Abstract

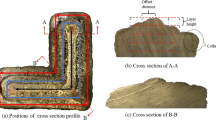

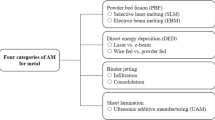

The forming system of wire and arc additive manufacture (WAAM) based on cold metal transfer (CMT) is a high build rate system for production of near-net shape components layer by layer, which is composed of industrial robot operation system and 3D path simulation software. In the 3D path simulation software, the working layout of the off-line virtual robot is carried for the imported three-dimensional model to screen the model wall thickness, correct process library, set process parameters, slice, layer, plan deposition path, form simulation and upload program to execution system. Among the whole system, the 3D path simulation software provides essential database for process control and an innovative planning path to coordinate industrial robot platform to build parts layer by layer. Furthermore, the experiment is also performed to study the stability of aluminum alloy forming using the WAAM-CMT system by establishing different experimental models and changing process parameters and process modes of industrial robot and Fronius digital welding machine embedded on robot operation platform.

Similar content being viewed by others

REFERENCES

J. Xiong, H. Gen, X. Lin, D. Huang, J. Li, and B. Zhang, Aeronaut. Manuf. Technol. 58 (23–24), 80 (2015). doi 10.16080/j.issn1671-833x.2015.23/24.080

C. Tian, J. Chen, P. Dong, J. He, and Y. Wang, Aeronaut. Manuf. Technol., 58 (2), 57 (2015).

X. Bu, Y. Chen, Y. Shen, and R. Liu, Ind. Technol. Innovations, 60 (4), 38 (2017). doi 10.14103/j.issn.2095-8412.2017.04.007

S. W. Williams, F. Martina, A. C. Addison, J. Ding, G. Pardal, and P. Colegrove, Mater. Sci. Technol. 32, 641 (2016). doi 10.1179/1743284715Y.0000000073

Y. Wang, X. Chen, and S. V. Konovalov, J. Surf. Invest.: X-ray, Synchrotron Neutron Tech. 11, 1317 (2017). doi 10.1134/S1027451017060210

W. E. Frazier, J. Mater. Eng. Perform. 23, 1917 (2014). doi 10.1007/s11665-014-0958-z

Z. Sun, Y. Lv, B. Xu, and Y. Liu, J. Acad. Armor. Force Eng. 28, 82 (2014).

Z. Liu, D. Xue, S. Han, J. Deng, L. Wang, and L. Yao, J. Nets. Force Eng. 8 (2), 21 (2016).

D. Ding, C. Shen, Z. Pan, D. Cuiuri, Huijun Li, N. Larkin, and S. van Duin, Comput.-Aided Des. 73, 66 (2016).

B. Dutta and F. H. (Sam) Froes, Met. Powder Rep. 72, 96 (2017). doi 10.1016/j.mprp.2016.12.062

B. Cong, J. Ding, and S. Williams, Int. J. Adv. Manuf. Technol. 76, 1593 (2015).

P. Magnoni, L. Rebaioli, I. Fassi, N. Pedrocchi, and L. M. Tosatti, Procedia Manuf. 11, 346 (2017). doi 10.1016/j.promfg.2017.07.117

A. Gomez Ortega, L. Corona Galvan, F. Deschaux-Beaume, B. Mezrag, and S. Rouquette Sci. Technol. Weld. Joining Science and Technology of Welding and Joining, 316 (2017). doi 10.1080/13621718.2017.1388995

C. Zhang, Y. Li, M. Gao, and X. Zeng, Mater. Sci. Eng., A 711, 415 (2017).

J. Li, H. Li, H. Wei, and Y. Gao, Int. J. Adv. Manuf. Technol. 84, 705 (2016). doi 10.1007/s00170-015-7734-6

Author information

Authors and Affiliations

Corresponding authors

Additional information

The article is published in the original.

Rights and permissions

About this article

Cite this article

Xizhang Chen, Su, C., Wang, Y. et al. Cold Metal Transfer (CMT) Based Wire and Arc Additive Manufacture (WAAM) System. J. Surf. Investig. 12, 1278–1284 (2018). https://doi.org/10.1134/S102745101901004X

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S102745101901004X