Abstract

This review is concerned with the leading methods of bottom-up material preparation for thermal-to-electrical energy interconversion. The advantages, capabilities, and challenges from a material synthesis perspective are surveyed and the methods are discussed with respect to their potential for improvement (or possibly deterioration) of application-relevant transport properties. Solution chemistry-based synthesis approaches are re-assessed from the perspective of thermoelectric applications based on reported procedures for nanowire, quantum dot, mesoporous, hydro/solvothermal, and microwave-assisted syntheses as these techniques can effectively be exploited for industrial mass production. In terms of energy conversion efficiency, the benefit of self-assembly can occur from three paths: suppressing thermal conductivity, increasing thermopower, and boosting electrical conductivity. An ideal thermoelectric material gains from all three improvements simultaneously. Most bottom-up materials have been shown to exhibit very low values of thermal conductivity compared to their top-down (solid-state) counterparts, although the main challenge lies in improving their poor electrical properties. Recent developments in the field discussed in this review reveal that the traditional view of bottom-up thermoelectrics as inferior materials suffering from poor performance is not appropriate. Thermopower enhancement due to size and energy filtering effects, electrical conductivity enhancement, and thermal conductivity reduction mechanisms inherent in bottom-up nanoscale self-assembly syntheses are indicative of the impact that these techniques will play in future thermoelectric applications.

Export citation and abstract BibTeX RIS

1. Introduction

In thermoelectric (TE) energy conversion, waste heat is directly converted into electricity. When a thermoelectric material is exposed to a temperature gradient, the charge carriers—electrons in n-type and holes in p-type materials—diffuse from one side of the solid material to the other. In a power generation mode taking advantage of the Seebeck effect, a temperature gradient is used to generate electrical current as the diffusion of electrons is from the hot side towards the cold side and vice versa for holes. The opposite effect (using an electrical current to force a temperature gradient) can be used in a refrigeration mode and takes advantage of the Peltier effect (scheme

Scheme 1. Thermal to electrical energy interconversion. (a) Schematic of the device structure of a thermoelectric energy conversion device. (b) Seebeck effect: temperature difference across a thermoelectric can cause the charge carries to be drawn towards the cold junction resulting in a formation of an electromotive force which can be used for power generation when connected to a load in an electrical circuit. (c) Peltier effect: when a TE material is subjected to an electrical current, a temperature difference due to the charge carries diffusion is formed which can be used for the refrigeration applications.

Download figure:

Standard image High-resolution imageThe design of high performance thermoelectric materials can have a sizeable impact on the commercial industry as a sustainable energy recycler for the constant losses demonstrated by the excess waste provided by current manufacturing processes [1]. The performance of a thermoelectric material can be described by a non-dimensional quantity zT, defined as

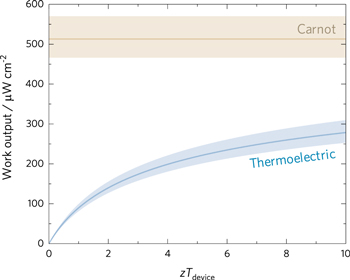

where σ is the electrical conductivity, S is the Seebeck coefficient, L is the Lorenz number, T is the absolute temperature, and κ = κe + κl is the thermal conductivity comprised of electronic (κe) and lattice (κl) components. The energy conversion efficiency at optimum efficiency is related to the Carnot efficiency, ηCarnot, and figure of merit, zT, as indicated by the following equation [2]

where Thot and Tcold are the temperatures at the hot and cold side of the device, respectively, and where the properties we are concerned with are taken across the range of temperatures over which the device operates, zTdevice. A more detailed discussion of the relationship between temperature-dependent material properties and device efficiency is given in [3]. The graphical representation of the efficiency as a function of zTdevice is shown in figure 1 using a hot side temperature of 773 K and a cold side temperature of 300 K. Note that as an upper limit, this correlates to a Carnot efficiency of 61.2%. For an energy conversion technology to be considered practical, the efficiency should be greater than one third of the Carnot efficiency [1], hence the zTdevice required for practical energy conversion over the temperature range Thot to Tcold can be expressed as

Comparison with state-of-the-art reports of zTdevice over this temperature, which is highest for top-down synthesized materials [4–7], demonstrates that while progress has been made to increase efficiency, materials performance is still the realm in which improvements must be made before thermoelectric energy conversion can become a practical technology.

Figure 1. Materials performance parameters required for practical thermal-to-electrical energy interconversion. (a) Power generation efficiency as a function of device figure-of-merit (zTdevice) at hot- and cold-side temperatures of 773 and 300 K, respectively, shown in comparison with values of zTdevice for state-of-the-art bulk materials for energy generation over the same temperature range: SnSe [6], Na-doped PbTe–SrTe [4], K-doped PbTe–PbS [5], and Na-doped SnSe [7]. The maximum efficiency is limited by the Carnot efficiency, and practical energy conversion technologies [1] are defined as having η ≥ ηCarnot/3, which will require zTDevice ≥ 1.87 for the given operating temperatures. (b) For hot- and cold-side temperatures over the range of 300–1000 K, a zTdevice ranging from 1.75 to 3 is required to demonstrate an efficiency of one third the Carnot efficiency.

Download figure:

Standard image High-resolution imageAccording to equation (1), emphasis in materials engineering should be placed on enhancing the power factor (S2σ) while suppressing the thermal conductivity (κ). However, in reality, these properties are related to each other and act in opposite trends with respect to carrier concentration. As all three of the transport properties (S, σ, and κ) change interdependently, the carrier concentration can be adjusted to the value that leads to the maximum zT, which is carried out by deliberate p-type or n-type doping. For most cases, the optimum carrier concentration [8] is ∼1018–1020 cm−3. The carrier concentration needs to be optimized regardless of the material fabrication process (top-down or bottom-up). The carrier concentration needs to be optimized regardless of the material fabrication process (top-down or bottom-up) which can be dominated by presence of defects and vacancies [9].

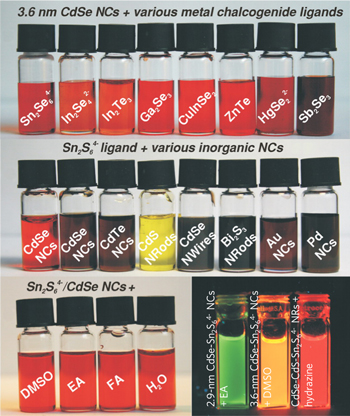

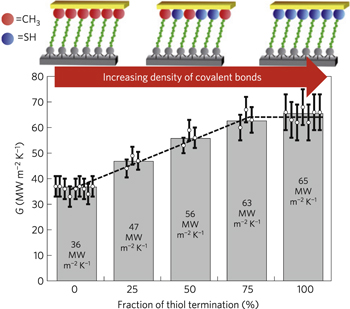

Other than possessing a high zT, any developed synthesis approach should be capable of the mass production of thermally and mechanically stable materials at low cost. Developing these production techniques is crucial especially for potential operations in large industries such as petroleum refining and primary metals manufacturing. A majority of previous investigations are based on top-down (solid-state) methods for material preparation, and currently most of high zT thermoelectrics have been obtained using solid-state synthesis processes [4–7, 10]. Each approach—solid-state or bottom-up—has its own advantages and limitations. Compared to the solid-state methods, bottom-up synthesis has been relatively overlooked and we argue that the highest potential for impact lays in investigations utilizing chemistry-based approaches. In contrast to thermoelectrics, solution-based approaches have long been utilized for various applications such as energy storage (batteries [11], supercapacitors [12]), solar cells [13–15] and catalysis [16]. There are many well-developed synthesis methods in these fields that can potentially be adapted to modify the electronic or thermal performance of nanostructured materials [17–19]. For instance, chemical routes have been discovered to control the shape, morphology, and dimensionality of inorganic materials that enable manipulation of their physico-chemical properties [20–23]. Ligand exchange techniques have been introduced for improvements of electrical properties in nanocrystals [24]. These are unique capabilities of bottom-up methods that have rarely been exploited for thermoelectric purposes. Bottom-up techniques such as microwave rapid synthesis also have inherent potential for mass-production. Ultra-high specific surface area nanomaterials such as mesoporous materials [25] offer the ability to tune transport both intrinsically and extrinsically on a macroscopic scale, yet these materials are difficult to synthesize through known top-down approaches with the exception of electroless etching of silicon [26, 27]. In addition, bottom-up synthesis offers the ability to leverage new transport phenomena into technology, such as thermal transport mechanisms at the organic–inorganic interfaces [28] and dissipationless surface-state transport phenomena [29–31].

A survey of obtained zT values illustrating the current state-of-the-art for bottom-up processed thermoelectrics is shown in figure 2. The reports can be divided into three groups: (i) Bi/Sb-chalcogenides for low temperature applications (below 500 K), (ii) Pb-chalcogenides for medium to high temperature ranges (300–900 K), and (iii) oxide thermoelectrics for temperatures above 900 K. The obtained values are promising and indicate the potential of solution processed thermoelectrics. In regard to the goal of zTdevice > ∼1.75 needed for practical energy conversion, more efforts are necessary. This survey emphasizes the potential of solution-processed thermoelectrics and the need for future investigations, including computational materials design effors, on other materials apart from Bi or Pb-chalcogenides.

