Abstract

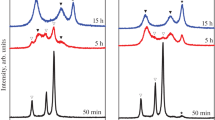

We obtain titanium carbohydrides by the high-energy ball milling (HEBM) of titanium in a planetary ball mill in toluene. Depending on the duration of HEBM, face-centered cubic (FCC) and hexagonal close packed (HCP) carbohydrides with different carbon and hydrogen contents are obtained. The structural-phase state and the thermal stability of the solid phase of the reaction mixture, during successive stages of mechanosynthesis, are investigated by means of X-ray diffraction, differential scanning calorimetry, thermal desorption, and scanning electron microscopy. At short milling times (50 min), the endothermic peak appears at a temperature of 430°C due to the α → β phase transformation in Ti in the presence of hydrogen. Hydrogen stabilizes β-Ti, reducing its formation temperature to 300°C. The exothermic peak, at about 530°C, corresponds to the deformation-energy release of the crushed Ti powder. Processing in the planetary mill for 5 h leads to the formation of an α-Ti (HCP) and Ti carbohydride (HCP and FCC) mixture. We state that for the HCP carbohydrides, a higher hydrogen desorption temperature is observed as compared to the FCC carbohydrides. The correlation of the thermal desorption peaks and the differential scanning calorimetry curves is discussed. We make assumptions concerning the mechanisms of the thermally stimulated structural-phase transformations of the carbohydrides.

Access this article

We’re sorry, something doesn't seem to be working properly.

Please try refreshing the page. If that doesn't work, please contact support so we can address the problem.

Similar content being viewed by others

REFERENCES

L. Li and M. O. Lai, Mater. Des. 16, 33 (1995). https://doi.org/10.1016/0261-3069(95)00005-J

H. Gleiter, Acta Mater. 48, 1 (2000). https://doi.org/10.1016/S1359-6454(99)00285-2

M. A. Meyers, A. Mishra, and D. J. Benson, Prog. Mater. Sci. 51, 427 (2006). https://doi.org/10.1016/j.pmatsci.2005.08.003

C. Suryanarayana, Mater. Sci. 46, 1 (2001). http://www.crystallography.ru/MA/articles/MA&MM2001.pdf.

R. Ebrahimi-Kahrizsangi, M. Abdellahi, and M. Bahmanpour, Int. J. Self-Propag. High-Temp. Synth. 25, 5 (2016). https://link.springer.com/article/10.3103/ S1061386216010039.

M. S. El-Eskandarany, Mechanical Alloying: Nanotechnology, Materials Science and Powder Metallurgy, 2nd ed. (Elsevier, Oxford, 2015).

C. Suryanarayana, J. Alloys Compd. 509, 229 (2011). https://doi.org/10.1016/j.jallcom.2010.09.063

M. S. El-Eskandarany, J. Alloys Compd. 305, 225 (2000). https://doi.org/10.1016/S0925-8388(00)00692-7

In-Jin Shona, Hyoung-Gon Joa, and H. Kwon, Int. J. Refract. Met. Hard Mater. 48, 187 (2015). https://doi.org/10.1016/j.ijrmhm.2014.09.011

M. Razavi, M. R. Rahimipour, and R. Mansoori, J. Alloys Compd. 450, 463 (2008). https://doi.org/10.1016/j.jallcom.2006.11.013

I. A. Evdokimov, R. R. Khairullin, R. Kh. Bagramov, V. V. Aksenenkov, S. A. Perfilov, A. A. Pozdnyakov, B. A. Kul’nitskii, and A. N. Kirichenko, Izv. VUZov, Poroshk. Metall. Funkts. Pokrytiya, No. 3, 76 (2020). https://doi.org/10.17073/1997-308X-2020-3-76-84

S. Zhang and S. C. Tam, J. Mater. Process. Technol. 67, 112 (1997). https://doi.org/10.1016/S0924-0136(96)02828-2

A. Montone, J. Grbovic, A. Bassetti, L. Mirenghi, P. Rotolo, E. Bonetti, L. Pasquini, and M. V. Antisari, Mater. Sci. Forum 494, 137 (2005). https://doi.org/10.4028/www.scientific.net/MSF.494.137

L. Shaw, M. Zawrah, J. Villegas, H. Luo, and D. Miracle, Metall. Mater. Trans. A 34, 159 (2003). https://doi.org/10.1007/s11661-003-0217-7

W. Lee and Sl. Kwun, J. Alloy Compd. 240, 193 (1996). https://doi.org/10.1016/0925-8388(96)02224-4

G. A. Dorofeev, V. L. Lad’yanov, A. N. Lubnin, V. V. Mukhgalin, O. M. Kanunnikova, and V. V. Aksenova, Int. J. Hydrogen Energy 39, 9690 (2014). https://doi.org/10.1016/j.ijhydene.2014.04.101

H. Z. Xiao, Scr. Metall. Mater. 27, 571 (1992). https://doi.org/10.1016/0956-716X(92)90342-C

V. A. Lavrenenko, M. M. Antonova, and V. Zh. Shemet, Kinetics of Processes in Hydride Systems (Naukova Dumka, Kiev, 1992) [in Russian].

L. Lu M. Lai, and S. Zhang, J. Mat. Res. Bull. 29, 889 (1994). https://doi.org/10.1007/978-1-4615-5509-4_8

T. S. Suzuki and M. Nagumo, Scr. Metall. Mater. 32, 1215 (1995). https://doi.org/10.1016/0956-716X(95)00128-I

A. S. Bolokang, D. E. Motaung, C. J. Arendse, and T. F. G. Muller, Adv. Powder Technol. 26, 632 (2015). https://doi.org/10.1016/j.apt.2015.01.013

O. M. Kanunnikova, V. V. Aksenova, and G. A. Dorofeev, Mater. Sci. Forum 946, 351 (2019). doi 10.4028/www.scientific.net/MSF.946.351

Y. Chen and J. S. Williams, J. Alloys Compd. 217, 181 (1995). https://doi.org/10.1016/0925-8388(94)01338-1

U. Zwicker, Titanium and Titanium Alloys (Springer, Berlin, 1974; Metallurgiya, Moscow, 1989).

ACKNOWLEDGMENTS

We are grateful to D.G. Kalyuzhny for obtaining the TDS data for the ground powders.

The studies were carried out using equipment of the Center for physical and physicalchemical methods of analysis, research of the properties and characteristics of surfaces, nanostructures, materials and products, Udmurt Federal Research Center, Ural Branch, Russian Academy of Sciences.

Funding

The work is performed within research and development program no. 121030100001-3.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

We declare that we have no conflicts of interest.

Additional information

Translated by I. Dikhter

Rights and permissions

About this article

Cite this article

Aksenova, V.V., Kanunnikova, O.M., Burnyshev, I.N. et al. Thermal Stability of Carbohydrides Obtained by the High-Energy Ball Milling of Titanium in a Toluene Medium. J. Surf. Investig. 16, 68–72 (2022). https://doi.org/10.1134/S1027451022010025

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S1027451022010025