure PHB at different measurement and crystallization temperatures. (a) Tc=60 °C and (c) Tc=100 °C. (b) is an expansion of (a) for q between 1.1 and 2.5 nm−1. (d) is an expansion of (b) for q between 1.1 and 2.4 nm−1. In (b) and (d), some curves were horizontally shifted for better visualization.

A third peak located at a q value of 1.85 nm−1 was observed in the samples crystallized at 100 °C. In addition, an incipient peak at 2.03 nm−1 was observed for the sample crystallized at 60 °C, and the intensity of this peak increased in the measurements at higher temperatures (Figures 1b and d). This peak may be owing to third-order scattering17 or insertion of lamellas within the original lamellas, which produces two lamellar distances.18 In Figure 1d, the approximate position of the maximum of the peak is marked for Tc=100 °C. For a temperature <70 °C, the position of the peak is nearly constant, and for temperatures between 70 and 120 °C, the peak shifts to higher q values. In addition, for temperatures higher than 120 °C, the position of the peak shifts to lower q values.

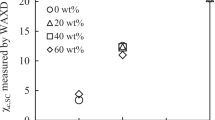

According to the literature,19, 20 a one-dimensional correlation function (α) was calculated using Equation 1 for the SAXS measurements performed by subjecting the blends to different temperatures. Using α, the thicknesses of each phase was estimated by considering a two-phase structure (that is, crystalline and amorphous) with dimensions La and Lc, respectively.19 The dimension of the lamella (L) is assumed to be La+Lc. The analysis of α allows for the extraction of the L1 and L2 dimensions. However, to assign L1 to Lc or La, further considerations need to be taken into account because the electronic density in a two-phase structure can be exchanged without affecting the correlation function.19 The assignment of Li (i=1,2) to Lc or La can be achieved using the DSC results.21 In a previous study, the assignment of each phase from the results of DSC and SAXS measurements performed at room temperature for PHB/DGEBA blends crystallized at room temperature was conducted.15 Therefore, in this study, the assignment at different temperatures was performed using these results. Extrapolation to low q values was carried out using Guinier’s model,7 and extrapolation to high q values was carried out based on Porod’s law.22, 23 Owing to the characteristics of these results regarding the existence of secondary peaks, the L, Lc and La values are considered to be mean values. In the PHB spectra, the one-dimensional correlation function was calculated from the spectra for the entire q range. However, for the blends, some restrictions were applied because the background tends to increase as a function of q at high values. Therefore, the spectra were shortened.

In Figure 2, the L, La and Lc values for all of the studied compositions and crystallization temperatures are shown as a function of the measurement temperature. In most cases, L exhibited an increase as the temperature increased, which can be attributed to two processes. The first process results in a slight increase, and the second process results in a strong and nonmonotonic increase. La as a function of temperature also results in an increase when the temperature was increased in nearly all cases. However, some specific deviations from this general observation have been further analyzed.

As shown in Figure 2b for PHB, La exhibits different behaviors as a function of temperature for the different crystallization temperatures. For the samples crystallized at 100 °C, La has a tendency to increase over the entire range of temperatures. However, for the sample crystallized at 60 °C, La remained constant until a temperature of 60 °C is reached, and then, La increased. This behavior was also observed for the studied blends.

For Lc of pure PHB crystallized at 60 °C, the results in Figure 2c indicate that the parameter is approximately constant in a temperature range of 30–110 °C. However, at temperatures higher than 110 °C, Lc substantially increased as the temperature increased. However, for the samples crystallized at 100 °C, Lc decreased until a temperature of ~130 °C was reached, and then Lc increased. For 90/10 PHB/DGEBA, the behavior is approximately similar to that described above, as shown in Figure 2f. However, for 70/30 PHB/DGEBA (Figure 2i) and 50/50 PHB/DGEBA (Figure 2l) at a crystallization temperature of Tc=100 °C, no decrease was not observed, and Lc was approximately constant. The Lc values for PHB are in agreement with those reported by Chiu et al. in a temperature range of 70–125 °C.24 However, the trend in Lc reported by these authors for PHB/poly(vinyl acetate) blends indicate that Lc increased when the PHB content decreased, which is different from the behavior observed in this study. The obtained values (Figure 2c, f, i and l) indicate that Lc decreased for the 90/10 PHB/DGEBA blend with respect to PHB and remains constant for the 70/30 PHB/DGEBA blend for both Tc used. However, for the 50/50 PHB/DGEBA blend, Lc remained constant for Tc=100 °C and increased for Tc=80 °C.

