Abstract

Polymer-electrolyte fuel cells are a promising energy-conversion technology. Over the last several decades significant progress has been made in increasing their performance and durability, of which continuum-level modeling of the transport processes has played an integral part. In this review, we examine the state-of-the-art modeling approaches, with a goal of elucidating the knowledge gaps and needs going forward in the field. In particular, the focus is on multiphase flow, especially in terms of understanding interactions at interfaces, and catalyst layers with a focus on the impacts of ionomer thin-films and multiscale phenomena. Overall, we highlight where there is consensus in terms of modeling approaches as well as opportunities for further improvement and clarification, including identification of several critical areas for future research.

Export citation and abstract BibTeX RIS

This is an open access article distributed under the terms of the Creative Commons Attribution 4.0 License (CC BY, http://creativecommons.org/licenses/by/4.0/), which permits unrestricted reuse of the work in any medium, provided the original work is properly cited.

Fuel cells may become the energy-delivery devices of the 21st century. Although there are many types of fuel cells, polymer-electrolyte fuel cells (PEFCs) are receiving the most attention for automotive and small stationary applications. In a PEFC, fuel and oxygen are combined electrochemically. If hydrogen is used as the fuel, it oxidizes at the anode releasing proton and electrons according to

![Equation ([1])](https://content.cld.iop.org/journals/1945-7111/161/12/F1254/revision1/jes_161_12_F1254eqn1.jpg)

The generated protons are transported across the membrane and the electrons across the external circuit. At the cathode catalyst layer, protons and electrons recombine with oxygen to generate water

![Equation ([2])](https://content.cld.iop.org/journals/1945-7111/161/12/F1254/revision1/jes_161_12_F1254eqn2.jpg)

Although the above electrode reactions are written in single step, multiple elementary reaction pathways are possible at each electrode. During the operation of a PEFC, many interrelated and complex phenomena occur. These processes include mass and heat transfer, electrochemical reactions, and ionic and electronic transport.

Over the last several decades significant progress has been made in increasing PEFC performance and durability. Such progress has been enabled by experiments and computation at multiple scales, with the bulk of the focus being on optimizing and discovering new materials for the membrane-electrode-assembly (MEA), composed of the proton-exchange membrane (PEM), catalyst layers, and diffusion-media (DM) backing layers. In particular, continuum modeling has been invaluable in providing understanding and insight into processes and phenomena that cannot be resolved or uncoupled through experiments. While modeling of the transport and related phenomena has progressed greatly, there are still some critical areas that need attention. These areas include modeling the catalyst layer and multiphase phenomena in the PEFC porous media.

While there have been various reviews over the years of PEFC modeling1–7 and issues,8–14 as well as numerous books and book chapters, there is a need to examine critically the field in terms of what has been done and what needs to be done. This review serves that purpose with a focus on transport modeling of PEFCs. This is not meant to be an exhaustive review of the very substantial literature on this topic, but to serve more as an examination and discussion of the state of the art and the needs going forward. In this fashion, the review focuses a bit more on the recent modeling issues and advances and not as much on the various approaches that are historical or outside the scope of current issues.

This review is organized as follows. First, some background introduction into PEFC transport modeling is accomplished including the general governing equations, modeling dimensionality, and a discussion on empirical modeling and the dominant mechanisms, with a focus on the generalized governing equations for the different mechanisms and phenomena. Next, we critically examine multiphase-flow and catalyst-layer modeling. For the former, we will introduce several treatments and then focus on current issues including effective properties, some microscale modeling, phase-change behavior, and the impact and existence of interfaces. For catalyst-layer modeling, we discuss incorporating structural details into the modeling framework, and focus on consideration of ionomer thin-films, as well as transport in ionomer-free zones, and finally touch on the intersection between transport modeling and durability. The next section focuses on future perspectives including interactions between modeling and experiments, modeling variability, open-source modeling, and an overall summary of the article.

Background

In this section, some background information is provided in order to orient the reader for the more detailed discussions below concerning multiphase-flow and catalyst-layer modeling and phenomena. As noted, the physics of most models is similar with the differences being in the scale of the model and phenomena investigated, treatment of the various transport properties, and boundary conditions. In this section, first a discussion of model dimensionality is made, followed by a general description and review of macroscale, empirical modeling. Finally, the general governing equations are presented. As noted above, within this section the focus is on the state-of-the-art equations for the different mechanisms, layers, and phenomena, and not on the specific models that have been used and which models have used which equations. Thus, the equations presented are generalized and classified and represent the key foundational precepts that are required for a more in-depth investigation into the critical phenomena in the following sections.

Although this is a review focused on transport modeling, one needs to be aware of the thermodynamics of the cell. From this perspective, a PEFC converts the intrinsic chemical energy of a fuel into electrical and heat energies. The associated Gibbs free energy can be converted to a potential by

![Equation ([3])](https://content.cld.iop.org/journals/1945-7111/161/12/F1254/revision1/jes_161_12_F1254eqn3.jpg)

where nh is the number of electrons transferred in reaction h and F is Faraday's constant. Similarly, one can define the enthalpy potential as

![Equation ([4])](https://content.cld.iop.org/journals/1945-7111/161/12/F1254/revision1/jes_161_12_F1254eqn4.jpg)

and thus the total heat released by the PEFC can be given by

![Equation ([5])](https://content.cld.iop.org/journals/1945-7111/161/12/F1254/revision1/jes_161_12_F1254eqn5.jpg)

where V is the cell potential. Thus, if the cell potential equals the enthalpy potential, there is no net heat loss/gain. As reference, for hydrogen and oxygen going to liquid water at standard conditions, the reversible and enthalpy potentials are 1.229 and 1.48 V, respectively. To change to different conditions for this reaction, one can use thermodynamic expressions for temperature as well as a Nernst equation for composition,

![Equation ([6])](https://content.cld.iop.org/journals/1945-7111/161/12/F1254/revision1/jes_161_12_F1254eqn6.jpg)

where ai is the activity of species i, and R is the ideal-gas constant. From thermodynamics, the equilibrium and enthalpy potentials depend on the phase of water produced (i.e., liquid or vapor), and in this review it is assumed that water is produced in the condensed (liquid) phase next to the membrane (i.e.,  in equation 6). Since the associated liquid and vapor cell potentials are related by the vapor pressure of water, there is no issue in assuming a vapor product as long as the heat of vaporization/condensation is accounted for in the energy balance.

in equation 6). Since the associated liquid and vapor cell potentials are related by the vapor pressure of water, there is no issue in assuming a vapor product as long as the heat of vaporization/condensation is accounted for in the energy balance.

