Abstract

To evaluate the effect of chromophore location on electroluminescent performance, three types of block copolymers consisting of polyfluorene and polytriarylamine with benzothiadiazole (BT) moieties were synthesized and characterized. A BT unit was incorporated at the junction between blocks (BP 1) in the polytriarylamine block (BP 2) or in the polyfluorene block (BP 3). An electroluminescent device based on BP 1 exhibited the best performance. This result is reasonably explained by considering the difference in recombination probability in the phase-separated active layers. Different chemical structures of emitting sites afford different emission wavelengths, which are dependent on the electron-donating nature of substituents on the BT rings.

Similar content being viewed by others

Introduction

Organic light-emitting diodes (OLEDs) based on luminescent-conjugated polymers have many advantages over other existing light technologies, including their light weight, simple battery operation, high visibility and quick response. One of the key benefits of polymer light-emitting devices (PLEDs) or polymer OLEDs is that they can be completely assembled by solution-based processing. The advantage that solution processing can provide is in the potential for fabricating devices with large surface areas, including flexible items, signage and related applications.1, 2, 3, 4, 5, 6, 7, 8, 9, 10

Polyfluorenes (PFs) and their derivatives have been extensively studied in recent years because of their high photoluminescence (PL) and electroluminescence efficiencies, as well as good thermal properties.11, 12, 13, 14, 15 Moreover, the emission of PFs can be easily tuned to access the entire visible region by introducing narrow bandgap monomers into the PF backbone.16, 17, 18, 19, 20 Nevertheless, there are some drawbacks that continue to interrupt their potential applicability such as low hole mobility.21 Because of the high ionization potential of PFs, a high energy barrier exists for hole injection into PF from indium tin oxide or poly(3,4-ethylenedioxythiophene)/polystyrene sulfonate (PEDOT:PSS). Hole transporting moieties have been introduced to PF backbones to improve brightness, efficiency, operation stability, balanced carrier injection and charge carrier transport properties of charge carrier.22, 23

We previously reported the synthesis of PF-b-polytriarylamine (PF-b-PTAA) block copolymers for OLEDs device via Suzuki coupling polymerization followed by C–N coupling polymerization, in which the PTAA backbone was modified with triethyleneoxide groups.24 PF-b-PTAA exhibited better performance in OLEDs than conventional PF homopolymer because the segregation of PTAA in the vicinity of PEDOT:PSS via hydrogen bonding leads to facile hole injection from an anode and/or efficient electron blocking by PTAA moieties.25 We also reported a novel methodology for tuning the emission color. PF-b-PTAAs are chemically modified with an emitting (narrow bandgap) moiety at the junction of two blocks.26, 27 Because of the microphase separation, it is considered that the emitting sites are mainly located at the interface of phase-separated domains. As a result, more efficient energy transfer and carrier traps are anticipated. In fact, the introduction of phenoxazine26 and benzothiadiazole (BT)27 units at the junction resulted in green and orange emissions, respectively. In our recent paper, we synthesized orange-emitting PF-b-PTAAs containing BT moieties in the junctions between blocks (BP 1), and applied them to white OLEDs using the blend with PF as the emitting layer.28 However, the effect of the chromophore location on electroluminescent performance is still unclear. In this study, in addition to BP 1, we synthesize two types of PF-b-PTAAs containing a BT moiety introduced in either the PTAA block (BP 2) or in the PF block (BP 3) and elucidate the location effect on EL performance in devices fabricated with these block copolymers.

Experimental procedures

Materials

All reagents and solvents were used without further purification unless stated otherwise. Tetrahydrofuran (THF) was distilled over sodium and benzophenone and stored under a nitrogen atmosphere. Toluene and o-dichlorobenzene were distilled over calcium hydride and stored under a nitrogen atmosphere. All the monomers, 2,7-dibromo-9-(4-methylphenyl)-9-(4-octylphenyl)fluorene (1), 2,7-bis(4,4,5,5-tetramethyl-1,3,2-dioxaborolan-2-yl)-9-(4-methylphenyl)-9-(4-octylphenyl)fluorene (2), (4′-bromobiphenyl-4-yl)-(4-{2-[2-(2-methoxyethoxy)ethoxy]ethoxy}phenyl)amine (3), 4,7-dibromobenzo[1,2,5]thiadiazole (4) and 4-(4′-bromophenyl)-7-[4″-(4‴-butylphenylamino)phenyl]-2,1,3-benzothiadiazole (5) were synthesized as reported previously.24, 27, 28

