Abstract

High-entropy alloy (HEA) superconductors—a new class of functional materials—can be utilized stably under extreme conditions, such as in space environments, owing to their high mechanical hardness and excellent irradiation tolerance. However, the feasibility of practical applications of HEA superconductors has not yet been demonstrated because the critical current density (Jc) for HEA superconductors has not yet been adequately characterized. Here, we report the fabrication of high-quality superconducting (SC) thin films of Ta–Nb–Hf–Zr–Ti HEAs via a pulsed laser deposition. The thin films exhibit a large Jc of >1 MA cm−2 at 4.2 K and are therefore favorable for SC devices as well as large-scale applications. In addition, they show extremely robust superconductivity to irradiation-induced disorder controlled by the dose of Kr-ion irradiation. The superconductivity of the HEA films is more than 1000 times more resistant to displacement damage than that of other promising superconductors with technological applications, such as MgB2, Nb3Sn, Fe-based superconductors, and high-Tc cuprate superconductors. These results demonstrate that HEA superconductors have considerable potential for use under extreme conditions, such as in aerospace applications, nuclear fusion reactors, and high-field SC magnets.

Similar content being viewed by others

Introduction

High-entropy alloys (HEAs), which are typically composed of multiple metallic elements, open new avenues for the design of novel functional materials because they have superior physical and mechanical properties to conventional alloys1,2,3,4,5,6,7,8. In general, HEAs have simple body-centered cubic (bcc), face-centered cubic (fcc), and hexagonal close-packed (hcp) structures3,4, although five or more elements randomly occupy one available crystallographic position, with each element having an atomic fraction between 5 and 35%1,3. Thermodynamically, a single phase solid solution in HEAs is considered due to a dominance of the entropy of mixing (ΔSmix) in the Gibbs free energy difference, ΔGmix = ΔHmix − TΔSmix, where T is the temperature and ΔHmix is the enthalpy of mixing that contributes to phase separation or the formation of multi-component alloys3,4. Because the elements have slightly different atomic sizes, the novel physical properties and high mechanical hardness of HEAs are believed to result from their large atomic disorder3,4,8.

The superconductivity of HEAs was discovered in 2014 in Ta–Nb–Hf–Zr–Ti multi-principal element alloy, attracting considerable interest in their pairing mechanism; generally, a high level of disorder in crystalline superconductors limits the formation of Cooper pairs partially owing to the decrease in the density of states or the increase in effective Coulomb repulsion between paired electrons9,10. In addition, the unique properties of HEAs, such as their high hardness, high strength, and excellent irradiation tolerance, are advantageous for use under extreme conditions such as those in aerospace applications, irradiation environments, and superconducting (SC) rotating machines2,3,4,6,11. Recently, the robust superconductivity of Ta–Nb–Hf–Zr–Ti HEAs under extremely high pressures of approximately 190 GPa has been reported5, where the unit cell volume of Ta–Nb–Hf–Zr–Ti HEAs was expected to be considerably compressed by ~53%. Since the lattice constant of a crystal is closely related to its electronic structure, we believe that HEA superconductors are not only interesting for fundamental studies of pairing mechanism, but also promising for applications under extreme conditions12. However, the critical current density (Jc), i.e., the maximum current density that can conduct electric current without any power dissipation, was reported to be 0.01–10 kA cm−2 for Co–Ni–Cu–Rh–Ir–Zr and Ta–Nb–Hf–Zr–Ti HEA superconductors. This value is extremely low for practical applications13,14.

Here, we report high-Jc Ta–Nb–Hf–Zr–Ti HEA SC thin films fabricated by pulsed laser deposition (PLD) and the extraordinarily robust superconductivity against irradiation-induced disorder verified using 200 keV Kr-ion irradiation. The HEA SC thin films were deposited on c-cut Al2O3 substrates over a wide range of substrate temperatures (Ts) from 270 to 620 °C. A film deposited at Ts = 520 °C showed the highest SC transition temperature (Tc = 7.28 K) and the largest Jc (>1 MA cm−2) at 4.2 K, which is promising for SC devices as well as large-scale applications. Moreover, the superconductivity of Ta–Nb–Hf–Zr–Ti HEA SC thin films was found to be approximately 1000 times more resistant to irradiation damage than that of other promising SC materials, including high-Tc cuprate superconductors. Taken together, these discoveries suggest that the HEA SC thin films possess considerable potential for technological applications under extreme conditions.