Figure 2. The reported high-zT thermoelectrics processed by using bottom-up synthesis approaches. The graph illustrates the temperature-dependent zT values for Bi/Sb chalcogenides for temperature ranges below 500 K (shown in red), for Pb chalcogenides for temperatures from 300 to 900 K (shown in blue), and for oxide thermoelectrics for temperatures above 900 K (shown in green). The curves are plotted based on: red colors: Bi0.5Sb1.5Te3 (Liu et al [32] 2018, p-type), Bi0.5Sb1.5Te3 (Zhang et al [33] 2017, p-type), Bi0.5Sb1.5Te3 (Zhang et al [34] 2016, p-type), Bi0.5Sb1.5Te3 (Mehta et al [35] 2012, p-type), Bi2Te3 (Zhang et al [36] 2012, n-type), Bi2Te2.8Se0.2 (Varghese et al [37] 2016, n-type) blue colors: PbS0.72Te0.28 (Ibáñez et al [38] 2013, n-type), PbTe0.1Se0.4S0.5–Cl (Ibáñez et al [39] 2015, n-type), PbS–Ag (Ibáñez et al [40] 2016, n-type), PbS (Xu et al [41] 2018, n-type) green colors: TiC0.5@TiOy–TiO2 (Ou et al [42] 2015, n-type), La, Nb-doped SrTiO3 (Wang et al [43] 2017, n-type) Ca3Ba0.05Co4O9+δ (Carvillo et al [44] 2015, p-type), SrTiO3/LaNb–SrTiO3 (Wang et al [45] 2018, n-type), ZnAl2O4 (Jood et al [46] 2011, n-type). Notes: in Liu et al [32], an average zT = 1.83 was obtained based on measurements on five pellets. In the study by Jood et al [46], the temperature-dependent thermal conductivity values were calculated using a modified Debye–Callaway model which extrapolated from a measured data point at ∼300 K.

Download figure:

Standard image High-resolution imageThis review is focused solely on bottom-up synthesis approaches for thermoelectric materials and no discussion on top-down methods is surveyed unless it is required for explanation of basic principles or models. An interested reader can refer to the previously published review articles on thermoelectrics prepared via solid-state approaches [47–49]. Distinguished from the available review or feature articles discussing bottom-up thermoelectrics [50–53], this review provides the reader with a comprehensive survey of the recent literature, basic synthesis and thermoelectric concepts for low dimensional nanomaterials, and paradigms that can potentially be adapted for thermoelectric applications as well as suggestions for future investigations. First, common material synthesis methods including syntheses of mesoporous materials, quantum dots, solvothermal, and microwave processes are surveyed. Secondly, various routes for improving power factor, and decreasing thermal conductivity relevant to solution-process syntheses are reviewed. In addition, basic models, relevant equations, and advanced characterization methods have been incorporated.

2. Bottom-up synthesis of thermoelectric nanomaterials and related devices

2.1. Mesoporous materials: synthesis and thermoelectric applications

Mesoporous materials have long been used for a wide range of applications [54]. The term mesoporous refers to a material with a high surface area and a monodisperse pore size distribution from 2 to 50 nm. Soft-template and hard-template methods are the common routes for the synthesis of highly ordered materials (scheme

Scheme 2. Methods for producing ordered mesoporous materials using nanoscale self-assembly. The soft-template technique is based on self-cooperation of the surfactants and inorganic precursors under a controlled chemistry (pH, molar ratios, solvents, surfactant concentrations, etc). After removing the surfactant, a mesoporous inorganic structure is obtained, usually silica produced by thermal decomposition of tetraethyl orthosilicate (TEOS). In the hard-template technique, the pores of the sacrificial template are filled with the desired inorganic precursor complexes. After in situ decomposition of the precursors and crystallization, the sacrificial template is removed, and a mesoporous inorganic structure is obtained as the inverse image of the template.

Download figure:

Standard image High-resolution imageIn a hard-template method also referred to as nano casting, the precursors are infiltrated through the template. Typically, highly ordered mesoporous silica [64, 65] are be used as templates although a desired polymer morphology can also be used as a template for the deposition of inorganic phases [56, 66]. Decomposition and crystallization of precursors takes place inside the template pores. After removal of the template, the final structure is obtained as a negative image of the parent template by etching the template in an aqueous solution of HF or NaOH for the silica templates or thermal calcination for carbon and polymer-based templates [67]. SBA-15 [68] is a well-known silica template with a two-dimensional (2D) structure of interconnected nanowires arranged in a p6mm mesostructure. KIT-6 [69, 70] is a high surface area silica template with a three-dimensional (3D) gyroidal mesostructure  Both templates have tunable pore sizes below 10 nm and offer high thermal stability up to 1473 K [71] and 1173 K [72] for SBA-15 and KIT-6, respectively. The main challenge in the hard-template method is infiltration of the precursor into the pores of the template. Therefore, the precursor should be gaseous, highly soluble or liquid with certain qualities that can result in a high amount of loading without chemically reacting with the template [73]. An abundance of hydrogen bonds such as hydroxyl groups facilitates infiltration of precursors. Each method of soft-template or had-template has challenges and is appropriate for different chemistries. For instance, in soft-templating, controlling the chemistry of the reaction is difficult which is why most inorganic structures are based on tetraethyl orthosilicate (TEOS) chemistries, and in hard-templating gaining a high-loading and selective template removal can be problematic.

Both templates have tunable pore sizes below 10 nm and offer high thermal stability up to 1473 K [71] and 1173 K [72] for SBA-15 and KIT-6, respectively. The main challenge in the hard-template method is infiltration of the precursor into the pores of the template. Therefore, the precursor should be gaseous, highly soluble or liquid with certain qualities that can result in a high amount of loading without chemically reacting with the template [73]. An abundance of hydrogen bonds such as hydroxyl groups facilitates infiltration of precursors. Each method of soft-template or had-template has challenges and is appropriate for different chemistries. For instance, in soft-templating, controlling the chemistry of the reaction is difficult which is why most inorganic structures are based on tetraethyl orthosilicate (TEOS) chemistries, and in hard-templating gaining a high-loading and selective template removal can be problematic.

A large number of ordered mesoporous materials have been synthesized using both hard and soft-template approaches that are listed in specialized reviews [25, 58]. The majority of reported mesoporous crystalline materials are metal oxides with measured Brunauer–Emmett–Teller surface areas (SBET) on the order of 100–200 m2 g−1. Examples include Nb2O5 (p6mm, SBET = 196 m2 g−1) [74, 75], SnO2 (p6mm, SBET = 180 m2 g−1) [74, 75], Co3O4 (p6mm, SBET = 367 m2 g−1) [76] produced using soft-templating, and Co3O4 (p6mm, SBET = 101–122 m2 g−1) [77, 78], Co3O4 ( SBET = 92, 130 m2 g−1) [79, 80], SnO2 (p6mm, SBET = 160 m2 g−1) [81], ZnO (p6mm, I4132, SBET = 192–202 m2 g−1) [82], WO3 (p6mm,

SBET = 92, 130 m2 g−1) [79, 80], SnO2 (p6mm, SBET = 160 m2 g−1) [81], ZnO (p6mm, I4132, SBET = 192–202 m2 g−1) [82], WO3 (p6mm,  SBET = 81.8, 54.3 m2 g−1) [83–86], and MoO3 (Pbnm, SBET = 50–63 m2 g−1) [87] produced using hard-templating. These ordered mesostructures provide an opportunity to reduce the relatively high thermal conductivities associated with large band gap oxide thermoelectrics [88, 89]. For instance, a linear suppression of thermal conductivity has been reported in SrTiO3 by reducing the grain boundaries below 100 nm even approaching the minimum value calculated by Cahill's model [90, 91]. This is promising regarding the fact that most reported oxide mesoporous materials have characteristic sizes tunable to below 10 nm. However, to the best of our knowledge, there has been no report investigating the use of mesoporosity in oxide thermoelectrics.

SBET = 81.8, 54.3 m2 g−1) [83–86], and MoO3 (Pbnm, SBET = 50–63 m2 g−1) [87] produced using hard-templating. These ordered mesostructures provide an opportunity to reduce the relatively high thermal conductivities associated with large band gap oxide thermoelectrics [88, 89]. For instance, a linear suppression of thermal conductivity has been reported in SrTiO3 by reducing the grain boundaries below 100 nm even approaching the minimum value calculated by Cahill's model [90, 91]. This is promising regarding the fact that most reported oxide mesoporous materials have characteristic sizes tunable to below 10 nm. However, to the best of our knowledge, there has been no report investigating the use of mesoporosity in oxide thermoelectrics.

