Abstract

Oxygen vacancies in complex oxides are indispensable for information and energy technologies. There are several means to create oxygen vacancies in bulk materials. However, the use of ionic interfaces to create oxygen vacancies has not been fully explored. Herein, we report an oxide nanobrush architecture designed to create high-density interfacial oxygen vacancies. An atomically well-defined (111) heterointerface between the fluorite CeO2 and the bixbyite Y2O3 is found to induce a charge modulation between Y3+ and Ce4+ ions enabled by the chemical valence mismatch between the two elements. Local structure and chemical analyses, along with theoretical calculations, suggest that more than 10% of oxygen atoms are spontaneously removed without deteriorating the lattice structure. Our fluorite–bixbyite nanobrush provides an excellent platform for the rational design of interfacial oxide architectures to precisely create, control, and transport oxygen vacancies critical for developing ionotronic and memristive devices for advanced energy and neuromorphic computing technologies.

Similar content being viewed by others

Introduction

Owing to the critical role of tunable oxygen defects, mixed ionic and electronic conducting oxides have become key components in many energy technologies, including energy conversion and generation1, solar hydrogen production2, humidity/gas detection3, and catalytic conversion of toxic species in automobile exhausts4. In particular, ceria (CeO2) has attracted extensive attention for its good ionic conductivity and remarkable redox capability5 and hence is widely used as a heterogeneous catalyst6 and oxygen storage component4. Because the key element is the oxygen vacancy7, the creation of oxygen vacancies is a prerequisite for such CeO2-based ionic materials and devices. CeO2 has a fluorite-type structure with a coordination number of 8 for Ce to O atoms8, so aliovalent chemical doping (e.g., yttrium, samarium, and gadolinium) into CeO2 is one of the conventional approaches9 to create oxygen vacancies. Nanoscaling, interfacing, and straining thin films are also known mechanisms to create oxygen vacancies10,11,12. However, the implementation of these approaches for practical applications requires further advancements because the fundamental understanding of oxygen vacancy formation at the atomic level is still lacking.

It was proposed that a space charge region (SCR)12,13,14 could be formed by interfacing the fluorite CeO2 (space group \(Fm\bar 3m \), a = 5.412 Å) with a bixbyite oxide, such as Y2O3 (space group \(Ia \bar 3 \), a = 10.607 Å), along the [100] direction15,16. The bixbyite structure has a “pseudofluorite” structure with an ordered array of vacant oxygen sites occurring on every fourth site (Supplementary Fig. 1), providing an ideal atomic arrangement for forming an interfacial charge layer that originates from the valence mismatch between Ce(4+) and Y(3+). However, the formation of an atomically well-defined (001) interface between the two binary oxides is energetically unfavorable, as the (001) surface has the highest surface energy among the low-index surfaces for both materials. In contrast, the (111) surfaces of fluorite and bixbyite structures are energetically more favorable because of their low surface energy17,18. Thus, determining the viability of the artificial creation of oxygen vacancies at an atomically well-defined (111) interface and understanding the (111) fluorite–bixbyite interface could open a new avenue toward the development of high-performance oxide-based ionotronic devices. Moreover, the Ce4+O2/Y3+2O3 interface offers an interfacial condition similar to that of semiconductor and perovskite-oxide heterointerfaces having polar discontinuity19,20,21. Therefore, understanding the details of the interfacial oxygen vacancy formation reported herein will provide useful insights into developing a novel concept of two-dimensional (2D) ionic channels using atomically engineered oxide interfaces.

In this work, we investigate the viability of colossal formation of oxygen vacancies in CeO2/Y2O3 superlattices with atomically well-defined (111) interfaces formed within a nanobrush architecture (Fig. 1). The nanobrush superlattices offer many advantages over 2D thin films, including much larger surface areas and a larger number of interfaces than exist in planar films, which are useful for many applications in various technologically relevant areas22.

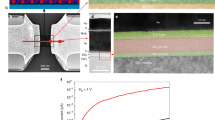

a A cross-sectional HAADF-STEM image of a [(CeO2)6 u.c./(Y2O3)2 u.c.]200 nanobrush superlattice with a thickness of 1.4 μm grown on a (001) YSZ-buffered silicon substrate, taken along the [110] direction. Because of the nonuniform thickness of sublayers originating from faceting, we use the average thickness of the individual layers. Note that oxide nanostructures were grown on (001) YSZ-buffered silicon substrates, as TEM imaging for samples grown directly on YSZ was difficult because of severe charging of electrons. The scale bar corresponds to 50 nm. b Atom probe tomography (APT) reconstruction with Ce and Y atoms displayed as red and blue points, respectively, showing a three-dimensional view of the free-standing [(CeO2)6 u.c./(Y2O3)2 u.c.]200 internal structure. The scale bar corresponds to 20 nm. c Schematic of a (111) interface between CeO2 (fluorite) and Y2O3 (bixbyite), in which red and blue circles represent oxygen atoms in CeO2 and Y2O3, respectively. Cations are not shown. The (111) Y2O3/CeO2 interface is a combination of three different anion arrays, C1, C2, and C3. A cross-section of the C1 array shows a perfect match between numbers of oxygen atoms on interfacing CeO2 and Y2O3 sides. In contrast, on the Y2O3 side of the interface, a cross-section shows on average one oxygen vacancy every four sites in the C2 array and one oxygen vacancy every two sites in the C3 array.

