Abstract

Here it is investigated the effect of the antiferromagnet Cr2O3 on the magnetic properties of ferromagnetic Fe72Ga28 thin films. Sputtered Fe72Ga28 layers have their magnetization in the sample plane with a magnetic fluctuation that gives rise to magnetic ripple. In order to turn its magnetization into the out of plane (OOP) direction, it has been magnetically coupled with Cr2O3 that has magnetic moments along the c-axis, that is the perpendicular direction when properly aligned. Cr2O3 has been obtained from Cr oxidation, whereas Fe72Ga28 has been deposited on top of it by sputtering in the ballistic regime. Although a uniaxial in-plane magnetic anisotropy is expected for Fe72Ga28 thickness above 100 nm, the interfacial coupling with Cr2O3 prevents this anisotropy. The formation of stripe domains in Fe72Ga28 above a critical thickness reveals the enhancement of the out of plane component of the Fe72Ga28 magnetization with respect to uncoupled layers. Due to the interface coupling, the Fe72Ga28 magnetization turns into the out-of-plane direction as its thickness is gradually reduced, and a perpendicular magnetic anisotropy of 3·106 erg·cm−3 is inferred from experimental results. Eventually, the coupling between Cr2O3 and Fe72Ga28 promotes an exchange-bias effect that has been well fitted by means of the random field model.

Similar content being viewed by others

Introduction

Control of the magnetization is an important issue for the development of pioneering magnetic devices. Typically, thin films have the magnetization in the sample plane in order to reduce the energy of the system1. However, in many applications as for example: high density magnetic storage, spintronic devices, non-volatile random access memories, logic devices, skyrmions or sensors, materials with OOP magnetization are desirable2,3,4,5,6.

Systems with large perpendicular magnetic anisotropy (PMA) such as L10 FePt and CoPt thin films are extensively investigated but, their large coercivity and switching fields can represent a drawback for their integration in devices7,8. Therefore, it is of interest the investigation of other materials with PMA, or the possibility of turning the magnetization into the OOP direction. Stripe domains appear above a critical thickness when a moderate PMA is present9. In permalloy films, stripes have been observed because of columnar growth10, but they have also been promoted when coupled with NdCo11. Recently, the magnetization direction has been tuned in Fe–N layers by ion implantation and heat treatment conditions9, and by annealing in Fe87Si9B1312. Even more notably, the control of the magnetic anisotropy by means of voltage has been observed at magnetic transition metal/oxide interfaces2.

FeGa alloys are extensively studied because of their large magnetostriction constant and low coercivity13,14,15,16. Also interesting is the possibility in sputtered Fe72Ga28 layers of controlling the in-plane magnetic anisotropy by growth conditions17,18,19 or by thermal treatments combined with mechanical stress20. Molecular beam epitaxy (MBE) FeGa can exhibit domain stripes due to a low PMA21,22,23, but the general behavior observed by magnetic force microscopy (MFM) in FeGa deposited either by electrodeposition24, sputtering25 or even MBE26 is a magnetic ripple due to magnetic fluctuations in layers with magnetization in the sample plane.

In this work, we have explored the possibility of turning the Fe72Ga28 magnetization into the OOP direction when appropriately coupled with Cr2O3, an antiferromagnet that has its magnetic moments along the hexagonal c-axis being possible to have moments in the perpendicular direction when properly aligned27,28,29. Although Cr2O3 has already been coupled with ferromagnetic metals30,31,32, the interaction with Fe72Ga28 seems not a trivial problem. Fe72Ga28 has already been coupled with TbFe2 in [Fe72Ga28/TbFe2] multilayers to turn its magnetization into the OOP direction33,34. However, only a tilt of the magnetization of around 25° with respect to the sample plane was achieved despite the large PMA of TbFe233,34. Here we show that by means of a suitable experiment design in terms of layer thickness and materials, it is possible to reach an effective interfacial interaction that enables to turn the Fe72Ga28 magnetization into the OOP direction. In addition, because of the interfacial interaction we have observed exchange-bias effect in the perpendicular direction being possible to fit the experimental exchange-bias fields (HE) by means of the random field model35,36,37.

