Abstract

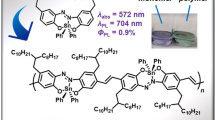

A series of poly(phenylene-vinylene)-based copolymers are synthesized using the Gilch method incorporating monomers with sterically bulky sidechains. The photochemical upconversion performance of these polymers as emitters are investigated using a palladium tetraphenyltetrabenzoporphyrin triplet sensitizer and MEH-PPV as reference. Increased incorporation of sterically bulky monomers leads to a reduction in the upconversion efficiency despite improved photoluminescence quantum yield. A phosphorescence quenching study indicates issues with the energy transfer process between the triplet sensitizer and the copolymers. The best performance with 0.18% upconversion quantum yield is obtained for the copolymer containing 10% monomer with bulky sidechains.

Similar content being viewed by others

Introduction

Triplet–triplet annihilation upconversion (TTA-UC), also known as triplet fusion, is a photochemical process by which two lower energy photons can be used to produce one photon of higher energy1. It sees use in raising the efficiency of solar cells above their thermodynamic limit (the Shockley-Queisser limit)2,3. To achieve efficient TTA-UC, several photochemical processes must effectively take place, which are often performed by a two-component system, with a “triplet sensitizer” and “emitter” (Fig. 1). The role of the triplet sensitizer is to absorb incoming light and efficiently generate the triplet excited state via intersystem crossing (ISC). The triplet excitons generated may then be transferred to an emitter molecule to generate the triplet excited state of the emitter through triplet energy transfer (TET). Two emitters in their triplet excited states may then annihilate, allowing one emitter to return to the ground state and the other emitter to preferably form the singlet excited state (TTA). The emitter molecule can then produce a photon with higher energy than the original incident photon used to excite the sensitizer.

The upconversion quantum yield (ΦUC) is a product of all the quantum yields for photochemical processes involved, given by the equation:

where ΦISC is the ISC quantum yield, ΦTET is the TET quantum yield, ΦTTA is the TTA quantum yield, and ΦPL is the photoluminescence quantum yield4. ΦTTA can be further separated into the contact triplet pair formation efficiency and the factor f5, which is a measure of the probability of generating the singlet excited state after TTA, since singlet, triplet and quintet states are all possible outcomes. This factor may differ significantly between different emitters6,7,8,9.

Typically, in TTA upconversion systems, only small molecule emitters are used in conjunction with transition metal porphyrin-based triplet sensitizers. Many of the most efficient upconversion systems use platinum(II) octaethylporphyrin (PtOEP) as the triplet sensitizer and 9,10-diphenylanthracene (DPA) as the emitter or derivatives thereof10,11,12. Very few examples exist of polymer-based emitters. They typically consist of molecular emitter chromophores pendant on polymeric backbones11,13,14,15,16. In these studies, the aim was to create condensed or solid-state systems where the TTA upconversion processes were not dependent on molecular diffusion. Unfortunately, the covalently linkage of the chromophores negatively impacted the upconversion performance. The reasons for this include lower ΦPL of the emitter, lower TET rate and/or efficiency, shorter triplet lifetimes and lower TTA efficiency. In some cases, the covalently linked chromophores did not even perform as well as systems where chromophores are simply dispersed in polymer matrices17,18,19.

Even fewer studies used conjugated polymers as emitters20,21,22,23,24. Polyfluorenes, with either simple alkyl side-chains20, a spiro-bisfluorene motif21, or aryl side-chains on a fused polyfluorene22,23, have been reported. Another example of a conjugated polymer emitter shown by Monkman and co-workers used a commercially available poly(phenylene-vinylene) (PPV) copolymer with the trade name “Super yellow PPV” with palladium(II) tetraphenyltetrabenzoporphyrin (PdTPTBP) as the triplet sensitizer24. The use of PPV emitters over other conjugated polymers may be particularly advantageous owing to their high singlet–triplet excited state energy gap25. Additionally, Lyskov et al. have shown that the triplet exciton transport may proceed via a fast intramolecular diffusion along the PPV backbone26, not possible for small molecule emitters. This improvement of triplet exciton transport may not necessarily be limited to PPVs but is expected to be a general property of conjugated polymers with planar geometry. In this study, a series of PPV-based copolymers were synthesized, characterized and their upconversion performance as emitters measured. The primary objective was to investigate the effect of increasing composition of monomers with bulky sidechains starting with the well-known poly[2-methoxy-5-(2-ethylhexyloxy)-1,4-phenylenevinylene] (MEH-PPV). The proposed PPV copolymers P1–P6 have fluorenyloxy side chains with an ethylene glycol spacer to decouple the electronic interactions between the fluorenyl unit and the polymer backbone (Fig. 2). The dioctylfluorene units are introduced to insulate the polymer backbone, such that high ΦPL can be achieved by reducing aggregation-induced quenching.