Synthesis of BT-terminated PF (PF 1) and its block copolymer (BP 1)

BT-terminated PF (PF 1) and its block copolymer with PTAA (BP 1) were synthesized according to the procedure reported in our recent paper.28

Synthesis of triethyleneoxide-terminated PF (PF 2)

To a 10-ml, round-bottom flask equipped with a stopcock and a condenser were added 1 (0.0787 g, 0.131 mmol), 2 (0.100 g, 0.143 mmol), 3 (0.008 g, 0.020 mmol), Pd(PPh3)4 (0.001 g, 0.5 mol%), 2 m aqueous solution of K2CO3 (2 ml) and toluene (2 ml) under a nitrogen atmosphere, and the mixture was stirred and heated to 80 °C for 72 h. After the reaction was complete, 50 ml of toluene was added, and the resulting solution was washed with a saturated aqueous solution of NaCl and dried with MgSO4. The solution was concentrated and then poured into methanol to precipitate the product, which was isolated by filtration and then washed with acetone using a Soxhlet extractor for 24 h to give PF 2 in 76.9% yield (0.100 g). Proton nuclear magnetic resonance (1H NMR) (400 MHz, CDCl3), δ (p.p.m.): 7.88–7.67 (m, 35H; Ar H), 7.64–7.4 (m, 96H; Ar H), 7.2–6.8 (m, 211H; Ar H), 7.65–7.43 (m, 101H; Ar H), 5.63 (s, 1H; NH), 4.13 (m, 2H; CH2O), 3.87 (m, 2H; CH2O), 3.76 (m, 2H; CH2O), 3.67 (m, 2H; CH2O), 3.56 (m, 2H; CH2O), 3.4 (s, 3H, CH3), 2.63–2.46 (m, 49H; CH2), 2.3 (s, 75H; CH3), 1.68–1.5 (m, 50H; CH2), 1.47–1.16 (m, 247H; C5H10) and 0.9–0.81 (m, 70H; CH2).

Synthesis of BP 2

To a 20-ml two-necked round-bottom flask equipped with a stopcock and a condenser were added PF 2 (0.06 g, 0.015 mmol), 3 (0.119 g, 0.30 mmol), 5 (0.0154 g, 0.030 mmol) Pd(OAc)2 (0.0014 g, 0.006 mmol), t-BuONa (0.033 g, 0.35 mmol) and toluene (3 ml) under a nitrogen atmosphere. After three freeze–pump–thaw cycles, P(t-Bu)3 (7.5 μl, 0.01 mmol) was added at room temperature. The mixture was stirred under reflux for 24 h. The recovery of the resulting polymer was similar to the isolation and purification of PF 2. The yield of BP 2 was 0.154 g (91.3%). 1H NMR (400 MHz, CDCl3), δ (p.p.m.): 8.1–7.35 (m, 22H; Ar H), 7.21–6.77 (m, 20H; Ar H), 4.14 (m, 2H; CH2O), 3.87 (m, 2H; CH2O), 3.76 (m, 2H; CH2O), 3.67 (m, 2H; CH2O), 3.57 (m, 2H; CH2O), 3.39 (s, 3H, CH3), 2.65–2.43 (m, 2H; CH2), 2.23 (s, 3H; CH3), 1.69–1.47 (m, 2H; CH2), 1.41–1.16 (m, 10H; C5H10), 0.96 (m, 0.1H; CH3) and 0.86 (m, 2H; CH3).