Results

Precision synthesis of a (111) fluorite–bixbyite nanobrush

Figure 1a shows a cross-sectional high-angle annular dark-field (HAADF) image obtained using scanning transmission electron microscopy (STEM) from a 1.4-μm-thick CeO2/Y2O3 nanobrush superlattice grown on a Y2O3-stabilized ZrO2 (YSZ)-buffered (001) silicon substrate. The Z-contrast (Z denotes the atomic number) HAADF image clearly reveals alternating stacks of CeO2 (ZCe = 58) and Y2O3 (ZY = 39) layers. The [(CeO2)6 u.c./(Y2O3)2 u.c.]200 nanobrush superlattice was grown by pulsed laser deposition under an extremely nonequilibrium supersaturated condition, which is far away from the conventional condition optimized for the layer-by-layer growth of 2D thin films. Despite the porous architecture with single-crystalline bristles and the large thickness, the created nanostructure was highly epitaxial and (001)-oriented, as confirmed by X-ray diffraction (XRD) 2θ−θ scans and pole figure measurements (Supplementary Fig. 2). Based upon the XRD data, the epitaxial orientation relationship of the CeO2/Y2O3 nanobrush superlattice on the YSZ-buffered (001) silicon substrate was Y2O3(001)∥CeO2(001)∥YSZ(001)∥Si(001), a finding also confirmed by selected area electron diffraction (Supplementary Fig. 3). While a variety of oxide nanostructures—such as nanorods23,24, nanowires25, nanobelts26, and nanonails27—have been successfully demonstrated, our nanobrush architecture is a revolutionary new form of oxide nanostructure in which the growth is governed by both diffusion-limited aggregation and the shadow effect (Supplementary Fig. 4). The details of the growth mechanism for oxide nanobrush architectures were reported elsewhere28. Interestingly, a characteristic chevron pattern can be seen within each bristle. This chevron pattern originates from the {111} facet formation for both CeO2 and Y2O3, owing to the lowest surface energy17,18. The interface connection of the {111} facets of the CeO2 and Y2O3 sublayers was the key to the spontaneous formation of oxygen vacancies on the CeO2 side, as discussed below.

We performed atom probe tomography (APT) on the CeO2–Y2O3 nanobrush to reveal the three-dimensional (3D) geometry of the nanobristles. Owing to the small nanobristle size (only ~30 nm in the lateral dimension), the growth of a nanobristle on a micron-wide silicon-tip for APT was highly challenging. Nevertheless, we successfully grew a nanobrush sample on a special silicon microtip array and prepared an APT specimen via focused ion beam (FIB) milling, as shown in Supplementary Fig. 5. Figure 1b shows an APT image (see also Supplementary Movie 1 for 3D view) of a (CeO2)6 u.c./(Y2O3)2 u.c. nanobristle. The APT investigation confirmed the chevron pattern on the nanobristles. The overall “Christmas tree-like” shape of the bristles and the chevron pattern on each bristle are only visible along the <110> direction, whereas the <100> directional view reveals a horizontal layer-by-layer stacking of superlattices, clearly visualizing the 3D geometry of the nanobrush samples.

Figure 1c schematically shows top and cross-sectional views of the oxygen coordination mismatch at the (111) interface between the fluorite and the bixbyite, depicting the underlying mechanism for the formation of oxygen vacancies. Only oxygen atoms are shown to reveal the difference in the oxygen network between (111)CeO2 and (111)Y2O3. While the structure of a (001) fluorite/bixbyite interface is rather simple (Supplementary Fig. 1), the oxygen network along the (111) plane is rather complex, forming a triangular network of oxygen vacant sites in Y2O3. The cross-sectional views cut along the C1, C2, and C3 directions clearly visualize the oxygen mismatch between the two materials. This interfacial oxygen coordination mismatch can explain the underlying mechanism behind the formation of the interfacial oxygen vacancies. To cope with the valence mismatch in Y3+ vs. Ce4+, the following two scenarios were considered: (1) formation of an oxygen interstitial in Y2O3 and (2) formation of an oxygen vacancy in CeO2.