Experimental section

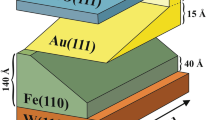

30 nm-thick Cr2O3 was synthetized from the evaporation of Cr on glass substrates that was subsequently oxidized in oxygen atmosphere at 750 °C during 3 h. Fe72Ga28 layers with a thickness ranging from 240 to 20 nm were grown by the DC magnetron sputtering technique in the ballistic regime at room temperature on top of the Cr2O3. The sputtering deposition was carried out in oblique incidence with an angle between the vapor beam and the perpendicular to the sample of about 25° and a distance of 9 cm between target and substrate. This direction of the vapor beam within the sample plane is taken as the reference direction to control the direction of the in-plane uniaxial anisotropy axis when created16,17,38. Fe72Ga28 films were deposited from a target with a composition of Fe72Ga28 with a diameter of 5 cm and a thickness of 2 mm using an Ar pressure of 3·10−3 mbar and a growth power of 90 W in all cases. A 20-nm thick Mo layer was used as a capping layer to avoid FeGa oxidation. Mo was also deposited with a power of 90 W and with an Ar pressure of 3·10−3 mbar. Therefore, the structure of the studied samples is: glass/ Cr2O3/Fe72Ga28/Mo. For further comparisons, we have also deposited single Fe72Ga28 layers with thickness of 20 and 150 nm between Mo buffer and capping layers to avoid oxidation.

We have used X-ray diffractometry (XRD) in the Bragg–Brentano configuration to study the structural properties. Measurements were performed in a Philips X’Pert MPD using the Cu Kα wavelength (1.54056 Å). A Digital Instruments Nanoscope IIIa instrument was used to obtain MFM images. We monitored the cantilever’s phase of oscillation while the magnetic tip was scanning the sample surface to work in the phase detection mode. The distance between sample and surface was 40 nm on average (lift mode)33. The MFM measurements were performed without magnetic field after an OOP magnetic field of 10 kOe was applied. The topography of the samples has also been obtained in this microscope working as an Atomic Force Microscope (AFM).

In-plane and OOP hysteresis loops were performed in a vibrating sample magnetometer (VSM) from LakeShore 7304 at room temperature. In the sample plane, we measured loops at different angles between the applied magnetic field and the in-plane reference direction. As a reference direction, we considered as 0° the beam incidence direction in the sample plane17,38. Hysteresis loops at 5 K were measured in a SQUID EverCool MPMS SQUID magnetometer from Quantum Design after field-cooling (FC) at 1 kOe from 360 K and zero-field-cooling (ZFC) at 0 kOe from 360 K. To reduce any hypothetical systematic error from the SQUID, a field step of 10 Oe has been used in the low field region of the hysteresis loops. Also, the comparison between FC and ZFC hysteresis loops has been used to cross-check the shift in the field axis. At low temperature, only OOP loops were recorded. Magnetic moment versus temperature was also measured with the magnetic field in the perpendicular direction.

Results and discussion

In the XRD measurements we have only observed diffractions peaks related to either Cr2O3, FeGa or Mo (Fig. 1a). We have analyzed the possibility of Fe72Ga28 oxidation because of its growth on top of Cr2O3, but XRD measurements do not show evidences of oxidation within the resolution technique. The diffraction peaks related to FeGa are similar to what we have previously reported about sputtered Fe72Ga28 thin films being the (110) the main diffraction peak16,17,18,19. For Fe72Ga28 we can determine the lattice parameter (a) thanks to Bragg’s law:

where \({d}_{hkl}\) is the family of planes,\(\theta\) the diffraction angle, and \(\lambda\) the radiation wavelength (Cu Kα in this case). In the cubic system, we can obtain a from dhkl since:

where h, k, and l are the Miller indexes of the family of planes. From experimental results for the (110) peak we have determined a lattice parameter of 2.90 Å, in agreement with previous works17,18.