Synthesis of triethyleneoxide-terminated PF containing BT (PF 3)

To a 10-ml, round-bottom flask equipped with a stopcock and a condenser were added 1 (0.071 g, 0.118 mmol), 2 (0.099 g, 0.143 mmol), 3 (0.008 g, 0.019 mmol), 4 (0.003 g, 0.012 mmol), Pd(PPh3)4 (0.001 g, 0.5 mol%), 2 m aqueous solution of K2CO3 (2 ml) and toluene (2 ml) under a nitrogen atmosphere, and the mixture was stirred and heated at 80 °C for 72 h. The resulting polymer was purified in a manner similar to PF 2. The yield was 0.085 g (69.6%). 1H NMR (400 MHz, CDCl3), δ (ppm): 8.22–7.67 (m, 35H; Ar H), 7.66–7.42 (m, 96H; Ar H), 7.2–6.74 (m, 176H; Ar H), 5.6 (s, 1H; NH), 4.14 (m, 2H; CH2O), 3.87 (m, 2H; CH2O), 3.75 (m, 2H; CH2O), 3.68 (m, 2H; CH2O), 3.57 (m, 2H; CH2O), 3.39 (s, 3H, CH3), 2.62–2.42 (m, 57H; CH2), 2.3 (s, 67H; CH3), 1.55 (m, 65H; CH2), 1.39–1.14 (m, 317H; C5H10), 1.06 (t, J=7.3 Hz, 3H; CH3) and 0.92–0.77 (m, 70H; CH2).

Synthesis of BP 3

To a 20-ml two-necked round-bottom flask equipped with a stopcock and a condenser were added PF 3 (0.06 g, 0.006 mmol), 3 (0.024 g, 0.060 mmol), Pd(OAc)2 (0.0014 g, 0.006 mmol), t-BuONa (0.007 g, 0.070 mmol) and toluene (3 ml) under a nitrogen atmosphere. After three freeze–pump–thaw cycles, P(t-Bu)3 (7.5 μl, 0.01 mmol) was added at room temperature. The mixture was stirred under reflux for 24 h. The yield of BP 3 was 0.049 g (61.6%). 1H NMR (400 MHz, CDCl3), δ (p.p.m.): 8.2–7.3 (m, 95H; Ar H), 7.2–6.76 (m, 130H; Ar H), 4.14 (m, 2H; CH2O), 3.87 (m, 2H; CH2O), 3.75 (m, 2H; CH2O), 3.70 (m, 2H; CH2O), 3.56 (m, 2H; CH2O), 3.38 (s, 3H, CH3), 2.68–2.41 (m, 32H; CH2), 2.3 (s, 37H; CH3), 1.55 (m, 43H; CH2), 1.41–1.14 (m, 196H; C5H10) and 0.94–0.78 (m, 60H; CH3).

Analytical methods

1H NMR spectra were obtained on a an ECX300 or ECX400 instrument (JEOL, Tokyo, Japan) at 300 or 400 MHz at 25 °C. Deuterated chloroform was used as a solvent with tetramethylsilane as an internal standard. Number- and weight-average molecular weights (Mn and Mw) and polydispersity index (PDI) were determined by gel permeation chromatography (GPC) with a an RI-2031 detector (JASCO, Tokyo, Japan) eluting with chloroform at a flow rate of 0.5 ml min−1 at room temperature and calibrated by standard polystyrene samples. Differential scanning calorimetry (DSC) was performed on a DSC-8230 (Rigaku, Tokyo, Japan) under a nitrogen atmosphere at heating and cooling rates of 10 °C min−1. Ultraviolet–visible (UV–vis) absorption spectra were obtained on a V-570 spectrophotometer (JASCO), and PL spectra were obtained with a an FP-6500 spectrophotometer (JASCO) with an excitation at 380 nm. All measurements were carried out in film and solution states. Cyclic voltammetry measurements were conducted at room temperature on a Model HZ-5000 potentiogalvanostat (Hokuto Denko, Tokyo, Japan) equipped with a typical three-electrode cell, with a working electrode (glassy carbon electrode), a reference electrode (Ag/AgCl), and a counter electrode (Pt wire) at a scanning rate of 0.1 V s−1. In all measurements, acetonitrile and tetrabutylammonium tetrafluoroborate (0.1 m) were used as solvent and supporting electrolyte, respectively. The measurements were performed using thin films prepared on the working electrode by dip-coating. The highest occupied molecular orbital and lowest unoccupied molecular orbital levels were determined from the onset of each oxidation and reduction wave.