Results and discussion

Crystal structure and SC transition in HEA thin films

Figure 1a shows a schematic of the bcc crystal structure of Ta–Nb–Hf–Zr–Ti superconductors with a compositional ratio of Ta:Nb:Hf:Zr:Ti = 1:2:1:1:1, where each color represents the expected atomic fraction of each element occupying one crystallographic site. For instance, the Nb atom, which is indicated by the green color, accounts for a fraction of 1/3, whereas Ta, Hf, Zr, and Ti each account for 1/6. The X-ray diffraction (XRD) patterns of θ–2θ scans of the Ta–Nb–Hf–Zr–Ti HEA SC thin films fabricated on c-cut Al2O3 substrates indicated that all the films with the bcc crystal structure had a preferred orientation of (110), regardless of the substrate temperature (Ts), as shown in Fig. 1b. The inset of Fig. 1b shows a cross-sectional scanning electron microscopy (SEM) image of the film fabricated at Ts = 520 °C with a thickness of approximately 700 nm. The lattice parameter a0 with respect to Ts for the HEA SC thin films are summarized in Fig. 1c, and the film deposited at Ts = 520 °C, which exhibits the highest XRD peak intensity, has a0 = 3.358 Å, which is similar to that of bulk Ta1/6Nb2/6Hf1/6Zr1/6Ti1/6 HEA superconductors13. The slight peak shift and low intensity for the thin films fabricated at Ts values other than 520 °C are more closely related to the substrate temperature than the compositional ratio of the films15,16 (see Supplementary Table 1 and Supplementary Figs. 1–3).

a Schematic of the bcc lattice with randomly distributed atoms of the Ta1/6Nb2/6Hf1/6Zr1/6Ti1/6 HEA superconductor. b XRD results for Ta–Nb–Hf–Zr–Ti HEA SC thin films deposited on a c-cut Al2O3 substrate at Ts = 270, 370, 470, 520, 570, and 620 °C, indicating a (110) preferred orientation. The inset shows a cross-sectional SEM image for the film fabricated at Ts = 520 °C. c The lattice parameter (a0) of HEA SC thin films with respect to substrate temperature Ts. d, e Temperature dependence of the electrical resistivity (ρ) and magnetization (M) for the Ta–Nb–Hf–Zr–Ti HEA SC thin films, respectively. Here, ρ(T) and M(T) were normalized to the ρ at the Tc onset (ρn) and the absolute zero-field-cooled (ZFC) M value at 1.8 K, respectively, for comparison. The field-cooled (FC) and ZFC M(T) were measured at 5 Oe (applied perpendicularly to the film plane).

Figure 1d presents the temperature dependence of the electrical resistivity (ρ) of the Ta–Nb–Hf–Zr–Ti HEA SC thin films grown at Ts = 270, 370, 470, 520, 570, and 620 °C, where ρ(T) is normalized to the ρ value at the Tc onset (ρn) for comparison. All the films exhibited a sharp SC transition, and the film fabricated at 520 °C showed the highest SC transition temperature (Tc = 7.28 K). Here, the Tc from the ρ(T) curves (TcR) was determined by the 50% transition of ρn, as indicated by the solid line and arrow in Fig. 1d. The bulk SC transition for the HEA SC thin films, which was investigated using zero-field-cooled (ZFC) and field-cooled (FC) dc magnetization (M), also showed similar trends to the ρ(T) curves, as shown in Fig. 1e. All the films exhibited clear Meissner signals and sharp SC transitions in the ZFC M(T) curves, reflecting their high quality. Here, M(T) was normalized to the absolute ZFC M value at 1.8 K for comparison, and the Tc from the M(T) curves (TcM) was determined by the irreversible points of the ZFC and FC M(T) curves, as indicated by the arrow representing the film deposited at the optimal Ts = 520 °C.

The dependence of the magnetic field of the SC phase transition is selectively displayed for the Ta–Nb–Hf–Zr–Ti HEA SC thin film deposited at the optimal Ts = 520 °C in Fig. 2a, where various magnetic fields from 0 to 9 T were applied perpendicularly to the film plane (see also Supplementary Fig. 4). Although the magnitude of the applied magnetic field increased, the SC transition of the HEA SC thin films did not broaden considerably, revealing that the HEA superconductor has a strong vortex pinning strength17,18. In general, because the number of vortices is proportional to the magnetic field and the vortex motion generates an electric field, an increase in the magnetic field results in a broad SC transition in type-II superconductors with weak vortex pinning strengths19,20.

