Abstract

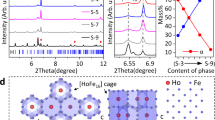

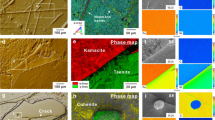

Rare earth (RE) addition to steels to produce RE steels has been widely applied when aiming to improve steel properties. However, RE steels have exhibited extremely variable mechanical performances, which has become a bottleneck in the past few decades for their production, utilization and related study. Here in this work, we discovered that the property variation of RE steels stems from the presence of oxygen-based inclusions. We proposed a dual low-oxygen technology, and keeping low levels of oxygen content in steel melts and particularly in the raw RE materials, which have long been ignored, to achieve impressively stable and favourable RE effects. The fatigue life is greatly improved by only parts-per-million-level RE addition, with a 40-fold improvement for the tension–compression fatigue life and a 40% enhancement of the rolling contact fatigue life. We find that RE appears to act by lowering the carbon diffusion rate and by retarding ferrite nucleation at the austenite grain boundaries. Our study reveals that only under very low-oxygen conditions can RE perform a vital role in purifying, modifying and micro-alloying steels, to improve the performance of RE steels.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$29.99 / 30 days

cancel any time

Subscribe to this journal

Receive 12 print issues and online access

$259.00 per year

only $21.58 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

Data availability

All data are available in the main text or the Supplementary Information. Raw data are available from the corresponding author upon reasonable request.

Code availability

The Vienna Ab initio Simulation Package, used to perform first-principles calculations, is a source suite of computational tools available at www.vasp.at.

References

Luyckx, L. A. in Industrial Applications of Rare Earth Elements (ed. Gschneidner, K. A.) 43–78 (ACS, 1981).

Waudby, P. E. Rare earth additions to steel. Int. Metal. Rev. 23, 74–98 (1978).

Smith, J. D. M. The rare earths. Nature 120, 583–584 (1927).

Spedding, F. H. & Daane, A. H. The Rare Earths (Krieger, 1961).

Smirnov, L. A., Rovnushkin, V. A., Oryshchenko, A. S., Yu Kalinin, G. & Milyuts, V. G. Modification of steel and alloys with rare-earth elements. Part 1. Metallurgist 59, 1053–1061 (2016).

Nuri, Y., Ohashi, T., Hiromoto, T. & Kitamura, O. Solidification microstructure of ingots and continuously cast slabs treated with rare earth metal. Tetsu Hagane 66, 618–627 (1980).

Wang, L. M., Lin, Q., Ji, J. W. & Lan, D. N. New study concerning development of application of rare earth metals in steels. J. Alloy. Compd. 408–412, 384–386 (2006).

Vahed, A. & Kay, D. A. R. Thermodynamics of rare earths in steelmaking. Metall. Trans. B 7, 375–383 (1976).

Lillieqvist, G. A. & Mickelson, C. G. Properties of cast steels improved with rare earth element additions. JOM 4, 1024–1031 (1952).

Adabavazeh, Z., Hwang, W. S. & Su, Y. H. Effect of adding cerium on microstructure and morphology of Ce-based inclusions formed in low-carbon steel. Sci. Rep. 7, 46503 (2017).

Garrison, W. M. & Maloney, J. L. Lanthanum additions and the toughness of ultra-high strength steels and the determination of appropriate lanthanum additions. Mater. Sci. Eng. A 403, 299–310 (2005).

Jiang, X. & Song, S. H. Enhanced hot ductility of a Cr–Mo low alloy steel by rare earth cerium. Mater. Sci. Eng. A 613, 171–177 (2014).

Chen, L., Ma, X. C., Wang, L. M. & Ye, X. N. Effect of rare earth element yttrium addition on microstructures and properties of a 21Cr–11Ni austenitic heat-resistant stainless steel. Mater. Des. 32, 2206–2212 (2011).