Artificial formation of oxygen vacancies at the (111) interface

To confirm the viability of highly confined formation of oxygen vacancies at a (111) interface in a CeO2–Y2O3 nanobrush, we performed a systematic STEM study. Figure 2 shows HAADF and low-angle annular dark-field (LAADF) images obtained from both the tip and middle parts of a [(CeO2)6 u.c./(Y2O3)2 u.c.] nanobristle. In the HAADF images (Fig. 2a, b), the chevron pattern of a stack of alternating CeO2 and Y2O3 layers is clearly visible. As indicated in Fig. 2e, the angle between the two {111} facets is ~70.5°, which can readily be seen when viewed along the [110] direction, confirming the formation of (111) interfaces. The STEM images also reveal that the outer portion of each layer is thinner than its center part. In addition, a fast Fourier transform analysis clearly shows a fully coherent interface (i.e., free from any dislocations) formed between CeO2 and Y2O3 layers (Supplementary Fig. 6). Moreover, at the edge region of the bristles in the HAADF images, the CeO2 layers encase the Y2O3 layers. The capping yields vertically connected CeO2 (Supplementary Fig. 7). This may be attributed to the lower Ehrlich–Schwoebel barrier29 for CeO2 on Y2O3 than for Y2O3 on CeO2.

a, b HAADF images and c, d their corresponding LAADF images taken from the top and middle regions of a free-standing CeO2/Y2O3 nanobristle along the [110] direction. As indicated by the yellow dashed lines, the brighter contrast at the outer parts of the CeO2 sublayers in the LAADF images suggests locally enhanced lattice distortions due to the formation of oxygen vacancies. The scale bar corresponds to 5 nm. e Magnified HAADF image showing atomically abrupt interfaces and {111} Ce facets between CeO2 and Y2O3 layers. The scale bar corresponds to 2 nm. f Geometric phase analysis of the HAADF image shown in e reveals a lattice expansion of the outer parts of the CeO2 layers.

The two interfacial reconstruction scenarios mentioned previously, i.e., (1) formation of an oxygen interstitial on the Y2O3 side and (2) formation of an oxygen vacancy and subsequent Ce3+ ions on the CeO2 side, can result in a local lattice distortion. Such structural disorder can be detected by LAADF imaging, as it leads to electron dechanneling of the incident e-beam30,31. As shown in Fig. 2c, d, the LAADF images reveal an enhanced intensity at the interface between CeO2 and Y2O3. Through a careful examination of the images, we found that the bright contrast originated from the CeO2 side of the interfaces (see the yellow lines in Fig. 2a–d). Note that we have not observed any bixbyite Ce2O3 structures at the CeO2/Y2O3 interface, as confirmed by HAADF imaging (Supplementary Fig. 8). Considering the fact that the lattice mismatch between Ce2O3 and Y2O3 is ~10%, the formation of the bixbyite Ce2O3 phase may not be energetically favorable at the interfaces. LAADF imaging also confirmed that the structurally distorted layer owing to the chemical expansion spanned over ~1 nm in thickness (Supplementary Fig. 9). In addition, a previous TEM study reported a large lattice expansion occurred in CeO2 nanoparticles, owing to the formation of oxygen vacancies with Ce3+ ions, without changing the original fluorite structure32. Thus, our results suggest that the highly localized formation of a large number of oxygen vacancies on the CeO2 side of the interfaces was responsible for the observed electron dechanneling. The formation of interfacial oxygen vacancies was further confirmed by a geometric phase analysis (GPA) of STEM images. As shown in Fig. 2f, the GPA result reveals a significant lattice expansion by up to 3% for the CeO2 interfacial regions, consistent with the LAADF results. Furthermore, we can also exclude the possibility of the formation of oxygen interstitials on the Y2O3 side of the interface—one of the two interfacial reconstruction scenarios mentioned earlier based upon the STEM data—as we have not observed any atomic structural changes in Y2O3 interfacial layers.