Methods

Materials

Commercial reagents were purchased from Univar, Sigma-Aldrich, AK Scientific, Matrix Scientific, Ajax Finechem, and Labchem, and were used as received. The reference MEH-PPV polymer was purchased commercially from Lumtec (https://lumtec.com.tw/). Anhydrous toluene, diethyl ether, dichloromethane, and tetrahydrofuran were obtained from alumina drying columns. For reactions carried out under inert conditions, standard Schlenk techniques were used. Solvents were sparged with nitrogen gas for several hours prior to use, and the reaction vessels were sealed with a rubber septum under a nitrogen atmosphere. Thin layer chromatography (TLC) was done using Merck-Millipore Silica gel glass plates (60G F254), with a 254 nm and 365 nm light mercury lamp used for identifying spots. 1H NMR (400 MHz) and 13C NMR (100 MHz) spectra were obtained in CDCl3, on a 400 MHz Varian spectrometer. NMR peaks were referenced to the CHCl3 solvent peak. UV–Vis spectroscopy was performed on an Agilent Technologies Cary 50 UV–Vis, using an L = 0.01 cm cell to account for the high concentration of the samples. Photoluminescence spectroscopy was performed on a Varian Cary Eclipse fluorimeter using a triangular cell in a front-facing fluorescence experiment to minimize sample reabsorption. Absolute photoluminescence quantum yield of the samples was determined via an integrating sphere method using an integrating sphere accessory (F3018, Horiba Jobin Yvon) on a Fluorolog-3 fluorimeter (see Supplementary Information for Experimental Details).

Synthesis procedures

Compound 2

9,9-Dioctyl-9H-fluoren-2-ol 1 (3.8 g, 9.34 mmol), ethylene carbonate (1.9 g, 21.6 mmol), potassium carbonate (4 g, 28.9 mmol), and tetrabutylammonium bromide (0.4 g, 1.2 mmol) were dissolved in 80 ml of DMF and heated to 110 °C overnight under nitrogen atmosphere. The mixture was then cooled and poured into water. The product was then extracted with ethyl acetate and washed with 5% w/v aqueous lithium chloride. The organic layer was then collected and diluted with hexanes and dried over magnesium sulfate. The mixture was then filtered through a thin layer of silica, then the solvent was evaporated. Mass = 4.2 g (quant.).

1H NMR (400 MHz, CHCl3, δ): 7.61 (m, 2H), 7.28 (m, 2H), 7.23 (m, 1H), 6.89 (m, 2H), 4.15 (t, J = 4.5Hz, 2H), 4.01 (t, J = 4.2Hz, 2H), 2.06 (s, 1H), 1.91 (m, 4H), 1.11 (m, 21H), 0.82 (t, J = 7.1Hz, 6H), 0.62 (m, 4H); 13C NMR (100 MHz, CDCl3, δ):158.50, 152.75, 150.20, 140.91, 134.64, 126.67, 125.98, 122.68, 120.34, 118.86, 112.70, 109.56, 69.40, 61.61, 55.04, 40.53, 31.77, 30.03, 29.22, 23.69, 22.58, 14.05; HRMS (ESI) m/z: [M]+ calcd for C31H46O2, 450.3498; found, 450.3498.

Compound 3

Triphenylphosphine (2.44 g, 9.3 mmol) was dissolved in 15 ml of DCM and cooled to 0 °C. A solution of N-bromosuccinimide (1.67 g, 9.3 mmol) in 15 ml of DCM was added to the mixture dropwise. Then (2-((9,9-dioctyl-9H-fluoren-2-yl)oxy)ethan-1-ol 2 (4.2 g, 9.3 mmol) in 15 ml of DCM was added to the mixture dropwise. The mixture was then poured into hexanes and filtered through a thin layer of silica. The solvent was then evaporated, and the product was loaded onto celite. The product was then purified by DCVC eluting with 0, 0.5, 1, 2, 3% ethyl acetate in hexanes. Mass = 3.5 g (73%)

1H NMR (400 MHz, CHCl3, δ): 7.61 (m, 2H), 7.29 (m, 2H), 7.24 (m, 1H), 6.88 (m, 2H), 4.36 (t, J = 6.3Hz, 2H), 3.68 (t, J = 6.3Hz, 2H), 1.91 (m, 4H), 1.11 (m, 21H), 0.82 (t, J = 7.1Hz, 6H), 0.61 (m, 4H); 13C NMR (100 MHz, CDCl3, δ):157.96, 152.80, 150.23, 140.82, 134.94, 126.68, 126.06, 122.70, 120.37, 118.91, 112.96, 109.85, 68.20, 55.07, 40.47, 31.76, 30.00, 29.22, 29.21, 29.20, 23.67, 22.58, 14.05; HRMS (ESI) m/z: [M]+ calcd for C31H45OBr, 512.2654; found, 512.2655.