Chalcogenide compound semiconductors (group IV–VI and V–VI) such as the families of (Pb, Sn)(S, Se, Te) and (Bi, Sb)2(S, Se, Te)3 are among the most relevant for thermoelectric energy conversion [8]. An ordered mesoporous metal chalcogenide can be regarded as either a negative image of a quantum dot (QD) superlattice structure or an inverse image of nanowires. If such a highly ordered material is synthesized, there exists a possibility of tuning the electronic band gap by varying the wall thickness [92, 93]. Despite the successful routes developed for the synthesis of highly ordered mesoporous silicates and metal oxides, similar approaches for metal chalcogenides face many challenges. These include complicated chemistry, a compatible surfactant removal process, and a lack of compatible precursors for S, Se, and Te [25, 92] which demands more investigations before mesoporous materials in this category become widely available. For metal chalcogenides, both soft-template and hard-template methods have been tested but few successful highly ordered materials have been reported [25]. These successful attempts consist of mesoporous CdS, MoS2 and WS2 through hard-templating [94, 95]. Another approach focuses on using cation exchange to convert a parent mesoporous material such as CdS into other mesoporous structures such as CuS and Ag2S [96, 97]. For the hard-template method, the challenge is that, unlike the metal oxides, the template should be infiltrated with both precursors for the metal as well as the chalcogen which in most cases causes the blockage of the pores by the second precursor [25]. A single precursor containing both metal and chalcogen was shown to be successful by in situ conversions of [(Cu6(TePh)6(PPh2Et)5] into Cu2Te [98], Cd(XPh)2TMEDA (X: S, Se, Te, TMEDA: tetramethylethylenediamine) into Cd(S, Se, Te) [99], and [Cd10S16C32H80N4O28] into ordered mesoporous CdS (SBET =160 m2 g−1, average pore size of 6 nm) [94]. In the case of CdS, ZnS, and In2S3, Lui et al [100] reported the formation of complex precursors using thiourea as the sulfur source and the appropriate metal nitrate precursor which were capable of filling pores in SBA-15 to create replicate mesoporous structures. A second method that has been developed is to fill the pores of the template with only the metal precursor and then thermochemically convert the metal complex using a gaseous precursor for the chalcogens, usually by a treatment in H2S or H2Se. This second method has produced highly ordered mesoporous MoS2 and WS2 with p6mm and  layered structures [95], ordered mesoporous MoSe2 [101], and first-row transition-metal sulfides FeS2, CoS2, and NiS2 [102]. Recently, a gaseous transformation of highly ordered double gyroid (

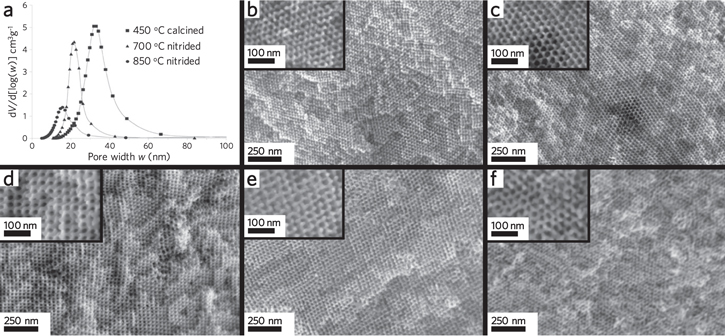

layered structures [95], ordered mesoporous MoSe2 [101], and first-row transition-metal sulfides FeS2, CoS2, and NiS2 [102]. Recently, a gaseous transformation of highly ordered double gyroid ( ) mesoporous Nb2O5 to NbN by annealing under NH3 was carried out by Robbins et al [103] for superconductivity applications. Most impressive, the morphology of the free-standing films were preserved after high temperature NH3 treatment at 865 °C (figure 3). So far, none of these approaches have been investigated for thermal or thermoelectric energy conversion applications.

) mesoporous Nb2O5 to NbN by annealing under NH3 was carried out by Robbins et al [103] for superconductivity applications. Most impressive, the morphology of the free-standing films were preserved after high temperature NH3 treatment at 865 °C (figure 3). So far, none of these approaches have been investigated for thermal or thermoelectric energy conversion applications.

Figure 3. Retention of an ordered inorganic mesostructure after thermochemical conversion 850 °C: the case of Nb2O5 into NbN. (a) Pore size distribution of Nb2O5 (450 °C) and after conversion to NbN (700 °C, 850 °C). The double gyroid morphology of the free-standing films (b), (e) after NH3 treatment at 700 °C, (c), (f) after nitriding at 850 °C, and (d) Nb2O5 after calcination at 450 °C in air. Adapted from [103]. © The Authors, some rights reserved; exclusive licensee American Association for the Advancement of Science. Distributed under a Creative Commons Attribution NonCommercial License 4.0.

Download figure:

Standard image High-resolution imageBulk silicon has a thermal conductivity at room temperature with a broad spectral range of constituent phonon mean free paths (MFPs) [104], which has led to efforts to reduce its thermal conductivity by introducing low-dimensionality [26] or porosity. The broad spectral nature of phonon MFPs in Si, with 90% of bulk κ arising from phonons with MFPs up to 8 μm, makes this material particularly sensitive to size effects and mesostructuring thus we will discuss Si as special case. We note that most thermoelectric materials exhibit more spectrally narrow κ distributions than silicon [105, 106], which means only sub-10 nm features may alter thermal transport properties. For Si, Lee and Grossman [107] predicted a two-fold increase in the thermopower at carrier concentrations less than 2 × 1019 cm−3, with an overall two-fold enhancement in zT at room temperature due to porosity. Their calculation predicted a 200-fold reduction in the lattice thermal conductivity with only a 2–4-fold reduction in the electrical conductivity. In contrast to Si, numerical modeling of SixGe1−x alloys predicted zT degradations due to the porosity arising from a strong reduction in the electrical conductivity despite the beneficial reduction in thermal conductivity and enhancement of Seebeck coefficient (due to the carrier filtering effect) [108]. Due to the contradictory conclusions of these computational predictions, and lack of experimental consensus, additional basic research is required to address the posed hypotheses. Experimental measurements of disordered nanoprous Si [109] showed several orders of magnitude reduction in electrical conductivity. This indicates the importance of having a highly ordered mesoporous material compared to a random disordered porous structure. Arens-Fischer et al [110] measured the thermal conductivity of electrochemically etched porous silicon with porosity in the range of P = 64%–89% using the 3ω technique. The porous structure and corresponding details were not described. As the porous material is a composite of solid and vacuum (or assumed medium with κ = 0), the relationship between measured (effective) and intrinsic (solid) thermal conductivity can be expressed as a function of the porosity. Thermal conductivity across interfaces is a function of adhesion energy [111, 112], thus many porous materials can be analyzed as follows especially for the case of single crystalline silicon frameworks, hot pressing, or spark plasma sintering (SPS). To gain a better understanding of the effects of porosity, Arens-Fischer et al [110] used a simple equation to model the effective thermal conductivity of the porous Si, κeff, as [113]

where P is the porosity, (1 − P) is the volume fraction, and κsolid is the thermal conductivity of the solid phase within the porous medium. The measurements showed 3–5 orders of magnitude thermal conductivity reduction compare to the bulk Si values over a temperature range of 300–35 K. Several additional studies have been performed on the thermal conductivity of electrochemically etched porous Si [114–120]. Song and Chen [121] reported temperature dependent (50–300 K) in-plane thermal conductivity of single crystal Si with periodically fabricated micropores, and a more than three-fold reduction in κ (e.g. 40 W m−1 K−1 at room temperature). Temperature dependent thermal conductivity scaling was observed even at the micron size level of the pores.

The Eucken [122, 123] and Russel [124] models can be used in order to estimate the effective thermal conductivity in porous media as

and

respectively. We note that this is in line with the paradigm of spectral thermal conductivity proposed by Minnich et al [104] Most relevant to the ordered mesoporous materials prepared by nanoscale self-assembly, Fang et al [125] reported the thermal conductivity of a mesoporous nanocrystalline Si thin film prepared via a magnesium reduction of polymer-templated silica with a porosity of 25%–35%, measured by the 3ω method. The samples showed a reduction in κ of 3–5 orders of magnitude compared to the bulk values. At low temperatures, the measured thermal conductivity showed a dependence of κ ∝ T2, similar to that predicted by the Cahill model [90] for the minimum lattice thermal conductivity of amorphous and disordered crystalline materials. An effective thermal conductivity expression was used in order to model the experimental data [126]

where κsolid represents the thermal conductivity of the solid medium which was replaced by a combination of the effective medium approximation (EMA) [127, 128] and kinetic theory, or the minimum value by Cahill's model [90].

So far, only two experimental investigations have reported thermoelectric properties of a mesoporous material: Tang and coworkers [129] reported the thermoelectric measurements of 'holey silicon' prepared by nano-sphere lithography and block copolymer lithography. The holey silicon membrane with 35% porosity exhibited a two orders of magnitude reduction in thermal conductivity approaching the amorphous limit, with a room temperature zT of 0.4. The second study was carried out by Zhang, Stucky and coworkers [36] on an n-type Bi2Te3 monolith. Colloidal silica nanospheres (LUDOX) were used as the hard-template and was mixed with stoichiometric amounts of precursors. After crystallization under a H2 atmosphere at 400 °C, a 4 M aqueous sodium hydroxide solution was employed in order to remove the silica hard-template. The transport measurements were conducted on hot-pressed pellets. Structural characterizations showed a disordered porous material with SBET = 28.4 m2 g−1 and pore size distribution between 5 and 30 nm. After hot-pressing, the original isotropic spherical nanopores were preserved and transformed into anisotropic ellipsoidal shapes. Compared to the bulk (condensed) sample, the mesoporous sample indicated a slightly lower electrical conductivity in the direction perpendicular to the pressing but exhibited a clear reduction in the parallel direction. However, the thermal conductivity was reduced by more than 50% (a 60% reduction in relative lattice thermal conductivity, a 20% in electrical conductivity) leading to a zT of 0.7 at 480 K. This demonstrated a 45% enhancement compared to the measured value for the bulk sample over the range 400–500 K (figure 4).