(a) XRD diffraction patterns of the samples studied in this work. The measurement for a 30 nm-thick Cr2O3 layer on glass has been included for further comparisons. Curves are shifted for clarity. (b) Magnetic moment versus temperature for the Cr2O3/Fe72Ga28(20 nm) sample. Inset: Detail of the measurement.

On the other hand, the diffraction peaks of Cr2O3 show no variations upon the deposition of Fe72Ga28 on top of it as it can be inferred from the comparison with a single layer of Cr2O3 deposited in the same growth conditions (Fig. 1a). Experimental diffraction peaks for Cr2O3 appear at the same diffraction angles than for the file used for identification (01-084-0312) and therefore, it has a rhombohedral structure with lattice parameters a = b = 4.95 Å and c = 13.56 Å. Cr2O3 layers are not fully c-oriented since (012), (104) and (116) diffraction peaks for Cr2O3 have been detected by XRD. However, it is expected a magnetic contribution along the perpendicular direction due to these family of planes. The Nèel temperature (TN) of the Cr2O3 has been obtained from the measurement of the magnetization as a function temperature (Fig. 1b). The experimental value of TN = 297 K is just 10 K below that of bulk Cr2O3, TN = 307 K. Finally, we have also analysed the morphology of the samples by AFM (Fig. 2) being obtained a root mean square (rms) roughness of around 2 nm for the final stack.

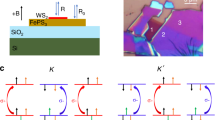

Sputtered Fe72Ga28 layers deposited in the ballistic regime develop in-plane magnetic anisotropy above 100 nm16,18. Nevertheless, the coupling with Cr2O3 completely eliminate this in-plane anisotropy even for thicknesses well above 100 nm (Fig. 3a). This can be understood considering that a sample will show PMA if two conditions are fulfilled: i) it is magnetically isotropic in the sample plane, and ii) the OOP direction is an easy axis in comparison to any direction in the sample plane. Therefore, the absence of in-plane magnetic anisotropy is a necessary condition for the PMA to be developed. We have ruled out that magnetostriction and strain have any effect on this modification of the magnetic anisotropy since we have not observed differences of the Fe72Ga28 lattice parameter with respect to uncoupled single layers. In fact, when strain has been used to manipulate the magnetic anisotropy in Ga-rich FeGa thin films, only the direction within the sample plane was modified20.

(a) In-plane room temperature hysteresis loops recorded for different angles between the reference direction taken as the reference beam direction and the applied magnetic field (filled square) 0°, (filled circle) 30°, and (filled triangle) 60° for the Cr2O3/Fe72Ga28(240 nm) sample. (b) OOP hysteresis loops recorded at room temperature for samples with different FeGa thickness (filled square) 20 nm, (filled circle) 40 nm, (filled triangle) 80 nm, (filled down triangle) 160 nm, and (filled diamond) 240 nm. (c) In plane and perpendicular hysteresis loops at room temperature for an uncoupled 20 nm Fe72Ga28 thin film. (d) Comparison of in plane (open square) and perpendicular (filled square) hysteresis loops at room temperature for the Cr2O3/Fe72Ga28(20 nm) sample.

The VSM hysteresis loops reveal the change of the magnetization direction from in-plane to OOP as the Fe72Ga28 thickness is reduced (Fig. 3b). We can quantitively monitor this evolution by means of the OOP squareness (Mr/Mmax) defined as the ratio between the remanence (Mr) and the maximum magnetization (Mmax) obtained in the perpendicular hysteresis loops. In Table 1 we can observe how the squareness increases as the Fe72Ga28 thickness is reduced, mostly for a thickness below 80 nm. The OOP squareness and hysteresis loops of coupled layers can be compared with those of a Fe72Ga28 thin film grown in similar conditions (Table 1; Fig. 3c). The OOP squareness of a single layer is much lower with respect to that of a Fe72Ga28 with the same thickness but coupled to Cr2O3. Finally, in Fig. 3d it is presented the comparison between in-plane and OOP hysteresis loops for the Cr2O3/Fe72Ga28(20 nm) sample to show the magnetization direction has been turned into the perpendicular direction becoming the OOP direction an easy axis.