Kim, S.-T., Jeon, S.-H., Lee, I.-S. & Park, Y.-S. Effects of rare earth metals addition on the resistance to pitting corrosion of super duplex stainless steel – Part 1. Corros. Sci. 52, 1897–1904 (2010).

Liu, C. et al. Effect of inclusions modified by rare earth elements (Ce, La) on localized marine corrosion in Q460NH weathering steel. Corros. Sci. 129, 82–90 (2017).

Fu, H. G., Xiao, Q., Kuang, J. C., Jiang, Z. Q. & Xing, J. D. Effect of rare earth and titanium additions on the microstructures and properties of low carbon Fe–B cast steel. Mater. Sci. Eng. A 466, 160–165 (2007).

Wu, Y. M., Wang, L. M. & Du, T. Thermodynamics of rare earth elements in liquid iron. J. Less Common Met. 110, 187–193 (1985).

Han, Q. Y., Dong, Y. C., Feng, X., Xiang, C. X. & Yang, S. F. Equilibria between rare earth elements and sulfur in molten iron. Metall. Trans. B 16, 785–792 (1985).

Kojola, N., Ekerot, S., Andersson, M. & Jönsson, P. G. Pilot plant study of nozzle clogging mechanisms during casting of REM treated stainless steels. Ironmak. Steelmak. 38, 1–11 (2011).

Li, D. Z. et al. Inclusion flotation-driven channel segregation in solidifying steels. Nat. Commun. 5, 5572 (2014).

Plummer, J. Solidification: homogenized steel. Nat. Mater. 14, 13 (2015).

Cao, Y. F., Chen, Y. & Li, D. Z. Formation mechanism of channel segregation in carbon steels by inclusion flotation: X-ray microtomography characterization and multi-phase flow modeling. Acta Mater. 107, 325–336 (2016).

Bhadeshia, H. K. D. H. Steels for bearings. Prog. Mater. Sci. 57, 268–435 (2012).

Graulov, A., Ziese, V. & Zandbergen, H. W. TEM/SEM investigation of microstructural changes within the white etching area under rolling contact fatigue and 3D crack reconstruction by focused ion beam. Scr. Mater. 57, 635–638 (2007).

Grad, P., Reuscher, B., Brodyanski, A., Kopnarski, M. & Kerscher, E. Mechanism of fatigue crack initiation and propagation in the very high cycle fatigue regime of high-strength steels. Scr. Mater. 61, 838–841 (2012).

Bhadeshia, H. & Honeycombe, R. Steels: Microstructure and Properties 3rd edn, 110 (Butterworth-Heinemann, 2006).

Suresh, F. Fatigue of Materials 2nd edn, 86–89 (Cambridge Univ. Press, 1998).

Ritchie, R. O. The conflicts between strength and toughness. Nat. Mater. 10, 817–822 (2011).

Koyama, M. et al. Bone-like crack resistance in hierarchical metastable nanolaminate steel. Science 355, 1055–1057 (2017).

Lin, Q. et al. Effects of rare earth on behavior of precipitation and properties in microalloyed steels. J. Rare Earth. 21, 167–171 (2003).

Zhao, Y. Y., Wang, J. F., Zhou, S. & Wang, X. D. Effects of rare earth addition on microstructure and mechanical properties of a Fe–15Mn–1.5Al–0.6C TWIP steel. Mater. Sci. Eng. A 608, 106–113 (2014).

Hsu, T. Y. Effect of rare earth element on isothermal and martensitic transformation in low carbon steels. ISIJ Int. 38, 1153–1164 (1998).

Boccalini, M. Jr, Corrêa, A. V. O. & Goldenstein, H. Rare earth metal induced modification of γ-M2C, γ-M6C, and γ-MC eutectics in as cast M2 high speed steel. Mater. Sci. Tech. 15, 621–626 (1999).