Figure 4. Experimental thermoelectric transport properties in mesoporous n-type Bi2Te3. (a) Electrical conductivity, (b) Seebeck coefficient, (c) thermal conductivity, and (d) zT as a function of temperature. Solid and open symbols depict transport perpendicular and parallel to the direction of hot-pressing, respectively. Squares represent the bulk (condensed) sample and circles represent the mesoporous material with a specific surface area of ∼30 m2 g−1. [36] John Wiley & Sons. © 2012 WILEY‐VCH Verlag GmbH & Co. KGaA, Weinheim.

Download figure:

Standard image High-resolution imageSeveral studies of chemically synthesized thermoelectric materials [35, 38–40, 130, 131] have reported lower mass density compared to the theoretical values due to inter particle voids formed during cold-pressing, hot-pressing, or SPS. This type of porosity results in a lack of confidence when interpreting transport phenomena in even the highest performing top-down-synthesized thermoelectric, SnSe [6, 132], and should not be neglected during analysis of experimental results. A simple Maxwell–Eucken model [133, 134] has been developed and is commonly used to account for the effects of porosity in both electrical and thermal conductivities of pressed pelletized materials:

where the 100% dense (corrected) solid conductivity value, κsolid, is obtained from the measured porous (effective) conductivity, κeff, the porosity P, and the parameter β which is in the range of 1–3 for spherical pores. Note that β = ½ in the original Eucken model [122, 123] given by equation (5).

2.1.1. Outlook

The main advantage of using mesoporous materials for thermoelectric applications is their ability to suppress the lattice thermal conductivity. This reduction needs to be more than any possible degradation in electrical conductivity. There is a possibility of enhancing the thermopower due to the electron confinement effect if a highly ordered material can be synthesized. Despite the promise of this mesostructural class of materials, few studies have reported the effects of mesoporosity on thermoelectric properties. For the bulk thermoelectrics, the study of mesoporous Bi2Te3 [36] indicated the existence of the mesopores even after hot-pressing. The benefit of having a high surface area is not limited to effects on phonon scattering. Having access to the surface of a material provides many advantages for thermochemical processing [103] and extrinsic control over the chemical potential [135]. For instance, the pores can be filled with a properly designed secondary phase in order to induce the filtering effect of low energy charge carriers. Due to the contradictory conclusions of the few available computational predictions, and lack of experimental consensus with only two studies available for validation, additional basic research efforts are required to address the posed hypotheses of the effect of mesoporosity on thermal and thermoelectric performance. Synthesis methods for mesoporous heavy metal chalcogenide materials, improving the electrical properties, and improving the mechanical and thermal stabilities are the major challenges for future investigations.

2.2. Quantum dots (QDs): synthesis and thermoelectric applications

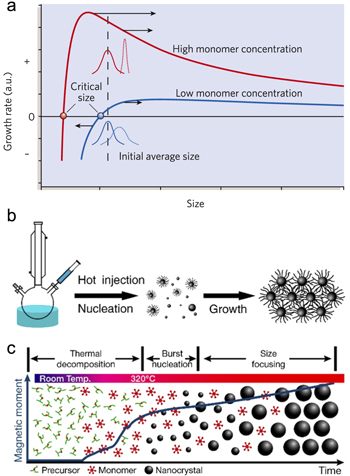

Quantum dots (QDs, mainly semiconductor nanocrystals) have received significant attention in different scientific fields and for varied technological applications mainly because their physical properties can be tuned by controlling their size, shape, composition, and modification of their surface chemistry. A typical QD synthesis procedure consists of three components: (i) precursors (the sources of inorganic materials), (ii) surfactants (ligands), and (iii) solvents [20]. Generally, a ligand's role is to passivate the surface of the nanocrystals. During the synthesis, precursors decompose upon heating at the reaction temperature, and form a supersaturation of monomers. Monomers are molecular species originating from dissolution of the precursor which can either join or leave the nucleated nanocrystals later in the reaction, resulting in their growth or shrinkage. The formation of monomers is followed by a nucleation step. Monomers present in the reaction join the formed nucleation seeds and cause them to grow which eventually shapes the final nanocrystals through a rearrangement of the atoms [20]. Crystallization occurs during the reaction. The reaction temperature is important and should be high enough to allow precursor decomposition and nanocrystal annealing/crystallization and low enough to avoid instability of common organic materials present in the reaction (temperatures are in the range of 200 °C–400 °C) [20]. This relatively low temperature range overcomes the cohesive energy per atom and, therefore, nanocrystals crystallize because the cohesive energy is related to the melting temperature of nanoparticles which, in turn, is a function of size—smaller size corresponds to a lower melting point [20, 136]. At any given monomer concentration, there exists a critical size at which the particle dissolution rate is equal to the growth rate. Particles smaller than the critical size are not stable and have negative growth rates whereas larger particles have positive growth rates. The critical nanoparticle size is a function of the monomer concentration in such a way that higher concentrations correspond to smaller critical size [137]. As figure 5(a) illustrates, both high and low monomer concentrations exhibit maximum peaks in their growth rate-size relationship. This is due to the fact that when particles grow and become larger, the growth rate becomes slower because continuing the growth requires more atoms to join [20]. Two mechanisms are proposed in order to explain the kinetics of the growth process with high and low monomer concentrations: (i) growth by diffusion (narrowing, or focusing) [138] and (ii) the Ostwald ripening effect [139] (broadening, or defocusing). According to the former model, and because a high monomer concentration corresponds to a smaller critical size, it is more likely that the particle size distribution range does not fall into the critical size regime. Because the growth rate is inversely proportional to the particle radius, smaller particles grow faster than the larger ones and therefore the obtained size distribution can be focused [140]. In contrast, a low monomer concentration corresponds to both slower growth and a larger critical size. This dictates that the smaller particles are not thermodynamically stable and tend to deplete into the solution, releasing monomers which deposit onto the surface of larger particles (known as Ostwald ripening effect [139]). This model assumes that the solubility of the particles is a function of their size, in which smaller particles dissolve in the solution and are consumed by larger ones [141]. In other words, at the beginning of the reaction and upon dissolution of the precursor, the monomer concentration is enhanced above the critical value required for the nucleation to start. By proceeding with the reaction, monomers are consumed due to nanocrystal nucleation and growth and the monomer concentration falls below the nucleation critical value causing nucleation events to cease. At this point the monomer concentration is still higher than the monomer critical value needed to avoid the dissolution of smaller particles, and as nucleation has already been stopped the remaining monomers are consumed for the growth of existing nanocrystals. If the reaction continues further, the monomer concentration falls below the equilibrium critical value. Once this happens, the particles smaller than the critical size are not thermodynamically favorable anymore and will deplete in the form of monomer back in the solution (Ostwald ripening) [142].

Figure 5. Kinetics of quantum dot (QD) nucleation and growth. (a) Focusing (defocusing) model in a high (low) monomer concentration regime. At a high monomer concentration, the corresponding critical size is lower than the average nanoparticle size and allows all particles to grow. Because small particles grow faster, the resulting size distribution can be narrow. In a low monomer concentration situation, the critical size is large and rests within the size distribution range of the nanocrystals. This causes small particles to dissolve into the solution and join to the surface of the larger particles and resulting in a broadened size distribution. Reprinted by permission from Macmillan Publishers Ltd: Nature [20]. Copyright 2005. (b) The hot injection QD synthesis method consists of the injection of a room temperature precursor into to the solution at high temperature. Due to the solution temperature drop arising from injection, the nucleation and growth periods are separated which can result in a narrow size distribution. (c) In a heat-up (non-injection) technique, all precursors are present at the beginning of the reaction and at room temperature. Nucleation starts upon heating the solution. The nucleation and growth are not separated and the main challenge is to keep the balance in between the two. Reprinted with permission from [140]. Copyright 2015 American Chemical Society.

Download figure:

Standard image High-resolution imageIn general, hot-injection and heat-up (also known as non-injection) methods are the most common techniques for the synthesis of nanocrystals. Hot-injection involves rapid nucleation of monomers by an injection of a room temperature precursor into a hot solution of surfactants (figure 5(b)) [140]. The main feature of this method is that the nucleation and growth are separated which leads to a more focused size distribution. This separation is followed by an inevitable reaction temperature drop due to the injection. The disadvantage of this technique is that both scalability and reproducibility are difficult. For instance, the temperature drop upon injection does not have a linear relationship with the volume injected. Unless automated, the injection time varies from person to person which will affect the reproducibility [142]. In contrast, in the heat-up technique all the precursors are present at the beginning of the reaction. At room temperature, the nucleation rate should be negligible and as the reaction proceeds further, the nucleation rate increases. The heating rate and the precursor reactivities are the two important parameters. Although the heat-up method is more favorable for reproducibility and scalability, the main challenge is the overlap between the nucleation time and the growth period which can result in a broad size distribution (figure 5(c)). A rapid heating rate will result in a smaller average size and narrower size distribution. In such a situation, the nucleation is much faster than the growth which leads to a high concentration of nuclei. As the growth is distributed among a larger total number of nanocrystals, the size distribution can focus. A moderately reactive precursor is more favorable compared to a precursor with a high or low reactivity because of the balance created between nucleation and growth periods [142].