The perpendicular magnetic anisotropy, KFM, can be experimentally inferred taking into account that:

being MFM the saturation magnetization of the Fe72Ga28, and HK the anisotropy field in the hard direction. For the samples with Fe72Ga28 thickness of 20 nm and 40 nm the in-plane is a hard axis, and we have obtained an average value of KFM of 3·106 erg cm−3 (Table 1) for a MFM = 1100 emu cm−326. For higher Fe72Ga28 thickness, the OOP direction is not a clear easy axis due to the progressive turning of the magnetization into the perpendicular direction as the FeGa thickness is reduced.

MFM images can also be used to monitor the influence of the Cr2O3 on the Fe72Ga28 magnetic behavior (Fig. 4). When Fe72Ga28 is no coupled (Fig. 4a), it is observed the magnetic contrast known as magnetic ripple in agreement with previous works24,25,26. However, due to the interfacial coupling with Cr2O3, the OOP component of the magnetization of Fe72Ga28 is enhanced, and stripe domains start to be visible in the MFM images (Fig. 4b–d).

MFM images taken at remanence after an applied magnetic field of 10 kOe was applied in the perpendicular direction. (a) 150 nm-thick uncoupled Fe72Ga28 layer. With a blue line it is indicated an example of the magnetic contrast known as ripple. (b) Cr2O3/Fe72Ga28(160 nm), (c) Cr2O3/Fe72Ga28(80 nm), and (d) Cr2O3/Fe72Ga28(40 nm). In (b), (c) and (d), a red line is used to highlight examples of areas where magnetic stripes can be observed.

In ferromagnetic materials with PMA, the quality factor Q is defined as39:

For materials with moderate or low PMA, Q < 1, stripe domains appear above a critical thickness (tcr):

where Aex is the exchange energy per unit length. When Q > 0.1, stripe domains are wider than the layer thickness, whereas they exhibit a periodicity equals to the layer thickness if Q < 0.1.

Taking into account the experimental value inferred for the perpendicular magnetic anisotropy, KFM = 3·106 erg/cm3, and MFM = 1100 emu cm−326, it is inferred a Q of 0.3 in our samples and therefore, stripes are expected above a critical thickness. Considering Aex = 1.7·10−6 erg cm−1 from the literature22,23,40, and using Eq. (5), it is obtained an experimental tcr of 44 nm. This is in agreement with our experimental findings in which stripes have only been observed for Fe72Ga28 thickness ≥ 40 nm. In fact, if we take this experimental value as tcr, a KFM of 4·106 erg cm−3 is calculated, close to the experimental inferred value from experimental hysteresis loops, 3·106 erg cm−3. Finally, from the MFM images we have obtained a stripe period between 110 and 125 nm by means of the power spectral density (supplementary information). This stripe periodicity higher than the layer thickness is consistent with the quality factor Q higher than 0.1 calculated in our samples.

In addition to the rotation of the Fe72Ga28 direction magnetization towards the perpendicular direction, we have observed an exchange-bias effect related to the Cr2O3/ Fe72Ga28 interfacial coupling as indicated by the shift of the OOP hysteresis loop in the horizontal axis (HE) at 5 K after a FC process at 1 kOe (Fig. 5). This exchange-bias phenomenon in the perpendicular direction is related to the exchange-coupling between the antiferromagnetic Cr2O3, and the ferromagnetic Fe72Ga2841. For a Fe72Ga28 thickness of 20 nm, HE is − 21 Oe, and − 11 Oe for a thickness of 40 nm. For the lowest FeGa thickness, exchange-bias effect has been observed at least up to 200 K.