Compound 5

2-(2-Bromoethoxy)-9,9-dioctyl-9H-fluorene 3 (3.5 g, 6.8 mmol), dimethyl 2,5-dihydroxyterephthalate 4 (0.62 g, 2.74 mmol), potassium carbonate (1.9 g, 13.7 mmol), and tetrabutylammonium bromide (0.56 g, 1.68 mmol) were dissolved in 50 mL of DMF and heated to 110 °C overnight under nitrogen atmosphere. The mixture was then cooled and poured into water. The product was then extracted with chloroform and washed with 5% w/v aqueous lithium chloride. The organic layer was then collected and dried over magnesium sulfate. The mixture was then filtered through a thin layer of silica, then the solvent was evaporated, and the product was loaded onto celite. The product was then purified by DCVC eluting with 0, 1, 2, 5, 10, 20% ethyl acetate in hexanes. Mass = 2.01 g (67%)

1H NMR (400 MHz, CHCl3, δ): 7.62 (m, 6H), 7.31 (m, 4H), 7.24 (m, 2H), 6.95 (m, 4H), 4.45 (m, 8H), 3.90 (s, 6H), 1.95 (m, 8H), 1.12 (m, 45H), 0.84 (t, J = 7.1Hz, 12H), 0.65 (m, 8H); 13C NMR (100 MHz, CDCl3, δ): 165.73, 158.56, 152.74, 152.36, 150.22, 140.96, 134.65, 126.70, 125.99, 125.36, 122.69, 120.34, 118.89, 118.45, 112.84, 109.75, 69.44, 66.90, 55.07, 52.36, 40.57, 31.79, 30.08, 29.26, 23.75, 22.60, 14.08; HRMS (ESI) m/z: [M]+ calcd for C72H98O8, 1090.7262; found, 1090.7262.

Compound 6

Lithium aluminium hydride (0.724 g, 19 mmol) was dissolved in 40 mL of diethyl ether and cooled to 0 °C. A solution of dimethyl 2,5-bis(2-((9,9-dioctyl-9H-fluoren-2-yl)oxy)ethoxy)terephthalate 5 (2.01 g, 1.84 mmol) in 20 ml of diethyl ether was added dropwise to the mixture. The mixture was then allowed to slowly warm to room temperature overnight. The mixture was then cooled to 0 °C, and 0.7 ml of water was added dropwise to the mixture, followed by 0.7 ml of 1 M aqueous sodium hydroxide, and finally another 2.1 ml of water. The mixture was then stirred at room temperature for 15 min. Then 4 g of magnesium sulfate was added, and the mixture was stirred for another 15 mins. The mixture was then filtered through a thin layer of silica. The solvent was evaporated, and the product was loaded onto celite. The product was then purified by DCVC eluting with 0, 5, 10, 20% ethyl acetate in hexanes. Mass = 1.91 g (quant).

1H NMR (400 MHz, CHCl3, δ): 7.60 (m, 4H), 7.28 (m, 4H), 7.24 (m, 2H), 6.97 (s, 2H), 6.61 (m, 4H), 4.71 (s, 4H), 4.40 (m, 8H), 1.92 (m, 8H), 1.12 (m, 45H), 0.82 (t, J = 7.1Hz, 12H), 0.62 (m, 8H); 13C NMR (100 MHz, CDCl3, δ): 158.30, 152.82, 151.10, 150.24, 140.87, 134.80, 130.42, 126.67, 126.00, 122.71, 120.42, 118.91, 113.89, 112.99, 109.39, 68.15, 66.78, 62.03, 55.09, 40.46, 31.77, 30.03, 29.23, 29.21, 23.71, 22.58, 14.06; HRMS (ESI) m/z: [M]+ calcd for C70H98O6, 1034.7363; found, 1034.7362.

Compound 7

(2,5-Bis(2-((9,9-dioctyl-9H-fluoren-2-yl)oxy)ethoxy)-1,4-phenylene)dimethanol 5 (1.91 g, 1.84mmol) and 0.34 ml of pyridine were dissolved in 20 ml of chloroform and cooled to 0 °C. A solution of thionyl chloride (0.43 ml) in 9 ml of chloroform was added dropwise to the mixture. The mixture was then allowed to slowly warm to room temperature and stirred for 2 h. The mixture was then poured into saturated aqueous sodium bicarbonate. The product was then extracted with chloroform and then the organic layer was collected and dried over magnesium sulfate. The mixture was then filtered through a thin layer of silica and the solvent was evaporated. The mixture was stirred in hexanes and filtered. The product was then washed with cold hexanes. Mass = 1.54 g (78%)

1H NMR (400 MHz, CHCl3, δ): 7.61 (d, J = 8.5Hz, 4H), 7.30 (m, 4H), 7.23 (m, 2H), 7.08 (s, 2H), 6.93 (m, 4H), 4.69 (s, 4H), 4.41 (s, 8H), 1.93 (m, 8H), 1.11 (m, 44H), 0.82 (t, J = 7.1Hz, 12H), 0.63 (m, 8H); 13C NMR (100 MHz, CDCl3, δ): 158.53, 152.79, 150.83, 150.25, 140.92, 134.67, 127.94, 126.67, 125.97, 122.70, 120.34, 118.88, 115.40, 112.82, 109.78, 68.52, 66.89, 55.06, 41.08, 40.50, 31.77, 30.04, 29.23, 29.22, 23.72, 22.58, 14.06; HRMS (ESI) m/z: [M]+ calcd for C70H96O2Cl2, 1070.6686; found, 1070.6686.