Ligands (surfactants) are used in order to passivate and stabilize the surface of QDs, compensating for their high surface-to-volume ratios [137, 143]. Proper use of a surfactant can also increase the surface tension at the solvent-nanoparticle interface and lead to a narrower particle size distribution [137]. The adhesive energy of the surfactant is a key factor that plays an important role in the crystal growth which can alter the reaction kinetics [144] and nanocrystal morphology [145]. The surfactant adhesion energy should allow the surface of the nanoparticle to be accessible for growth while the entire particle is protected against aggregation [20]. In addition, recent synthesis advancements have demonstrated the ability to epitaxially connect and couple all the QDs in the form of a superlattice structure [146–149]. First, ligand-cap superlattices are synthesized, and then, are attached by a selective binding of the ligand to a specific crystal facet. Removal of the ligand, causes the nanocrystals to fuse together in the specific orientation [149] (figure 6).

Figure 6. Observation of delocalized electronic behavior in an ordered, ligand-free QD superlattice. (a) Annular dark-field scanning transmission electron microscopy (STEM) of a PbSe superlattice. (b) High resolution STEM showing crystallographic continuity across the inter-QD connections. (c) Reflections of a square superlattice by grazing incidence small-angle x-ray scattering (GISAXS) image and (d) alignment of the atomic lattice shown by grazing incidence wide-angle x-ray scattering (GIWAXS). (e) Gate-voltage dependent electron and hole localization lengths extracted from the measured temperature dependence of the electrical conductance, also shown in units of the QD radius a0. Adapted by permission from Macmillan Publishers Ltd: Nature Materials [149], Copyright 2016.

Download figure:

Standard image High-resolution image2.2.1. Outlook

Many studies have reported synthesis of QD materials that are attractive for thermoelectricity such as PbS [150, 151], PbSe [148], PbTe [152], Bi2Te3 [153], Bi2S3, SnS [154], SnSe [155, 156], and SnTe [157] mainly for photovoltaic purposes. Controlling the kinetics of the reaction as well as using proper surfactants and precursors can result in a narrow size distribution. A narrow size distribution, can potentially boost the thermopower and reduce the lattice thermal conductivity through size effects. Most promising, synthesis of a defect-free QD superlattice as per [149] can improve electrical properties through delocalization of charge transport.

2.3. Hydro/solvothermal and microwave synthesis of thermoelectric nanomaterials

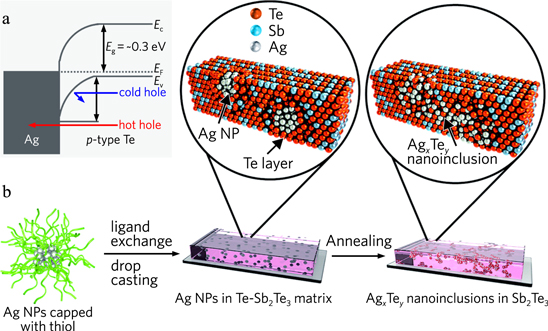

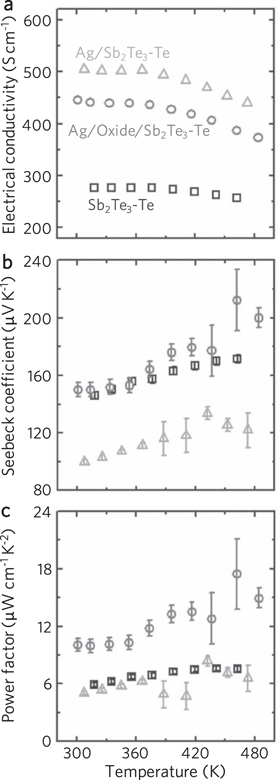

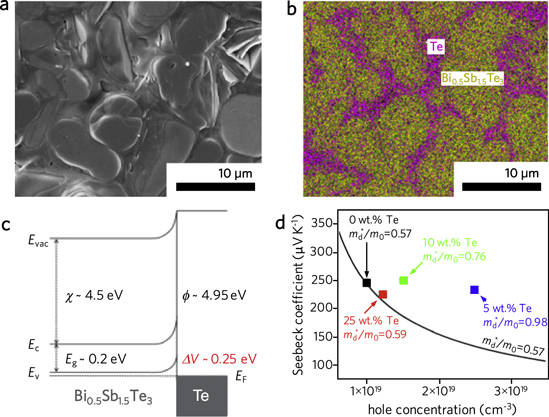

In a hydro/solvothermal process, the synthesis constituents such as precursors, solvents, surfactants, and reduction agents are allowed to react under a high-pressure and temperature, usually in a sealed Teflon autoclave. In microwave synthesis, the reaction is sealed and heated by microwave radiation allowing for faster processing on the order of minutes. Several studies have reported the use of hydro/solvothermal synthesis of materials for thermoelectric applications such as PbTe [158], Bi2Te3 [159, 160], La0.2Bi1.8Te3 [161], CoSb3 [162], PbTe nanowires [163], nanoboxes [164], and nanocubes[165], Sb2Te3 [166–170], Sb2Te3–Te [171], (Bi1–xSbx)2Te3 [172–174], S-doped Ag2Te [175], SnxSb2Te3+x [176], and p-type Sb2Te3/poly(3,4-ethylenedioxythiophene) [177]. The hydro/solvothermal thermal method can also be used as a post-synthesis treatment to modify already made materials via grain boundary engineering. Ji and Tritt et al [160] reported modification of commercial p-type (Bi0.2Sb0.8)2Te3 powders by a hydrothermal treatment in a solution of AOH, and ABH4, where A = Na, K, and Rb (figure 7). The untreated and treated x-ray diffraction data showed no extra peaks and suggested no intercalations or formation of a new crystalline phase. However, a hump feature was observed which was attributed to an amorphous constituent of a new phase which dramatically changed thermoelectric properties. Selected area electron diffraction (SAED) patterns of the treated samples showed cubic symmetry against the hexagonal symmetry of the un-treated samples, suggesting the existence of a secondary crystallinity from the bare materials along with a non-crystalline phase. An interesting observation was that this coating layer could be easily removed by a short ultrasonication, suggesting that the coating layer is loosely bound to the parent material which also introduces an elastic mismatch at the boundaries. Transport measurements indicated that the power factor was retained upon post-synthesis hydrothermal surface treatment, and even increased for Rb treatment. The electrical conductivity was improved due to an enhancement of carrier concentrations resulting in overall improvement of the thermoelectric power factor, σS2. All surface-treated samples exhibited lower thermal conductivities compared to those of the bare (Bi0.2Sb0.8)2Te3. In the case of Na treatment, a 15% reduction in room temperature thermal conductivity was reported.

Figure 7. Post-synthesis hydrothermal surface treatment to control carrier concentration in a thermoelectric nanomaterial. Transmission electron microscopy analysis of a sodium-treated (Bi0.2Sb0.8)2Te3 nanoparticle: (a) selected area electron diffraction pattern (SAED) of the Na surface layer, (b) SAED of the composite nanoparticle, and (c) TEM image of the composite nanoparticle. (d) Energy-dispersive x-ray spectroscopy indicating a surface coating of Na on the (Bi0.2Sb0.8)2Te3 nanoparticle. (e) Post-synthesis alkali metal salt solvothermal treatment of the (Bi0.2Sb0.8)2Te3 samples exhibit increased thermoelectric figure of merit zT due to simultaneous enhancement of thermopower and reduction of lattice thermal conductivity. Reprinted from [160], with the permission of AIP Publishing.

Download figure:

Standard image High-resolution imageMicrowave rapid-synthesis methods have been used for preparation of a large variety of materials [178–180]. Studies that used microwave-assisted synthesis for thermoelectric applications include Sb2Te3 [181, 182], TiNiSn [183], TiNiSb0.05Sn0.5 [184], Bi2Se3 [185], Cu3(Sb0.94In0.06)Se4 [186]. Thermoelectric measurements of a TiNiSn and TiCoSb ternary intermetallic system prepared via a rapid microwave-assisted method showed zT values ∼0.4 at a temperature of 780 K [187]. Mehta and Ramanath et al [35] reported synthesis of sulfur-doped n- and p-type pnictogen (Bi, Sb) chalcogenide nanoplates by a microwave assisted method. In the synthesis, thioglycolic acid (CH2COOHSH) was used as the structure directing agent which also acted as the source of sulfur-doping. It was observed that increasing the microwave dose resulted in larger plates with little changes in their thickness (∼5–20 nm). The dried powders were packed into a pellet using a hydraulic press, resulting in a density ∼60%–70%. The pellets were then sintered under vacuum at 10−7 Torr and 300 °C–400 °C in order to obtain compacted pellets with relative densities of ∼92%. The samples showed high room temperature electrical conductivities in the range from 300 to 2500 S cm−1. Bismuth chalcogenide samples exhibited n-type behavior and antimony chalcogenide samples showed p-type behavior, although Bi2Te3 is known to be p-type in the presence of bismuth anti-site defect acceptors common in bulk synthesis [8, 188] and n-type in the presence of chalcogen vacancies [189] and oxidation [190] such as has been reported for single-crystal (Bi1–xSbx)2Te3 nanoplates [135, 191]. The observed change in the behavior of the microwave-synthesized materials was attributed to the sulfur doping. Having high power factors and very low thermal conductivity (0.5 ≤ κ ≤ 1.4), the microwave synthesized samples demonstrated high thermoelectric performance with zT as high as 1.1, which is 25%–250% higher than those of bulk counterparts and alloys [8].