a Representative ρ(T) curves under various magnetic fields ranging from 0 to 9 T for the HEA SC thin film fabricated at the optimal Ts = 520 °C, where the direction of the applied magnetic field was perpendicular to the ab plane of the films. b Upper critical field (μ0Hc2) as a function of the temperature for the HEA SC thin films, determined by 50% of the SC transition from the ρn at each magnetic field. Red dashed lines for Ts = 270 and 520 °C indicate representative linear fits for the estimation of dHc2/dT near Tc. c Tc and μ0Hc2 at zero Kelvin, μ0Hc2(0), with respect to the substrate temperature Ts. Here, TcR and TcM were determined by the 50% transition of ρn and the irreversible points of the ZFC and FC M(T) curves, respectively, and the μ0Hc2(0) was estimated using the Werthamer–Helfand–Hohenberg model. Tc and μ0Hc2(0) exhibit a similar behavior with respect to Ts, implying that the high Tc of HEA SC thin films leads to a large μ0Hc2(0). The error bars on the μ0Hc2(0) reflect the uncertainties in the linear fitting of dHc2/dT around Tc. Half-transparent shades are guides to the eyes.

Figure 2b shows the upper critical field (μ0Hc2) as a function of the temperature for the HEA SC thin films, where μ0Hc2(T) was obtained from the ρ(T, H) curves using the same criterion that was employed for TcR (50% of ρn). The red dashed lines indicate the linear slope of Hc2 near Tc for the films deposited at Ts = 270 and 520 °C, where (dHc2/dT)T=Tc is −2.17, −2.44, −2.63, −2.41, −2.51, and −1.73 T K−1 for the HEA SC thin films deposited at Ts = 270, 370, 470, 520, 570, and 620 °C, respectively. The upper critical field at zero Kelvin, μ0Hc2(0), was evaluated using the Werthamer–Helfand–Hohenberg (WHH) formula in the dirty limit:21

The estimated μ0Hc2(0) values of the HEA SC thin films and the SC transition temperatures determined from the electrical resistivity (TcR) and magnetization (TcM) are displayed in Fig. 2c. It is observed that μ0Hc2(0) with respect to Ts exhibits a similar tendency to Tc, indicating that a higher Tc can induce a larger μ0Hc2(0) of the HEA SC thin films. However, the μ0Hc2(0) of the thin films fabricated at temperatures above the optimal Ts = 520 °C showed a more rapid reduction compared to the decrease in Tc. Despite the high Tc, small slope values of (dHc2/dT)T=Tc have also been reported in (TaNb)1−x(HfZrTi)x HEA superconductors by controlling the mixing entropy or application of pressure5,15,16. Typically, because the SC coherence length (ξ) in dirty type-II superconductors is proportional to the mean free path (l) of the charge carriers, Hc2(0) can be improved by adjusting the disorder level22,23.

Critical current density of HEA SC thin films

Figure 3a and b show the magnetic field dependence of the critical current density (Jc) at 2.0 K and 4.2 K, respectively, for Ta–Nb–Hf–Zr–Ti HEA SC bulk and SC thin films deposited at different temperatures. The Jc data for the bulk sample are for the high-quality Ta1/6Nb2/6Hf1/6Zr1/6Ti1/6 superconductor with TcM = 7.8 K used as the target for the deposition of HEA SC thin films in this study (see Supplementary Fig. 5a). All the films exhibited substantially larger Jc values than the bulk sample—particularly those grown at Ts = 470, 520, and 570 °C (see also Supplementary Fig. 5). For example, the magnitudes of Jc for a film deposited at the optimal Ts = 520 °C, which had Jc > 1 MA cm−2, were approximately 820 and 790% larger than those of the bulk sample at 2.0 K (@ 3.4 T) and 4.2 K (@ 2 T), respectively. Here, the magnitude of Jc(@ 0 T) of the HEA SC thin films is comparable to that of the most widely used commercial superconductor NbTi alloy24,25,26. A higher Jc(@ 0 T), i.e., self-field Jc, in SC thin films compared to bulk samples is commonly observed for most SC materials, including MgB2 and high-Tc cuprates27,28. This is thought to be because the self-field Jc is confined to the surface area associated with lower critical field (Hc1) and London penetration depth (λ) rather than distributed over the entire cross-sectional area28,29. The strong field performance of Jc of the HEA SC thin films is considered to be closely associated with the intrinsic internal disorder caused by the slightly different atomic sizes of the constituent atoms (see Supplementary Fig. 6). The large reduction in the low-field Jc at 2.0 K resulted from the large flux jump due to thermal instability (see Supplementary Fig. 7)30,31, indicating that the Jc of the HEA SC thin films can be further improved32. The red dashed lines indicate Jc = 0.1 MA cm−2, which is a common benchmark for large-scale practical applications of superconductors such as high-field SC magnets33. Relative magnitudes of Jc at 2.0 and 4.2 K at 1 T were described in Fig. 3c. The large Jc values over a wide range of film growth temperatures suggest that HEA superconducting thin films not only have considerable potential for SC devices, but also can replace conventional SC alloys in practical engineering applications.