Interfacial cerium valence modulation

The interfacial oxygen vacancy formation was further investigated by electron energy-loss spectroscopy (EELS), which highlighted the elemental distributions, atomic configurations, and bonding states of both Ce and O. Figure 3a shows an elemental map produced using the Ce-M4,5 edge in the vicinity of the (111)CeO2/(111)Y2O3 interface, revealing interfaces that are not only structurally well-defined but also chemically sharp. Background-subtracted Ce-M4,5 edge spectra obtained from each atomic plane across the (111)CeO2/(111)Y2O3 interface are shown in Fig. 3b. The peak positions of Ce-M4,5 edges are shifted to a lower energy-loss region for the reduced CeO2 interfacial layers, as compared with that of the CeO2 interior layer. The Ce-M4,5 edges originate from transitions between the 3d and 4f states (M4 corresponds to the 3d3/2 to 4f5/2 transition and M5 corresponds to the 3d5/2 to 4f7/2 transition) combined with ligand hole effects and valence-sensitive fine structures. Thus, spatially resolved chemical information33,34 was obtained from EELS measurements. Using linear combinations of Ce-M4,5 reference spectra from CeO2 and Ce2O334, the valence states of the reduced cerium atoms near the interface were roughly estimated to be Ce+3.3 (the nearest to the interface) and Ce+3.6 (the second nearest), which correspond to CeO1.65 and CeO1.8, respectively, as illustrated in Fig. 3c. These oxidation states led to 17.5% and 10% of missing oxygen atoms, respectively, which was indeed a large amount, especially considering the robust interface lattice structures observed by STEM. Background-subtracted O-K spectra averaged along the (111)O planes show a considerable number of oxygen vacancies are formed at interfaces to cope with the interfacial charge mismatch (Supplementary Fig. 10). It is worth stressing that such an interfacial charge modulation is a powerful method of creating a high concentration of oxygen vacancies. Interestingly, our STEM and EELS results suggest that the formation of oxygen vacancies at the (111) interface between the fluorite and the bixbyite is not attributable to the creation of SCRs in the CeO2 layer, in which the calculated Debye length (λ) of ~2.4 nm at 300 K16,35 can result in a ~10 nm thick regime of overlapping space charges (4λ)12.

a Atomic-resolution EELS map for the Ce-M4,5 edges from a local area in a CeO2–Y2O3 nanobristle, revealing an atomically abrupt (111) interface. The scale bar corresponds to 1 nm. b Ce-M4,5 EELS spectra averaged along the (111)Ce atom planes. The dashed lines indicate the chemical shift of the Ce-M5 and Ce-M4 edges at the interface between CeO2 and Y2O3 as indicated by the EELS spectra in red. The latter were taken from the two interfacial CeO2 layers interleaved by a Y2O3 layer, indicating the presence of reduced CeO2 layers (~2 u.c. thick). c Average Ce valence states in the (111)Ce atom planes indicated in b, revealing the valence change in interfacial CeO2 layers.

Spatial distributions of oxygen defects at the (111) interface

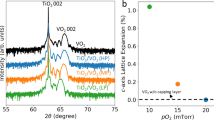

To clarify the role of the (111) interface in creating the oxygen vacancies, the defect formation energy of a neutral oxygen vacancy complex, \(({\mathrm{Ce}}_{{\mathrm{Ce}}}^\prime - {\mathrm{V}}_{\mathrm{O}}^{ \cdot \cdot } - {\mathrm{Ce}}_{{\mathrm{Ce}}}^\prime )^ \times\), at the (111) interface was computed by density functional theory (DFT) calculations (Supplementary Fig. 11). The DFT calculations indicated that the positive charge of oxygen vacancies was always compensated by two Ce3+ ions (Supplementary Fig. 12). In addition, the DFT results revealed that the formation energies of oxygen vacancies and Ce3+ ions at the heterointerface were ~1.8 and ~0.5 eV, respectively. These values are lower than those in bulk CeO2 as a result of the lower electronic state of the polaron (i.e., reduced cerium cations, \({\mathrm{Ce}}_{{\mathrm{Ce}}}^\prime\)) and the easier local lattice relaxation at the interface. These low formation energies increased the number of both the oxygen vacancies and the Ce3+ ions at the interface, leading to the segregation of oxygen vacancies on the CeO2 side of the interface, as shown in Fig. 4. The calculation result showing up to 10% oxygen loss at the interface is quantitatively in good agreement with experimental observations of the EELS data shown in Fig. 3b, c. It is also worth noting that the vacancy segregation was not driven solely by an electrostatic potential at the interface, as the (111) surface was nonpolar so that an SCR could not easily form, and the defect concentration in ceria was high enough to screen out any electrostatic potential (Supplementary Fig. 13). Therefore, the (111) fluorite–bixbyite interface could induce a larger number of oxygen vacancies without the creation of an SCR, which differs from the mechanism proposed for (001) interfaces of fluorite–bixbyite systems in previous studies15,16. As was confirmed by STEM imaging, classical force field (FF) simulation also confirmed that the CeO2 side of the interfaces always remained as the fluorite structure, even though the interface had a high concentration of oxygen vacancies (Supplementary Fig. 14).

Distribution profiles of oxygen vacancy (top) and Ce3+, Ce4+ (bottom) equilibrated at 700 °C in CeO2 and Y2O3 calculated by hybrid Monte Carlo (MC) and molecular dynamics (MD) simulations. The interfaces enrich Ce3+ and oxygen vacancies simultaneously within CeO2. The concentration of oxygen vacancies can reach up to 10% at the interface, spanning over ~1 nm.