Model Dimensionality

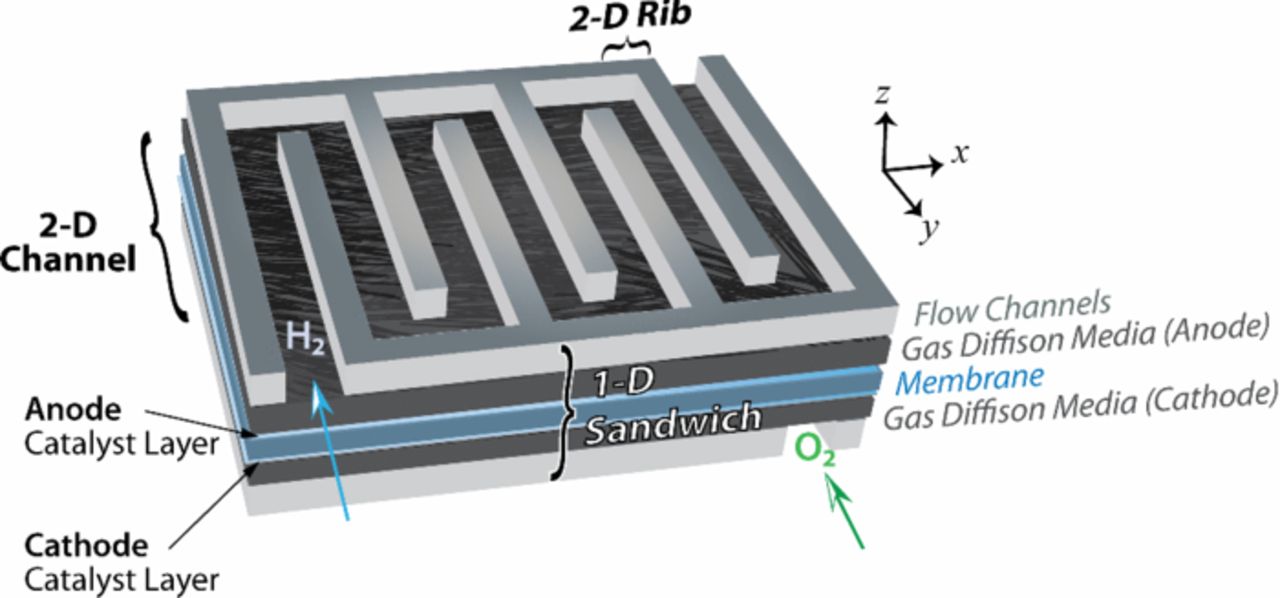

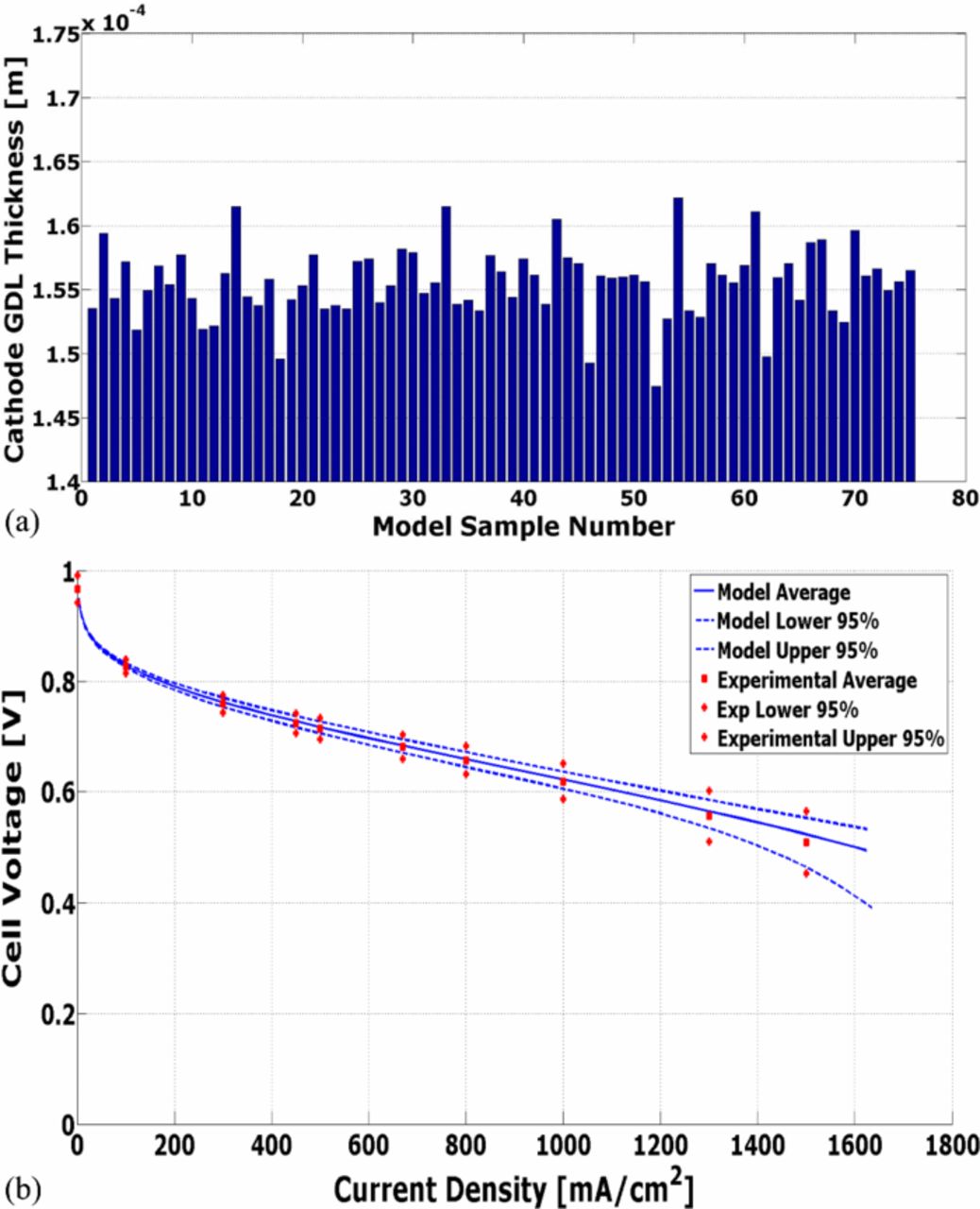

Just as with scale, there is an issue of model dimensionality in that higher dimensional models better represent reality but at a greater computational expense. A lower-dimensionality model sacrifices some spatial fidelity but often allows for more complex physics to be incorporated. Due to increases in computational power, more multi-dimensional models are being employed, with perhaps the ideal tradeoff being the 1+2-D model framework. Figure 2 displays the various model dimensionalities and major cell components.