2.3.1. Outlook

Hydro/solvothermal and microwave-assisted syntheses can be used for large-scale production of thermoelectric nanomaterials. Both methods show a flexibility for tailoring structures and controlling bulk and surface chemical compositions. Similar to all solution-based methods, there is a possibility of self-doping during synthesis through reaction components such as impurities in the precursors, solvents, and surfactants and can be either beneficial or detrimental to thermoelectric performance. The work conducted by Mehta and Ramanath et al [35] showed that the traditional view of bottom-up materials as possessing too low a quality—especially regarding electrical conductivity—to perform well as thermoelectrics is not appropriate. Using proper additives to dope the samples, e.g. with sulfur, and with a post-treatment method to remove the insulating organics, e.g. thermal annealing, can greatly enhance the electrical conductivity. This indicates the adaptability of microwave-assisted synthesis for mass productions, where even a domestic microwave can perform the reaction in a time period of ∼30–60 s.

2.4. Flexible thermoelectrics

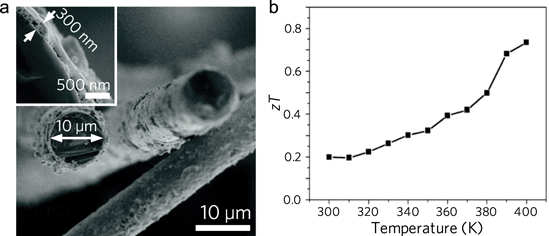

Flexibility for thermoelectric devices opens opportunities for daily applications such as wearable modules that can operate using body heat and cooling by natural convection. Although device efficiencies and power densities are low, we will review important advancements in this application area where bottom-up synthesis is uniquely suited to make advances in this technology. Fabrication of a flexible thermoelectric for power generation was demonstrated by coating PbTe onto flexible glass fibers [192]. In the process, fibers were placed into a PbTe colloidal nanocrystal solution. After drying, the native insulating ligand was exchanged in a solution of 0.1 M hydrazine diluted with acetonitrile. After washing with anhydrous acetonitrile, the samples were dried again. The procedure was repeated until the desired thickness of PbTe was obtained (figure 8).

Figure 8. Flexible glass fibers coated with thermoelectric nanocrystals. (a) SEM image of the obtained coating of PbTe on glass fibers as a flexible thermoelectric material. (b) zT values over the temperature range of 300–400 K. Adapted with permission from [192]. Copyright 2012 American Chemical Society.

Download figure:

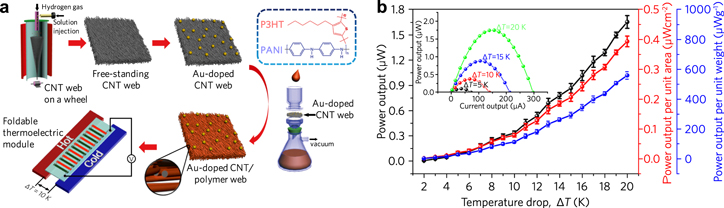

Standard image High-resolution imageA foldable thermoelectric device was fabricated by embedding polyaniline (PANI), and poly(3-hexylthiophene) (P3HT) in a matrix of Au-doped carbon nanotubes (CNTs) [193] (figure 9). This device demonstrated a zT of 0.2 and a power generation of 1.74 μW were measured in a module of seven p–n junctions with a 20 K temperature difference operating at room temperature. Although this advancement is promising, we note the maximum power density of ∼0.4 μW cm−2 is, by nearly two orders of magnitude, too low for practical applications.

Figure 9. Foldable Au-doped CNT/polymer thermoelectrics. (a) Schematic of the fabrication process and thermoelectric module geometry. (b) Maximum power output (black), maximum power output per area (red), and maximum power output per weight (blue) as a function of temperature difference ΔT at near room temperature. (Inset) Corresponding device current versus power curves. Adapted with permission from [193]. Copyright 2016 American Chemical Society.

Download figure:

Standard image High-resolution imageCNT-based flexible thermoelectrics have also been demonstrated using n-type Ag2Te nanoparticles [194]. After the composite nanoparticle/CNT was synthesized, the thiol-capping ligands on the sample surfaces were removed by thermal annealing at 400 °C. A reduction in the electrical conductivity data was observed due to the phase change of Ag2Te from a monoclinic structure (β phase) to a face-centered cubic one (FCC, α phase). Samples showed a Seebeck coefficient in the range of −30 to −228 μV K−1, electrical conductivity of 100–200 S cm−1, and total thermal conductivity as low as 0.7 W m−1 K−1 over the temperature range of 325–525 K [194]. To create flexible materials based on semiconducting inorganic nanomaterials alone, a five-step vacuum filtration fabrication of a Cu1.75Te nanowires/poly(vinylidene fluoride) (PVDF) (2:1) composite was developed [195] which incorporated high pressure processing to increase the interparticle conductance (figure 10). A room-temperature thermopower of 9.6 μV K−1 and electrical conductivity of 2490 S cm−1 with a power factor of 23 μW m−1 K−2 were measured [196].

Figure 10. Schematic of the sample fabrication process for an inorganic nanowire-based flexible composite thermoelectric film. (a) Cu1.75Te nanowires are first vacuum filtered in order to form a film. (b) The obtained film is transferred onto a sacrificial glass substrate and is pressed under 30 MPa and (c) subsequently annealed at 150 °C under vacuum. (d) A poly(vinylidene fluoride) (PVDF) solution is drop-cast onto the dried sample. (e) By heating at 80 °C, the composite is peeled from the substrate and (f) the flexible thermoelectric composite is obtained. Reprinted with permission from [195]. Copyright 2015 American Chemical Society.

Download figure:

Standard image High-resolution imagePaper-based thermoelectric generators have also been developed through impregnation by dipping cellulose paper into solutions of p- and n-type colloidal QDs (PbS and Bi-doped PbTe, respectively) [197]. To remove the native oleic acid ligands from the QDs, subsequent ligand exchange was performed by placing the paper into 0.1 M KOH in methanol for PbS QDs, and into 0.1 M NH4I in methanol for Bi-doped PbTe QDs. Preparation of a wearable fabric-based thermoelectric generator was reported using cotton and polyester yarns as the matrix, which was dip-coated by a composite of aqueous polyurethane, CNTs, and PEDOT:PSS [198]. The generators showed low values of optimal electrical conductivity (∼138 S cm−1) and thermopower (∼10 μV K−1), leading to a power factor of just 1.41 μW m−1 K−2 at room temperature. Modification of the PEDOT:PSS polymer thermoelectric [199] was demonstrated by adding small amount of chemically exfoliated MoS2 nanosheets, resulting in a Seebeck enhancement from 15 to 20 μV K−1 without a significant reduction in electrical conductivity. Thus, a power factor more than 30 times higher than the CNT/PEDOT:PSS composite [198] was obtained (45.6 μW m−1 K−2) with only a 4 wt% addition of MoS2 [199]. Other investigations on flexible thermoelectrics include Te nanowires/reduced graphene oxide (rGO) [200], n-type Cu doped Bi2Se3 nanoplates [201], Ni/PVDF nanocomposites [202], and multiwall carbon nanotubes/PVDF [203].

2.4.1. Outlook

Although these results demonstrate a low zT, and also very low power outputs, the synthesis techniques could be promising for other material chemistries or composites at optimum doping concentrations, such as increasing the conductivity of flexible oxide-based composites [196]. Substrates such as PVDF, cotton, polyester, carbon nanotubes and rGO can all be used as flexible supports. Despite the practical production issues for daily use of these composites as wearable fabrics [204–206], many questions and concerns remain such as weight, cost, biological compatibility, stability, and efficiency require continued and thorough investigation. An encouraging production method is to design inks containing materials printable on flexible and robust fabrics [207–210]. Although promising in terms of applications, the expectation for power production is still bound the Carnot limit of efficiency. For instance, the Carnot efficiency for an irreversible heat engine connecting a human at 37 °C and an ambient environment at 20 °C is 5.48%. If one uses the entire body surface area [211] (1.79 ± 0.181 m2, error calculated as ± one pooled standard deviation [212] from different populations) and a daily energy output of 14.51 MJ day−1 [213], we can estimate an adult will generate a heat on the order of 167.9 W (corresponding to a flux of 9.4 ± 0.9 mW cm−2). In the Carnot (upper) limit of efficiency, this corresponds to power output of 9.2 W (corresponding to 513 ± 6 μW cm−2). For zTdevice on the order of 1, the efficiency will be on the order of 0.96% and power output will be on the order of 1.61 W (corresponding to 90 ± 1 μW cm−2). With a goal of producing 5 W from a wearable thermoelectric skin, zTdevice will need to be improved to at least 10. Our estimate of the upper limit of power density that can be produced from human-based thermoelectric power generation is shown in figure 11.

Figure 11. Potential of human-based thermoelectric power generation. Output power density achievable from a thermoelectric device as a function of zTdevice (blue curved line). The output of a Carnot engine operating between the 37 °C and 20 °C is shown for comparison (brown straight line). Minimum and maximum values are shown as shaded regions and account for variations in body surface area) [211] assuming a relatively high daily energy output for a healthy adult [213].