Discussion

There have been several studies of creating oxygen defects, understanding the underlying mechanism for their formation, and probing their existence in mixed ionic and electronic conducting materials13,14. However, identifying a new means to artificially create and control highly confined interfacial oxygen vacancies has been a huge challenge. The present work elucidates that interfaces between the fluorite CeO2 and the bixbyite Y2O3 can provide an excellent platform for developing new ionic materials. Creating atomically sharp (111) fluorite/bixbyite interfaces in the nanobrush architecture provides a completely new approach to spontaneously creating oxygen vacancies through interfacial charge modulation. In contrast to the well-known SCR effect, the (111) fluorite/bixbyite interface creates and confines oxygen vacancies within two to three atomic layers on the CeO2 side of the (111) interface. It is remarkable that a large number of oxygen vacancies can be accommodated by taking advantage of the novel interface architecture while leaving the lattice structure intact.

We further demonstrated a new “synthesis science” approach36 to making a specific interfacial nanomaterial with a vertically aligned geometry and a largely increased area of the (111)-oriented surface. As shown in Fig. 1a, our CeO2–Y2O3 nanobrush has a highly porous topography. Therefore, the quantitative information on porosity was important for accurately determining the surface area, which was an extremely challenging task. The difficulty was overcome by using small-angle neutron scattering (SANS), as shown in Supplementary Fig. 15. The SANS results revealed that the upper limit of the porosity was ~49%. More details on the SANS measurement and data analysis can be found elsewhere28. The high porosity is highly advantageous for many technical applications, in which a large contact area can improve (electro-)chemical activity, e.g., electrodes of solid oxide fuel/electrolysis cells37, oxygen permeation membranes38, chemical sensors39, and catalysts40. In our study, the SANS data confirmed that the ~1.4-μm-thick nanobrushes had a surface area that is over 200 times greater than that of a 2D thin film. Therefore, these advances are major technical accomplishments that provide a new means to develop high-performance energy conversion devices, novel catalysts, nonvolatile memories, and memristive computing devices.

Methods

Synthesis of nanobrush samples

Micron-thick single-crystalline fluorite–bixbyite (CeO2–Y2O3) nanobrush superlattices were fabricated using pulsed laser epitaxy (KrF, λ = 248 nm) with sintered CeO2 and Y2O3 targets. While all of the samples studied were grown on single-crystal (001) YSZ substrates, the samples for STEM and APT were grown on YSZ-buffered (001) silicon substrates without deteriorating the sample quality to avoid the charging effect resulting from the highly insulating YSZ substrate. Details on the growth of a YSZ buffer layer and the epitaxial relationship of YSZ and silicon can be found elsewhere41,42,43,44. All of the samples were deposited at 700 °C at an oxygen partial pressure of 100 mTorr. The sample structure and crystallinity were characterized by high-resolution four-circle XRD.

Scanning transmission electron microscopy

Cross-sectional TEM specimens were prepared using ion milling after mechanical thinning and precision polishing. HAADF and LAADF imaging and EELS analysis were carried out in a scanning transmission electron microscope (Nion UltraSTEM100) operated at 100 keV. The microscope is equipped with a cold field-emission gun and an aberration corrector for sub-Ångstrom resolution. Inner detector angles of 78 and 30 mrad were used for HAADF and LAADF imaging, respectively. The convergence semiangle for the electron probe was set to 30 mrad.

Atom probe tomography

APT specimens were prepared by first coating a silicon microtip array with the CeO2/Y2O3 nanobristles. An FEI Nova 200 dual-beam scanning electron microscope/FIB was used to fabricate APT needles from the nanobrushes grown on the silicon microtip array. A 300 nm platinum layer was deposited by FIB, followed by several annular milling steps and a final 2 kV mill to fabricate needle-shaped specimens ready for APT analysis. After sample preparation, the specimen was loaded into the LEAP 4000XR and analyzed using laser mode with a 10 ps/100 pJ laser pulse, a 50 K base temperature, a 125 kHz pulse repetition rate, and a detection rate of 1 ion per 500 pulses. Reconstruction and analysis were performed using the CAMECA integrated visualization and analysis software package.

Density functional theory calculations

In this work, the DFT calculations were performed with VASP45,46,47 using the projector augmented wave method. Generalized gradient approximation with the PBE exchange correlation functional48 and an energy cutoff of 500 eV were used. To properly simulate Ce3+, a Hubbard U correction49 was applied to the Ce 4f orbital with U = 5 eV. The model of the CeO2/Y2O3 {111} interface was constructed according to the TEM observation, in which Y2O3 was stretched biaxially by 1.4% and CeO2 was compressed by 1.4%. The interface model consisted of 24 Y2O3 and 48 CeO2. The simulation cell was hexagonal with a = 1.535 nm, c = 1.880 nm, and γ = 120°. Both the CeO2 layer and the Y2O3 layer were 0.94 nm thick. For all calculations, a k-point mesh of 2 × 2 × 1 was used. The vacancy formation energy was computed by removing a neutral oxygen atom close to the interface or in the middle of the CeO2 layer.