Device fabrication

Before fabrication of a device, a glass slide with indium tin oxide patterns was washed by an alkaline cleaner under sonication, and rinsed with distilled water. The substrate was subsequently washed with electronic grade 2-propanol under sonication, rinsed with clean electronic grade 2-propanol and dried with nitrogen. PEDOT:PSS with 30 nm of thickness was spin-coated on the substrate at 2500 r.p.m. for 45 s from the dispersion in water filtered through a 0.2 μm membrane filter, followed by annealing at 200 °C for 1 h under air. Then, the polymer solution of o-dichlorobenzene was spin-coated on top of the PEDOT:PSS layer at various revolutions per minute, followed by annealing at 120 °C for 1 h under argon atmosphere. Later, BCP (2,9-dimethyl-4,7-diphenyl-1,10-phenanthroline) with a thickness of 50 nm was deposited by thermal evaporation in carbon pot at 230 °C under vacuum at a rate of 1.5 Å s−1. For the cathode, 0.5 nm of lithium fluoride was deposited onto the organic layer of thickness at a rate of 0.1 Å s−1, followed by 100 nm of aluminum (Al) at a rate of and 4.0 Å s−1 using tantalum boats. Finally, a metal can with barium oxide as a drying agent was set onto PLED under air and passivated with an epoxy resin (XNR 5570-B1; Nagase ChemteX Corporation, Osaka, Japan) irradiated with UV light.

Results and discussion

Synthesis of block copolymers

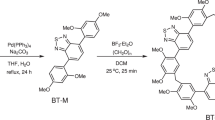

Three types of block copolymers consisting of PF and PTAA with a BT moiety were designed in to investigate the effect of the location of the emitting BT moiety as shown in Scheme 1 for BP 2, Scheme 2 for BP 3 and our previous work for BP 1.28 As presented in Figures 1 and 2, a BT unit is incorporated at the junction between blocks (BP 1),28 in the PTAA block (BP 2), and in the PF block (BP 3). The precursors (PFs 1–3) were synthesized via a Suzuki–Miyaura coupling polymerization. The polymerization conditions are summarized in Table 1. PF 1 terminated with a BT-containing diphenylamine unit was converted to BP 1, which possessed a BT moiety at the junction, via palladium catalyzed C–N coupling polymerization. PF 2 containing diphenylamine moieties at the chain ends was converted to BP 2 via a similar C–N coupling copolymerization of monomer 3 with BT-containing diphenylamine monomer 5. In the resulting block copolymer, BT units were in the PTAA block. PF 3 was prepared by the copolymerization with BT-containing monomer 4 and then converted to BP 3 using a procedure similar to what was used in the preparation of BP 1. The characteristics of PFs 1–3 and BPs 1–3 are summarized in Tables 2 and 3.

Chemical structures of the precursors (PFs 1–3) and the block copolymers (BPs 1–3) were confirmed by 1H NMR as shown in Supplementary Figures S1 and 2 and previous work.28 All precursors exhibited N–H signals at ~5.8 p.p.m., suggesting the introduction of monomers 5 (for PF 1) and 3 (PFs 2 and 3). PF 1 also shows a signal that can be assigned to the methyl group and aromatic methine in monomer 5.28 In the case of PF 2, signals arising from a trioxyethylene group from 3.3 to 4.2 p.p.m., as well as an N–H signal were observed (Supplementary Figure S1a). The 1H NMR spectrum for PF 3 (Supplementary Figure S1b) is similar to that of PF 2. As discussed later, incorporation of monomer 4 was confirmed by UV and PL spectra. In the spectra of all BPs, the intensity of the signals for trioxyethylene group increased relative to the precursors, indicating the formation of block copolymers. In BPs 1 and 2, methyl signals derived from monomer 5 appeared, which made it possible to estimate the BT content (BP 1; 0.7 mol%, BP 2; 1.1 mol%). Because the BT content in BP 3 cannot be determined by 1H NMR, the value is assumed to be the same as the feed ratio. The molar ratio of the repeating unit of each block copolymer was estimated from 1H NMR, and is summarized in Table 3.

