Abstract

Nanoelectromechanical system (NEMS) sensors and actuators could be of use in the development of next-generation mobile, wearable and implantable devices. However, these NEMS devices require transducers that are ultra-small, sensitive and can be fabricated at low cost. Here, we show that suspended double-layer graphene ribbons with attached silicon proof masses can be used as combined spring–mass and piezoresistive transducers. The transducers, which are created using processes that are compatible with large-scale semiconductor manufacturing technologies, can yield NEMS accelerometers that occupy at least two orders of magnitude smaller die area than conventional state-of-the-art silicon accelerometers. With our devices, we also extract the Young’s modulus values of double-layer graphene and show that the graphene ribbons have significant built-in stresses.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$29.99 / 30 days

cancel any time

Subscribe to this journal

Receive 12 digital issues and online access to articles

$119.00 per year

only $9.92 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

Data availability

The data that support the plots within this paper and other findings of this study are available from the corresponding author on reasonable request.

Code availability

A high-level description of the FEA model of the devices is available from the corresponding author on reasonable request.

References

Borgia, E. The internet of things vision: key features, applications and open issues. Comput. Commun. 54, 1–31 (2014).

del Rosario, M., Redmond, S. & Lovell, N. Tracking the evolution of smartphone sensing for monitoring human movement. Sensors 15, 18901–18933 (2015).

Brigante, C. M. N., Abbate, N., Basile, A., Faulisi, A. C. & Sessa, S. Towards miniaturization of a MEMS-based wearable motion capture system. IEEE Trans. Ind. Electron. 58, 3234–3241 (2011).

Shasha Liu, P. & Tse, H.-F. Implantable sensors for heart failure monitoring. J. Arrhythm. 29, 314–319 (2013).

Bolotin, K. I. et al. Ultrahigh electron mobility in suspended graphene. Solid State Commun. 146, 351–355 (2008).

Lee, C., Wei, X., Kysar, J. W. & Hone, J. Measurement of the elastic properties and intrinsic strength of monolayer graphene. Science 321, 385–388 (2008).

Koenig, S. P., Boddeti, N. G., Dunn, M. L. & Bunch, J. S. Ultrastrong adhesion of graphene membranes. Nat. Nanotechnol. 6, 543–546 (2011).

Lau, C. N., Bao, W. & Velasco, J. Jr Properties of suspended graphene membranes. Mater. Today 15, 238–245 (2012).

Gómez-Navarro, C., Burghard, M. & Kern, K. Elastic properties of chemically derived single graphene sheets. Nano Lett. 8, 2045–2049 (2008).

Bunch, J. S. et al. Electromechanical resonators from graphene sheets. Science 315, 490–493 (2007).

Chen, C. Y. & Hone, J. Graphene nanoelectromechanical systems. Proc. IEEE 101, 1766–1779 (2013).

Smith, A. D. et al. Electromechanical piezoresistive sensing in suspended graphene membranes. Nano Lett. 13, 3237–3242 (2013).

Kumar, M. & Bhaskaran, H. Ultrasensitive room-temperature piezoresistive transduction in graphene-based nanoelectromechanical systems. Nano Lett. 15, 2562–2567 (2015).

López-Polín, G. et al. Increasing the elastic modulus of graphene by controlled defect creation. Nat. Phys. 11, 26–31 (2015).

López-Polín, G. et al. The influence of strain on the elastic constants of graphene. Carbon 124, 42–48 (2017).

Neumaier, D., Pindl, S. & Lemme, M. C. Integrating graphene into semiconductor fabrication lines. Nat. Mater. 18, 525 (2019).

Li, X. et al. Large-area synthesis of high-quality and uniform graphene films on copper foils. Science 324, 1312–1314 (2009).

Hurst, A. M., Lee, S., Cha, W. & Hone, J. A graphene accelerometer. In 2015 28th IEEE Int. Conf. on Micro Electro Mechanical Systems (MEMS) 865–868 (IEEE, 2015).

Blees, M. K. et al. Graphene kirigami. Nature 524, 204–207 (2015).

Matsui, K. et al. Mechanical properties of few layer graphene cantilever. In 2014 27th IEEE Int. Conf. on Micro Electro Mechanical Systems (MEMS) 1087–1090 (IEEE, 2014).

Zhang, P. et al. Fracture toughness of graphene. Nat. Commun. 5, 3782 (2014).

Shekhawat, A. & Ritchie, R. O. Toughness and strength of nanocrystalline graphene. Nat. Commun. 7, 10546 (2016).

Ruiz-Vargas, C. S. et al. Softened elastic response and unzipping in chemical vapor deposition graphene membranes. Nano Lett. 11, 2259–2263 (2011).

