Abstract

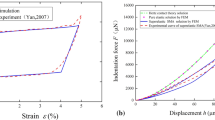

The shape-memory effect and superelasticity properties of NiTinol alloys make them a versatile candidate for various engineering and biomedical applications. The use of these alloys as biomedical implants necessitates the study of any long-term creep failure possibility. The present study utilizes the finite element method to investigate this creep behavior of NiTinol alloys under static and dynamic loading conditions over a long period. The Maxwell creep model has been implemented, as well as validated with the polypropylene and low-density polyethylene. Further, the same model has been utilized for the creep analysis of NiTinol with suitable material properties and assumptions, for a time of 10,000 h. The results demonstrated the application of sinusoidal varying loads, the creep strain observed was lower as compared to other loading conditions, and in the case of static load, higher creep strain values were experienced than that of the dynamic smooth step loading case.

Similar content being viewed by others

References

D. Shinde, P.V. Katariya, K. Mehar, M.R. Khan, S.K. Panda, H.K. Pandey, Struct. Eng. Mech. 68(5), 519–526 (2018)

K. Mehar, P. Mishra, S. Panda, Mech. Adv. Mater. Struct. 1–13 (2020)

P.V. Katariya, A. Das, S.K. Panda. in IOP Conference Series: Materials Science and Engineering, vol. 1 (2018), p. 1–6

T. Cengiz, M. Kurt, Eur. Phys. J. Plus 135(9), 1–12 (2020)

Q. Kan, G. Kang, S. Guo, Int. J. Comput. Methods 9(1), 1240022 (2012)

J.M. Jani, M. Leary, A. Subic, M.A. Gibson, Mater. Des. 56, 1078–1113 (2014)

S.K. Patel, B. Behera, B. Swain, R. Roshan, D. Sahoo, A. Behera, Mater. Today Proc. 33, 5548–5551 (2020)

M. Kök, H.S.A. Zardawi, I.N. Qader, M.S. Kanca, Eur. Phys. J. Plus 134(5), 197 (2019)

J. Latalski, R. Rusinek, Eur. Phys. J. Plus 132(8), 341 (2017)

K.E. Wilkes, P.K. Liaw, JOM 52(10), 45–51 (2000)

J.G. Boyd, D.C. Lagoudas, Int. J. Plast. 12(6), 805–842 (1996)

F. Auricchio, R.L. Taylor, J. Lubliner, Comput. Methods Appl. Mech. Eng. 146(3–4), 281–312 (1997)

M. Azaouzi, A. Makradi, S. Belouettar, Mater. Des. 41, 410–420 (2012)

F. Nematzadeh, S. Sadrnezhaad, Sci. Iran. 19(6), 1564–1571 (2012)

A. Kaya, I. Kaya, H.E. Karaca, Microw. Opt. Technol. Lett. 55(12), 2976–2984 (2013)

J.W. Mwangi, L.T. Nguyen, V.D. Bui, T. Berger, H. Zeidler, A. Schubert, J. Manuf. Process. 38, 355–369 (2019)

K. Maleckis, et al., Ann. Biomed. Eng. 46(5), 684–704 (2018)

C. Jin, R.-H. Liu, S.-P. Zhong, L.-Z. Wang, Y.-B. Fan, Int. J. Comput. Methods 16(03), 1842007 (2019)

E. Dordoni, L. Petrini, W. Wu, F. Migliavacca, G. Dubini, G. Pennati, J. Funct. Biomater. 6(2), 299–317 (2015)

F. Migliavacca, L. Petrini, P. Massarotti, S. Schievano, F. Auricchio, G. Dubini, Biomech. Model. Mechanobiol. 2(4), 205–217 (2004)

C. Shanahan, S.A. Tofail, P. Tiernan, Mater. Des. 121, 143–153 (2017)

A. Mukiierjee, J. Appl. Phys. 39(5), 2201–2204 (1968)

H. Kato, T. Yamamoto, S. Hashimoto, S. Miura, Mater. Trans. JIM 40(4), 343–350 (1999)

S.M. Oppenheimer, A.R. Yung, D.C. Dunand, Scr. Mater. 57(5), 377–380 (2007)

C. Lexcellent, P. Robinet, J. Bernardini, D. Beke, P. Olier, Mat.-wiss. u. Werkstofftech. 36(10), 509–512 (2005)

S. Raj, R. Noebe, Mater. Sci. Eng. A 581, 145–153 (2013)

N. Nguyen-Thanh, T. Rabczuk, H. Nguyen-Xuan, S. Bordas, Finite Elem. Anal. Des. 47(5), 519–535 (2011)

C. Thai-Hoang, N. Nguyen-Thanh, H. Nguyen-Xuan, T. Rabczuk, S. Bordas, KSCE J. Civ. Eng. 15(2), 347–361 (2011)

H. Nguyen-Xuan, G. Liu, C.a. Thai-Hoang, T. Nguyen-Thoi, Comput. Methods Appl. Mech. Eng. 199(9–12), 471–489 (2010)

H. Nguyen-Xuan, L.V. Tran, C.H. Thai, S. Kulasegaram, S.P.A. Bordas, Compos. Part. B Eng. 64, 222–234 (2014)

C.H. Thai, H. Nguyen-Xuan, S.P.A. Bordas, N. Nguyen-Thanh, T. Rabczuk, Mech. Adv. Mater. Struc. 22(6), 451–469 (2015)

