Abstract

Grain boundary conductivity limitations are ubiquitous in material science. We show that illumination with above-bandgap light can decrease the grain boundary resistance in solid ionic conductors. Specifically, we demonstrate the increase of the grain boundary conductance of a 3 mol% Gd-doped ceria thin film by a factor of approximately 3.5 at 250 °C and the reduction of its activation energy from 1.12 to 0.68 eV under illumination, while light-induced heating and electronic conductivity could be excluded as potential sources for the observed opto-ionic effect. The presented model predicts that photo-generated electrons decrease the potential barrier heights associated with space charge zones depleted in charge carriers between adjacent grains. The discovered opto-ionic effect could pave the way for the development of new electrochemical storage and conversion technologies operating at lower temperatures and/or higher efficiencies and could be further used for fast and contactless control or diagnosis of ionic conduction in polycrystalline solids.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$29.99 / 30 days

cancel any time

Subscribe to this journal

Receive 12 print issues and online access

$259.00 per year

only $21.58 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

Data availability

Source data are provided with this paper. Source data for Figs. 1–4 and Supplementary Figs. 9–11 are available from the online data repository Figshare with identifier https://doi.org/10.6084/m9.figshare.c.5707109.v4. Remaining data that support the findings of this study are available from the corresponding authors upon reasonable request.

Change history

03 March 2022

In the version of this article initially published, the address for IREC was imprecisely written and has now been updated in the HTML and PDF versions of the article.

References

Kreuer, K. D. Proton conducting oxides. Annu. Rev. Mater. Res. 33, 333–359 (2003).

Tuller, H. L. & Nowick, A. S. Doped ceria as a solid oxide electrolyte. J. Electrochem. Soc. 122, 255–259 (1975).

Skinner, S. J. & Kilner, J. A. Oxygen ion conductors. Mater. Today 6, 30–37 (2003).

Hu, Y.-S. Batteries: getting solid. Nat. Energy 1, 16042 (2016).

Garbayo, I. et al. Glass-type polyamorphism in Li-garnet thin film solid state battery conductors. Adv. Energy Mater. 8, 1702265 (2018).

Pfenninger, R., Struzik, M., Garbayo, I., Stilp, E. & Rupp, J. L. M. A low ride on processing temperature for fast lithium conduction in garnet solid-state battery films. Nat. Energy 4, 475–483 (2019).

Whittingham, M. S. Lithium batteries and cathode materials. Chem. Rev. 104, 4271–4301 (2004).

Pagani, F. et al. Epitaxial thin films as a model system for Li-ion conductivity in Li4Ti5O12. ACS Appl. Mater. Interfaces 10, 44494–44500 (2018).

Janek, J. & Zeier, W. G. A solid future for battery development. Nat. Energy 1, 16141 (2016).

Brett, D. J. L., Atkinson, A., Brandon, N. P. & Skinner, S. J. Intermediate temperature solid oxide fuel cells. Chem. Soc. Rev. 37, 1568–1578 (2008).

Adler, S. B. Factors governing oxygen reduction in solid oxide fuel cell cathodes. Chem. Rev. 104, 4791–4843 (2004).

Gao, Z., Mogni, L. V., Miller, E. C., Railsback, J. G. & Barnett, S. A. A perspective on low-temperature solid oxide fuel cells. Energy Environ. Sci. 9, 1602–1644 (2016).

Mai, A., Haanappel, V. A. C., Uhlenbruck, S., Tietz, F. & Stöver, D. Ferrite-based perovskites as cathode materials for anode-supported solid oxide fuel cells. Part I. Variation of composition. Solid State Ion. 176, 1341–1350 (2005).

Takamura, H., Okumura, K., Koshino, Y., Kamegawa, A. & Okada, M. Oxygen permeation properties of ceria-ferrite-based composites. J. Electroceram. 13, 613–618 (2004).

Meng, Y. et al. Review: recent progress in low-temperature proton-conducting ceramics. J. Mater. Sci. 54, 9291–9312 (2019).

Knauth, P. Inorganic solid Li ion conductors: an overview. Solid State Ion. 180, 911–916 (2009).

Kerman, K., Luntz, A., Viswanathan, V., Chiang, Y.-M. & Chen, Z. Review—practical challenges hindering the development of solid state Li ion batteries. J. Electrochem. Soc. 164, A1731–A1744 (2017).

Rahaman, M. N. Ceramic Processing and Sintering 2nd edn (CRC Press, 2003).