Chen, Z., Lin, Y.-M., Rooks, M. J. & Avouris, P. Graphene nano-ribbon electronics. Physica E 40, 228–232 (2007).

Balandin, A. A. Low-frequency 1/f noise in graphene devices. Nat. Nanotechnol. 8, 549–555 (2013).

Lin, Y.-M. & Avouris, P. Strong suppression of electrical noise in bilayer graphene nanodevices. Nano Lett. 8, 2119–2125 (2008).

Kavitha, S., Daniel, R. J. & Sumangala, K. A simple analytical design approach based on computer aided analysis of bulk micromachined piezoresistive MEMS accelerometer for concrete SHM applications. Measurement 46, 3372–3388 (2013).

Lynch, J. P. et al. Design of piezoresistive MEMS-based accelerometer for integration with wireless sensing unit for structural monitoring. J. Aerosp. Eng. 16, 108–114 (2003).

Shivaraman, S. et al. Free-standing epitaxial graphene. Nano Lett. 9, 3100–3105 (2009).

Frank, I. W., Tanenbaum, D. M., Zande, A. Mvander & McEuen, P. L. Mechanical properties of suspended graphene sheets. J. Vac. Sci. Technol. B 25, 2558–2561 (2007).

Senturia, S. D. Microsystem Design Ch.10 (Kluwer, 2002).

Castellanos-Gomez, A., Singh, V., van der Zant, H. S. J. & Steele, G. A. Mechanics of freely-suspended ultrathin layered materials: mechanics of 2D materials. Ann. Phys.-Berlin 527, 27–44 (2015).

Traversi, F. et al. Elastic properties of graphene suspended on a polymer substrate by e-beam exposure. New J. Phys. 12, 023034 (2010).

Li, P., You, Z., Haugstad, G. & Cui, T. Graphene fixed-end beam arrays based on mechanical exfoliation. Appl. Phys. Lett. 98, 253105 (2011).

Li, Y., Zheng, Q., Hu, Y. & Xu, Y. Micromachined piezoresistive accelerometers based on an asymmetrically gapped cantilever. J. Microelectromech. Syst. 20, 83–94 (2011).

Bunch, J. S. et al. Impermeable atomic membranes from graphene sheets. Nano Lett. 8, 2458–2462 (2008).

Garcia-Sanchez, D. et al. Imaging mechanical vibrations in suspended graphene sheets. Nano Lett. 8, 1399–1403 (2008).

Yazdi, N., Ayazi, F. & Najafi, K. Micromachined inertial sensors. Proc. IEEE 86, 1640–1659 (1998).

Zhu, S.-E., Ghatkesar, M. K., Zhang, C. & Janssen, G. Graphene based piezoresistive pressure sensor. Appl. Phys. Lett. 102, 161904 (2013).

Benameur, M. M. et al. Electromechanical oscillations in bilayer graphene. Nat. Commun. 6, 8582 (2015).

Zheng, X., Chen, X., Kim, J.-K., Lee, D.-W. & Li, X. Measurement of the gauge factor of few-layer graphene. J. Micro/Nanolith. MEMS MOEMS 12, 013009–013009 (2013).

Huang, M., Pascal, T. A., Kim, H., Goddard, W. A. & Greer, J. R. Electronic-mechanical coupling in graphene from in situ nanoindentation experiments and multiscale atomistic simulations. Nano Lett. 11, 1241–1246 (2011).

Nicholl, R. J. T. et al. The effect of intrinsic crumpling on the mechanics of free-standing graphene. Nat. Commun. 6, 8789 (2015).

Wung, T.-S., Ning, Y.-T., Chang, K.-H., Tang, S. & Tsai, Y.-X. Vertical-plate-type microaccelerometer with high linearity and low cross-axis sensitivity. Sens. Actuat. A 222, 284–292 (2015).

Fischer, A. C. et al. Integrating MEMS and ICs. Microsyst. Nanoeng. 1, 15005 (2015).

Roy, A. L. & Bhattacharyya, T. K. Design, fabrication and characterization of high performance SOI MEMS piezoresistive accelerometers. Microsyst. Technol. 21, 55–63 (2015).

Zhang, L., Lu, J., Kurashima, Y., Takagi, H. & Maeda, R. Development and application of planar piezoresistive vibration sensor. Microelectron. Eng. 119, 70–74 (2014).

Plaza, J. A., Collado, A., Cabruja, E. & Esteve, J. Piezoresistive accelerometers for MCM package. J. Microelectromech. Syst. 11, 794–801 (2002).

Manzeli, S., Allain, A., Ghadimi, A. & Kis, A. Piezoresistivity and strain-induced band gap tuning in atomically thin MoS2. Nano Lett. 15, 5330–5335 (2015).