N. Nguyen-Thanh, H. Nguyen-Xuan, S.P.A. Bordas, T. Rabczuk, Comput. Methods Appl. Mech. Eng. 200(21–22), 1892–1908 (2011)

P. Phung-Van, A. Ferreira, H. Nguyen-Xuan, M.A. Wahab, Compos. Part. B Eng. 118, 125–134 (2017)

S. Yin, J.S. Hale, T. Yu, T.Q. Bui, S.P. Bordas, Compos. Struct. 118, 121–138 (2014)

H. Nguyen-Xuan, T. Rabczuk, N. Nguyen-Thanh, T. Nguyen-Thoi, S. Bordas, Comput. Mech. 46(5), 679–701 (2010)

P. Phung-Van, L.V. Tran, A. Ferreira, H. Nguyen-Xuan, M. Abdel-Wahab, Nonlinear Dyn. 87(2), 879–894 (2017)

N. Valizadeh, S. Natarajan, O.A. Gonzalez-Estrada, T. Rabczuk, T.Q. Bui, S.P. Bordas, Compos. Struct. 99, 309–326 (2013)

S. Natarajan, S. Chakraborty, M. Ganapathi, M. Subramanian, Eur. J. Mech. A Solid 44, 136–147 (2014)

E. Atroshchenko, S. Tomar, G. Xu, S.P. Bordas, Int. J. Numer. Methods Eng. 114(10), 1131–1159 (2018)

B. Marussig, J. Zechner, G. Beer, T.-P. Fries, Comput. Methods Appl. Mech. Eng. 284, 458–488 (2015)

P. Yu, C. Anitescu, S. Tomar, S.P.A. Bordas, P. Kerfriden, Comput. Methods Appl. Mech. Eng. 342, 251–286 (2018)

Q. Hu, F. Chouly, P. Hu, G. Cheng, S.P. Bordas, Comput. Methods Appl. Mech. Eng. 341, 188–220 (2018)

V.P. Nguyen, C. Anitescu, S.P. Bordas, T. Rabczuk, Math. Comput. Simul. 117, 89–116 (2015)

S. Natarajan, A. Ferreira, S. Bordas, E. Carrera, M. Cinefra, A. Zenkour, Math. Probl. Eng. 2014, 1–13 (2014)

S. Natarajan, G. Manickam, Finite Elem. Anal. Des. 57, 32–42 (2012)

P. Phung-Van, et al., Int. J. Nonlin. Mech. 76, 190–202 (2015)

T. Xiang, S. Natarajan, H. Man, C. Song, W. Gao, Compos. Struct. 118, 634–642 (2014)

S. Natarajan, P.M. Baiz, M. Ganapathi, P. Kerfriden, S. Bordas, Comput. Struct. 89(15–16), 1535–1546 (2011)

S. Natarajan, P.M. Baiz, S. Bordas, T. Rabczuk, P. Kerfriden, Compos. Struct. 93(11), 3082–3092 (2011)

T.V. Mathew, S. Natarajan, E. Martínez-Pañeda, Compos. Struct. 204, 43–51 (2018)

S. Natarajan, S. Chakraborty, M. Thangavel, S. Bordas, T. Rabczuk, Comput. Mater. Sci. 65, 74–80 (2012)

H. Nguyen-Xuan, T. Rabczuk, S. Bordas, J.-F. Debongnie, Comput. Methods Appl. Mech. Eng. 197(13–16), 1184–1203 (2008)

T. Yu, T.Q. Bui, P. Liu, S. Hirose, Int. J. Mech. Mater. Des. 12(1), 85–107 (2016)

P. Phung-Van, T. Nguyen-Thoi, T. Le-Dinh, H. Nguyen-Xuan, Smart Mater. Struct. 22(9), 095026 (2013)

S. Natarajan, G. Manickam, S. Bordas, Front. Aerosp. Eng. 2(2), 91–97 (2013)

J. Videla, C. Anitescu, T. Khajah, S.P. Bordas, E. Atroshchenko, Comput. Math. Appl. 77(9), 2369–2395 (2019)

S. Pozhil, N.M. Menon, S.D. Waigaonkar, V. Chaudhari, Mater. Today Proc. 28, 888–892 (2020)

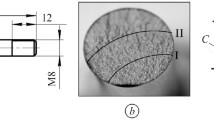

Three-point flexural test. 2020 July 2020]; Available from: https://en.wikipedia.org/wiki/Three-point_flexural_test

Nickel titanium. 2020 [cited 2020 July 2020]; Available from: https://en.wikipedia.org/wiki/Nickel_titanium

Funding

The authors have no relevant financial or nonfinancial interests to disclose.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors have no conflicts of interest to declare that are relevant to the content of this article.

Rights and permissions

About this article

Cite this article

Shaikh, S.F., Panda, S.K., Sharma, N. et al. Creep behavior of Nickel–Titanium shape-memory alloys under static and dynamic loadings: an FEM approach. Eur. Phys. J. Plus 136, 124 (2021). https://doi.org/10.1140/epjp/s13360-021-01080-0

Received:

Accepted:

Published:

DOI: https://doi.org/10.1140/epjp/s13360-021-01080-0