The GPC traces of precursors and block copolymers are presented in Supplementary Figure S3. The Mn and PDI determined by GPC are summarized in Tables 2 and 3. As shown in Table 2, the Mn of end-functionalized PF precursors ranged from 9700 to 10 800 with a PDI from 2.2 to 2.4. Similar molecular weights and PDIs of each precursor were obtained because each polymerization was carried out using the same imbalance of dibromo and diborate monomers in the presence of the same ratio of monobromo monomer (3 or 5). In all the cases, changes in Mn were observed after C–N coupling polymerization. Judging from the chemical composition, and the larger PDI, it is somewhat difficult to incorporate PTAA blocks in BP 3, for unknown reasons. All the block copolymers were soluble in common organic solvents such as chloroform and tetrahydrofuran, indicating that thin films can be fabricated by a solution process.

The glass transition temperature (Tg) of the copolymers was determined from a DSC thermogram. The DSC curves of the block copolymers are presented in Supplementary Figure S4. All the block copolymers showed double Tgs at ~120 and 170–175 °C, corresponding to Tgs values of PF and PTAA, respectively, which were similar to the values of block copolymers without a BT unit as reported previously.24 Tg values of the copolymers are summarized in Table 3. The observation of double Tgs suggests that the copolymers exhibit microphase-separated structures.

Optical properties

The optical properties of BPs were investigated using UV–vis absorption and PL measurements in chloroform (10 mg ml−1) and as films. Figure 3 shows UV–vis and PL spectra of BPs, and the optical properties are summarized in Table 4. All the BPs show similar UV–vis absorption profiles consisting of main absorptions from PF and PTAA units, and a small tail from the BT moieties in both solution and film states. In the PL spectra of the solution for BPs 1 and 2, the main emission from the PF moiety was observed as well as a slight emission from the incorporated BT unit at 520–600 nm. It is noteworthy that relatively strong emission is observed in the solution of BP 3 in the range of 480–600 nm. This result cannot be explained only by the high BT content in BP 3, even while taking the concentration dependence into consideration. This strong emission suggests that the more efficient Förster-type energy transfer from the PF block to the BT unit occurs in the dilute solution of BP 3. This assumption is reasonable because incorporation of a BT unit into the PF chain in BP 3 assures the BT in the vicinity of the PF, even in the dilute solution. In the film state, all BPs exhibit orange emissions because Förster-type energy transfer occurs more effectively in the film state. Relatively strong blue emissions were still observed in BPs 1 and 2 related to the BT’s location, as mentioned above. On the other hand, BP 3 afforded similar PL spectra in the solution and film state because the effective energy transfer occurs even in the solution state.

Optical properties of the block copolymers in solution and film state: (a) UV–vis absorption spectra in solution. (b) UV–vis absorption spectra in solid state. (c) PL spectra in solution. (d) PL spectra in solid state. A full color version of this figure is available at the Polymer Journal journal online.

As listed in Table 4, the wavelengths at maximum emission were 528, 568 and 575 nm for BPs 1–3, respectively. The emission wavelengths of the BT moieties are dependent on the nature of the substituents on the BT unit. In BPs 2 and 3, diarylaminophenyl and fluorenyl groups are symmetrically attached at 4 and 7 positions of the BT units, respectively. In BP 1, the groups are attached asymmetrically. Diarylaminophenyl groups are stronger electron donors than fluorenyl groups; therefore, the observed results are reasonable because the emission wavelength is redshifted when the electron-donating nature of the substituents are increased.29