a, b Magnetic field dependence of the critical current density (Jc) for HEA SC thin films at 2.0 and 4.2 K, respectively. All the films show remarkably large Jc values at 0 T compared with that of the bulk HEA SC sample, as well as promising field performance. The low-field Jc at 2.0 K is lower than that at 4.2 K because of the considerable flux jump at 2.0 K. The red dashed line marks Jc = 100 kA cm−2, which is a common benchmark for large-scale applications such as high-field SC magnets. c Relative levels of Jc at 2.0 and 4.2 K at 1 T show that HEA superconductors are available for widespread applications.

Effect of ion irradiation on HEA SC thin films

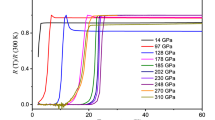

Robust superconductivity with respect to disorder has been proposed on the basis of experimental observations of the insensitivity of the Tc of HEA superconductors to the disorder introduced by different levels of constituent atoms16,34. In addition, the stable superconductivity of HEAs containing the radioactive element U makes HEA superconductors promising for application in heavy-irradiation environments, such as in aerospace applications and nuclear fusion6,7. However, to the best of our knowledge, no studies have investigated the effect of ion irradiation on HEA superconductors. To examine the stability of the SC phase of HEAs against irradiation damage, high-quality HEA SC thin films were systematically irradiated with low-energy 200 keV Kr ions35,36,37. Figure 4a shows the ρ(T) curves for the irradiated Ta–Nb–Hf–Zr–Ti HEA SC thin films with a thickness of 115 nm, where ρ(T) was normalized by ρn for comparison. The inset of Fig. 4a presents a cross-sectional SEM image used for ion irradiation. The disorder levels were adjusted using amounts of irradiated Kr ions from 1.5 × 1014 to 3 × 1016 Kr ions cm−2, corresponding to displacements per atom (dpa) from 0.38 to 76.92 (see Supplementary Fig. 8). The superconductivity of the HEA SC thin film was remarkably resistant to the displacement damage produced by irradiation. The TcR of 7.0 K for the pristine film decreased gradually as the level of dpa increased, but remained at 3.4 K at dpa = 12.82. For further increases in the dpa level, strikingly, the TcR showed an increase rather than a decrease and reached 4.3 K at the extreme damage level of dpa = 76.92.

a ρ(T) curves near Tc for the 200 keV Kr-ion-irradiated Ta–Nb–Hf–Zr–Ti HEA SC thin films with a thickness of 115 nm, where ρ(T) was normalized by ρn for comparison. The Tc of HEA SC thin films decreases gradually with an increase in dpa, but for dpa > 12.82 (left triangles), strikingly, the Tc exhibits an increase despite the increase in the dpa level (see the arrow direction). b Tc/Tc,0 with respect to dpa for representative SC materials with potential for practical applications, where Tc,0 represents the Tc of the pristine sample and p and n for Nb3Sn indicate proton irradiation and neutron irradiation, respectively. The Ta–Nb–Hf–Zr–Ti HEA SC thin films show a remarkably robust superconductivity against irradiation-induced disorder compared with that of the other SC materials. Half-transparent shades are guides to the eyes.

Figure 4b shows a plot of Tc as a function of dpa for Ta–Nb–Hf–Zr–Ti HEA SC thin films and other superconductors with potential for practical application, such as Nb3Sn38, MgB239, YBa2Cu3O7−x40, and K-doped BaFe2As241. Here, Tc was normalized to the Tc of each pristine sample (Tc,0) for comparison. With an increase in the dpa value, Tc decreased monotonically and is expected to be completely suppressed below dpa = 1 for the other superconductors. However, the range of the dpa values for the HEA SC thin films differed significantly from those for the other superconductors: the superconductivity of the HEA SC thin films was over 1000 times more resistant to displacement damage than that of the other superconductors. The suppression of Tc in crystalline SC materials against dpa is generally considered to be a result of the disorder effect associated with SC gap pairing symmetry and the degradation of crystallinity due to atomic disorder38,42. In contrast, the extraordinarily stable SC phase of HEAs against irradiation-induced disorder could be related to the occurrence of amorphization-recrystallization and the high interstitial–vacancy recombination rate associated with the high atomic-level stress and/or high-level lattice distortion in HEAs resulting from their high configuration entropy3,43,44,45. In addition, the random occupation of lattice sites of the constituent atoms of HEAs seems related to the robust superconductivity of HEAs against irradiation damage, because the atomic positions in the lattice altered by the recombination may have little effect on the characteristic of HEAs16. Our irradiation study of Ta–Nb–Hf–Zr–Ti HEA SC thin films manifests the excellent robustness of the SC phase against irradiation damage, which is expected to open the door to many potential applications of HEA superconductors.