Figure 2. Schematic of spatial domains and associated modeling including the PEFC sandwich.

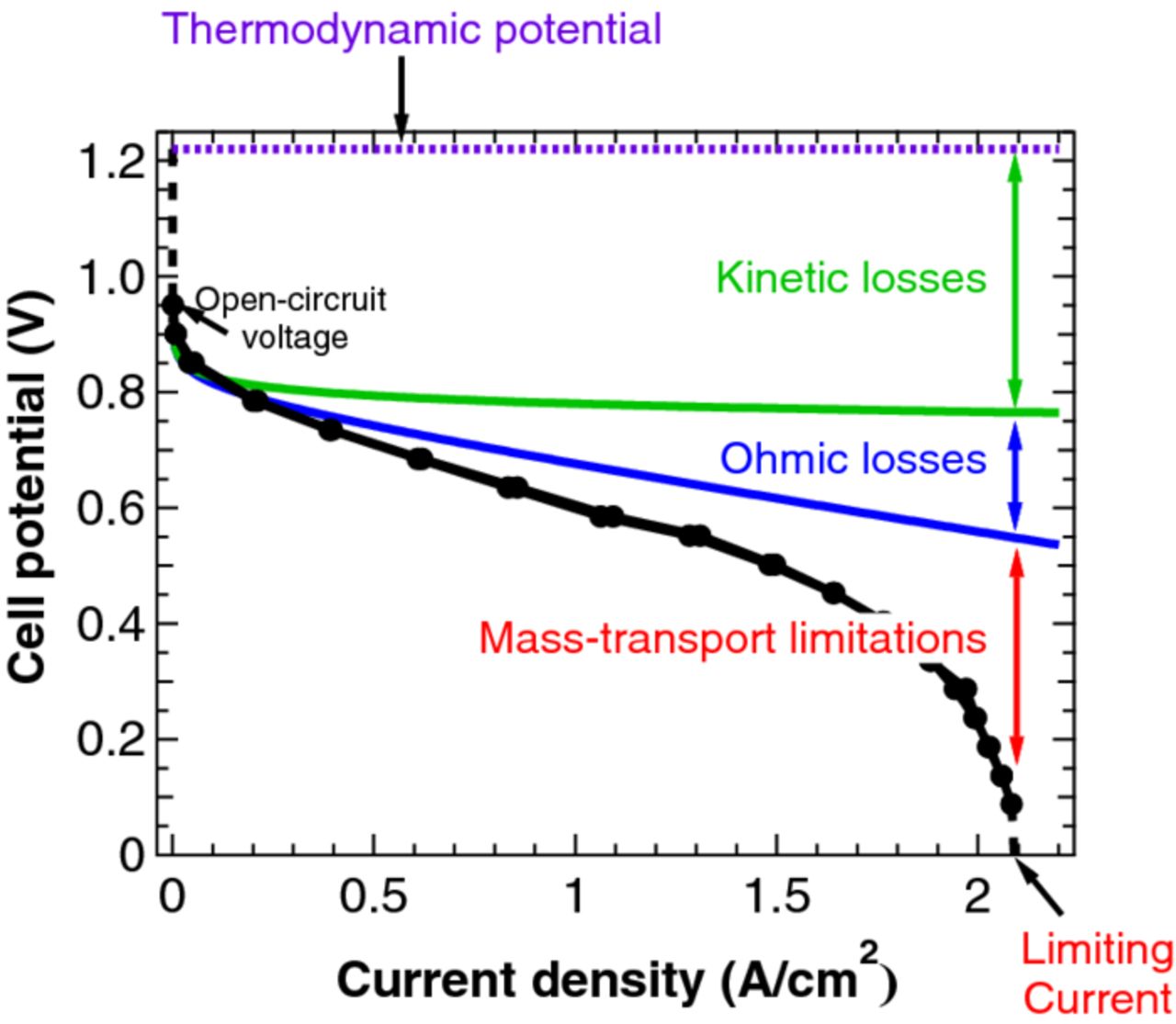

Zero-dimensional (0-D) models relate system variables such as cell voltage, current, temperature, pressure, gas flow rate or any other property using simple empirical correlations without any consideration of the spatial domain. 0-D models are used to determine kinetic and net ohmic resistance parameters from a polarization performance curve.15–22 A typical 0-D model equation for a polarization curve is

![Equation ([7])](https://content.cld.iop.org/journals/1945-7111/161/12/F1254/revision1/jes_161_12_F1254eqn7.jpg)

and accounts for the major losses as shown in Figure 1. The first term on the right corresponds to the thermodynamic cell potential. The second and third terms represent the loss in cell potential to kinetic resistance where b is the effective Tafel slope. The fourth term accounts for the loss to ohmic resistance, R', and the last represents the limiting current caused by concentration overpotential. As 0-D models do not provide fundamental understanding of PEFC operation, they have limited suitability for predicting performance for different operating conditions or optimizing the design. Empirically-based models are often 0-D models and can allow for some prediction of behavior of a specific material set under certain operating windows as discussed below.

Figure 1. Sample polarization curve showing dominant losses.

One dimensional (1-D) models describe the physical phenomena occurring in one spatial dimension typically across the membrane-electrode assembly.23–25 Comprehensive 1-D models incorporate electrochemical reaction at the porous electrodes, transport of gas and liquid species through porous gas-diffusion media (DM) or porous-transport layers (PTLs), and transport of charged species like electrons and protons. Proper interfacial internal boundary conditions are used to couple the different processes across layer boundaries. Along-the-channel 1-D models focus on the transport and depletion of fuel and oxygen along the channel and its effects on current density.

