Abstract

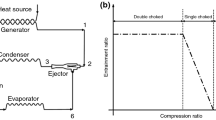

Ejectors have been utilized in many industries such as steam power plants, nuclear reactors, desalination system, refrigeration, etc. However, due to the low coefficient of ejector performance, the ejector refrigeration systems are less used than the other methods (compression or absorption refrigeration systems). On the other hand, nucleated droplets in wet steam ejectors cause erosion/corrosion in the walls. In this research, the effects of surface heating on the ejector performance in the refrigeration system have been investigated. Flow simulation in the ejector is performed using Fluent software in two-phase mode. Then, by analyzing the outlet ejector parameters, the practical heat value is obtained. Criteria for investigating the effect of surface heating are entrainment ratio of the ejector, coefficient of performance of ejector refrigeration cycle, wetness, number of droplets, droplets radius, and entropy. The results show that the surface heating reduces the wetness and entrainment ratio at the end of the primary nozzle. In addition, an applicable value for surface heating has been obtained and a relatively good wetness reduction (0.81%) is achieved.

Similar content being viewed by others

Abbreviations

- J :

-

Nucleation rate (m−3 s−1)

- h :

-

Enthalpy (J kg−1)

- k :

-

Turbulent dissipation rate (m2 s−3)

- \({K}_{B}\) :

-

Boltzmann’s constant

- M :

-

Mass of one molecule (mg)

- \(\dot{m}\) :

-

Mass flow rate (kg s−1)

- P :

-

Pressure (Pa)

- \(Q\) :

-

Surface heating (Kw/m2)

- \({q}_{c}\) :

-

Condensation coefficient (-)

- r :

-

Radius of droplets (μm)

- T :

-

Temperature (K)

- u :

-

Velocity (m s−1)

- X :

-

Spatial component (m)

- COE:

-

Cost of electrical energy

- COP:

-

Coefficient of performance

- CR:

-

Compression ratio (−)

- DAR:

-

Droplet Average Radius (μm)

- ER:

-

Entrainment ratio (−)

- ILE:

-

Entropy at the end of the primary nozzle

- LND:

-

The average logarithm of the number of droplets

- MOW:

-

Mean Wetness

- α :

-

Thermal conductivity

- β :

-

Liquid mass fraction (−)

- Γ:

-

Mass generation rate (kg m−3 s−1)

- \({\delta }_{ij}\) :

-

Rate of mixing layer growth

- \(\varepsilon \) :

-

Turbulence dissipation (s−1)

- η :

-

Number of liquid droplets (m−3)

- μ :

-

Dynamic viscosity (Pa s)

- \(\rho \) :

-

Density (kg m−3)

- σ :

-

Liquid surface tension (N m−1)

- eff:

-

Effective

- evap:

-

Evaporator

- d :

-

Discharge

- Gen:

-

Generator

- \(l\) :

-

Liquid

- \(p\) :

-

Primary

- \(s\) :

-

Secondary

- \(v\) :

-

Gas (vapor)

References

L.P. Lombard, J. Ortiz, C. Pout, A review on buildings energy consumption information. Energy Build. 40(3), 394–398 (2008)

J. Gagan, K. Śmierciew, M. Lukaszuk, D. Butrymowicz, Investigations of thermal performance of ejection refrigeration system driven by low grade heat. Appl. Therm. Eng. 130, 1121–1138 (2018)

M. Isaac, D.P. van Vuuren, Modeling global residential sector energy demand for heating and air conditioning in the context of climate change. Energy Policy 37(2), 507–521 (2009)

S. He, Y. Li, R.Z. Wang, Progress of mathematical modeling on ejectors. Renew. Sustain. Energy Rev. 13, 1760–1780 (2009)

M. Bencharifa, H. Nesreddineb, S. Croquer, P. Sébastien, P. SaidZida, The benefit of droplet injection on the performance of an ejector refrigeration cycle working with R245fa. Int. J. Refrig. 113, 276–287 (2020)

F. Foroozesh, A.B. Khoshnevis, E. Lakzian, Improvement of the wet steam ejector performance in a refrigeration cycle via changing the ejector geometry by a novel EEC (Entropy generation, Entrainment ratio, and Coefficient of performance) method. Int. J. Refrig. 110, 248–261 (2020)

J.A. Expósito, F.J. Sanches de la Flor, J. Salmerón, Single-Phase Ejector geometry optimization by means of a multi-Objective evolutionary algorithm and a surrogate CFD model. Energy 164(1), 46–64 (2018)

V. Van Nguyen, S. Varga, J. Soares, V. Dvorak, A.C. Oliveira, Applying a variable geometry ejector in a solar ejector refrigeration system. Int. J. Refrig. 113, 187–195 (2020)