In summary, we fabricated high-quality Ta–Nb–Hf–Zr–Ti HEA SC thin films using the PLD method. A large critical current density of Jc > 1 MA cm−2 was realized, and a Jc of 0.1 MA cm−2—a common benchmark for large-scale application—was maintained under magnetic fields of approximately 3.4 and 2.0 T at 2.0 and 4.2 K, respectively. In addition, the superconductivity of the HEA SC thin films was over 1000 times more robust to displacement damage than that of other representative SC materials, such as Nb3Sn, MgB2, Fe-based superconductors, and high-Tc cuprates. Taken together with the wide range of growth temperatures for high-quality thin films, these results demonstrate the great potential of HEA superconductors for practical applications under various extreme environments, such as aerospace applications, high-field SC magnets, and irradiation environments.

Methods

Fabrication of Ta–Nb–Hf–Zr–Ti HEA SC thin films

A Ta1/6Nb2/6Hf1/6Zr1/6Ti1/6 HEA SC target with a diameter of 15 mm and bulk samples A and B were prepared using a planetary ball-milling (FRITSCH GmbH, PULVERISETTE 5, Germany) and hot-press sintering process3. Ta (99.98%), Nb (99.8%), Hf (99.6%), Zr (99.5%), and Ti (99.5%) powders with a compositional ratio of 1:2:1:1:1 were loaded in a stainless-steel jar equipped with a stainless-steel ball in an Ar atmosphere to prevent oxidation. Ball milling with a ball to HEA powder ratio of 10: 1 was performed at a rotation speed of 400 rpm for 24 h using a planetary ball milling machine, after which the powder was sintered via a hot-press sintering method at 1000 °C for 1 h under a uniaxial pressure of 50 MPa.

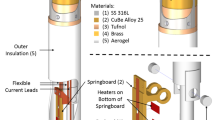

High-quality Ta–Nb–Hf–Zr–Ti HEA SC thin films were fabricated on c-cut Al2O3 substrates (10 mm × 10 mm) using a PLD technique. The laser beam was generated using a KrF excimer laser (λ = 248 nm, IPEX864; LightMachinery) and the thin films were deposited using a laser energy density of ~3.85 J cm−2 and a repetition rate of 10 Hz in a high vacuum state of ~10−6 Torr. Thin films were fabricated with substrate temperatures (Ts) ranging from 270 to 620 °C, and all the films exhibited superconductivity. By controlling the growth time, we obtained Ta–Nb–Hf–Zr–Ti HEA SC thin films with thicknesses in the range of 115–700 nm.

Ion irradiation and characterization of thin films

Kr ions with a beam energy of 200 keV were used to irradiate Ta–Nb–Hf–Zr–Ti HEA SC thin films with a thickness of 115 nm at the Korea Multi-Purpose Accelerator Complex (KOMAC) in Gyeongju. Kr ion levels of 1.5 × 1014, 5 × 1014, 1 × 1015, 3 × 1015, 5 × 1015, 7 × 1015, 1 × 1016, and 3 × 1016 Kr ions cm−2 were irradiated onto the films at room temperature, with a tilt angle of 7° to avoid channeling effects during the irradiation. The displacement damage produced in the Ta1/6Nb2/6Hf1/6Zr1/6Ti1/6 HEA superconductor (density of 9.9 g cm−3) by the 200 keV Kr-ion irradiation was estimated using the Stopping and Range of Ions in Matter (SRIM) Monte Carlo simulation program with averaged displacement threshold energy values of 90 eV (Ta), 78 eV (Nb), 61 eV (Hf), 40 eV (Zr), and 30 eV (Ti)46,47. The simulated target displacement values from the SRIM program were converted into displacements per atom (dpa) values using the following relationship (see also Supplementary Fig. 8):

where ρHEA = 5.226 × 1022 atoms cm−3 is the atomic density of Ta1/6Nb2/6Hf1/6Zr1/6Ti1/6. The doses 1.5 × 1014, 5 × 1014, 1 × 1015, 3 × 1015, 5 × 1015, 7 × 1015, 1 × 1016, and 3 × 1016 Kr ions cm−2 corresponded to dpa values of 0.38, 1.28, 2.56, 7.69, 12.82, 17.95, 25.64, and 76.92, respectively.