Two-dimensional models use the 1-D model direction and another direction (across-the-channel or along-the-channel).1 Across-the-channel models focus on a cross section of the flow channel including the rib and channel. This approach addresses the effects of the solid rib and channel on the distribution of species such as electrons and water. As the rib is essentially a current and heat collector, its contact with the gas-diffusion layer (GDL) blocks that portion of it to the gas channel. This reduces the mass transport to and from the electrode region directly underneath the rib. Along-the-channel 2-D models incorporate the effect of fuel and oxygen depletion and water accumulation on the current distribution along the channel and across the cell sandwich. Distribution of water, temperature, and reacting species within the PEFC can be predicted by the model. This also helps in understanding the different types of channel configuration and flow direction which cannot be addressed with 1-D modeling. Most of the 2-D models assume that the flow channel can be approximated as a straight channel. Such an assumption may ignore the transport through the porous media under the ribs (e.g., for serpentine channels), but simplifies the model greatly. One can also use arguments of spatial separation to assume that the conditions in the cell sandwich only propagate and interact along the channel and not by internal gradients. This finding led to a group of models referred to as pseudo-2-D or 1+1-D models. Instead of solving the coupled conservation equations in a 2-D domain, the 1-D model is solved at each node along the channel. This reduces the computational requirement without the complexity of solving the equations in a 2-D domain.

The significant decrease in computing costs has promoted complex and computationally intensive numerical modeling including full 3-D models. In addition to understanding distribution of species and current, these models show the distribution of temperature and fluid in the 3-D spatial domain, especially the effect of cooling channels, channel cross section, and channel turn effects. Similar to pseudo 2-D models, there is also a class of models termed pseudo 3-D or 1+2-D. In this formulation, the along-the-channel direction is only interacting at the boundaries between cell components, but instead of 1-D sandwich models, 2-D across-the-channel models are used. Such a structure is probably the best tradeoff between computational cost and model fidelity.

While the above classification is geared more toward macroscale modeling, similar delineations can be made on the microscale, where continuum equations are still used and remain valid. Typically, these models have much smaller domains and are often of higher dimensionality since they are focused on specific phenomena. For example, modeling transport at the local scale of ions through a catalyst layer often requires 2-D and 3-D models to account for the correct geometry and geometry-dependent physics. Finally, one can also examine multiscale models as being multi-dimensional. For example, as mentioned, there are 3-D models at the microscale that can determine properties which are subsequently used in a macroscale model that maybe is a 1-D model. Also, within the porous catalyst layer (see section below), typically one uses an expression or submodel for reaction into the reactive particle as well as across the domain, which, when taken together, can be considered as two separate dimensions.

Empirical-Based Modeling

As discussed above, there is extensive literature on modeling of transport processes in PEFCs and at various dimensions and physics. The approach currently taken by many fuel-cell developers is to first develop a comprehensive database from experiments conducted on a well-defined, representative material system. These experiments focus on in-situ and ex-situ measurement methods with resolution normal to the membrane to quantify transport processes at critical material interfaces, in addition to bulk-phase transport. Based on these component-level studies, models are developed in a simplified computational package that can be effectively used as an engineering tool, for assessment of the effects of material properties, design features, and operating conditions on PEFC performance.26 Such models are often classified as 0-D, although they can contain more detailed descriptions of the physics from the experiments. Thus, the model is of the form

![Equation ([8])](https://content.cld.iop.org/journals/1945-7111/161/12/F1254/revision1/jes_161_12_F1254eqn8.jpg)

where ηHOR is the kinetic loss from the HOR, ηORR is the kinetic loss from the ORR,  is the ohmic loss from electron transport,

is the ohmic loss from electron transport,  is the ohmic loss from proton transport, and ηtx is the mass-transport loss. The reversible potential is often determined empirically from the open-circuit voltage or by a thermodynamic expression. The kinetic overpotentials can be determined based on experimental measurements of Tafel slopes (see equation 7). With regard to transport, researchers are focused on quantifying and modeling the last three transport terms in equation 8, which can be compared to the associated expressions given by equation 7. Electron, ion (proton), and mass transport are all strongly influenced by water transport and early work in collecting these losses for a comprehensive model was limited to operating conditions where the relative humidity (RH) was less than 100% or the impact of liquid-water accumulation was not accounted for explicitly.27 However, because of the effect of even small temperature gradients on water transport and phase change, the thermal transport resistance and the resulting saturation gradients are now being considered in parametric fuel-cell models.28,29 Below, we detail the various expressions and touch on empirical methods to obtain them.

is the ohmic loss from proton transport, and ηtx is the mass-transport loss. The reversible potential is often determined empirically from the open-circuit voltage or by a thermodynamic expression. The kinetic overpotentials can be determined based on experimental measurements of Tafel slopes (see equation 7). With regard to transport, researchers are focused on quantifying and modeling the last three transport terms in equation 8, which can be compared to the associated expressions given by equation 7. Electron, ion (proton), and mass transport are all strongly influenced by water transport and early work in collecting these losses for a comprehensive model was limited to operating conditions where the relative humidity (RH) was less than 100% or the impact of liquid-water accumulation was not accounted for explicitly.27 However, because of the effect of even small temperature gradients on water transport and phase change, the thermal transport resistance and the resulting saturation gradients are now being considered in parametric fuel-cell models.28,29 Below, we detail the various expressions and touch on empirical methods to obtain them.

Electronic resistance

The ohmic loss associated with the mobility of electrons is most strongly influenced by the contact resistances between the various diffusion layers with only a small contribution from the through-plane bulk electrical resistance. This resistance can be measured using the as-made GDM, typically consisting of both the GDL and microporous layer (MPL). To measure the resistance, two sheets of GDL with the MPLs facing each other are placed in a fixture with compression plates made of the flow field (current collector) material and geometry.30 For a given stress, this experiment results in a lumped electrical resistance that consists of all contact resistances along with the weighted average of the through-plane and in-plane bulk resistances as they apply to the flowfield geometry. For a more detailed model or multi-dimensional approaches, the in-plane and contact resistances are measured independently.31 The bulk electrical resistance in the relatively thin electrode is negligible.

Protonic resistance

In addition to the electronic resistance through the solid phase, the protonic resistance through the PEM is part of the total ohmic resistance. The protonic resistance has a strong dependence on the RH in the adjacent electrodes and is only a weak function of temperature.32 The membrane conductance as it varies with RH can be characterized by in-situ33 or ex-situ34 methods. Furthermore, the sum of the electronic and protonic resistances is normally validated with AC impedance at high frequency during PEFC experiments at various operating conditions.