Several theories of crystallization in polymers have been proposed, and the Hoffman-Lauritzen theory is one of the most utilized.25 In this model, a process of layer-by-layer growth and the formation of a secondary nucleus created by the attachment of a refolded layer has been proposed. However, in the last two decades, a new model based on a multistep process involving a mesomorphic state and native and stabilized crystals has been proposed. This model has been applied to different polymers to explain the results obtained from the rate of spherulite growth as well as other processes. In PHB, this model was applied to explain the evolution of the SAXS parameters as a function of time.7 In this study, a new region that transforms into a mesomorphic layer and then into crystallites was analyzed.

In general, Lc−1 exhibits a linear behavior with Tc, as expressed by Equation 2 in the Hoffman-Lauritzen theory.25 When the results obtained by Heo et al.17 and Chiu et al.24 as well as those reported in this study are plotted to show Tc as a function of Lc−1, an approximately linear behavior is observed even though curvature is observed at low crystallization temperatures.

In Equation 2, Lg is the initial crystal thickness, γ is the lamellar thickening factor, σe is the fold surface free energy, ΔH is the enthalpy of melting,  is the equilibrium melting temperature and δL is a weak function of temperature and typically approximately zero.21, 24, 25

is the equilibrium melting temperature and δL is a weak function of temperature and typically approximately zero.21, 24, 25

If the Lc results shown in Figure 2 are used in Equation 2, the γ.σe product can be obtained. If more information is unavailable, the γ or σe value cannot be calculated using only Equation 2. However, the γ. σe product enables the determination of whether the variation in Lc is due to different degrees of supercooling or there is variation in the parameter involved in the crystallization (γ and σe). Therefore, the γ.σe product was calculated using the previously reported  values15 and a ΔH value of 1.85 × 108 J m−3.1 The calculus was applied to measurements of PHB crystallized at 100 °C to avoid possible deviations owing to the cooling process in the sample crystallized at 60 °C. The γ.σe product decreases monotonically with the DGEBA content in the blend for the mentioned Tc (that is, from 0.079 J m−2 for PHB to 0.068 J m−2 for PHB/DGEBA 90/10, 0.061 J m−2 for PHB/DGEBA 70/30 and 0.052 J m−2 for PHB/DGEBA 50/50). However, if the value reported by Pearce et al.4 for σe (0.046 J m−2) was used, a γ value of 1.71 was calculated, which is lower than that reported by Dubini Paglia et al. (that is, 1/0.3≈3.3) for PHB calculated from a Tm as a function of Tc plot.26

values15 and a ΔH value of 1.85 × 108 J m−3.1 The calculus was applied to measurements of PHB crystallized at 100 °C to avoid possible deviations owing to the cooling process in the sample crystallized at 60 °C. The γ.σe product decreases monotonically with the DGEBA content in the blend for the mentioned Tc (that is, from 0.079 J m−2 for PHB to 0.068 J m−2 for PHB/DGEBA 90/10, 0.061 J m−2 for PHB/DGEBA 70/30 and 0.052 J m−2 for PHB/DGEBA 50/50). However, if the value reported by Pearce et al.4 for σe (0.046 J m−2) was used, a γ value of 1.71 was calculated, which is lower than that reported by Dubini Paglia et al. (that is, 1/0.3≈3.3) for PHB calculated from a Tm as a function of Tc plot.26