Hybrid Monte Carlo and molecular dynamics with classical force field

The vacancy and Ce3+ concentration profiles were computed with a hybrid MC and MD algorithm using a classical FF. The simulation technique is well documented in the original paper50 and our previous work51. The simulation was started with a uniform distribution of Ce3+ and oxygen vacancies in the CeO2 layer. In the MC simulation, only Ce3+ and Ce4+ ions were allowed to swap their positions, whereas in the MD simulation, the oxygen vacancies could diffuse to either Y2O3 or CeO2 layers. More than 105 MC trials and 6 ns MD simulations at 600 °C were performed. The defect concentration profiles were obtained by averaging the last 5000 configurations of each single calculation.

Small-angle neutron scattering

Room-temperature SANS measurements were performed using EQ-SANS at the Spallation Neutron Source at Oak Ridge National Laboratory52,53. Data were collected in 60 Hz mode with a Q-range between ~0.015 and 0.35 Å−1. The 2D scattering data were reduced using the MantidPlot software according to standard procedures54. The SANS signals from CeO2–Y2O3 nanobrush samples were subtracted the background scattering from a YSZ bare substrate.

Data availability

Data supporting the findings of this study are available from the corresponding author upon reasonable request.

Code availability

The VASP code, which is available for purchase, was used for the calculations in this paper. The configuration files used in these calculations are all available upon request from the authors.

References

Chueh, W. C. & Haile, S. M. Electrochemistry of mixed oxygen ion and electron conducting electrodes in solid electrolyte cells. Annu. Rev. Chem. Biomol. Eng. 3, 313–341 (2012).

Wang, G. et al. Hydrogen-treated TiO2 nanowire arrays for photoelectrochemical water splitting. Nano Lett. 11, 3026–3033 (2011).

Barsan, N., Koziej, D. & Weimar, U. Metal oxide-based gas sensor research: How to? Sens. Actuators B 121, 18–35 (2007).

Yao, H. C. & Yao, Y. F. Y. Ceria in automotive exhaust catalysts: I. Oxygen storage. J. Catal. 86, 254–265 (1984).

Skorodumova, N. V., Simak, S. I., Lundqvist, B. I., Abrikosov, I. A. & Johansson, B. Quantum origin of the oxygen storage capability of ceria. Phys. Rev. Lett. 89, 166601 (2002).

Trovarelli, A. Catalytic properties of ceria and CeO2-containing materials. Catal. Rev. 38, 439–520 (1996).

Esch, F. et al. Electron localization determines defect formation on ceria substrates. Science 309, 752–755 (2005).

Wu, L. et al. Oxidation state and lattice expansion of CeO2−x nanoparticles as a function of particle size. Phys. Rev. B 69, 125415 (2004).

Balazs, G. B. & Glass, R. S. AC-impedance studies of rare-earth-oxide doped ceria. Solid State Ion. 76, 155–162 (1995).

Kim, S., Fleig, J. & Maier, J. Space charge conduction: simple analytical solutions for ionic and mixed conductors and application to nanocrystalline ceria. Phys. Chem. Chem. Phys. 5, 2268–2273 (2003).

Balaji Gopal, C. et al. Equilibrium oxygen storage capacity of ultrathin CeO2-δ depends non-monotonically on large biaxial strain. Nat. Commun. 8, 15360 (2017).

Sata, N., Eberman, K., Eberl, K. & Maier, J. Mesoscopic fast ion conduction in nanometre-scale planar heterostructures. Nature 408, 946–949 (2000).

Guo, X. & Maier, J. Comprehensive modeling of ion conduction of nanosized CaF2/BaF2 multilayer heterostructures. Adv. Funct. Mater. 19, 96–101 (2009).

Maier, J. Ionic conduction in space charge regions. Prog. Solid State Chem. 23, 171–263 (1995).

Shen, W. D., Jiang, J. & Hertz, J. L. Beneficial lattice strain in heterogeneously doped ceria. J. Phys. Chem. C. 118, 22904–22912 (2014).

Shen, W. D. et al. Two-dimensional vacancy trapping in yttria doped ceria. Solid State Ion-. 255, 13–20 (2014).

Walsh, A. & Catlow, C. R. A. Structure, stability and work functions of the low index surfaces of pure indium oxide and Sn-doped indium oxide (ITO) from density functional theory. J. Mater. Chem. 20, 10438–10444 (2010).