The crystal structure of the fabricated Ta–Nb–Hf–Zr–Ti HEA SC thin films was investigated using an X-ray diffractometer (Rigaku miniflex-600 diffractometer, Cu-Kα1 radiation, λ = 1.541 Å). The thicknesses and compositional ratios of the thin films were examined using scanning electron microscope and energy-dispersive X-ray spectrometry, respectively. The SC transition temperature (Tc) of the fabricated Ta–Nb–Hf–Zr–Ti HEA SC thin films was evaluated from the temperature dependence of the electrical resistivity (ρ) and magnetization (M) using a physical property measurement system (PPMS 9 T, Quantum Design) and a magnetic property measurement system (MPMS 5 T, Quantum Design), respectively. The ρ(T) was measured using the standard four-probe method with an Au coating on the four-point contact regions to achieve good ohmic contact, and the upper critical field (μ0Hc2) was estimated by measuring the ρ(T) curve in the magnetic field from 0 to 9 T in the PPMS. The critical current density (Jc) of the HEA SC thin films as a function of the magnetic field was calculated from the magnetization hysteresis (M–H) loops based on Bean’s critical state model (Jc = 15ΔM/rV) (see Supplementary Fig. 7). Here, the M–H loops were measured using MPMS, and ΔM is the difference in M values at the same magnetic field in the M–H loops, V is the volume of the film, and r is the radius corresponding to the total area of the surface of the film48. The direction of the magnetic field was perpendicular to the ab plane of the film for Hc2(T) and Jc(H).

Data availability

The authors declare that all the data supporting the finding of this study are available within this article and its Supplementary Information files and are available from the corresponding author on reasonable request.

References

Yeh, J.–W. et al. Nanostructured high-entropy alloys with multiple principal elements: Novel alloy design concepts and outcomes. Adv. Eng. Mater. 6, 299–303 (2004).

Sun, L. & Cava, R. J. High-entropy alloy superconductors: Status, opportunities, and challenges. Phys. Rev. Mater. 3, 090301 (2019).

Wang, X., Guo, W. & Fu, Y. High-entropy alloys: Emerging materials for advanced functional applications. J. Mater. Chem. A 9, 663–701 (2021).

Kitagawa, J., Hamamoto, S. & Ishizu, N. Cutting edge of high-entropy alloy superconductors from the perspective of materials research. Metals 10, 1078 (2020).

Guo, J. et al. Robust zero resistance in a superconducting high-entropy alloy at pressures up to 190 GPa. Proc. Natl Acad. Sci. USA 114, 13144–13147 (2017).

Shi, T. et al. Current development of body‑centered cubic high‑entropy alloys for nuclear applications. Tungsten 3, 197–217 (2021).

Nelson, W. L. et al. Superconductivity in a uranium containing high entropy alloy. Sci. Rep. 10, 4717 (2020).

Chen, S. et al. Simultaneously enhancing the ultimate strength and ductility of high-entropy alloys via short-range ordering. Nat. Commun. 12, 4953 (2021).

Anderson, P. W., Muttalib, K. A. & Ramakrishnan, T. V. Theory of the “universal” degradation of Tc in high-temperature superconductors. Phys. Rev. B 28, 117–120 (1983).

Kirkpatrick, T. R. & Belitz, D. Suppression of superconductivity by disorder. Phys. Rev. Lett. 68, 3232–3235 (1992).

George, E. P., Curtin, W. A. & Tasan, C. C. High entropy alloys: A focused review of mechanical properties and deformation mechanisms. Acta Mater. 188, 435–474 (2020).

Loa, I., Kunc, K., Syassen, K. & Bouvier, P. Crystal structure and lattice dynamics of AlB2 under pressure and implications for MgB2. Phys. Rev. B 66, 134101 (2002).

Kim, G. et al. Strongly correlated and strongly coupled s-wave superconductivity of the high entropy alloy Ta1/6Nb2/6Hf1/6Zr1/6Ti1/6 compound. Acta Mater. 186, 250–256 (2020).

Mizuguchi, Y., Kasem, M. R. & Matsuda, T. D. Superconductivity in CuAl2-type Co0.2Ni0.1Cu0.1Rh0.3Ir0.3Zr2 with a high-entropy-alloy transition metal site. Mater. Res. Lett. 9, 141–147 (2021).

Zhang, X., Winter, N., Witteveen, C., Moehl, T. & Xiao, Y. Preparation and characterization of high-entropy alloy (TaNb)1−x(ZrHfTi)x superconducting films. Phys. Rev. Res 2, 013375 (2020).

von Rohr, F., Winiarski, M. J., Tao, J., Klimczuk, T. & Cava, R. J. Effect of electron count and chemical complexity in the Ta–Nb–Hf–Zr–Ti high-entropy alloy superconductor. Proc. Natl Acad. Sci. USA 113, E7144–E7150 (2016).