Role of the rigid amorphous fraction

Regarding the variations observed in La as a function of temperature, some experimental results that have been reported in the literature must be considered. In PHB, partial vitrification of the amorphous chain located at an interphase with the crystalline phase at crystallization temperatures <70 °C has been reported.12 This vitrification develops a region that prevents the growth of PHB crystals. In contrast, at temperatures higher than 70 °C, this vitrification does not develop. This region (the intermediate nanophase is referred to as the RAF) is noncrystalline and arises from the continuation of the partially crystallized macromolecules across the phase boundaries because the polymer molecules are much longer than the crystal nanophase.10, 12 The RAF mobility is lower than that of the unstrained amorphous phase, which is typically referred to as the mobile amorphous fraction. Therefore, for the La results corresponding to Tc=60 °C shown in Figure 2b, when the measurement temperature increased but remained <70 °C, the RAF imposed a constraint on the mobility of the macromolecules because La is nearly constant. However, the constraint starts to relax at a measurement temperature of 70 °C. At higher measurement temperatures, an increase in La was observed because the constraint imposed by the RAF is overcome at 70 °C. The RAF did not developed at Tc higher than 70 °C.12 Therefore, for a crystallization temperature of 100 °C, La increased with the measurement temperature without constraint, as shown in Figure 2b.

In Figure 2c, the Lc values can be divided into two sets. The first set corresponds to Tc=60 °C (crystallization temperature below the limit of 70 °C for RAF vitrification), and the second set overcomes the limit (that is, Lc values corresponding to Tc=100 °C). In the first set, the RAF enforces a limitation on the melting and recrystallization process, which stabilizes the crystals. Therefore, Lc is approximately constant until a measurement temperature of 110 °C is reached. At this temperature, the RAF does not exert an influence because the melting and recrystallization process prevails, and a new population of crystals is developed, which result in broadening and deformation of the peak in the SAXS curves. Therefore, the mean Lc increased. In the second set, no RAF developed at the crystallization temperature, or a small amount of RAF developed and then underwent isothermal crystallization.12 As shown in Figure 2c, for the second set, Lc decreased as a function of the measurement temperature to 120 °C. Heo et al.17 observed that Lc was not influenced by the melting of smaller, less perfect crystals or secondary crystals but by melting of larger, more perfect crystals during the heating of PHB crystallized at 125, 135 and 145 °C. This phenomenon partially explains why no increase in Lc was observed at Tc=100 °C because an increase in the mean Lc is expected when the melting of secondary crystals is important. However, the observed decrease in Lc indicates a more complex scenario. For Tc=100 °C, this decrease can be explained by assuming that Lc is not influenced by the melting of small crystals. However, partial melting of large crystals does occur. The absence of the coupled RAF reduces the stability of these crystals. Therefore, the results presented in this study provide additional insight to that provided by Heo et al., because extends the crystallization temperature range. Shick et al.13 noted that devitrification is a consequence of morphological changes due to the melting of small crystals but not temperature changes.

Hama et al.18 analyzed SAXS results using a model of lamellar structures inserted between the originally existing lamellae. These inserted lamellae produce a secondary peak in the SAXS spectra that is observed at high q values and is associated with a second long period owing to the insertion of the new lamellae. Hama et al. assumed that the insertion of the new lamellae was exactly in the middle of the original lamellae.

In our results obtained in pure PHB, a peak that is consistent with that reported by Hama et al. was observed. This peak was mentioned (at the beginning when Figure 1 was described) as the third peak located at q values of 1.59 and 1.85 nm−1. In the samples crystallized at 60 °C and 100 °C, the ratio between the maximum of the peak at a high q with respect to the principal peak is ≈1.95 for the measurement at 30 °C. Similarly, La does not exhibit substantial variation as a function of Tc.

The presence of the RAF limits the growth of crystals at 60 °C and stabilizes these crystals. In addition, the RAF may also prevent secondary crystallization. Therefore, the secondary peak at high q values is practically nonexistent compared with that of the sample crystallized at 100 °C. Then, at 100 °C, the secondary crystallization is significant.

However, for blends with a high DGEBA content (for example, PHB/DGEBA blends with a ratio of 50/50), the secondary crystallization could be less important. DGEBA could be an obstacle to secondary crystallization in the interlamellar region, which may result in the formation of fewer secondary lamellae.

In Figure 3, a schematic representation of the crystal, RAF and mobile amorphous fraction regions is shown for both cases (that is, Tc=60 °C and Tc=100 °C) and PHB and the PHB /DGEBA 50/50 blend. The DGEBA molecules, which are represented as ^, are segregated to the amorphous region, and the shaded region, which is occupied by the RAF, is important for Tc=60 °C. The more important changes when the DGEBA content increases occur for the amorphous dimension.