Yang, Z., Woo, T. K., Baudin, M. & Hermansson, K. Atomic and electronic structure of unreduced and reduced CeO2 surfaces: A first-principles study. J. Chem. Phys. 120, 7741–7749 (2004).

Baraff, G. A., Appelbaum, J. A. & Hamann, D. R. Self-consistent calculation of the electronic structure at an abrupt GaAs-Ge interface. Phys. Rev. Lett. 38, 237–240 (1977).

Harrison, W. A., Kraut, E. A., Waldrop, J. R. & Grant, R. W. Polar heterojunction interfaces. Phys. Rev. B 18, 4402–4410 (1978).

Ohtomo, A., Muller, D. A., Grazul, J. L. & Hwang, H. Y. Artificial charge-modulation in atomic-scale perovskite titanate superlattices. Nature 419, 378–380 (2002).

Pollock, T. M., Lipkin, D. M. & Hemker, K. J. Multifunctional coating interlayers for thermal-barrier systems. MRS Bull. 37, 923–931 (2012).

Lu, X. et al. Facile synthesis of large-area manganese oxide nanorod arrays as a high-performance electrochemical supercapacitor. Energy Environ. Sci. 4, 2915–2921 (2011).

Jiang, J., Henry, L. L., Gnanasekar, K. I., Chen, C. & Meletis, E. I. Self-assembly of highly epitaxial (La,Sr)MnO3 nanorods on (001) LaAlO3. Nano Lett. 4, 741–745 (2004).

Wang, Z. L. & Song, J. Piezoelectric nanogenerators based on zinc oxide nanowire arrays. Science 312, 242–246 (2006).

Kong, X. Y. & Wang, Z. L. Spontaneous polarization-induced nanohelixes, nanosprings, and nanorings of piezoelectric nanobelts. Nano Lett. 3, 1625–1631 (2003).

Lao, J. Y., Huang, J. Y., Wang, D. Z. & Ren, Z. F. Hierarchical oxide nanostructures. J. Mater. Chem. 14, 770–773 (2004).

Lee, D. et al. Nonequilibrium synthesis of highly porous single-crystalline oxide nanostructures. Adv. Mater. Interfaces 4, 1601034 (2017).

Pierre-Louis, O., D’Orsogna, M. R. & Einstein, T. L. Edge diffusion during growth: The kink ehrlich-schwoebel effect and resulting instabilities. Phys. Rev. Lett. 82, 3661–3664 (1999).

Cowley, J. M. & Huang, Y. Dechanneling contrast in annular dark-field STEM. Ultramicroscopy 40, 171–180 (1992).

Muller, D. A., Nakagawa, N., Ohtomo, A., Grazul, J. L. & Hwang, H. Y. Atomic-scale imaging of nanoengineered oxygen vacancy profiles in SrTiO3. Nature 430, 657–661 (2004).

Hailstone, R. K., DiFrancesco, A. G., Leong, J. G., Allston, T. D. & Reed, K. J. A study of lattice expansion in CeO2 nanoparticles by transmission electron microscopy. J. Phys. Chem. C 113, 15155–15159 (2009).

Karnatak, R. et al. X-ray absorption studies of CeO2, PrO2, and TbO2. I. Manifestation of localized and extended f states in the 3d absorption spectra. Phys. Rev. B 36, 1745 (1987).

Garvie, L. & Buseck, P. Determination of Ce4+/Ce3+ in electron-beam-damaged CeO2 by electron energy-loss spectroscopy. J. Phys. Chem. Solids 60, 1943–1947 (1999).

Hwang, J. H. & Mason, T. O. Defect chemistry and transport properties of nanocrystalline cerium oxide. Z. Phys. Chem. 207, 21–38 (1998).

U.S. Department of Energy, Office of Science. Report of the Basic Energy Sciences Workshop on Basic Research Needs for Synthesis Science for Energy Relevant Technology (U.S. Department of Energy, Office of Science, 2016).

Chueh, W. C., Hao, Y., Jung, W. & Haile, S. M. High electrochemical activity of the oxide phase in model ceria–Pt and ceria–Ni composite anodes. Nat. Mater. 11, 155–161 (2012).

Liu, S., Tan, X., Shao, Z. & Diniz da Costa, J. C. Ba0.5Sr0.5Co0.8Fe0.2O3-δ ceramic hollow-fiber membranes for oxygen permeation. Aiche J. 52, 3452–3461 (2006).

Huang, X. J. & Choi, Y. K. Chemical sensors based on nanostructured materials. Sens. Actuators B 122, 659–671 (2007).

Xie, X., Li, Y., Liu, Z.-Q., Haruta, M. & Shen, W. Low-temperature oxidation of CO catalysed by Co3O4 nanorods. Nature 458, 746–749 (2009).