Ghorbani, S. R. et al. Flux pinning and vortex transitions in doped BaFe2As2 single crystals. Appl. Phys. Lett. 100, 072603 (2012).

Jung, S. –G. et al. Influence of carbon-ion irradiation on the superconducting critical properties of MgB2 thin films. Supercond. Sci. Technol. 32, 025006 (2019).

Fisher, D. S., Fisher, M. P. A. & Huse, D. A. Thermal fluctuations, quenched disorder, phase transitions, and transport in type-II superconductors. Phys. Rev. B 43, 130–159 (1991).

Kwok, W. K., Fendrich, J. A., van der Beek, C. J. & Crabtree, G. W. Peak effect as a precursor to vortex lattice melting in single crystal YBa2Cu3O7-δ. Phys. Rev. Lett. 73, 2614–2617 (1994).

Werthamer, N. R., Helfand, E. & Hohenberg, P. C. Temperature and purity dependence of the superconducting critical field, Hc2. III. Electron spin and spin-orbit effects. Phys. Rev. 147, 295–302 (1966).

Bose, S., Raychaudhuri, P., Banerjee, R. & Ayyub, P. Upper critical field in nanostructured Nb: Competing effects of the reduction in density of states and the mean free path. Phys. Rev. B 74, 224502 (2006).

Niu, H. J. & Hampshire, D. P. Disordered nanocrystalline superconducting PbMo6S8 with a very large upper critical field. Phys. Rev. Lett. 91, 027002 (2003).

Cooley, L. D. & Motowidlo, L. R. Advances in high-field superconducting composites by addition of artificial pinning centres to niobium–titanium. Supercond. Sci. Technol. 12, R135–R151 (1999).

Nishigaki, K. & Takeda, M. Influence of thickness on parallel and perpendicular field dependences of Jc of NbTi films. Physica C 357–360, 1373–1376 (2001).

Boutboul, T., Naour, S. L., Leroy, D., Oberli, L. & Previtali, V. Critical current density in superconducting Nb–Ti strands in the 100 mT to 11 T applied field range. IEEE Trans. Appl. Supercond. 16, 1184–1187 (2006).

Xu, S. Y. et al. High critical current density and vortex pinning of epitaxial MgB2 thin films. Phys. Rev. B 68, 224501 (2003).

Talantsev, E. F., Crump, W. P. & Tallon, J. L. Universal scaling of the self-field critical current in superconductors: From sub-nanometre to millimeter size. Sci. Rep. 7, 10010 (2017).

Talantsev, E. F., Crump, W. P. & Tallon, J. L. Thermodynamic parameters of single- or multi-band superconductors derived from self-field critical currents. Ann. Phys. 529, 1700197 (2017).

Denisov, D. V. et al. Onset of dendritic flux avalanches in superconducting films. Phys. Rev. Lett. 97, 077002 (2006).

Bag, P., Su, Y.–C., Kuo, Y.–K., Lai, Y.–C. & Wu, S.–K. Physical properties of face-centered cubic structured high-entropy alloys: Effects of NiCo, NiFe, and NiCoFe alloying with Mn, Cr, and Pd. Phys. Rev. Mater. 5, 085003 (2021).

Choi, E. –M. et al. Enhancement at low temperatures of the critical current density for Au-coated MgB2 thin films. Appl. Phys. Lett. 84, 82–84 (2004).

Larbalestier, D., Gurevich, A., Feldmann, D. M. & Polyanskii, A. High-Tc superconducting materials for electric power applications. Nature 414, 368–377 (2001).

von Rohr, F. O. & Cava, R. J. Isoelectronic substitutions and aluminium alloying in the Ta–Nb–Hf–Zr–Ti high-entropy alloy superconductor. Phys. Rev. Mater. 2, 034801 (2018).

Jung, S. –G. et al. Field-induced quantum breakdown of superconductivity in magnesium diboride. NPG Asia Mater. 13, 55 (2021).

Parkin, D. M. Radiation effects in high-temperature superconductors: A brief review. Metall. Trans. A 21A, 1015–1019 (1990).

Nordlund, K. et al. Defect production in collision cascades in elemental semiconductors and fcc metals. Phys. Rev. B 57, 7556–7570 (1998).