General polymerization method

Potassium tert-butoxide (20 eq.) was dissolved in dry degassed THF (made to 0.4 M) and stirred at room temperature under nitrogen atmosphere. Then the monomer(s) (1 eq.) were added dropwise as a solution of dry degassed THF (made to 0.035 M) to the mixture. The mixture was then allowed to stir overnight at room temperature. The mixture was then diluted with THF and poured into 10 times the reaction volume of methanol with vigorous stirring. The suspension was then centrifuged to collect the polymer, which was then washed 3 times with methanol and then dried in a vacuum oven overnight. Example procedure for P4 provided below. See Table S2 in the Supporting Information file for synthesis details for P1 to P6. GPC traces are shown in Fig. S17.

Example procedure: synthesis of P4

Potassium tert-butoxide (0.317 g) was dissolved in 7 ml of dry degassed THF and stirred at room temperature under nitrogen atmosphere. Then 2,2ʹ-((((2,5-bis(chloromethyl)-1,4-phenylene)bis(oxy))bis(ethane-2,1-diyl))bis(oxy))bis(9,9-dioctyl-9H-fluorene) 7 (0.114 g, 0.106 mmol) and 1,4-bis(bromomethyl)-2-((2-ethylhexyl)oxy)-5-methoxybenzene 8 (0.045 g, 0.106 mmol) were added dropwise as a solution in 4 ml of dry degassed THF to the mixture. The mixture was then allowed to stir overnight at room temperature. The mixture was then diluted with THF and poured into 110 ml of methanol with vigorous stirring. The suspension was then centrifuged to collect the polymer, which was then washed 3 times with methanol and then dried in a vacuum oven overnight. Mass = 0.084 g (63%)

Upconversion experiments

Upconversion samples were degassed three times via freeze-pump-thaw cycles prior to analysis. Upconversion spectra were taken using an Ocean Optics USB spectrometer with 300 μm fiber optic cable.

The upconversion quantum yields were measured using the following equation:

using a degassed solution of MEH-PPV (0.5 mg/mL) with PdTPTBP (7.5 μM) in chloroform as the reference material. The \({\Phi }_{UC}\) of the MEH-PPV standard material was determined to be 0.039% with 632 nm excitation (band pass filtered HeNe laser) with an intensity of 985 mW/cm2 via an integrating sphere method with a LABSPHERE (model number: 4P-GPS-053-SL) and detected with a liquid nitrogen cooled CCD camera from Princeton Instruments (series number: SP2500). Band pass filters for both short and long pass filters were obtained from Thorlabs (Edgepass filter range). This was used as the reference (ΦRef) for all other values given.

The values for the triplet energy transfer quantum yields were determined by comparing the integrated emission from the sensitizer with/without the polymer present, using the following equation:

where Ipolymer represents the spectra of the sample with the polymer present and Iblank is the sample without the polymer.

Results

Synthesis and characterization

The synthesis of the new PPV copolymers first began by alkylation of dioctylfluorenol 1 with ethylene carbonate to install the glycol spacer 2 in a quantitative yield (Fig. 3). The alcohol 2 was then converted to the corresponding bromide 3 in a 73% yield. The bromide 3 was installed via an alkylation onto the methyl ester terephthalate core 4 in a 67% yield. The methyl ester 5 were reduced with lithium aluminium hydride to produce the corresponding alcohol 6 in a quantitative yield. Monomer 7 was produced in a 78% yield by treating the alcohol 6 with thionyl chloride and pyridine. Attempts made using thionyl chloride in the absence of pyridine failed to produce the desired product, due to the susceptibility of the glycol unit to acidic conditions, this property made purification via column chromatography difficult. The single crystal structure of monomer 7 was then obtained from slowly cooling a saturated solution in DMF. The structure showed an unusual kink in one of the octyl chains on each fluorene as it packed closely with neighbouring units (For more details see Table S1, Fig. S16). However, the fluorene units remained distant from the phenylene core ensuring electronic decoupling with the polymer backbone as desired. The PPV copolymers P1–P6 were then prepared by Gilch polymerization27 in THF with various ratios of monomer 7 and the MEH monomer 8 (Fig. 4). Reaction yields ranged between 63 and 99% (Table S2). It is important to note here that the exact monomer ratio incorporated into the polymers could not be determined using standard methods such as NMR, UV–Vis absorption or photoluminescence spectroscopy. The NMR signals are broad as expected for polymers and there were no distinct chemical shifts for the monomers that allow integration of the signals. Estimates from either the UV–Vis absorbance intensities or fluorescence peak emission shift leads to unrealistic values. This may be due to the nature of the statistically random copolymerization which may form a range of different chromophores each with their own extinction coefficients with varying photoluminescent quantum yields. The monomer feed ratios (n:m) were not expected to exactly match the true copolymer ratios, since the Gilch polymerization produced a statistically random polymer. However, a sufficiently large enough range of comonomer ratios ensured that trends in properties were maintained.