Lee, G.-H. et al. High-strength chemical-vapor-deposited graphene and grain boundaries. Science 340, 1073–1076 (2013).

Salvetat, J.-P. et al. Elastic and shear moduli of single-walled carbon nanotube ropes. Phys. Rev. Lett. 82, 944 (1999).

Zandiatashbar, A. et al. Effect of defects on the intrinsic strength and stiffness of graphene. Nat. Commun. 5, 3186 (2014).

Han, J., Ryu, S., Kim, D.-K., Woo, W. & Sohn, D. Effect of interlayer sliding on the estimation of elastic modulus of multilayer graphene in nanoindentation simulation. EPL 114, 68001 (2016).

Wei, X. et al. Recoverable slippage mechanism in multilayer graphene leads to repeatable energy dissipation. ACS Nano 10, 1820–1828 (2016).

Nicholl, R. J. T., Lavrik, N. V., Vlassiouk, I., Srijanto, B. R. & Bolotin, K. I. Hidden area and mechanical nonlinearities in freestanding graphene. Phys. Rev. Lett. 118, 266101 (2017).

Fan, X. et al. Direct observation of grain boundaries in graphene through vapor hydrofluoric acid (VHF) exposure. Sci. Adv. 4, eaar5170 (2018).

Smith, A. D., Vaziri, S., Rodriguez, S., Östling, M. & Lemme, M. C. Large scale integration of graphene transistors for potential applications in the back end of the line. Solid State Electron. 108, 61–66 (2015).

Wagner, S. et al. Graphene transfer methods for the fabrication of membrane-based NEMS devices. Microelectron. Eng. 159, 108–113 (2016).

Acknowledgements

This work was supported by the European Research Council through the Starting Grant M&M’s (No. 277879) and InteGraDe (307311), the Swedish Research Council (GEMS, 2015-05112), the China Scholarship Council through a scholarship grant, the German Federal Ministry for Education and Research project NanoGraM (BMBF, 03XP0006C) and the German Research Foundation (DFG, LE 2440/1-2). Funding through the European Commission (Graphene Flagship, 785219) is acknowledged. The authors thank C. Aronsson for help with device processing, M. Bergqvist for support with the measurement set-up, M. Fielden for help with AFM indentation experiments and J. Schell for help with LDV experiments. The authors also thank C. Rusu, D. Kolev and P. Johannisson for discussions about LDV characterization.

Author information

Authors and Affiliations

Contributions

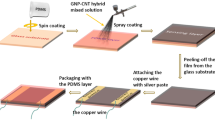

X.F., F.N., F.F., A.C.F., A.D.S. and M.C.L. conceived and designed the experiments. A.D.S., S.W., M.Ö. and M.C.L. developed the graphene transfer method. S.S. performed packaging of all devices. F.F. designed the measurement circuits and contributed to acceleration measurements. S.W. carried out the Raman characterization. X.F. fabricated the devices (substrate preparation, graphene transfer and patterning, and proof mass release) and performed the experiments, including device characterization (optical microscopy, SEM imaging, white-light interferometry, AFM tip indentation, LDV measurements and electrical characterization) and acceleration measurements, and wrote the manuscript. F.N. provided guidance in the experiments and manuscript writing. X.F., F.F., H.R., F.N. and M.C.L. analysed the experimental results. X.F., H.R. and F.N. analysed the simulation results. All authors discussed the results and commented on the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note: Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Supplementary Information

Supplementary Sections 1–26.

Supplementary Video 1

FEA simulation results depicting the dominant Z-mode movement of the proof mass of device 1 with resonance frequency of 50.15 kHz.

Supplementary Video 2

LDV measurements showing the resonant Z-mode movement of the proof mass of device 14 with resonance frequency of 24.2 kHz.

Supplementary Video 3

LDV measurement showing the deflection of the proof mass of device 14 at an applied 1 g acceleration and an excitation frequency of 21.688 kHz.

Rights and permissions

About this article

Cite this article

Fan, X., Forsberg, F., Smith, A.D. et al. Graphene ribbons with suspended masses as transducers in ultra-small nanoelectromechanical accelerometers. Nat Electron 2, 394–404 (2019). https://doi.org/10.1038/s41928-019-0287-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41928-019-0287-1

This article is cited by

-

Microwave synthesis of molybdenene from MoS2

Nature Nanotechnology (2023)

-

Van der Waals device integration beyond the limits of van der Waals forces using adhesive matrix transfer

Nature Electronics (2023)

-

Large-area integration of two-dimensional materials and their heterostructures by wafer bonding

Nature Communications (2021)