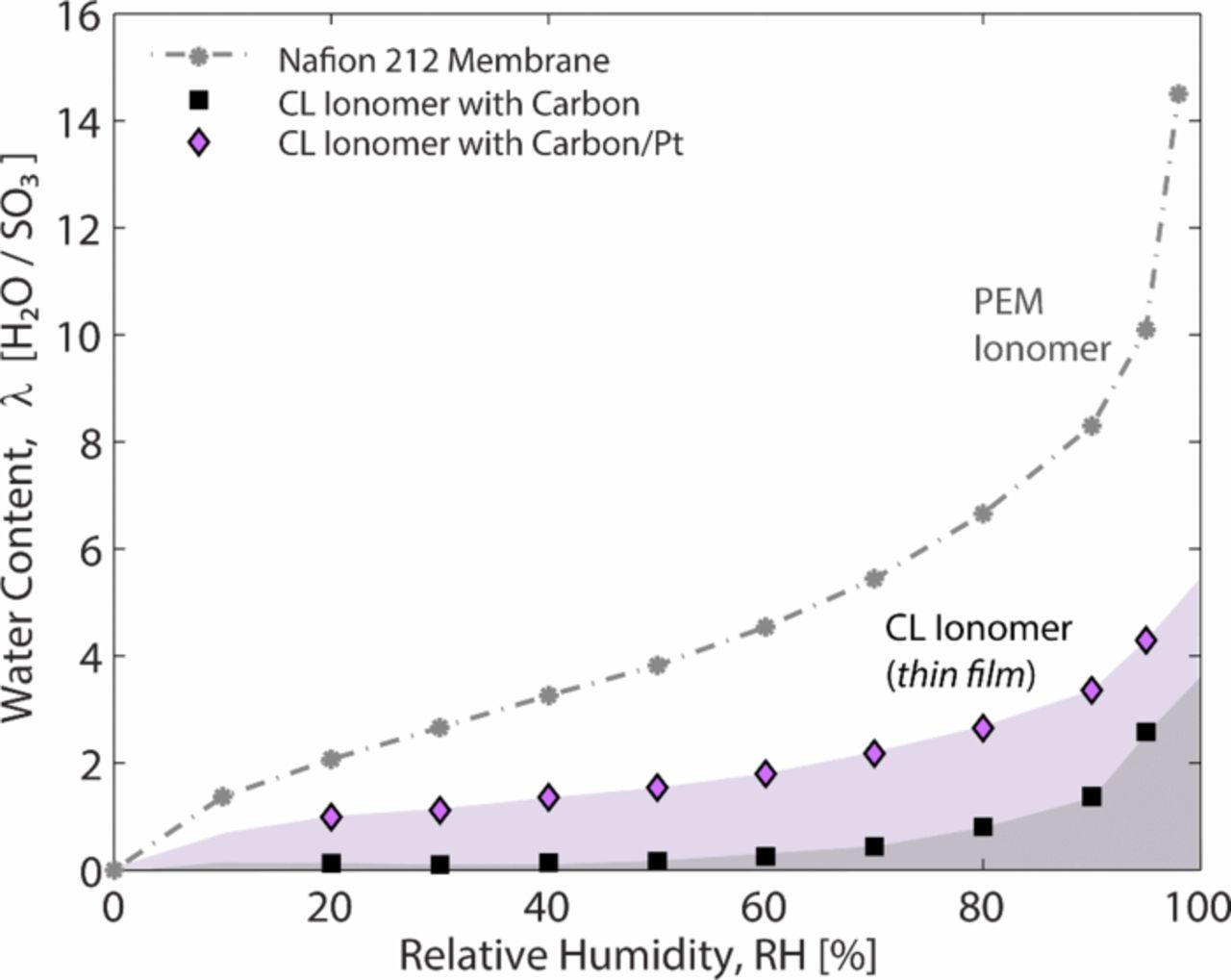

Resistance to proton transport also occurs in the dispersed electrodes where a thin film of electrolyte is responsible for a lateral transport relative to the membrane plane. In addition to being a function of RH (as with the membrane), this resistance is also dependent on current density due to the variation in electrode utilization depth as current draw increases.35 The electrode effectiveness can be modeled theoretically with Tafel kinetics, and this is used to correct an area-based proton resistance in the anode and cathode electrodes which is commonly measured with H2/N2 AC impedance32 and an associated transmission-line model.36 This method of characterizing the proton resistance in the electrode requires an assumption of uniform ionomer film thickness and connectivity. The ionomer film is difficult to characterize, and if this film was discontinuous with significant variations in thickness, the idealized proton resistance would under-predict the loss associated with proton mobility in the electrode. The ionomer film and its associated effects are discussed in more detail in a later section.

Thermal resistance

All of the voltage loss terms in equation 8 have some functionality with temperature. To predict accurately the reaction kinetics and the gas composition at the catalyst surface, the temperature profile through the PEFC sandwich must be established. There are several methods for characterizing the bulk and contact resistances of PEFC components as reviewed by Zamel and Li37 and Wang et al.6 The total thermal resistance is used to solve the heat equation in one of two dimensions based on the heat flux from the cathode catalyst layer. At high RH conditions, where proton resistance is minimized along with the product water flux from the cathode catalyst layer, such an analysis elucidates regions of phase change within the open volume of the diffusion layers and gas-delivery channels.