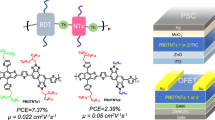

Device performance

The performance of the EL devices based on block copolymers with the device structure of indium tin oxide/PEDOT:PSS/polymer/BCP/lithium fluoride/Al was evaluated. The EL spectra for devices based on BPs are presented in Figure 4, and the wavelengths of the emission peaks and the CIE coordinates are listed in Table 5. Green emission was observed from the BP 3 device with the CIE coordinate of (0.37, 0.58), and orange emission was observed from devices made with BPs 1 and 2, where the CIE coordinates were (0.52, 0.47) and (0.59, 0.43), respectively. Differences in emission wavelength are a result of the different chemical structures of the emitting site, as addressed in the discussion of the PL spectrum. Furthermore, in all EL spectra, no blue emission was observed; nevertheless, slight emission in the blue region was observed in the PL spectra for the thin films. As previously discussed for devices made from BP 1,28 the BT moieties in BP 1 play the role of a trap site, considering the fact that the energy levels of the highest occupied molecular orbital and lowest unoccupied molecular orbital of emitting BT moieties30 lie between the HOMO of PTAA (−5.3 eV)24 and the lowest unoccupied molecular orbital of PF (−2.70 eV).13 Owing to the similarity, this consideration is applicable to the cases of devices made with BPs 2 and 3. Cyclic voltammograms of BPs are presented in Supplementary Figure S5. HOMO levels of BPs were estimated to be −5.32 eV in BP 1,28 and −5.31 eV in BP 2, which are similar to that of PTAA (−5.3 eV).24 It is difficult to determine the HOMO level of BP 3 because there is no oxidation peak in BP 3 due to the low PTAA content. The lowest unoccupied molecular orbital levels of BPs were −2.72 eV for BP 1,28 −2.76 eV for BP 2 and −2.76 eV for BP 3, which were similar to that of PF (−2.70 eV).13 Figure 5 shows the energy level diagrams for BP 1 and BP 2 compared with indium tin oxide as an anode and PEDOT/PSS as the hole injection-layer material. The HOMO levels of BP 1 and BP 2 suitably match the work function of PEDOT/PSS (−5.1 eV), while there was an energy barrier of ~0.20 eV between the HOMO of PEDOT/PSS and those of the BPs.

The effect of the location of the BT moieties was particularly apparent in electrical EL characteristics as shown in Figure 6 and Table 5. The turn-on voltage for a device made from BP 3 was higher than those of other devices. This is probably a result of the low electron blocking ability of the BP 3 active layer because of low levels of PTAA. Electrons injected from the cathode easily pass through the active layer without recombination. As shown in Figure 6, the highest current efficiency was observed in the device prepared with BP 1. As discussed above, BPs presented here have phase-separated systems. On the assumption that hole and electron transport predominantly occurs in phase-separated PTAA and PF domains, respectively, recombination must occur near the interface between the PTAA and PF domains. In the BP 1 active layer, the emitting BP unit incorporated at the junction of two blocks is located at the interface, which is a favorable situation for the conversion to light.

The current efficiencies for devices based on BPs 2 and 3 were significantly lower than devices based on BP 1. As discussed for the emission spectra, BT moieties act as trap sites for both holes and electrons in both devices. This means that recombination does not occur in the PF domain to a significant degree, otherwise blue emission would be observed even in the EL spectrum. In the BP 2 active layer, BT units are located on the PTAA chain. Holes in the PTAA domain are efficiently trapped by the BT unit, and electrons exist preferentially in the PF domain. Under these conditions, the probability for recombination of holes and electrons is lower because electron injection from the PF to the PTAA domains is difficult owing to the high energy barrier. This is the reason why current efficiency for the device prepared with BP 2 is much lower than that of the BP 1 device. In the case of the BP 3 device, the BT unit is located on the PF chain, so a similar consideration is reasonable. Therefore, it is concluded that locating the emitting site at the junction is essential for higher recombination probabilities in the molecular design of block copolymer-based materials.

Conclusion

Green- or orange-emitting block copolymers consisting of PF and PTAA with BT moieties at the junction between PF and PTAA, in the PTAA chain, or in the PF chain, were successfully synthesized by Suzuki coupling polymerization followed by C–N coupling polymerization. When BT was incorporated into the PF chain, relatively strong emission from the BT units was observed even in the dilute solution resulting from the efficient Förster-type energy transfer from the PF block to the BT unit. Evaluation of electroluminescent performance for devices prepared with these synthesized block copolymers as phase-separated active layers revealed that the location of the emitting site at the junction provided the best current efficiency because of the higher recombination probability compared with other locations.