Pergolesi, D. et al. High proton conduction in grain-boundary-free yttrium-doped barium zirconate films grown by pulsed laser deposition. Nat. Mater. 9, 846–852 (2010).

Gregori, G., Merkle, R. & Maier, J. Ion conduction and redistribution at grain boundaries in oxide systems. Prog. Mater. Sci. 89, 252–305 (2017).

Kim, S., Kim, S. K., Khodorov, S., Maier, J. & Lubomirsky, I. On determining the height of the potential barrier at grain boundaries in ion conducting oxide. Phys. Chem. Chem. Phys. 18, 3023–3031 (2016).

Kim, S. & Maier, J. On the conductivity mechanism of nanocrystalline ceria. J. Electrochem. Soc. 149, J73 (2002).

Wu, J. F. & Guo, X. Origin of the low grain boundary conductivity in lithium ion conducting perovskites: Li3xLa0.67–xTiO3. Phys. Chem. Chem. Phys. 19, 5880–5887 (2017).

Ma, C. et al. Atomic-scale origin of the large grain-boundary resistance in perovskite Li-ion conducting solid electrolytes. Energy Environ. Sci. 7, 1638–1642 (2014).

Aguesse, F., López Del Amo, J. M., Roddatis, V., Aguadero, A. & Kilner, J. A. Enhancement of the grain boundary conductivity in ceramic Li0.34La0.55TiO3 electrolytes in a moisture-free processing environment. Adv. Mater. Interfaces 1, 1300143 (2014).

Mei, A. et al. Role of amorphous boundary layer in enhancing ionic conductivity of lithium–lanthanum–titanate electrolyte. Electrochim. Acta 55, 2958–2963 (2010).

García-Martín, S., Amador, U., Morata-Orrantia, A., Rodríguez-Carvajal, J. & Alario-Franco, M. Á. Structure, microstructure, composition and properties of lanthanum lithium titanates and some substituted analogues. Z. fur Anorg. und Allg. Chem. 635, 2363–2373 (2009).

Joshi, D. P. & Bhatt, D. P. Theory of grain boundary recombination and carrier transport in polycrystalline silicon under optical illumination. IEEE Trans. Electron Devices 37, 237–249 (1990).

Fergus, J. W. Electrolytes for solid oxide fuel cells. J. Power Sources 162, 30–40 (2006).

Schmitt, R. et al. A review of defect structure and chemistry in ceria and its solid solutions. Chem. Soc. Rev. 49, 554–592 (2020).

Avila-Paredes, H. J., Choi, K., Chen, C. T. & Kim, S. Dopant-concentration dependence of grain-boundary conductivity in ceria: a space-charge analysis. J. Mater. Chem. 19, 4837–4842 (2009).

Göbel, M. C., Gregori, G., Guo, X. & Maier, J. Boundary effects on the electrical conductivity of pure and doped cerium oxide thin films. Phys. Chem. Chem. Phys. 12, 14351–14361 (2010).

Gerstl, M. et al. The separation of grain and grain boundary impedance in thin yttria stabilized zirconia (YSZ) layers. Solid State Ion. 185, 32–41 (2011).

Peter, L. M. Dynamic aspects of semiconductor photoelectrochemistry. Chem. Rev. 90, 753–769 (1990).

Klotz, D., Ellis, D. S., Dotan, H. & Rothschild, A. Empirical in operando analysis of the charge carrier dynamics in hematite photoanodes by PEIS, IMPS and IMVS. Phys. Chem. Chem. Phys. 18, 23438–23457 (2016).

Harrington, G. F. et al. The interplay and impact of strain and defect association on the conductivity of rare-earth substituted ceria. Acta Mater. 166, 447–458 (2019).

Seager, C. H. Grain boundary recombination: theory and experiment in silicon. J. Appl. Phys. 52, 3960–3968 (1981).

De Souza, R. A. Oxygen diffusion in SrTiO3 and related perovskite oxides. Adv. Funct. Mater. 25, 6326–6342 (2015).

Rockenhäuser, C. et al. Microstructure evolution and cation interdiffusion in thin Gd2O3 films on CeO2 substrates. J. Eur. Ceram. Soc. 34, 1235–1242 (2014).

Beschnitt, S., Zacherle, T. & De Souza, R. A. Computational study of cation diffusion in ceria. J. Phys. Chem. C 119, 27307–27315 (2015).