Schematic representation of the limitation that the RAF imposes on the growth of the crystal depending on the crystallization temperature (Tc) and composition (pure PHB (a, b) and PHB/DGEBA 50/50 (c, d)) and its influence on Lc and La (see text). The symbol ^ represents the DGEBA molecule. The numeric values indicate the dimensions of the Lc or La obtained from SAXS and are expressed in nanometers.

In addition, because this effect is associated with the RAF mobility of PHB, the results shown in Figure 2k and l for PHB/DGEBA blends with a 50/50 ratio indicate that the described process exhibits less influence on the La and Lc parameters because the presence of DGEBA may affect the RAF mobilization and recrystallization process of PHB in the blend. This subject is specifically discussed further in this study. Figures 2e and h show the results for the intermediate states discussed.

Influence of DGEBA on the recrystallization and DGEBA segregation processes

In Figure 4, a plot of La, which was calculated using the results shown in Figure 2, is shown as a function of the PHB content, which was measured at 30 °C for the three crystallization temperatures studied. A nearly constant value was observed for both crystallization temperatures for the blends with a PHB content of 50 and 70%. As the PHB content increased from 70 to 100%, La decreased. A maximum La was observed for a PHB content of ~70%. No important differences were observed between the results obtained at different Tc values.

When DGEBA was added (decrease in PHB), the increase in La indicates that segregation toward the amorphous region occurred for a DGEBA content <30% (or PHB higher than 70%). For a DGEBA content higher than 30%, La does not continue to increase. Therefore, another type of segregation (that is, interfibrillar or interspherulitic) can be expected. This result was previously reported based on studies of PHB/DGEBA blends crystallized at lower temperatures.15 In the current study, the observed behavior of La as a function of the PHB content is independent of the crystallization temperature.

In Figure 2, for a given crystallization temperature, Lc substantially increases when the measurement temperature is higher than a determined temperature. This increase is associated with further crystallization and/or recrystallization,12 which increases the crystalline dimension. The temperature at which Lc increases is near 120 °C for Tc=60 °C and higher for Tc=100 °C (that is, close to 140 °C) based on previously reported results.12

In Figure 5, the DSC results are shown. Specifically, the thermograms corresponding to heating after isothermal crystallization at 60 and 100 °C at a rate of 10 °C min−1 are shown. The endothermic peaks are associated with melting of crystals, and a double peak was observed. According to Righetti et al.,12 the first peak indicates melting of the original crystals and the second one indicates melting of reorganized or recrystallized crystals. On the right side of the Figure 5, a magnified section is shown, where the onset of melting is indicated. The results confirm that the increase in Lc at high temperatures is owing to a melting and reorganization process or recrystallization process. The crystals formed at this stage have dimension that is higher than that of the original crystals, and an increase in the mean Lc value was observed.

Righetti et al. concluded that reorganization and recrystallization can develop during heating, which can result in the mobilization of the RAF. From the deformation of the SAXS spectra and the appearance of a second peak, recrystallization with a discontinuous lamellar dimension can exist. However, the principal peak shifts at lower q values, and reorganization cannot be disregarded.

The rate of increase in Lc as a function of temperature is similar for all of samples at Tc=60 °C. However, for Tc=100 °C, there is a change in the PHB/DGEBA 70/30 and 50/50 blends relative to the PHB/DGEBA 90/10 blend and PHB.

On the basis of these results, DGEBA promotes recrystallization by decreasing the recrystallization temperature in the blends and allowing for a higher Lc value to be reached compared to pure PHB. This result may be associated with the rejection of DGEBA out of the lamellas, which can also facilitate the transition from the crystal to the mesomorphic state and from this state to crystals with dimensions that are different from the original lamellae.

In the PHB/DGEBA blends, the authors recently reported a value of −0.86 for the interaction parameter in the molten state,15 which ensures an interaction force between DGEBA and amorphous PHB. In contrast, DGEBA is a smaller molecule than the other polymers used as components in blends with PHB. Therefore, a weak entropic force can be expected.

For a DGEBA content higher than 30%, interfibrillar or interspherulitic segregation can be expected. Therefore, DGEBA can move a greater distance out of the interlamellar region. The region where the DGEBA settles depends on the ratio between the diffusion rate and the crystal growth rate. If the diffusion is higher than the crystal growth rate, the DGEBA can move out of the spherulite toward the interspherulitic region. In this case, the composition in the front of the crystal can change, and the growth rate can also change as a function of time.