Having successfully synthesized the PPV copolymers P1–P6, their general and photophysical properties were determined. Comparing the data for all the synthesized copolymers (Table 1), the number-average molecular weight (Mn) spanned a relatively wide range, differing by a factor of six between the lowest and highest values. However, due to the stark difference in molecular weight of the repeat units derived from monomers 7 and 8 (1072.43 and 422.20 g/mol, respectively), it was more useful to calculate and compare the average chain lengths in number of phenylenevinylene repeat units instead. This provided the average number of chromophores in a chain, as shown below. The chromophore length was previously determined for PPVs at 11 repeat units by Kolshorn et al.28. It was clear that most polymer samples had similar number-average chain lengths, though the samples with n:m = 5:1 and 1:10 were noticeable outliers, differing by roughly a factor of two from the rest.

The UV–Vis absorption spectrum of the polymers showed peaks at 278, 316 and 497 nm with significant absorbance variation amongst the 6 samples (Fig. 5a). The absorbance variation was a result of the varying proportion of the fluorenyloxy comonomer unit. The peaks at 316 nm and 278 nm were attributed to the fluorene itself, and for all comonomer ratios except 1:5 and 1:10 (P5 and P6 respectively) the relative intensity of the fluorenyl band was greater than or equal to that of the PPV polymer backbone (λ = 497 nm). This was primarily due to a greater abundance of fluorenyl units compared to effective polymeric chromophores. There was only a small shift in the peak maxima of the photoluminescence spectrum for this series of PPV copolymers (Fig. 5b). The peak maxima varied from 548 nm for P1 (n:m = 1:0) to 560 nm for P6 (n:m = 1:10). This could be due to a slight twisting of the polymer backbone caused by steric repulsion of the fluorenyloxy side chains reducing effective conjugation, an effect which diminishes as the content of the MEH monomer increases. The ΦPL of the polymers (Table 1) show a convincing correlation to the proportion of the bulky fluorenyloxy comonomer unit in the polymers (see Supplementary Information, Fig. S23) with a decrease in the amount of the bulky fluorenyloxy comonomer unit accounting for a reduction in the ΦPL. With the reduction in the steric bulk, a higher degree of polymer backbone aggregation was likely increasing non-radiative processes.

Upconversion photophysics

All the PPV copolymers showed upconversion in chloroform solution with PdTPTBP as the sensitizer (Fig. 6). A commercial sample of MEH-PPV was used as a readily available reference material (see Supplementary Information for details). The upconversion emission was optimised using P6 by varying the polymer concentration with a fixed sensitizer concentration of 7.5 μM (Figs. S18, S19). The series of copolymers were then compared using the optimized conditions (copolymer concentration = 0.25 mg/ml), with an excitation power of 10,468 mW/cm2 at 632 nm. The copolymers showed a clear trend in which the quenching of the phosphorescence increased as the amount of the MEH comonomer incorporated increased, resulting in a greater upconverted emission intensity as the steric bulk decreased in moving from P1 to P6. However, the resulting upconverted intensity for MEH-PPV was lower than that of many of the copolymers.

Emission spectrum of PPV copolymers P1–P6 (0.25 mg/ml) and MEH-PPV (0.5 mg/ml) with PdTPTBP (7.5 μM) as the sensitizer in chloroform solution using 632 nm wavelength and 10,468 mW/cm2 power excitation without (a) and with (b) the use of a 600 nm short band pass filter. (a) Shows the phosphorescence emission of PdTPTBP centered at 800 nm as seen in the sensitizer-only sample, as well as the upconverted emission of the samples from 550 to 600 nm.

The ΦUC values of the copolymer increased sharply with decreasing steric bulk up until P4 n:m = 1:5 (Fig. 7), after which a plateau is reached at P6 n:m = 1:10, presumably due to the reduction in ΦPL. MEH-PPV has none of the bulky fluorenyloxy side chain comonomer and yet maintains a higher ΦUC than half of the PPV copolymers despite having a lower ΦPL than the copolymers. This implied that factors other than ΦPL in the TTA-UC process must be significantly impacting the ΦUC (Eq. (1)). By dividing both sides of Eq. (1) by the ΦPL, the value obtained focused on all the remaining processes, specifically the TET and TTA since the ISC was the same whilst using the same sensitizer:

The role of back energy transfer (BET) from the upconverted singlet state of the conjugated polymers and the PdTPTBP sensitizer on the observed upconversion efficiency, can be determined assuming diffusional interactions. The second order diffusional rate constant for chloroform at 298 K determined from the Stokes–Einstein and Smoluchowski relationships is 5.8 × 109 M−1 s−1. The concentration of PdTPTBP is 7.5 μM and, under these conditions, diffusional interactions with the polymer chains will occur on the microsecond time scale. Since the reported fluorescence lifetime of MEH-PPV, an exemplar of the conjugated polymers, is reported to be only 0.33 ns29, BET should not play a role in quenching the upconverted polymer singlet state.