Since the perpendicular magnetic anisotropy inferred in this work for Fe72Ga28 (KFM = 3·106 erg·cm−3) is higher than the theoretical value of Cr2O3 (KAF = 2·105 erg·cm−3)42, and some chemical roughness is expected at the Fe72Ga28/Cr2O3 interface, we have used the random field model proposed by Malozemoff35,36,37 to calculate the theoretical HE values. In this random field model, the AF layer breaks into domains, and the exchange-bias field is obtained by means of the expression:

where z is generally taken as the unity, and AAF is the exchange stiffness of the antiferromagnet that takes a value of 4·10−7 erg cm−142. With this expression (6) we obtain HE equals to − 26 Oe and − 13 Oe for Fe72Ga28 thickness of 20 and 40 nm, respectively, that are pretty close to the experimental − 21 Oe and − 11 Oe, respectively. This well agreement confirms the possibility of using this model in Cr2O3-based exchange-biased systems as also previously reported42.

Finally, from HE experimental values the interfacial exchange energy ΔE can be calculated:

For Fe72Ga28 of 20 nm and 40 nm, it is obtained a ΔE of 0.046 and 0.048 erg cm−2 that is similar than reported in previous works in which Cr2O3 has been coupled with other ferromagnets with values of 0.05 erg cm−2 at 5 K30,41. However, it is important to remark that we have obtained that interfacial energy using polycrystalline Cr2O3, not a fully c-oriented Cr2O3 with all the magnetic moments aligned in the perpendicular direction. Nevertheless, our experimental results point out that even in this situation, it is possible to gradually turn the Fe72Ga28 magnetization into the out of plane direction due to the combination of Cr2O3 with Fe72Ga28 that has a magnetic fluctuation that promotes magnetic ripple in the uncoupled layers25. Therefore, these results show the possibility of using polycrystalline layers for further applications such as tailoring of the magnetization direction.

Conclusions

In summary, we have studied the effect of the interfacial coupling between an antiferromagnet with magnetic moments along the c-axis (Cr2O3) and a ferromagnet (Fe72Ga28) with the magnetization in the sample plane but with a fluctuation that produces magnetic ripple. First of all, the in-plane magnetic anisotropy of Fe72Ga28 is completely vanished due to the coupling. Secondly, stripe domains are promoted due to the enhancement of the OOP component of the Fe72Ga28 magnetization. We have observed that the magnetization direction of Fe72Ga28 is gradually turned from in-plane to the OOP direction as the Fe72Ga28 thickness is reduced A perpendicular magnetic anisotropy of 3·106 erg·cm−3 has been inferred from experimental results in the Fe72Ga28 layers. It has also been observed exchange-bias phenomena in the perpendicular direction fitting the experimental data to the random field model.

References

S. Chikazumi. Physics of Ferromagnetism. Oxford Science Publications (1997).

Fert, A., Reyren, N. & Cros, V. Magnetic skyrmions: Advances in physics and potential applications. Nat. Rev. Mater. 2, 17031 (2017).

Dieny, B. & Chshiev, M. Perpendicular magnetic anisotropy at transition metal/oxide interfaces and applications. Rev. Mod. Phys. 89, 025008 (2017).

Sbiaa, R., Meng, H. & Piramanayagam, S. N. Materials with perpendicular magnetic anisotropy for magnetic random access memory. Phys. Status Solidi RRL 5, 413 (2011).

Umadevi, K., Bysakh, S., Arout Chelvane, J., Kamat, S. V. & Jayalaskhmi, V. Tailoring magnetic anisotropy in Tb–Fe–Co thin films by rapid thermal annealing. J. Alloys Compd. 663, 430 (2016).

Sander, D. et al. The 2017 magnetism roadmap. J. Phys. D Appl. Phys. 50, 363001 (2017).

Sbiaa, R., Law, R., Tan, E.-L. & Liew, T. Spin transfer switching enhancement in perpendicular anisotropy magnetic tunnel junctions with a canted in-plane spin polarizer. J. Appl. Phys. 105, 013910 (2009).

Krivorotov, I. N. et al. Time-domain measurements of nanomagnet dynamics driven by spin-transfer torques. Science 307, 228 (2005).

Garnier, L.-C. et al. Stripe domains reorientation in ferromagnetic films with perpendicular magnetic anisotropy. J. Phys. Mater. 3, 024001 (2020).

