Abstract

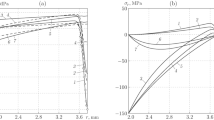

This paper presents an experimental and theoretical study of the influence of a tensile load on the relaxation of residual stresses in a hardened cylindrical specimen of ZhS6KP alloy under creep conditions at 800°C. An experimental study was conducted to investigate the distribution of the axial residual stress tensor component across the thickness of the hardened layer after hardening by air shot blasting using microbeads and after creep loading for 50 and 200 h under a tensile load of 150 and 250 MPa. A detailed theoretical analysis of the problem was performed. In all loading regimes, the calculated and experimental values of the residual stresses were found to be in good agreement. It was shown that at low tensile load, the relaxation rate decreased in comparison with the case of thermal exposure in the absence of a tensile load and, with increasing load intensity, it increased.

Similar content being viewed by others

References

I. A. Birger, Residual Stresses (Mashgiz, Moscow, 1963) [in Russian].

V. F. Pavlov, V. A. Kirpichev, and V. B. Ivanov, Residual Stresses and Fatigue Resistance of Toughened Parts with Stress Concentrators (Samara Scientific Center, Russian Acad. of Sci., Samara, 2008) [in Russian].

I. G. Grinchenko, Hardening of Parts from Heat-Resistant and Titanium Alloys (Mashinostroenie, Moscow, 1971) [in Russian].

B. A. Kravchenko, V. G. Krutzilo, and G. N. Gutman. Thermoplastic Hardening is a Reserve for Increasing the Strength and Reliability of Machine Parts (Samara State Technical University, Samara, 2000) [in Russian].

A. M. Sulima, V. A. Shuvalov, and Yu. D. Yagodkin, Surface Layer and Performance of Gas Turbine Engines (Mashinostroenie, Moscow, 1988) [in Russian].

V. P. Radchenko and M. N. Saushkin, Creep and Relaxation of Residual Stresses in Hardened Structures (Mashinostroenie, Moscow, 2005) [in Russian]

O. V. Kolotnikova, “Effectiveness of Hardening by Surface Plastic Deformation of Parts Operating at Elevated Temperatures,” Probl. Prochn., No. 2, 112–114 (1983).

V. P. Radchenko and M. N. Saushkin, “Mathematical Models of Recovery and Relaxation of Residual Stresses in the Surface-Hardened Layer of Cylindrical Structural Elements in Creep,” Izv. Vyssh. Uchebn. Zaved., Mashinostr., No. 11, 3–17 (2004).

V. P. Radchenko and M. N. Saushkin, “Direct Method of Solving the Boundary-Value Problem of Relaxation of Residual Stresses in a Hardened Cylindrical Specimen under Creep Conditions,” Prikl. Mekh. Tekh. Fiz. 50(6), 90–99 (2009) [J. Appl. Mech. Tech. Phys. 50 (6), 989–997 (2009)].

S. I. Ivanov, “Determination of Residual Stresses in a Cylinder by the Method of Rings and Stripes,” in Residual Stresses (Kuibyshev Aviation Institute, Kuibyshev, 1974), Issue 53, pp. 32–42 [in Russian].

S. I. Ivanov, “Determination of Residual Stresses in the Surface Layer of a Cylinder,” in Problems of the Strength of Aircraft Structural Elements (Kuibyshev Aviation Institute, Kuibyshev, 1971), Issue 48, pp. 153–168.

V. P. Radchenko, V. F. Pavlov, and M. N. Saushkin, “Determination of the Hardening Anisotropy Parameter and Residual Stresses in a Cylindrical Steel Specimen after Rolling,” Probl. Mashinostr. Prochn. Mashin, No. 4, 93–100 (2011).

V. P. Radchenko, M. N. Saushkin, and V. F. Pavlov, “Method of Calculating the Fields of Residual Stresses and Plastic Strains in Cylindrical Specimens with Allowance for Surface Hardening Anisotropy,” Prikl. Mekh. Tekh. Fiz. 52(2), 173–182 (2011) [J. Appl. Mech. Tech. Phys. 52 (2), 302–310 (2011)].

Yu. P. Samarin, Equation of State for Materials with Complicated Rheological Properties (Kuibyshev State University, Kuibyshev, 1979) [in Russian].

A. N. Badaev, “On the Determination of the Distribution Function of the Parameters of the Creep State Equation,” Probl. Prochn., No. 12, 22–26 (1984).

V. I. Kovpak and A. N. Badaev, “Unified Approach to Predicting Creep. Issues of Heat-Resistant Materials in the Statistical Aspects,” in Standardized Methods for the Determination of Creep and Rupture Strength (Izd. Standartov, Moscow, 1986), pp. 51–62 [in Russian].

V. P. Radchenko, M. N. Saushkin, and E. P. Goludin, “Stochastic Model of Nonisothermal Creep and Long-Term Strength of Materials,” Prikl. Mekh. Tekh. Fiz. 53(2), 167–174 (2012) [J. Appl. Mech. Tech. Phys. 53 (2), 292–298 (2012)].

Author information

Authors and Affiliations

Corresponding author

Additional information

Original Russian Text © V.P. Radchenko, E.P. Kocherov, M.N. Saushkin, V.A. Smyslov.

__________

Translated from Prikladnaya Mekhanika i Tekhnicheskaya Fizika, Vol. 56, No. 2, pp. 169–177, March–April, 2015.

Rights and permissions

About this article

Cite this article

Radchenko, V.P., Kocherov, E.P., Saushkin, M.N. et al. Experimental and theoretical studies of the influence of a tensile load on the relaxation of residual stresses in a hardened cylindrical specimen under creep conditions. J Appl Mech Tech Phy 56, 313–320 (2015). https://doi.org/10.1134/S0021894415020170

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0021894415020170