Attempts were made to realize upconversion in solid state films following a similar procedure to Monkman et al.24. Using drop casting onto quartz slides from degassed solutions of the polymer and 4 wt% of the sensitizer (PdTPTBP) before being press sealed to exclude oxygen. However, no upconversion signal was detected when excited with a 632 nm laser source. This is likely due to the low efficiency so that any upconversion signal is within the low signal-to-noise regime of the detector.

Comparing the ΦUC/ΦPL value between the PPV copolymers revealed a trend in which the value increased as the degree of steric bulk decreased (Fig. 7a). Naive extrapolation of this trend would suggest that a PPV with no side chain at all with a ΦPL of unity would be the ideal PPV-based emitter. However, this was unrealistic as sidechains are needed to enable solution processability of the polymer as well as to suppress the aggregation-caused quenching allowing for high ΦPL values. A similar relationship (Fig. 7b) can be seen between the ΦUC/ΦPL value and the ΦTET value for the polymers P1–P6, where ΦTET was obtained by comparing the integrated phosphorescence of copolymer samples with the sensitizer-only sample (Table 1, see Supplementary Information for experimental details). A substantial increase in upconversion performance was observed through an increased quenching of the phosphorescence from the sensitizer in moving from P3 to P4 which then began to plateau above an inflection point at P5 and P6 such that very little improvement was made from any additional phosphorescence quenching. This phenomenon was attributed to the steric bulk of the sidechains inhibiting TET from the sensitizer to the polymer emitter, thereby reducing the quenching of sensitizers’ phosphorescence. When the copolymers consisted mostly of non-bulky monomer (m > n), the triplet energy transfer became facile, and eventually the concentration of polymer triplet excitons become favourable for TTA. Any additional triplet excitons formed may increase the likelihood of TTA events, but with diminishing returns as the polymer becomes saturated and other quenching processes that do not result in upconverted emission become more likely30. Interestingly, MEH-PPV shows a deviation from this observed trend attributable to a combination of low fluorescence yield and inefficient triplet triplet–triplet annihilation. The presence of the fluorenyloxy comonomer units look to be important in maintaining a significant ΦUC, most likely by disfavoring aggregation-induced deactivation pathways.

Using Eq. (1), the values for ΦTTA can be obtained for the copolymer samples (Table 1). The ΦTTA showed a generally increasing trend throughout the copolymer series with the exception of P1. There is considerable uncertainty in the ΦTTA value for P1 due to very low upconversion emission signal. Assuming the same f value for all the copolymers9, the contact triplet pair formation efficiency followed the same trend as ΦTTA. The assumption is reasonable since the same emitter is present in every polymer, in the form of an alkyloxy PPV backbone. The low ΦTTA values may be attributed to triplet exciton traps decreasing the polymer triplet lifetimes or inefficient triplet–triplet annihilation processes though further spectroscopic studies will be needed to confirm this.

A further question to be considered is whether the TTA process leading to the upconverted emission is intra- or inter-molecular. An intramolecular process requires a second triplet excitation to be sensitized in a polymer chain within the lifetime of the initial triplet exciton residing on the polymer. The triplet lifetime of MEH-PPV in solution is reported to be ~ 100 microseconds31. The concentration of polymer chains (MEH-PPV) is 0.25 mg/ml or 1.2 × 10–5 M and if we assume, to a first approximation, the diffusion controlled rate of 5.8 × 109 M−1 s−1 there will be polymer collisions approximately every 14 microseconds. For the very high incident laser excitation flux required to observe upconversion in these samples (~ 8 × 1016 photons/s including 10% reflection losses on the front cell surface at 10 W/cm2) and high sensitizer absorbance one might expect efficient conversion to polymer triplets at the concentrations used, assuming a diffusion-controlled collision rate. Even allowing for spin statistical factors, efficient interpolymer chain triplet–triplet annihilation and intrachain triplet–triplet annihilation to form emitting singlets are feasible. However, the very low upconversion yields observed suggests both these processes are remarkably inefficient for these polymers. Further investigations using time-resolved spectroscopies are warranted to resolve the reasons for these inefficient triplet state processes.

The ΦUC values were measured as a function of excitation intensity for both the PPV copolymer P6 and MEH-PPV (Fig. 8). Both polymers showed an increase in ΦUC with increasing excitation intensity up to 10,000 mW/cm2. This rise can be attributed to an increase in the available triplet states. The highest ΦUC was obtained with copolymer P6 at 9195 mW/cm2 with a value of 0.18%. Plotting the data on log–log scale (Fig. S22) did not reveal the upconversion excitation threshold values as both linear and quadratic relationship gave reasonable fits in the excitation intensity range. We were unable to measure ΦUC over a greater range of excitation power due to equipment limitations.