Romera, M., Ranchal, R., Ciudad, D., Maicas, M. & Aroca, C. Magnetic properties of sputtered Permalloy/molybdenum multilayers. J. Appl. Phys. 110, 083910 (2011).

Markó, D. et al. Tunable ferromagnetic resonance in coupled trilayers with crossed in-plane and perpendicular magnetic anisotropies. Appl. Phys. Lett. 115, 082401 (2019).

Coïsson, M., Barrera, G., Celegato, F. & Tiberto, P. Rotatable magnetic anisotropy in Fe78Si9B13 thin films displaying stripe domains. Appl. Surf. Sci. 476, 402 (2019).

Ranchal, R. & Maestre, D. Growth and characterization of Fe1-xGax thin films from citrate-based electrolytes. J. Phys. D Appl. Phys. 47, 355004 (2014).

Clark, A. E., Restorff, J. B., Wun-Fogle, M., Lograsso, T. A. & Schlagel, D. L. Magnetostrictive properties of body-centered cubic Fe–Ga and Fe–Ga–Al alloys. IEEE Trans. Magn. 36, 3238 (2000).

Clark, A. E., Wun-Fogle, M., Lograsso, T. A. & Cullen, J. R. Effect of quenching on the magnetostriction on Fe1−xGax (0.13 < x < 0.21). IEEE Trans. Magn. 37, 2678 (2001).

Bartolomé, P., Begué, A., Muñoz-Noval, A., Ciria, M. & Ranchal, R. Unveiling the different physical origins of magnetic anisotropy and magnetoelasticity in Ga-Rich FeGa thin films. J. Phys. Chem. C 124, 4717 (2020).

Muñoz-Noval, A., Ordóñez-Fontes, A. & Ranchal, R. Influence of the sputtering flow regime on the structural properties and magnetic behavior of Fe–Ga thin films (Ga ∼ 30 at.%). Phys. Rev. B 93, 214408 (2016).

Muñoz-Noval, A., Fin, S., Salas-Colera, E., Bisero, D. & Ranchal, R. The role of surface to bulk ratio on the development of magnetic anisotropy in high Ga content Fe100−xGax thin films. J. Alloys Compd. 745, 413 (2018).

Muñoz-Noval, A., Salas-Colera, E. & Ranchal, R. Local and medium range order influence on the magnetic behavior of sputtered Ga-rich FeGa thin films. J. Phys. Chem. C 123, 13131 (2019).

Hontecillas, I., Figueruelo, I., Abad, S. & Ranchal, R. Tuning the magnetic anisotropy of Ga-rich FeGa thin films deposited on rigid substrates. J. Magn. Magn. Mater. 494, 165771 (2020).

Barturen, M. et al. Crossover to striped magnetic domains in Fe1−xGax magnetostrictive thin Films. Appl. Phys. Lett. 101, 092404 (2012).

Tacchi, S. et al. Rotatable magnetic anisotropy in a Fe0.8Ga0.2 thin film with stripe domains: Dynamics versus statics. Phys. Rev. B 89, 024411 (2014).

Fin, S. et al. In-plane rotation of magnetic stripe domains in Fe1−xGax thin films. Phys. Rev. B 92, 224411 (2015).

Ranchal, R., Fin, S. & Bisero, D. Magnetic microstructures in electrodeposited Fe1−xGax thin films (15 ≤ x ≤ 22 at.%). J. Phys. D: Appl. Phys. 48, 075001 (2015).

Bartolomé, P., Maicas, M. & Ranchal, R. Out of plane component of the magnetization of sputtered Fe72Ga28 layers. J. Magn. Magn. Mater. 514, 167183 (2020).

Begué, A., Proiettia, M. G., Arnaudas, J. I. & Ciria, M. Magnetic ripple domain structure in FeGa/MgO thin films. J. Magn. Magn. Mater. 498, 166135 (2020).

Kosub, T. et al. Purely antiferromagnetic magnetoelectric random access memory. Nat. Commun. 8, 13985 (2017).