Synthesis of polyfluorene 2 (PF 2) and BP 2.

Synthesis of polyfluorene 3 (PF 3) and BP 3.

References

Tang, C. W., VanSlyke, S. A. & Chen, C. H. Electroluminescence of doped organic thin films. J. Appl. Phys. 65, 3610–3616 (1989).

Yuji, H., Takeshi, S., Kenichi, S. & Kazuhiko, K. Influence of the emission site on the running durability of organic electroluminescent devices. Jpn J. Appl. Phys. 34, L824 (1995).

Granström, M. & Inganäs, O. White light emission from a polymer blend light emitting diode. Appl. Phys. Lett. 68, 147–149 (1996).

Tokito, S., Sakata, J. & Taga, Y. Organic/inorganic superlattices with ordered organic layers. J. Appl. Phys. 77, 1985–1989 (1995).

Christ, T., Greiner, A., Sander, R., Stümpflen, V. & Wendorff, J. H. Multicoloured chromophore for white-light-emitting diodes. Adv. Mater. 9, 219–222 (1997).

Kido, J., Hongawa, K., Okuyama, K. & Nagai, K. White light-emitting organic electroluminescent devices using the poly(N-vinylcarbazole) emitter layer doped with three fluorescent dyes. Appl. Phys. Lett. 64, 815–817 (1994).

Deshpande, R. S., Bulović, V. & Forrest, S. R. White-light-emitting organic electroluminescent devices based on interlayer sequential energy transfer. Appl. Phys. Lett. 75, 888–890 (1999).

Adachi, A., Manhart, S. A., Okita, K., Kido, J., Ohshita, J. & Kunai, A. Multilayer electroluminescent device using organosilicon polymer as hole transport layer. Synth. Met. 91, 333–334 (1997).

Strukelj, M., Jordan, R. H. & Dodabalapur, A. Organic multilayer white light emitting diodes. J. Am. Chem. Soc. 118, 1213–1214 (1996).

Lim, E., Jung, B.-J. & Shim, H.-K. Improved EL efficiency of fluorene-thieno[3,2-b]thiophene-based conjugated copolymers with hole-transporting or electron-transporting units in the main chain. J. Polym. Sci. A 44, 243–253 (2006).

Gross, M., Muller, D. C., Nothofer, H. G., Scherf, U., Neher, D., Brauchle, C. & Meerholz, K. Improving the performance of doped [pi]-conjugated polymers for use in organic light-emitting diodes. Nature 405, 661–665 (2000).

Friend, R. H., Gymer, R. W., Holmes, A. B., Burroughes, J. H., Marks, R. N., Taliani, C., Bradley, D. D. C., Dos Santos, D. A., Brédas, J. L., Lögdlund, M. & Salaneck, W. R. Electroluminescence in conjugated polymers. Nature 397, 121–128 (1999).

Neher, D. Polyfluorene homopolymers: conjugated liquid-crystalline polymers for bright blue emission and polarized electroluminescence. Macromol. Rapid Commun. 22, 1365–1385 (2001).

Scherf, U. & List, E. J. W. Semiconducting polyfluorenes—towards reliable structure–property relationships. Adv. Mater. 14, 477–487 (2002).

Knaapila, M. & Monkman, A. P. Methods for controlling structure and photophysical properties in polyfluorene solutions and gels. Adv. Mater. 25, 1090–1108 (2013).

Wu, Y.-S., Hwang, S.-W., Chen, H.-H., Lee, M.-T., Shen, W.-J. & Chen, C.-H. Efficient white organic light emitting devices with dual emitting layers. Thin Solid Films 488, 265–269 (2005).

Meerholz, K., Müller, C.-D. & Nuyken, O. in Organic Light Emitting Devices (eds. Müllen, K., Scherf, U.) Ch.9, 293–318 (Wiley, 2006)

Gong, X., Wang, S., Moses, D., Bazan, G. C. & Heeger, A. J. Multilayer polymer light-emitting diodes: white-light emission with high efficiency. Adv. Mater. 17, 2053–2058 (2005).