Conclusions

A series of PPV copolymers was synthesized to elucidate the key limiting factors of upconversion with conjugated polymers. It was found that the steric bulk on the sidechains of the polymer reduced the ΦUC of the polymer despite increasing the ΦPL. Analysing ΦUC and ΦPL with respect to ΦTET revealed sterically bulky sidechains hindered triplet energy transfer from the sensitizer to the polymer backbone. The best performing polymer was P6 with ΦUC of 0.18% at 635 nm excitation and 9,195 mW/cm2 power intensity.

Data availability

All data relevant to the discussion in this work is either shown in the manuscript or in the supporting information file. Raw data on compound characterisation and photophysical studies is available by contacting the corresponding author. The crystallographic data (CCDC 1992340) is available from The Cambridge Crystallographic Data Centre via www.ccdc.cam.ac.uk/data_request/cif.

References

Schulze, T. F. & Schmidt, T. W. Photochemical upconversion: Present status and prospects for its application to solar energy conversion. Energy Environ. Sci. 8, 103–125. https://doi.org/10.1039/C4EE02481H (2015).

Cheng, Y. Y. et al. Improving the light-harvesting of amorphous silicon solar cells with photochemical upconversion. Energy Environ. Sci. 5, 6953–6959. https://doi.org/10.1039/C2EE21136J (2012).

Shockley, W. & Queisser, H. J. Detailed balance limit of efficiency of p-n junction solar cells. J. Appl. Phys. 32, 510–519. https://doi.org/10.1063/1.1736034 (1961).

Monguzzi, A., Tubino, R., Hoseinkhani, S., Campione, M. & Meinardi, F. Low power, non-coherent sensitized photon up-conversion: Modelling and perspectives. PCCP 14, 4322–4332. https://doi.org/10.1039/C2CP23900K (2012).

Zhou, Y., Castellano, F. N., Schmidt, T. W. & Hanson, K. On the quantum yield of photon upconversion via triplet–triplet annihilation. ACS Energy Lett. 5, 2322–2326. https://doi.org/10.1021/acsenergylett.0c01150 (2020).

Bachilo, S. M. & Weisman, R. B. Determination of triplet quantum yields from triplet−triplet annihilation fluorescence. J. Phys. Chem. A 104, 7711–7714. https://doi.org/10.1021/jp001877n (2000).

Cheng, Y. Y. et al. On the efficiency limit of triplet–triplet annihilation for photochemical upconversion. Phys. Chem. Chem. Phys. 12, 66–71. https://doi.org/10.1039/B913243K (2010).

Deng, F., Blumhoff, J. & Castellano, F. N. Annihilation limit of a visible-to-UV photon upconversion composition ascertained from transient absorption kinetics. J. Phys. Chem. A 117, 4412–4419. https://doi.org/10.1021/jp4022618 (2013).

Saltiel, J., March, G. R., Smothers, W. K., Stout, S. A. & Charlton, J. L. Spin-statistical factor in the triplet-triplet annihilation of anthracene triplets. J. Am. Chem. Soc. 103, 7159–7164. https://doi.org/10.1021/ja00414a020 (1981).

Ogawa, T., Yanai, N., Monguzzi, A. & Kimizuka, N. Highly efficient photon upconversion in self-assembled light-harvesting molecular systems. Sci. Rep. 5, 10882. https://doi.org/10.1038/srep10882 (2015).

Lee, S. H., Ayer, M. A., Vadrucci, R., Weder, C. & Simon, Y. C. Light upconversion by triplet–triplet annihilation in diphenylanthracene-based copolymers. Polym. Chem. 5, 6898–6904. https://doi.org/10.1039/C4PY00920G (2014).

Gao, C. et al. Intramolecular versus intermolecular triplet fusion in multichromophoric photochemical upconversion. J. Phys. Chem. C 123, 20181–20187. https://doi.org/10.1021/acs.jpcc.9b07098 (2019).

Tilley, A. J., Robotham, B. E., Steer, R. P. & Ghiggino, K. P. Sensitized non-coherent photon upconversion by intramolecular triplet–triplet annihilation in a diphenylanthracene pendant polymer. Chem. Phys. Lett. 618, 198–202. https://doi.org/10.1016/j.cplett.2014.11.016 (2015).

Boutin, P. C., Ghiggino, K. P., Kelly, T. L. & Steer, R. P. Photon upconversion by triplet–triplet annihilation in Ru(bpy)3- and DPA-functionalized polymers. J. Phys. Chem. Lett. 4, 4113–4118. https://doi.org/10.1021/jz402311j (2013).

Yu, X., Cao, X., Chen, X., Ayres, N. & Zhang, P. Triplet–triplet annihilation upconversion from rationally designed polymeric emitters with tunable inter-chromophore distances. Chem. Commun. 51, 588–591. https://doi.org/10.1039/C4CC07589G (2015).