Fallarino, L., Binek, C. & Berger, A. Boundary magnetization properties of epitaxial Cr2−xAlxO3 thin films. Phys. Rev. B 91, 214403 (2015).

He, X. et al. Robust isothermal electric control of exchange bias at room temperature. Nat. Mater. 9, 579 (2010).

Lin, K.-W. & Guo, J.-Y. Tuning in-plane and out-of-plane exchange biases in Ni80Fe20/Cr-oxide bilayers. J. Appl. Phys. 104, 123913 (2008).

Yuan, W. et al. Crystal structure manipulation of the exchange bias in an antiferromagnetic film. Sci. Rep. 6, 28397 (2016).

Nozaki, T. et al. Positive exchange bias observed in Pt-inserted Cr2O3/Co exchange coupled bilayers. Appl. Phys. Lett. 105, 212406 (2014).

Bartolomé, P., Maicas, M., Biskup, N., Varela, M. & Ranchal, R. Investigation of the out of plane component of the magnetization of [Fe72Ga28(x nm)/Tb33Fe67(50 nm)]2 multilayers. Phys. Status Solidi A 215, 1800183 (2018).

Bartolomé, P. & Ranchal, R. Synthetic domain walls in [TbFeGa/TbFe]2 multilayers. Nanotechn. 31, 335715 (2020).

Malozemoff, A. P. Random-field model of exchange anisotropy at rough ferromagnetic-antiferromagnetic interfaces. Phys. Rev. B 35, 3679 (1987).

Malozemoff, A. P. Mechanisms of exchange anisotropy. J. Appl. Phys. 63, 3874 (1988).

Malozemoff, A. P. Heisenberg-to-Ising crossover in a random-field model with uniaxial anisotropy. Phys. Rev. B 37, 7673 (1988).

Maicas, M., Ranchal, R., Aroca, C., Sánchez, P. & López, E. Magnetic properties of permalloy multilayers with alternating perpendicular anisotropies. Eur. Phys. J. B 62, 267 (2008).

Hubert, A. & Schäfer, R. Magnetic Domains: The Analysis of Magnetic Microstructures. Springer (2008).

Gopman, D. B., Sampath, V., Ahmad, H., Bandyopadhyay, S. & Atulasimha, J. Static and dynamic magnetic properties of sputtered Fe–Ga thin films. IEEE Trans. Magn. 53, 6101304 (2017).

Nogués, J. & Schuller, I. K. Exchange bias. J. Magn. Magn. Mater. 192, 203 (1999).

Zheng, R. K., Liu, H., Wang, Y. & Zhang, X. X. Cr2O3 surface layer and exchange bias in an acicular CrO2 particle. Appl. Phys. Lett. 84, 702 (2004).

Acknowledgements

“CAI Difracción Rayos-X” from UCM is acknowledged for XRD measurements. This work has been financially supported through the projects RTI2018-097895-B-C43 of the Spanish Ministry of Science, Innovation, and Universities, MAT2017-87072-C4-3-P of the Spanish Ministry of Economy, Industry and Competitiveness, and ‘Plan Propio de la Universidad de Castilla – La Mancha’ (FEDER, EU) for the ‘Grupo de Materiales Magnéticos (GMM)’. The data that support the findings of this study are available from the corresponding author upon reasonable request.

Author information

Authors and Affiliations

Contributions

I.H. grew part of the samples and magnetically characterized the samples by VSM and MFM. M.M performed part of the MFM experiments, and helped with VSM measurements. J.P.A. helped with the VSM and performed SQUID experiments. RR. thought the experiments, and grew part of the samples. All authors contributed to the discussion of the results. R.R wrote the main manuscript. All authors reviewed the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Hontecillas, I., Maicas, M., Andrés, J.P. et al. Interfacial coupling effect of Cr2O3 on the magnetic properties of Fe72Ga28 thin films. Sci Rep 11, 13429 (2021). https://doi.org/10.1038/s41598-021-92640-y

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-021-92640-y

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.