Klärner, G., Lee, J.-I., Lee, V. Y., Chen, J.-P., Nelson, A., Markiewicz, D., Siemens, R., Scott, J. C. & Miller, R. D. Cross-linkable polymers based on dialkylfluorenes. Chem. Mater. 11, 1800–1805 (1999).

Chen, J. P. et al Efficient, blue light-emitting diodes using cross-linked layers of polymeric arylamine and fluorene. Synth. Met. 107, 129–135 (1999).

Khan, R. U. A., Poplavskyy, D., Kreouzis, T. & Bradley, D. D. C. Hole mobility within arylamine-containing polyfluorene copolymers: a time-of-flight transient-photocurrent study. Phys. Rev. B 75, 035215 (2007).

Zhang, Q. Polymer light-emitting diodes based on end-capped poly[9,9-di-(2′-ethylhexyl)fluorenyl-2,7-diyl]. Chin. J. Chem. 28, 1482–1486 (2010).

Lee, S. K., Ahn, T., Cho, N. S., Lee, J.-I., Jung, Y. K., Lee, J. & Shim, H. K. Synthesis of new polyfluorene copolymers with a comonomer containing triphenylamine units and their applications in white-light-emitting diodes. J. Polym. Sci. A 45, 1199–1209 (2007).

Tan, Y., Gu, Z., Tsuchiya, K. & Ogino, K. Synthesis and luminescent properties of block copolymers based on polyfluorene and polytriphenylamine. Polymer 53, 1444–1452 (2012).

Park, C., Yoon, J. & Thomas, E. L. Enabling nanotechnology with self assembled block copolymer patterns. Polymer 44, 6725–6760 (2003).

Jahanfar, M., Tan, Y., Tsuchiya, K., Shimomura, T. & Ogino, K. Polyfluorene-polytriarylamine block copolymer as an additive for electroluminescent devices based on polymer blends. Open J. Org. Polym. Mater. 3, 41–45 (2013).

Tsuchiya, K., Sakakura, T. & Ogino, K. Synthesis of triphenylamine copolymers and effect of their chemical structures on physical properties. Macromolecules 44, 5200–5208 (2011).

Kim, K., Inagaki, Y., Kanehashi, S. & Ogino, K. Incorporation of benzothiadiazole moiety at junction of polyfluorene-polytriarylamime block copolymer for effective color tuning in organic light emitting diode. J. Appl. Polym. Sci. 134, 45393 (2017).

Kato, S.-I., Matsumoto, T., Shigeiwa, M., Gorohmaru, H., Maeda, S., Ishi-i, T. & Mataka, S. Novel 2,1,3-benzothiadiazole-based red-fluorescent dyes with enhanced two-photon absorption cross-sections. Chem. Eur. J. 12, 2303–2317 (2006).

Liu, J., Zhou, Q. G., Cheng, Y. X., Geng, Y. H., Wang, L. X., Ma, D. G., Jing, X. B. & Wang, F. S. White electroluminescence from a single-polymer system with simultaneous two-color emission: polyfluorene as the blue host and a 2,1,3-benzothiadiazole derivative as the orange dopant. Adv. Funct. Mater. 16, 957–965 (2006).

Acknowledgements

This research was partially supported by Grant-in-Aid for Scientific Research (KAKENHI, Grant number 24550209) from the Japan Society for the Promotion of Science (JSPS).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Competing interests

The authors declare no conflict of interest.

Additional information

Supplementary Information accompanies the paper on Polymer Journal website

Supplementary information

Rights and permissions

About this article

Cite this article

Kim, K., Inagaki, Y., Kanehashi, S. et al. Synthesis of polyfluorene-polytriarylamine block copolymers with light-emitting benzothiadiazole moieties: effect of chromophore location on electroluminescent properties. Polym J 49, 721–728 (2017). https://doi.org/10.1038/pj.2017.40

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/pj.2017.40