Jacobsen, T., Chatzichristodoulou, C. & Mogensen, M. B. Fermi potential across working solid oxide cells with zirconia or ceria electrolytes. ECS Trans. 61, 203–214 (2014).

Gopal, C. B. & Haile, S. M. An electrical conductivity relaxation study of oxygen transport in samarium doped ceria. J. Mater. Chem. A 2, 2405–2417 (2014).

Dong, Y. & Chen, I. W. Oxygen potential transition in mixed conducting oxide electrolyte. Acta Mater. 156, 399–410 (2018).

Spiridigliozzi, L. et al. Engineered co-precipitation chemistry with ammonium carbonate for scalable synthesis and sintering of improved Sm0.2Ce0.8O1.90 and Gd0.16Pr0.04Ce0.8O1.90 electrolytes for IT-SOFC. J. Ind. Eng. Chem. 59, 17–27 (2018).

Sanna, S. et al. Fabrication and electrochemical properties of epitaxial samarium-doped ceria films on SrTiO3-buffered MgO substrates. Adv. Funct. Mater. 19, 1713–1719 (2009).

Acknowledgements

We thank G. F. Harrington for the valuable input on sample preparation and characterization and K. May for help with the atomic force microscopy measurements. T.D. and H.L.T. acknowledge support for their research from the US Department of Energy, Basic Energy Sciences under award number DE-SC0002633 (Chemomechanics of Far-From-Equilibrium Interfaces). D.K. acknowledges support by the Japan Society for the Promotion of Science Core-to-Core Program, A. Advanced Research Networks: ‘Solid Oxide Interfaces for Faster Ion Transport’, as well as funding from the Kakenhi Grant-In-Aid for young scientists, grant numbers 18K13993 and 20K15028. D.K. and H.L.T. appreciate preliminary discussions with H. Matsumoto of Kyushu University and T. Lippert and D. Pergolesi of the Paul Scherrer Institute. J.L.M.R., J.C.G.-R. and T.D. acknowledge the Swiss National Science Foundation for grant number BSSGI0_155986/1, and Equinor for grant Agr no. 4502981450. This work made use of the Materials Research Science and Engineering Center Shared Experimental Facilities at the Massachusetts Institute of Technology, supported by the National Science Foundation under award number DMR-14-19807. A portion of this work was performed at the Center for Nanoscale Systems, a member of the National Nanotechnology Coordinated Infrastructure Network, which was supported by the National Science Foundation under National Science Foundation award no. 1541959.

Author information

Authors and Affiliations

Contributions

H.L.T. conceived the concept; T.D. and D.K. performed all experiments except the atomic force microscopy and scanning electron microscopy experiments, which were performed by J.C.G.-R.; H.L.T. and J.L.M.R. supervised the work. The manuscript was written by T.D., D.K., J.L.M.R. and H.L.T., and all authors contributed to discussions and editing.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no conflict of interest.

Peer review

Peer review information

Nature Materials thanks Koji Amezawa and the other, anonymous, reviewer(s) for their contribution to the peer review of this work.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Extended data

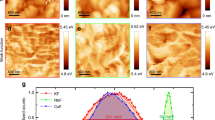

Extended Data Fig. 1 Additional polycrystalline sample measured at low temperatures.

Arrhenius plot of additional sample A1. As guide, the measurements of the epitaxial and polycrystalline samples from the main text are also plotted as full lines in the same color code as in the main text (same Figure appears as Supplementary Fig. S9).

Supplementary information

Supplementary Information

Supplementary Sections 1–19, Figs. 1–24 and Tables 1–6.

Source data

Source Data Fig. 1

Unprocessed impedance data.

Source Data Fig. 2

Temperature-dependent conductivity (fits of data from Fig. 1).

Source Data Fig. 3

SFITs (unprocessed raw data over time).

Source Data Fig. 4

IMPS (measured raw data and fitted time constant).

Source Data Extended Data Fig. 1

Unprocessed impedance data gathered from additional sample A1.

Rights and permissions

About this article

Cite this article

Defferriere, T., Klotz, D., Gonzalez-Rosillo, J.C. et al. Photo-enhanced ionic conductivity across grain boundaries in polycrystalline ceramics. Nat. Mater. 21, 438–444 (2022). https://doi.org/10.1038/s41563-021-01181-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41563-021-01181-2

This article is cited by

-

Electronic signatures of Lorentzian dynamics and charge fluctuations in lithiated graphite structures

Nature Communications (2023)