G. Zhang, S. Dykas, S. Yang, X. Zhang, H. Li, J. Wang, Optimization of the primary nozzle based on a modified condensation model in a steam ejector. Appl. Therm. Eng. 171, 115090 (2020)

M. Palacz, J. Smolka, W. Kus, A. Fic, Z. Bulinski, A.J. Nowak, K. Banasiak, A. Hafner, CFD-based shape optimization of a CO2 two-phase ejector mixing section. Appl. Therm. Eng. 95, 62–69 (2016)

J. Yan, S. Li, Z. Liu, Numerical investigation on optimization of ejector primary nozzle geometries with fixed/varied nozzle exit position. Appl. Therm. Eng 175, 115426 (2020)

F. Aligolzadeh, A. Hakkaki-Fard, A novel methodology for designing a multi-ejector refrigeration system. Appl. Therm. Eng. 151, 26–37 (2019)

D. Jingming, Q. Hu, Y. Mengqi, H. Zhitao, C. Wenbin, D. Liang, M. Hongbin, P. Xinxiang, Numerical investigation on the influence of mixing chamber length on steam ejector performance. Appl. Therm. Eng. 174, 115204 (2020)

M.S. Lee, H. Lee, Y.H.R. Radermacher, H.M. Jeong, Optimization of two-phase R600a ejector geometries using a non-equilibrium CFD model. Appl. Therm. Eng. 109, 272–282 (2016)

Y. Yang, N. Karvounis, J.H. Walther, H. Ding, C. Wen, Effect of area ratio of the primary nozzle on steam ejector performance considering no equilibrium condensations. Energy 237, 121483 (2021)

W. Sun, X. Ma, Y. Zhang, L. Jia, H. Xue, Performance analysis and optimization of a steam ejector through streamlining of the primary nozzle. Case Stud. Therm. Eng. 27, 101356 (2021)

S. Li, Y. Liu, Y. Liu, J. Zhang, Performance comparison of ejectors in ejector-based refrigeration cycles with R1234yf, R1234ze(E) and R134a. Environ. Sci. Pollut. Res. Int. 28–40, 57166–57182 (2021)

X. Feng, Z. Zhang, J. Yang, D. Tian, Numerical Study on Two-Phase Flow of Trans critical CO2 in Ejector. Springer Nature 11, 385–393 (2020)

X. Wang, H. Li, J. Dong, Numerical study on mixing flow behavior in gas-liquid ejector. Exp. Comput. Multiph. Flow 3, 108–112 (2021)

Y. Zhang, J. Zhao, Z. Liu, Numerical simulation and parameter study of ejector in casing gas recovery system. J. Mech. Sci. Technol. 35, 2689–2696 (2021)

M.A. Faghih Aliabadi, E. Lakzian, A. Jahangiri, I. Khazaei, Numerical investigation of effects polydispersed droplets on the erosion rate and condensation loss in the wet steam flow in the turbine blade cascade. Appl. Therm. Eng. 164, 114478 (2020)

M. Vatanmakan, E. Lakzian, M.R. Mahpeykar, Investigating the entropy generation in condensing steam flow in turbine blades with volumetric heating. Energy 147, 701–714 (2018)

M. Atmaca, C. Ezgi, Three-dimensional CFD modeling of a steam ejector. Energy Sources Part A Recovery Util. Environ. Eff. (2019). https://doi.org/10.1080/15567036.2019.1649326

I. Zine, K. Ameur, M. Falsafioon, M. Badache, Current advances in ejector modeling, experimentation and applications for refrigeration and heat pumps. Part 2 two-phase ejectors. Inventions 4, 1–16 (2019)

G. Besagni, R. Mereu, F. Inzoli, Ejector refrigeration: a comprehensive review. Renew. Sust. Energy Rev. 53, 373–407 (2016)

N. Sharifi, M. Boroomand, M. Sharifi, Numerical, assessment of steam nucleation on thermodynamic performance of steam ejectors. Appl. Therm. Eng. 52, 449–459 (2013)

N. Ruangtrakoon, S. Aphornratana, T. Sriveerakul, Experimental studies of a steam jet refrigeration cycle: effect of the primary nozzle geometries to system performance. Exp. Therm. Fluid Sci. 35, 676–683 (2011)

M.J. Moore, P.T. Walters, R.I. Crane, B.J. Davidson, Predicting the fog drop size in wet steam turbines. Wet Steam 4, 101–109 (1973)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Rahvard, A.J., Lakzian, E., Foroozesh, F. et al. An applicable surface heating in a two-phase ejector refrigeration. Eur. Phys. J. Plus 137, 179 (2022). https://doi.org/10.1140/epjp/s13360-021-02203-3

Received:

Accepted:

Published:

DOI: https://doi.org/10.1140/epjp/s13360-021-02203-3