Conclusions

The crystallization and melting processes in PHB and the PHB/DGEBA blends were studied using SAXS at several temperatures. The variation in the lamellar dimensions due to the addition of DGEBA was determined for two selected crystallization temperatures, and DGEBA content segregation was observed. The development of a rigid amorphous fraction during crystallization strongly influenced the variation in the crystalline and amorphous lamellae dimensions during posterior heating. The relaxation of the rigid amorphous fraction assists the crystallization process at crystallization temperatures higher than 70 °C, and the same rigid amorphous fraction constrains crystal development at crystallization temperatures less than this temperature limit. This process was studied using the changes in Lc with the crystallization temperature and ratio between the blend components. The segregation is interlamellar for a DGEBA content <30% and does not depend on the crystallization temperature. For a DGEBA content higher than 30%, the segregation can be interfibrillar or interspherulitic.

The segregation of DGEBA favors the recrystallization of PHB, as indicated by the results of Lc as a function of temperature. At high temperatures, the coexistence of lamellae with different dimensions was observed.

References

Barham, P. J., Keller, A., Otun, E. L. & Holmes, P. A. Crystallization and morphology of a bacterial thermoplastic: poly-3-hydroxybutyrate. J. Mater. Sci. 19, 2781–2794 (1984).

Xing, P., Dong, L., An, Y., Feng, Z., Avella, M. & Martuscelli, E. Miscibility and crystallization of poly(β-hydroxybutyrate) and poly(p-vinylphenol) blends. Macromolecules 30, 2726–2733 (1997).

Armentano, I., Fortunati, E., Burgos, N., Dominici, F., Luzi, F., Fiori, S., Jiménez, A., Yoon, K., Ahn, J., Kang, S. & Kenny, J. M. Processing and characterization of plasticized PLA/PHB blends for biodegradable multiphase systems. eXPRESS Polym. Lett. 9, 583–596 (2015).

Pearce, R., Brown, G. R. & Marchessault, R. H. Crystallization kinetics in blends of isotactic and atactic poly(β-hydroxybutyrate). Polymer 35, 3984–3989 (1994).

Kaito, A. Unique orientation textures formed in miscible blends of poly(vinylidene fluoride) and poly[(R)-3-hydroxybutyrate]. Polymer 47, 3548–3556 (2006).

Sawayanagi, T., Tanaka, T., Iwata, T., Abe, H., Doi, Y., Ito, K., Fujisawa, T. & Fujita, M. Real-time synchrotron SAXS and WAXD studies on annealing behavior of Poly[(R)-3-hydroxybutyrate] single crystals. Macromolecules 39, 2201–2208 (2006).

Guo, L., Spegazzini, N., Sato, H., Hashimoto, T., Masunaga, H., Sasaki, S., Takata, M. & Ozaki, Y. Multistep crystallization process involving sequential formations of density fluctuations, “intermediate structures”, and lamellar crystallites: poly(3-hydroxybutyrate) as investigated by Time-Resolved Synchrotron SAXS and WAXD. Macromolecules 45, 313–328 (2012).

Suttiwijitpukdee, N., Sato, H., Zhang, J. & Hashimoto, T. Effects of intermolecular hydrogen bondings on isothermal crystallization behavior of polymer blends of cellulose acetate butyrate and poly(3-hydroxybutyrate). Macromolecules 44, 3467–3477 (2011).

Strobl, G. Crystallization and melting of bulk polymers: New observations, conclusions and a thermodynamic scheme. Prog. Polym. Sci. 31, 398–442 (2006).

Di Lorenzo, M. L., Gazzano, M. & Righetti, M. C. The role of the rigid amorphous fraction on cold crystallization of poly(3-hydroxybutyrate). Macromolecules 45, 5684–5691 (2012).

Rastogi, S., Lippits, D. R., Terry, A. E. & Lemstra, P. J. in Progress in Understanding of Polymer Crystallization (eds Reiter, G. & Strobl, G. R.) Ch. 15, 285–327 (Springer-Verlag, Berlin, Germany, 2007)

Righetti, M. C., Tombari, E. & Di Lorenzo, M. L. The role of the crystallization temperature on the nanophase structure evolution of poly[(r)-3-hydroxybutyrate]. J. Phys. Chem. B 117, 12303–12311 (2013).