Diffusion resistance

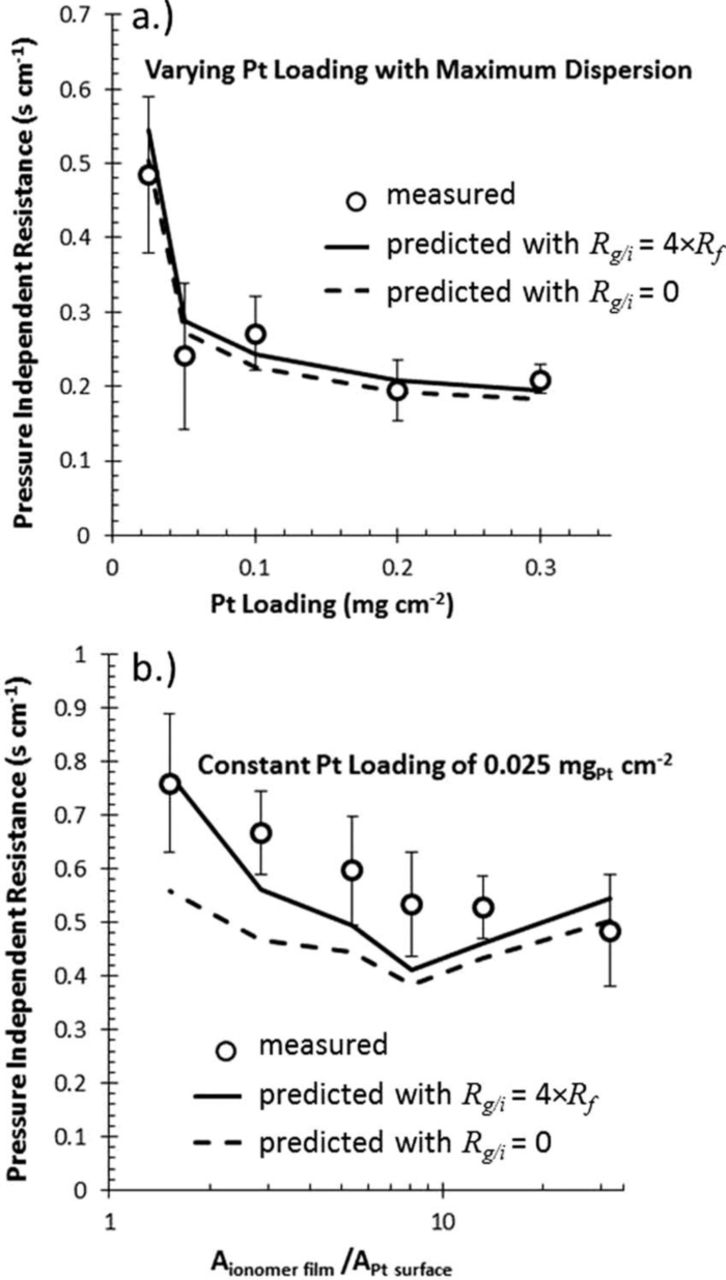

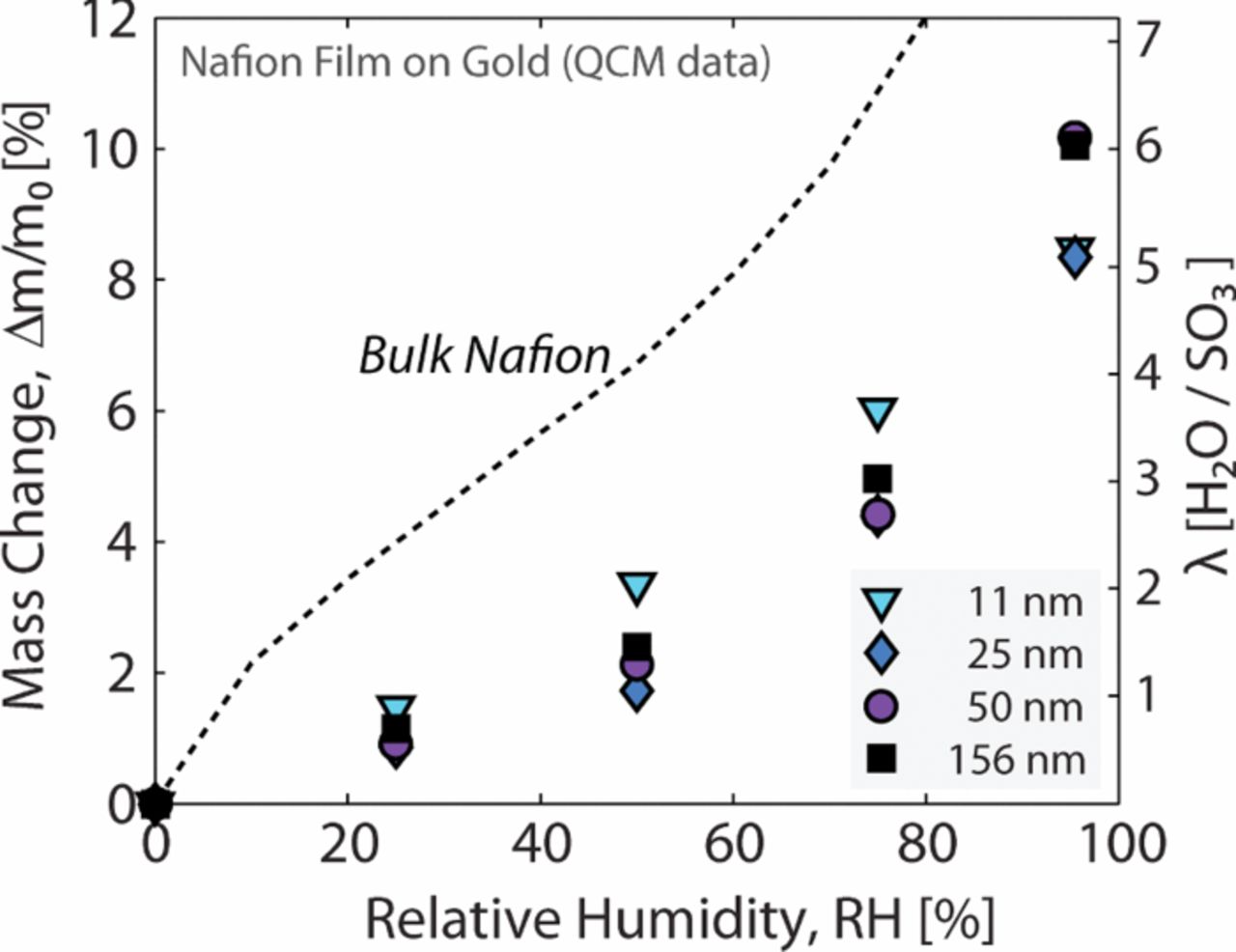

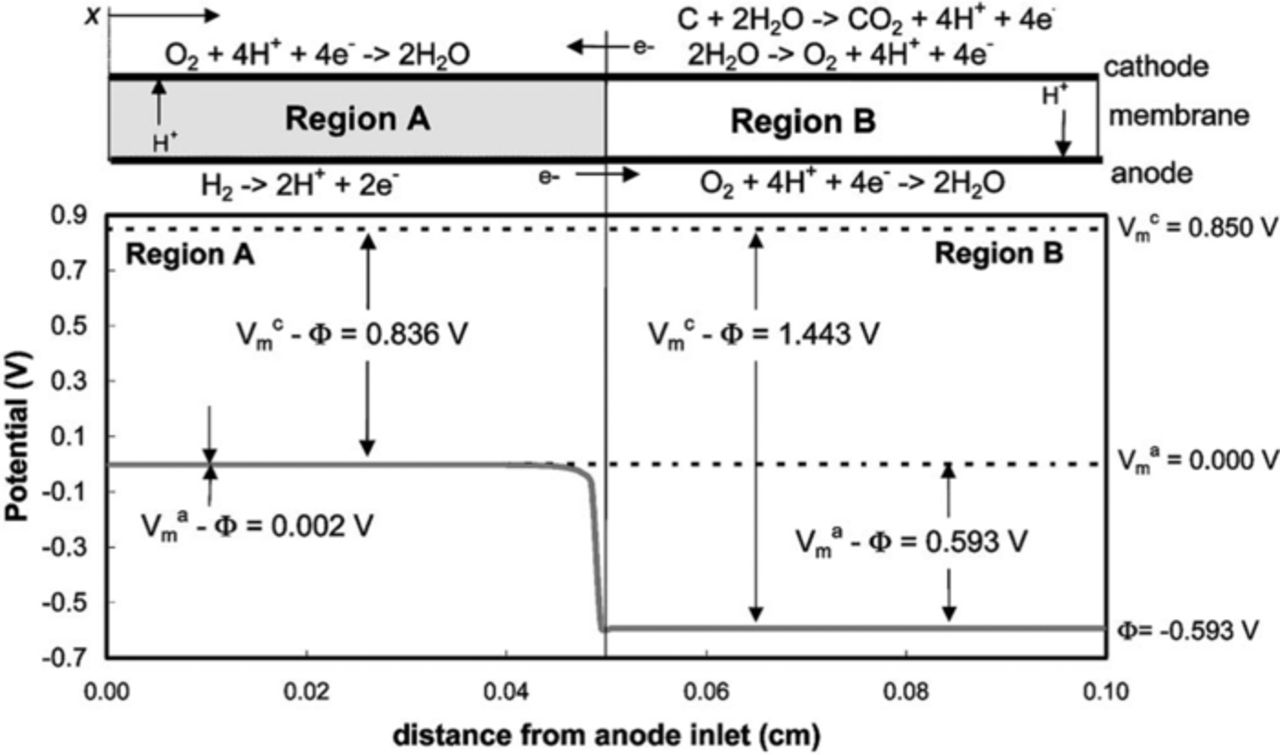

There are several length scales for which diffusion resistance must be characterized. For a given total pressure in the flow channel, the first resistance to mass transport is encountered at the GDL interface. The convective mass-transfer coefficient, computed from the Sherwood number for a given flow rate and channel geometry is used for single-phase conditions in the channel.38 The impact of liquid water in the gas channel is accomplish with a modified Sherwood number39 and by reducing the gas contact area using a surface-coverage ratio.40 In the GDM, the characterization of diffusion and governing parameters has been accomplished using various experiments combined with simple limiting-current or Fickian-type diffusion equations to get the values for use in equation 7 or 8.41–44 A more direct in-situ measurement of oxygen diffusion resistance has been presented in previous work by Baker et al.38 and Caulk et al.45 that established a method and analysis using limiting-current measurements under dry and oversaturated conditions for use in equation 7 or 8. Although these measurements result in a diffusion resistance while a two-phase condition exists in the PEFC assembly, the degree of saturation and its distribution is unknown; as a result, a direct correlation between saturation and the resulting change in the diffusion resistance is required to validate a simplified saturation model. The limiting-current analysis developed by Baker et al. can also be used to isolate the pressure-independent component of diffusion resistance (i.e., Knudsen diffusion and interfacial resistance through water/ionomer (combined with Henry's law)).38 Studies have shown that this interfacial resistance is a significant component of voltage loss as it scales with reduced platinum loading and that it is much higher than expected based on oxygen permeability through bulk ionomer as discussed in more detail in another section below.46–49 Currently in a parametric model, this resistance is accounted for by using an unrealistically thick ionomer or electrolyte layer with bulk ionomer (membrane) transport properties.

Membrane transport

Accurate prediction of the reactant partial pressure at the catalyst surface requires the solution of species throughout the PEFC assembly which is beyond the scope of empirical models. Although the thermal, electronic, protonic, and gas-phase transport resistances can be characterized, the water balance between the anode and cathode due to water permeation through the electrolyte must be accounted for. This water balance also complicates the prediction of phase change and most of the components of transport resistance are a function of the local liquid-water content. The key is to determine the net flux of water through the ionomer, which is a function of different driving forces including chemical potential and electro-osmosis driven by proton movement.50 For chemical-potential driven flow, there is still debate over the values of the transport coefficients and the possible existence of a humidity-dependent interfacial resistance in the membrane, where there is experimental support on both sides of the issue.51–68 The value of the electro-osmotic coefficient also varies significantly in literature,69–71 and since it scales with current density it plays a critical role in predicting the water balance. Given the above difficulties, many parametric models use an empirical effective electro-osmotic coefficient.