Hufenbach, J. et al. Effect of cerium addition on microstructure and mechanical properties of high-strength Fe85Cr4Mo8V2C1 cast steel. Mater. Sci. Eng. A 674, 366–374 (2016).

Buban, J. P. et al. Grain boundary strengthening in alumina by rare earth impurities. Science 311, 212–215 (2006).

Bohlen, J., Nürnberg, M. R., Senn, J. W., Letzig, D. & Agnew, S. R. The texture and anisotropy of magnesium–zinc–rare earth alloy sheets. Acta Mater. 55, 2101–2112 (2007).

Gutfleisch, O. et al. Magnetic materials and devices for the 21st century: stronger, lighter, and more energy efficient. Adv. Mater. 23, 821–842 (2011).

Acknowledgements

The work was supported by the National Natural Science Foundation (grant nos 52031013, U1708252 and 51725103). We are grateful for the support of and collaboration with the manufacturers of RE steels from many iron and steel companies in China, such as Zhejiang Tianma Bearing Co., Ltd.; Baotou Iron and Steel Group; Benxi Steel Group Corporation; Anshan Iron and Steel Group; Shougang Group; HBIS Group Co., Ltd.; Shandong Iron and Steel Group Co., Ltd.; Hubei Xinyegang Steel Co., Ltd.; Xining Special Steel Co., Ltd.; Xiwang Special Steel Co., Ltd.; and Magang (Group) Holding Co., Ltd. We are grateful to H. Ma and J. T. Wang for the calculations of carbon diffusion barriers and to Y. Zhao for the calculation of carbon diffusion coefficients. We are grateful to the referees for their substantial contributions in improving this work. Their constructive suggestions helped us to explore the in-depth mechanisms regarding the addition of RE to improve fatigue life, leading to the key findings of the differences between the traditional Al2O3 inclusions and the RE-oxysulfides/RE sulfides and their effects on fatigue crack initiation. They inspired us to perform reliable experimental procedures to elucidate the effects of RE in solution on carbon diffusion and to deeply understand the RE effect on the phase transition. The referees suggested rigorous scientific experiments to study fatigue performance under the same conditions and suggested carefully raking the details of the oxygen-controlling routes. All their invaluable comments and suggestions helped us significantly improve the quality and readability of this work. We all express heartfelt thanks to the referees and to the editors for their precious time, their openness to encourage in-depth explorations and their high standard to push for rigorous science, from which we have benefited greatly.

Author information

Authors and Affiliations

Contributions

D.L. conceived the study and proposed the main idea of a dual low-oxygen technology for resolving the long-term bottleneck problems of RE steels. P.W. performed nanoindentation, dilatometric experiments and TEM characterization of the sample after the fatigue measurements. X.-Q.C., Y. Chen and Y. Cao organized and performed the first-principles calculations; P.F., H.L., L. Zheng and X.H. performed the 52100 steel industrial experiments and inclusion analyses as well as fatigue measurements; Y. Luan performed the fatigue experiments of 52100 steels; J.G. performed the low-oxygen experiments in mischmetal; Y.Z., L. Zhang, X.M. and C.D. performed the TEM observation and analyses of RE in solution in different steels; C.Y. performed the fatigue experiments of 52100 steels; Z.J. performed the diffusion couple and S355 experiments; Y. Liu performed the inclusion electrolysis experiments; and M.S. performed the engineering validation. D.L., X.-Q.C. and P.W. wrote the manuscript with input from all other authors. All the authors including Y. Li discussed this manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Materials thanks Brian Thomas, Marcel Somers and the other, anonymous, reviewer(s) for their contribution to the peer review of this work.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Supplementary Information

Supplementary Figs. 1–17, Tables 1–8 and Notes I–IX.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Li, D., Wang, P., Chen, XQ. et al. Low-oxygen rare earth steels. Nat. Mater. 21, 1137–1143 (2022). https://doi.org/10.1038/s41563-022-01352-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41563-022-01352-9