Williams, A. K. et al. Thiol-ene click chemistry: A modular approach to solid-state triplet–triplet annihilation upconversion. J. Mater. Chem. C 6, 3876–3881. https://doi.org/10.1039/C7TC05729F (2018).

Monguzzi, A., Frigoli, M., Larpent, C., Tubino, R. & Meinardi, F. Low-power-photon up-conversion in dual-dye-loaded polymer nanoparticles. Adv. Funct. Mater. 22, 139–143. https://doi.org/10.1002/adfm.201101709 (2012).

Singh-Rachford, T. N., Lott, J., Weder, C. & Castellano, F. N. Influence of temperature on low-power upconversion in rubbery polymer blends. J. Am. Chem. Soc. 131, 12007–12014. https://doi.org/10.1021/ja904696n (2009).

Islangulov, R. R., Lott, J., Weder, C. & Castellano, F. N. Noncoherent low-power upconversion in solid polymer films. J. Am. Chem. Soc. 129, 12652–12653. https://doi.org/10.1021/ja075014k (2007).

Hertel, D., Bässler, H., Guentner, R. & Scherf, U. Triplet-triplet annihilation in a poly(fluorene)-derivative. J. Chem. Phys. 115, 10007–10013. https://doi.org/10.1063/1.1415446 (2001).

Laquai, F., Wegner, G., Im, C., Büsing, A. & Heun, S. Efficient upconversion fluorescence in a blue-emitting spirobifluorene-anthracene copolymer doped with low concentrations of Pt(II)octaethylporphyrin. J. Chem. Phys. 123, 074902. https://doi.org/10.1063/1.1992477 (2005).

Baluschev, S. et al. Upconversion photoluminescence in poly(ladder-type-pentaphenylene) doped with metal (II)-octaethyl porphyrins. Appl. Phys. Lett. 86, 061904. https://doi.org/10.1063/1.1857073 (2005).

Baluschev, S. et al. Enhanced operational stability of the up-conversion fluorescence in films of palladium–porphyrin end-capped poly(pentaphenylene). ChemPhysChem 6, 1250–1253. https://doi.org/10.1002/cphc.200500098 (2005).

Jankus, V. et al. Energy upconversion via triplet fusion in super yellow PPV films doped with palladium tetraphenyltetrabenzoporphyrin: A comprehensive investigation of exciton dynamics. Adv. Funct. Mater. 23, 384–393. https://doi.org/10.1002/adfm.201201284 (2013).

Köhler, A. & Beljonne, D. The singlet–triplet exchange energy in conjugated polymers. Adv. Funct. Mater. 14, 11–18. https://doi.org/10.1002/adfm.200305032 (2004).

Lyskov, I. et al. First-principles calculation of triplet exciton diffusion in crystalline poly(p-phenylene vinylene). J. Phys. Chem. C 123, 26831–26841. https://doi.org/10.1021/acs.jpcc.9b08203 (2019).

O’Shea, R. & Wong, W. W. H. Simple improvements to gilch synthesis and molecular weight modulation of MEH-PPV. Polym. Chem. 11, 2831–2837. https://doi.org/10.1039/D0PY00072H (2020).

Meier, H., Stalmach, U. & Kolshorn, H. Effective conjugation length and UV/vis spectra of oligomers. Acta Polym. 48, 379–384. https://doi.org/10.1002/actp.1997.010480905 (1997).

Samuel, I. D. W. et al. The efficiency and time-dependence of luminescence from poly (p-phenylene vinylene) and derivatives. Chem. Phys. Lett. 213, 472–478. https://doi.org/10.1016/0009-2614(93)89144-7 (1993).

Meroni, D., Monguzzi, A. & Meinardi, F. Photon upconversion in multicomponent systems: Role of back energy transfer. J. Chem. Phys. 153, 114302. https://doi.org/10.1063/5.0021253 (2020).

Burrows, H. D., da Miguel, M. G., Monkman, A. P., Hamblett, I. & Navaratnam, S. Transient absorption spectra of triplet states and charge carriers of conjugated polymers. J. Mol. Struct. 563–564, 41–50. https://doi.org/10.1016/S0022-2860(00)00787-0 (2001).

Acknowledgements

This work was supported by the ARC Centre of Excellence in Exciton Science (CE170100026). T. Warner is thanked for help with photophysical experiments.

Author information

Authors and Affiliations

Contributions

R.O. and W.W. conceived the experiments. R.O., C.G., T.C.O., J.M.W. and W.J.K. conducted the experiments, and R.O., K.P.G. and W.J.K. performed the analysis. R.O., T.C.O. and W.J.K. performed the figure generation. All authors reviewed the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

O’shea, R., Kendrick, W.J., Gao, C. et al. Revealing the influence of steric bulk on the triplet–triplet annihilation upconversion performance of conjugated polymers. Sci Rep 11, 19585 (2021). https://doi.org/10.1038/s41598-021-99179-y

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-021-99179-y

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.