Along-the-channel solution

The various resistances described above are assembled in a through-plane model with boundary conditions at the flow distributors that include total pressure, species concentration, temperature, and a reference potential of 0 V at the anode current collector. The cathode current collector potential is calculated based on equation 8, where electronic and protonic resistances are used to predict the ohmic losses and the diffusion and thermal resistances are used to predict the species partial pressures and temperature in the catalyst layers for calculation of the half-cell potentials, reaction kinetics, and membrane transport. This is typically solved in 1-D with average values over the geometric features.

Practical PEFC stacks have significant variation in the channel boundary conditions from the inlet to the outlet. To account for this, the parametric model is applied along-the-channel, assuming equipotential current collectors or by using a correlation for lateral potential difference through the current collector. This solution requires an accurate prediction of flow resistance in the channel. Although straight-forward for single-phase conditions, a two-phase pressure differential correlation is required once the flow distributor condition exceeds 100% RH.72–75 Additionally, PEFC systems typically operate with hydrogen stoichiometric ratios greater than 1.0, thereby requiring a methodology for recirculating exhaust anode flow. In this case the nitrogen and water content in the anode flow distributor due to crossover through the membrane must be accounted for as the diluted hydrogen feed stream will impact performance.

Basic Governing Equations

The above sections describe the methodologies and dimensionalities for modeling PEFCs based on a good amount of empiricism. To model PEFC behavior with more detailed physics at the continuum scale requires the use of overall conservation equations for mass, momentum, energy, and charge transport within the various subdomains or components. In addition, there is a need for expressions for overall kinetics and thermodynamics. The general physics equations are more or less known and used in their general forms, with the complications arising from the need to determine the correct boundary conditions, effective properties, and related transfer expressions. In this section, the general governing equations are presented including the conservation laws along with the general, well-known transport equations. As mentioned, the equations presented below have not necessarily been used as is since they represent generalized forms of specific modeling approaches in order to be concise and show the generality of the phenomena being modeled. Also, no model has really used all of the governing equations below as most focus on certain aspects; however, we believe that these equations should be used and are the foundation for the more detailed discussions in subsequent sections.