Bayati, M. R., Joshi, S., Molaei, R., Narayan, R. J. & Narayan, J. Ultrafast switching in wetting properties of TiO2/YSZ/Si(001) epitaxial heterostructures induced by laser irradiation. J. Appl. Phys. 113, 063706 (2013).

Chopra, A., Alexe, M. & Hesse, D. Fabrication and orientation control of highly cation-ordered epitaxial PbSc0.5Ta0.5O3 thin films on Si (100). J. Appl. Phys. 117, 044102 (2015).

Lee, H. N. et al. Epitaxial growth of non-c-oriented ferroelectric SrBi2Ta2O9 thin films on Si(100) substrates. Appl. Phys. A 71, 101–104 (2000).

Matthée, T. et al. Orientation relationships of epitaxial oxide buffer layers on silicon (100) for high‐temperature superconducting YBa2Cu3O7−x films. Appl. Phys. Lett. 61, 1240–1242 (1992).

Kresse, G. & Hafner, J. Ab initio molecular-dynamics simulation of the liquid-metal–amorphous-semiconductor transition in germanium. Phys. Rev. B 49, 14251–14269 (1994).

Kresse, G. & Hafner, J. Ab initio molecular dynamics for liquid metals. Phys. Rev. B 47, 558–561 (1993).

Kresse, G. & Joubert, D. From ultrasoft pseudopotentials to the projector augmented-wave method. Phys. Rev. B 59, 1758–1775 (1999).

Perdew, J. P., Burke, K. & Ernzerhof, M. Generalized gradient approximation made simple. Phys. Rev. Lett. 77, 3865–3868 (1996).

Dudarev, S. L. et al. Electronic structure and elastic properties of strongly correlated metal oxides from first principles: LSDA + U, SIC-LSDA and EELS study of UO2 and NiO. Phys. Status Solidi A 166, 429–443 (1998).

Lee, H. B., Prinz, F. B. & Cai, W. Atomistic simulations of grain boundary segregation in nanocrystalline yttria-stabilized zirconia and gadolinia-doped ceria solid oxide electrolytes. Acta Mater. 61, 3872–3887 (2013).

Sun, L., Marrocchelli, D. & Yildiz, B. Edge dislocation slows down oxide ion diffusion in doped CeO2 by segregation of charged defects. Nat. Commun. 6, 6294 (2015).

Heller, W. T. et al. The suite of small-angle neutron scattering instruments at Oak Ridge National Laboratory. J. Appl. Crystallogr. 51, 242–248 (2018).

Zhao, J. K., Gao, C. Y. & Liu, D. The extended Q-range small-angle neutron scattering diffractometer at the SNS. J. Appl. Crystallogr. 43, 1068–1077 (2010).

Arnold, O. et al. Mantid-data analysis and visualization package for neutron scattering and μ SR experiments. Nucl. Instrum. Methods Phys. Res. 764, 156–166 (2014).

Acknowledgements

The authors are grateful for helpful discussions with S.M. Haile, J. Maier, and H.L. Tuller. This work was supported by the US Department of Energy (DOE), Office of Science, Basic Energy Sciences, Materials Sciences and Engineering Division. A portion of this research used resources at the Center for Nanophase Materials Sciences (STEM and APT) and the Spallation Neutron Source (SANS), which are U.S. DOE Office of Science User Facilities operated by Oak Ridge National Laboratory. Theoretical calculations used resources at the National Energy Research Scientific Computing Center, a U.S. DOE Office of Science User Facility operated under Contract No. DE-AC02-05CH11231. X-ray absorption fine structure work used resources of the Advanced Photon Source, a U.S. DOE Office of Science User Facility operated for the U.S. DOE Office of Science by Argonne National Laboratory under Contract No. DE-AC02-06CH11357.

Author information

Authors and Affiliations

Contributions

D.L. and X.G. contributed equally to this work. D.L. synthesized samples and performed basic characterizations with the help of L.F. X.G. performed STEM imaging and EELS data analysis with the help of M.F.C. L.S. performed DFT calculations and MC/MD simulations with help from Q.L. under the direction of B.Y. Y.J. and K.H. conducted initial sample analysis. J.P. conducted APT measurements. T.O.F., E.J.G., W.T.H., and M.R.F performed EQ-SANS measurement and analysis. Y.C. and D.H. worked on XAFS measurements. H.N.L. initiated and coordinated the research. D.L., X.G., and H.N.L. wrote the manuscript with inputs from all authors.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Peer review information Nature Communication thanks the anonymous reviewers for their contributions to the peer review of this work.

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Source data

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Lee, D., Gao, X., Sun, L. et al. Colossal oxygen vacancy formation at a fluorite-bixbyite interface. Nat Commun 11, 1371 (2020). https://doi.org/10.1038/s41467-020-15153-8

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41467-020-15153-8

This article is cited by

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.