Schick, C., Wurm, A. & Mohamed, A. Vitrification and devitrification of the rigid amorphous fraction of semicrystalline polymers revealed from frequency-dependent heat capacity. Coll. Polym. Sci 279, 800–806 (2001).

Di Lorenzo, M. L. Spherulite growth rates in binary polymer blends. Prog. Polym. Sci. 28, 663–689 (2003).

Silva, L., Tognana, S. & Salgueiro, W. Miscibility in crystalline/amorphous blends of poly(3-hydroxybutyrate)/ DGEBA. J. Polym. Sci. B Polym. Phys. 51, 680–686 (2013).

Tognana, S., Silva, L. & Salgueiro, W. Crystallization in PHB/DGEBA blends. J. Polym. Sci. B: Polym. Phys 52, 882–886 (2014).

Heo, K., Yoon, J., Jin, K. S., Jin, S., Sato, H., Ozaki, Y., Satkowski, M. M., Noda, I. & Ree, M. Structural evolution in microbial polyesters. J. Phys. Chem. B 112, 4571–4582 (2008).

Hama, H. & Tashiro, K. Structural changes in isothermal crystallization process of polyoxymethylene investigated by time-resolved FTIR, SAXS and WAXS measurements. Polymer 44, 6973–6988 (2003).

Strobl, G. The Physics of Polymer, (Springer-Verlag, Berlin, Germany, 2007).

Cardoso, M. B. & Westfahl, H. Jr On the lamellar width distributions of starch. Carbohydrate Polymers 81, 21–28 (2010).

Plivelic, T. S., Cassu, S. N., Goncalves, M. C. & Torriani, I. L. Structure and morphology of poly(ɛ-caprolactone)/chlorinated polyethylene (PCL/PECl) blends investigated by DSC, Simultaneous SAXS/WAXD, and elemental mapping by ESI-TEM. Macromolecules 40, 253–264 (2007).

Ryan, A. J. SAXS correlation functions: New Software at Daresbury. Fibre Diffraction Review 3, 25–29 (1994).

Stribeck, N. X-Ray Scattering of Soft Matter, (Springer-Verlag, Berlin, Germany, 2007).

Hsiu-Jung, Chiu, Hsin-Lung, Chen, Tsang-Lang, Lin & Lin, J.S. Phase structure of poly(3-hydroxy butyrate)/poly(vinyl acetate) blends probed by small-angle X-ray scattering. Macromolecules 32, 4969–4974 (1999).

Hoffman, J. D., Davis, G. T. & Lauritzen, J. I. Jr . in Treatise on Solid State Chemistry: Crystalline and Noncrystalline Solids, (ed. Hannay, N. B.) Vol 3, 497–614 (Plenum Press, New York, NY, USA, 1976)

Dubini Paglia, E., Beltrame, P.L., Canetti, M., Seves, A., Marcandalli, B. & Martuscelli, E. Crystallization and thermal behaviour of poly (d(−) 3-hydroxybutyrate)/poly(epichlorohydrin) blends. Polymer 34, 996–1001 (1993).

Acknowledgements

We acknowledge the support of the Brazilian Synchrotron Light Laboratory (LNLS), CNPEM/MCT, line SAXS 1 (Project 7765; Proposals D11A-SAXS1–11725 and SAXS1-13691), Comisión de Investigaciones Científicas de la Provincia de Buenos Aires (CIC), the CIC grant program for projects of scientific and technological research 2013 (Res. 813/13), SECAT (UNCPBA) and ANPCyT-FONCyT, PICT 2013-0686, Argentina. We thank M Cardoso, JM. Polli, D Magalhaes, T Kalileand, L Cavalcanti and L Franca for their technical support during the measurements at LNLS.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Competing interests

The authors declare no conflict of interest.

Rights and permissions

About this article

Cite this article

Tognana, S., Salgueiro, W. Influence of the rigid amorphous fraction and segregation during crystallization in PHB/DGEBA blends. Polym J 47, 789–795 (2015). https://doi.org/10.1038/pj.2015.71

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/pj.2015.71