Download figure:

Standard image High-resolution image3. Thermoelectric phenomena related to enhancing performance in self-assembled nanomaterial systems

3.1. Quantum confinement effects for thermopower enhancement

Quantum confinement effects are responsible for modification of the electron density of states (DOS) in low dimensional thermoelectrics as described by e.g. Hicks and Dresselhaus for Bi2Te3 nanowires [214, 215] and thin films [214]. If the size of a semiconductor is significantly small, then the constraining morphology will affect the electron wavelength. In photovoltaic applications, the quantum confinement effect is well known as a phenomenon that occurs when the particle is smaller than the Bohr radius of an exciton (electron–hole pair) [216]. In thermoelectric applications, the quantum confinement effect is of interest because it can change the band gap, DOS, and Seebeck coefficient [216–218]. To explain this for the cases of metals and degenerate semiconductors, the Mott formula for the Seebeck coefficient can be used [219]

where S is the Seebeck coefficient, kB is the Boltzmann constant, T is the absolute temperature, q is the charge of the carriers (−e for electron and +e for holes), σ is the electrical conductivity, E is the energy and EF denotes the Fermi energy). It should be mentioned that the Mott formula is chosen rather than the general Seebeck coefficient equation derived from the Boltzmann transport equation for the sake of simplicity of understanding the argument. Because the electrical conductivity is related to the carrier concentration and mobility through σ = neμ, where n is the carrier concentration and μ is the mobility, one can rewrite equation (9) as:

From equation (10), it is understood that the Seebeck coefficient can be enhanced by two ways: (i) increase the energy dependence of the carrier concentration and (ii) increase the energy dependence of the mobility, both at the Fermi energy. The carrier concentration depends on the DOS at the Fermi energy. This means that a perturbation in the DOS near the Fermi level will increase the energy dependency of carrier concentration and therefore the Seebeck coefficient. This is also suggested using Mahan and Sofo's [217] theory which a Dirac delta function-shaped DOS near the Fermi level was predicted to maximize the figure of merit. In practice, this can be achieved by having a distortion in the DOS resulting from resonant-level doping [220] or by having a delta function-like DOS. This DOS, highly localized in energy, can be obtained through the quantum confinement effect. It is important to remember that, in both cases, the DOS singularity has to be properly aligned within ±2.4kBT of the Fermi level in order to maximize zT [217]. They also found that having two delta-functions or a background DOS will lower the ideal maximum zT. The effect of the background DOS will be significant, a 25% decrease in the maximum zT was predicted for only a 10% contribution from background DOS near the Fermi energy.

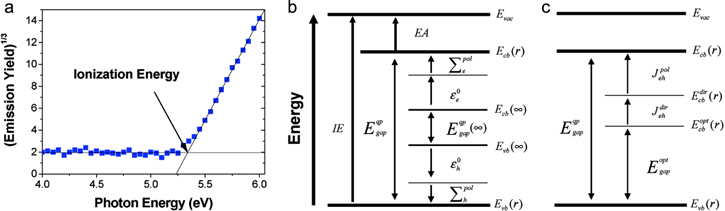

Another feature of the confinement effect is the widening of the electronic band gap when the particle size become smaller than its exciton's Bohr radius [221]. Figure 12 illustrates size dependency of the optical band gap in (Cd, Pb)(S, Se, Te)-family QDs [222].

Figure 12. Tunable optical band gap in thermoelectric quantum dots (QDs). Size dependency of the absorption spectra of the (a) CdSe, (b) CdTe, (c) PbS, and (d) PbSe QDs. Reprinted with permission from [223]. Copyright 2011 American Chemical Society.

Download figure:

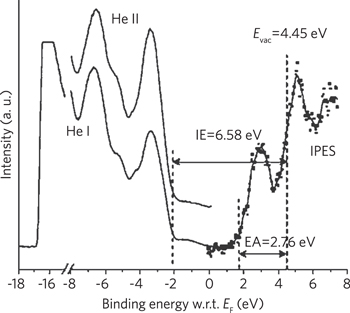

Standard image High-resolution imageThe measured optical band gap  from the absorption spectra can be related to the actual transport band gap Eg by the Brus theoretical particle-in-a-box model equation [224]

from the absorption spectra can be related to the actual transport band gap Eg by the Brus theoretical particle-in-a-box model equation [224]

where Ec is the conduction band minimum, Ev is the valence band maximum, q is the carrier charge, R is nanoparticle radius which can be measured by TEM or determined from the empirical correlations based on the first maximum absorption peak [225–227], εQD is the dielectric constant of the QD and ε0 is the vacuum permittivity. Thus, the enhancement of nanocrystal optical band gap is an indication of an electronic transport band gap widening. If the change in band gap is much larger than the changes in the Fermi energy due to size effects, the band edges distance themselves from the Fermi energy as the nanocrystal size decreases. As a result, the difference between the Fermi energy and the average energy of the mobile carrier increases, and this means that the Seebeck coefficient will increase [228]. This can be better understood by deriving the Seebeck coefficient expression starting from Boltzmann transport equation with the relaxation time approximation as [229]

where f0 is the Fermi–Dirac distribution, D is the DOS, and τ is the relaxation time. This equation indicates that Seebeck coefficient is proportional to the average energy difference from the Fermi level. This difference is weighted by the differential electrical conductivity at each level (integrand in the denominator of equation (12)) [229]. Therefore, if the Fermi level remains unchanged, decreasing of the crystal size can lead to an increase in the Seebeck coefficient (see figure 13). However, this does not necessarily result in an increase in overall power factor (S2σ); as was mentioned before, the best position for the Fermi energy is to be within a few kBT of the delta-function-like DOS. For instance, as the Fermi energy moves further from the band edge, the carrier concentration decreases. If the mobility remains constant, the electrical conductivity decreases significantly [228].

Figure 13. The continuous (Fermi–Dirac) to discrete distribution of DOS for the bulk materials and QDs respectively. The average energy of the mobile carrier, Eavg, moves away from the chemical potential, μ, resulting in enhancement of the Seebeck coefficient. Reprinted with permission from [228]. Copyright 2008 American Chemical Society.

Download figure:

Standard image High-resolution imageThe Fritzsche general expression [230] for the thermopower can provide useful physical insights into thermopower behavior of nanocrystals. Starting from equation (12) and using a single band assumption, one can derive

where

and m is the carrier mass. The origin of this equation comes from the fact that the Seebeck coefficient is a measure of the heat carried by a charge carrier per unit charge. The energy is measured from the Fermi energy which is an indication of entropy if divided by temperature. Each electron will contribute to the total Seebeck an amount relative to its contribution to the total electronic conduction [230]. For p-type QD systems, equation (13) is often reformulated as [231]

where

The transport energy level ET is defined as the energy at which the hopping mobility is above zero, and for a p-type material A is a roughly temperature independent constant called the 'heat-of-transport'. In nanocrystals, unlike the bulk materials, ET is not necessarily the edge of the DOS because of the low probability of finding a state with an energy difference smaller than kBT. Here ET is defined as the energy level that the carrier can hop with a noticeable mobility [231]. It is fruitful to understand the physical meaning of each term in equation (14). The first term indicates the average entropy change of the system due to thermal excitation of charge carriers to the transport level, and the second term is proportional to the average vibrational energy of the carriers beyond ET as they hop, weighted against their contribution to the total conduction [231, 232] (see figure 14). The value of A lies between 1 and 2 for bulk semiconductors and can be larger for the case of QD systems which have a sharper DOS profile [230, 231, 233, 234]. The curvature of the optical absorption data, as the optical DOS, can be used to estimate the energy dependency of DOS and therefore the value of A [231]. By plotting the Seebeck coefficient against the inverse temperature, one can extract EF–ET from the slope, and A from the ordinate intercept which corresponds to T→∞. There can be other contributions to the ordinate intercept such as the temperature dependency of DOS [235–238] or EF [233, 239]. Ko and Murray [231] used the Fritzsche general expression [230] in order to examine EF–ET as a function of size in p-type PbTe QDs. For the largest QDs with an average size of 11.5 nm, they found that the value of EF–ET was smaller than half of the optical band gap energy showing that the Fermi energy position was below the mid-gap energy. As the size of the QDs decreased, the band separation increased due to quantum confinement effects (see figure 14). As the authors stated, knowing the value of EF–ET can be beneficial, because for a known effective DOS and electrical conductivity, one can use this to estimate the carrier concentration. In addition, if ET is estimated, the change in position of EF can be tracked.

Figure 14. Fritzsche analysis of the Seebeck coefficient of QD systems. (a) Absorption spectra of PbTe QDs with different diameters. The data was used to calculate the curvature of the optical DOS for the heat-of-transport estimation. (b) Thermopower measurements plotted against the inverse temperature. The slope is an indication of the EF–ET values. (c) Schematic of the evolution of EF–ET as a function of size due to quantum confinement effects. Reprinted with permission from [231]. Copyright 2011 American Chemical Society.

Download figure:

Standard image High-resolution imageWang and Majumdar et al [228] reported the first thermopower measurements of a solution-based p-type PbSe QD superlattice with a strong quantum confinement effect. It was observed that as the nanocrystal size decreased from 8.6 to 4.8 nm, the thermopower increased from 700 to 1150 μV K−1 due to the quantum confinement effect. This size reduction also resulted in an order of magnitude decline of the electrical conductivity due to a decrease in the carrier concentration. Upon exposure of their material to oxygen, the conductivity increased by about an order of magnitude due to p-type doping, with a commensurate decrease in thermopower from 760 to 440 μV K−1. Additionally, post-treatment in the presence of hydrazine induced n-type doping. A transformation of Te nanowires to PbTe nanowires in a solvothermal reaction in a Teflon lid autoclave was reported by Tai and Guo et al [163] In their proposed reaction, Pb2+ cation were reduced to Pb atom in the the presence of hydrazine which then reacted with Te and formed PbTe nanowires with diameters ∼20–40 nm. The transport properties measurements were carried out on thin films, showing a high thermopower of 628 μV K−1 at room temperature. Performed DFT calculations indicated an enhancement of the local DOS near the Fermi level as the nanowires diameter decreased from 2.305 to 0.326 nm. Yan and Ma et al [240] reported a single step solvothermal synthesis of PbTe nanowires with a diameter range of 10–30 nm. Measurements of the transport properties of thin films on glass substrates showed a high thermopower of S > 470 μV K−1 at T = 375 and 425 K but a high resistivity of 2 × 10−3 Ω m at room temperature. No measurements for the mobility was reported.