Flükiger, R. et al. Variation of Tc, lattice parameter and atomic ordering in Nb3Sn platelets irradiated with 12 MeV protons: Correlation with the number of induced Frenkel defects. Supercond. Sci. Technol. 30, 054003 (2017).

Lee, J. M. et al. Influence of disorder strength on the superconducting mechanism of MgB2. Supercond. Sci. Technol. 35, 015001 (2022).

Lesueur, J., Dumoulin, L., Quillet, S. & Radcliffe, J. Ion-beam induced metal insulator transition in YBCO films. J. Alloy. Compd. 195, 527–530 (1993).

Torsello, D., Gozzelino, L., Gerbaldo, R., Tamegai, T. & Ghigo, G. Scaling laws for ion irradiation effects in iron‑based superconductors. Sci. Rep. 11, 5818 (2021).

Andersen, L., Ramires, A., Wang, Z., Lorenz, T. & Ando, Y. Generalized Anderson’s theorem for superconductors derived from topological insulators. Sci. Adv. 6, eaay6502 (2020).

Zhang, Z., Armstrong, D. E. J. & Grant, P. S. The effects of irradiation on CrMnFeCoNi high-entropy alloy and its derivatives. Prog. Mater. Sci. 123, 100807 (2022).

Egami, T., Guo, W., Rack, P. D. & Nagase, T. Irradiation resistance of multicomponent alloys. Metall. Mater. Trans. A 45, 180–183 (2014).

Nagase, T., Rack, P. D., Noh, J. H. & Egami, T. In-situ TEM observation of structural changes in nano-crystalline CoCrCuFeNi multicomponent high-entropy alloy (HEA) under fast electron irradiation by high voltage electron microscopy (HVEM). Intermetallics 59, 32–42 (2015).

Konobeyev, A. Y., Fischer, U., Korovin, Y. A. & Simakov, S. P. Evaluation of effective threshold displacement energies and other data required for the calculation of advanced atomic displacement cross-sections. Nucl. Eng. Technol. 3, 169–175 (2017).

The damage events by 200 keV Kr-ion irradiation in the Ta–Nb–Hf–Zr–Ti SC thin film were calculated using the SRIM software. (www.srim.org/).

Kim, H.–J. et al. High current-carrying capability in c-axis-oriented superconducting MgB2 thin films. Phys. Rev. Lett. 87, 087002 (2001).

Acknowledgements

We wish to acknowledge the outstanding support of the accelerator group and operators of KOMAC, KAERI. This study was supported by the National Research Foundation (NRF) of Korea through a grant funded by the Korean Ministry of Science and ICT (No. 2021R1A2C2010925 (T.P. and Y.H.) and 2021R1A2C20121340 (W.S.C.)) and by the Basic Science Research Program through the NRF of Korea funded by the Ministry of Education (NRF-2019R1F1A1055284 (J.M.L. and W.N.K.), NRF-2020R1I1A1A01067677 (J.H.K.), and NRF-2021R1I1A1A01043885 (S.-G.J. and Y.H.).

Author information

Authors and Affiliations

Contributions

S.-G.J. conceived the study. S.-G.J. and Y.H. fabricated the high-quality Ta–Nb–Hf–Zr–Ti HEA superconducting thin films and performed transport and magnetization measurements. J.H.K., R.H., and J.–S.R. prepared an HEA superconducting target and bulk samples. H.J., J.S., S.-G.J., and Y.H. performed Kr-ion irradiation. J.M.L., W.N.K., and W.S.C. assisted with the pulsed laser deposition. S.-G.J. and Y.H. analyzed the data. The manuscript was written by Y.H., S.-G.J., and T.P., with contributions from all authors.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Communications thanks Liling Sun, Jiro Kitagawa and the other anonymous reviewers for their contribution to the peer review of this work.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Jung, SG., Han, Y., Kim, J.H. et al. High critical current density and high-tolerance superconductivity in high-entropy alloy thin films. Nat Commun 13, 3373 (2022). https://doi.org/10.1038/s41467-022-30912-5

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41467-022-30912-5

This article is cited by

-

Topological nodal line in superfluid 3He and the Anderson theorem

Nature Communications (2023)

-

Synthesis and structural characterizations of CrCoFeNiMnx (0 ≤ x ≤ 1) high-entropy-alloy thin films by thermal reduction in hydrogen

Journal of Materials Science (2023)

-

Effect of Annealing in Eutectic High-Entropy Alloy Superconductor NbScTiZr

Journal of Superconductivity and Novel Magnetism (2023)

-

Microstructure and properties of AlCoCrFeNiTi high-entropy alloy coatings prepared by laser cladding based on the response surface methodology

The International Journal of Advanced Manufacturing Technology (2022)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.