Additional studies of quantum confinement effects yield qualitatively similar results, although the effect is less intense for nanowire-based systems compared to QD systems. Zhou and Yan et al [241] reported the transport properties of PbTe–PtTe2 multiphase nanoparticles sprayed on glass substrates. They observed that as the phase ratio of PbTe to PtTe2 was increased from 0.33 to 0.67, the average particle size grew from 30 to 52 nm. The Seebeck measurements of the pure PbTe particles exhibited a p-type material with S > 500 μV K−1 over a temperature range of 300–600 K. Quantum confinement effects were suggested as the reason for the high thermopower. The introduction of Pt to the nanoparticles, changed the material from p-type to n-type. As the phase ratio of PbTe decreased from 0.67 to 0 (pure PtTe2), the maximum of thermopower declined from 155 to 5 μV K−1. Thermopower of the samples with a PbTe ratio of 0.67 and 0.5 were 50%–100% higher than that of bulk n-type PbTe with similar charge carrier concentrations. As the ratio of PbTe decreased, the electrical conductivity increased and for the ratio of 0.5, a maximum electrical conductivity of 1 × 105 S m−1 was reported. Maksym and Talapin et al [242] synthesized PbTe nanocrystals capped with Sb2Te3 molecular metal chalcogenide complexes (MMCs) by replacing the oleic acid ligands. Another approach involved preparation of single phase (Bi, Sb)2Te3 and bi-phase PbTe–Sb2Te3 starting from Bi2S3 and PbS. The conversion of Bi2S3 and PbS to Bi2Te3 and PbTe was completed through an anion exchange of S2− by Te2− by reacting Bi2S3 and PbS with Sb2Te3 molecular metal chalcogenide complex containing excess Te. PbTe capped with Sb2Te3 showed a large p-type thermopower of 750 μV K−1, more than a two-fold increase versus that of the bulk PbTe at a comparable carrier density (1.3 × 1018 cm−3) [242]. The quantum confinement effect was proposed as an explanation for the high value of the Seebeck coefficient due the small size of the PbTe nanocrystals (2–30 nm) and a large exciton Bohr radius of 46 nm for PbTe [242, 243]. Unlike Wang and Majumdar et al's [228] study on PbSe, the hydrazine treatment of MMC-capped PbTe did not transform the material from p-type to n-type owing to the excess of Te in Sb2Te3 MMCs [242]. The measurements of (Bi, Sb)2Te3 thin films exhibited p-type Seebeck coefficients of 170–250 μV K−1. An n-type Seebeck of −245 μV K−1 was obtained through Se doping in the form of (Bi, Sb)2(Te, Se)3. We note that for larger diameter QD systems, doping will have a greater impact on tuning the thermopower than size control. For example, altering the carrier concentration by doping with iodine was found to dominate the thermopower of n-type PbTe QDs with diameters of 12, 29, and 48 nm, and negligible size dependency was found for this diameter range [244].

3.1.1. Outlook

Thermoelectric materials with large exciton Bohr radii [216] such as PbS (20 nm) [216], PbSe (46 nm) [216], PbTe (46 nm) [242, 243], InAs (34 nm) [216], and InSb (54 nm) [216] are good candidates for increased thermopower through quantum size effects. Considering the characteristic sizes needed to gain from this effect, bottom-up synthesis techniques are the optimal tools for the preparation of materials with crystal sizes capable of exhibiting confinement effects. Many synthetic recipes capable of tailoring the crystal size in different configurations such as quantum dots [18, 152, 245–247], thin nanosheets [248, 249], nanowires [250, 251], and nanorods [252–254] have been successfully developed. The electronic band gap widening measured by the absorption spectra of nanocrystals alone might not be sufficient to attribute thermopower enhancements to confinement effects. In this regard, an assessment of mobility and carrier concentration measurements is essential because a thermopower enhancement can be the result of a change in carrier concentration as well. In addition, the confinement effect does not necessarily guarantee a high thermoelectric power factor. The location of the chemical potential is the other factor that should be controlled carefully in these materials.

3.2. Energy filtering effects for thermopower enhancement

An additional approach to enhance the Seebeck coefficient is to increase the second term in equation (10), i.e. by increasing the energy dependence of the mobility at the Fermi energy. Starting from the Boltzmann transport equation with the relaxation time approximation and applying Ohm's law in the presence of an electric field, the carrier mobility for a semiconducting material can be written in the form of [229]

where q and m are the electron/hole charge and mass, respectively, τ is the relaxation time, and f0 is the Fermi–Dirac distribution. Equation (15) clearly shows that the energy dependence of mobility at the Fermi level can be enhanced by increasing the energy dependence of the scattering time i.e. (dτ/dE)∣EF. This implies that the charge carriers should be scattered differently according to their energies which is called the carrier energy filtering effect. Using the relaxation time approximation for small deviations from equilibrium, applying to elastic scatterings where energy is conserved, and for an isotropic scattering of a two-particle system, one can neglect the spatial non-uniformity and derive the following for the distribution function

where C is a constant of integration. This expression indicates that the relaxation time is the time needed for a system to relax from a nonequilibrium distribution f to an equilibrium state f0. There are different scattering mechanisms where each one may require different relaxation times. If one assumes that scattering mechanisms τi are independent of each other, Matthiessen's rule can be used to estimate the total relaxation time as  [255]. The scattering mechanism in semiconductors are more complicated than metals. In both cases electron–phonon scattering is more dominant than the electron–electron scattering. The electron–phonon scattering can be dominated by either acoustic or optical phonons. Ionized or neutral impurities can also induce scattering of the charge carriers. More details about different scattering mechanisms can be found in the literature [256–258]. The classic estimation of power law dependence of the scattering time on energy for a 3D semiconductor can be used for simplicity. In a parabolic band τ = τ0(T)·(ε*)λ–½ where ε* = (Ε–ΕCBM)/kΒΤ and τ0(T) is a function of temperature and can be found in [259] for different scattering mechanisms. The term E−½ arises from the energy dependence of the DOS for a parabolic band, D(E) ∝ E½. The value of λ is different for various scattering mechanisms: λ = 0 for acoustic phonon scattering, λ = 1 for optical phonon scattering, λ = ½ for neutral impurities and λ = 2 for ionized impurities [259]. This rough estimation hints that an increase in λ can potentially enhance the energy dependence of the scattering time and, as a consequence, the Seebeck coefficient e.g. by dominant ionized impurity doping [260, 261]. In another explanation, for a degenerate semiconductor the contributions of high energy carriers (hot carriers, E > EF for electrons) and low energy carriers (cold carriers, E < EF for electrons) to the thermopower are of opposite signs usually canceling each other's contribution to the total thermopower. If the cold carries can be selectively scattered significantly enough, the Seebeck coefficient will increase, and therefore the power factor can be enhanced with a small sacrifice in the electrical conductivity owing to a possible decrease in the mobility.

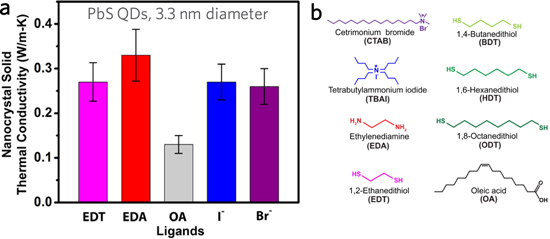

[255]. The scattering mechanism in semiconductors are more complicated than metals. In both cases electron–phonon scattering is more dominant than the electron–electron scattering. The electron–phonon scattering can be dominated by either acoustic or optical phonons. Ionized or neutral impurities can also induce scattering of the charge carriers. More details about different scattering mechanisms can be found in the literature [256–258]. The classic estimation of power law dependence of the scattering time on energy for a 3D semiconductor can be used for simplicity. In a parabolic band τ = τ0(T)·(ε*)λ–½ where ε* = (Ε–ΕCBM)/kΒΤ and τ0(T) is a function of temperature and can be found in [259] for different scattering mechanisms. The term E−½ arises from the energy dependence of the DOS for a parabolic band, D(E) ∝ E½. The value of λ is different for various scattering mechanisms: λ = 0 for acoustic phonon scattering, λ = 1 for optical phonon scattering, λ = ½ for neutral impurities and λ = 2 for ionized impurities [259]. This rough estimation hints that an increase in λ can potentially enhance the energy dependence of the scattering time and, as a consequence, the Seebeck coefficient e.g. by dominant ionized impurity doping [260, 261]. In another explanation, for a degenerate semiconductor the contributions of high energy carriers (hot carriers, E > EF for electrons) and low energy carriers (cold carriers, E < EF for electrons) to the thermopower are of opposite signs usually canceling each other's contribution to the total thermopower. If the cold carries can be selectively scattered significantly enough, the Seebeck coefficient will increase, and therefore the power factor can be enhanced with a small sacrifice in the electrical conductivity owing to a possible decrease in the mobility.