For a control segment, the general conservation equation for property ψ, representing any of the aforementioned transport processes, can be written as

![Equation ([9])](https://content.cld.iop.org/journals/1945-7111/161/12/F1254/revision1/jes_161_12_F1254eqn9.jpg)

The first term represents the time-dependent property and is neglected for description of steady-state operation, which is the favored approach to understand the mechanisms involved. However when it comes to application-specific models – such as automobile applications involving start-stop cycles – dynamic models are better suited. While a vast majority of PEFC models are steady-state models, there are transient models that address specific transient phenomena such as degradation mechanism,76,77 contamination effects,78 dynamic load-change effects,79,80 operational anomalies, and start-stop cycles and freeze start,5,81,82 and describe the transition of properties or system variables affecting PEFC operation.

The second term in equation 9 represents the change in the property ψ due to flux (N) of ψ into or out of the control segment under study. The flux denotes the transfer of property driven by imbalances within the system and is the result of system adjusting itself to bring certain equilibrium.

The third term (S) called the source term represents all of the processes that cause generation or decay of the property within the control segment. For example, a supersaturated vapor phase may condense within the control segment and leads to a decrease in vapor-phase concentration and an increase in liquid-phase concentration. This term incorporates all other terms such as reaction terms and phase-change terms that are not captured by the flux. The term couples different conservation laws within the segment.

Material transport

The conservation of material can be written as in equation 9 except that the physical quantity ψ could be p – partial pressure of a gas, c – concentration in solution, x – mole fraction of a particular species, w – mass fraction of a particular species, or ρ – density of a fluid. However, for the case of a mixture in a multiphase system, it is necessary to write material balances for each component in each phase k, which in summation governs the overall conservation of material,

![Equation ([10])](https://content.cld.iop.org/journals/1945-7111/161/12/F1254/revision1/jes_161_12_F1254eqn10.jpg)

In the above expression, ɛk is the volume fraction of phase k, ci,k is the concentration of species i in phase k, and si,k,l is the stoichiometric coefficient of species i in phase k participating in heterogeneous reaction l, ak,p is the specific surface area (surface area per unit total volume) of the interface between phases k and p, and ih,l-k is the normal interfacial current transferred per unit interfacial area across the interface between the electronically conducting phase and phase k due to electron-transfer reaction h and is positive in the anodic direction. It should be noted that the above equation is a generalized form that covers what almost all models use for the material balance, albeit with specific terms substituted for the general ones as discussed in the next sections.

The term on the left side of the equation is the accumulation term, which accounts for the change in the total amount of species i held in phase k within a differential control volume over time. The first term on the right side of the equation keeps track of the material that enters or leaves the control volume by mass transport as discussed in later sections. The remaining three terms account for material that is gained or lost (i.e., source terms, Sψ, in equation 9). The first summation includes all electron-transfer reactions that occur at the interface between phase k and the electronically conducting phase 1; the second summation accounts for all other interfacial processes that do not include electron transfer like evaporation or condensation; and the final term accounts for homogeneous chemical reactions in phase k. It should be noted that in terms of an equation count, for n species there are only n−1 conservation equations (where n is the number of components) needed since one can be replaced by the sum of the other ones, or, similarly, by the fact that the sum of the concentrations equals the total concentration (i.e., sum of mole fractions equals 1),

![Equation ([11])](https://content.cld.iop.org/journals/1945-7111/161/12/F1254/revision1/jes_161_12_F1254eqn11.jpg)

where cT, k is the total concentration of species in phase k.

In the above material balance (equation 10), one needs an expression for the flux or transport of material. Often, this expression stems from considering only the interactions of the various species with the solvent

![Equation ([12])](https://content.cld.iop.org/journals/1945-7111/161/12/F1254/revision1/jes_161_12_F1254eqn12.jpg)

where Deffi is the effective diffusion coefficient of species i in the gas mixture and v*k is the molar-averaged velocity of phase k

![Equation ([13])](https://content.cld.iop.org/journals/1945-7111/161/12/F1254/revision1/jes_161_12_F1254eqn13.jpg)

Substitution of equation 12 into equation 10 results in the equation for convective diffusion,

![Equation ([14])](https://content.cld.iop.org/journals/1945-7111/161/12/F1254/revision1/jes_161_12_F1254eqn14.jpg)

which is often used (or its analogous mass-based form) in simulations. In the above expressions, the reaction source terms are not shown explicitly, and the superscript 'eff' is used to denote an effective diffusion coefficient due to different phenomena or phases as discussed later in this review. For example, to account for Knudsen diffusion primarily in the MPLs and catalyst layers, one can use a diffusion coefficient that is a parallel resistance83

![Equation ([15])](https://content.cld.iop.org/journals/1945-7111/161/12/F1254/revision1/jes_161_12_F1254eqn15.jpg)

where the Knudsen diffusivity is given by

![Equation ([16])](https://content.cld.iop.org/journals/1945-7111/161/12/F1254/revision1/jes_161_12_F1254eqn16.jpg)

where d is the pore diameter and Mi is the molar mass of species i. This diffusion coefficient is independent of pressure whereas ordinary diffusion coefficients have an inverse dependence on pressure. Additionally, the diffusion coefficient is often modified for the tortuosity or path length required for the diffusion to occur in a multiphase system,

![Equation ([17])](https://content.cld.iop.org/journals/1945-7111/161/12/F1254/revision1/jes_161_12_F1254eqn17.jpg)

where τk is the tortuosity of phase k and is greater than 1.

If the interactions among the various species are important, then equation 12 needs to be replaced with the multicomponent Stefan-Maxwell equations that account for binary interactions among the various species

![Equation ([18])](https://content.cld.iop.org/journals/1945-7111/161/12/F1254/revision1/jes_161_12_F1254eqn18.jpg)

where xi is the mole fraction of species i and Deffi, j is the effective binary diffusion coefficient between species i and j. The first term on the right side accounts for pressure diffusion (e.g., in centrifugation) which often can be ignored, but, on the anode side, the differences between the molar masses of hydrogen and water vapor means that it can become important in certain circumstances.84 The second term on the right side stems from the binary collisions between various components. For a multicomponent system, equation 18 results in the correct number of transport properties that must be specified to characterize the system, ½n(n−1), where the ½ is because Deffi, j = Dj, ieff by the Onsager reciprocal relations. Finally, the third term on the right side represents Knudsen diffusion effects when incorporated rigorously and using the solid phase as the reference velocity.85

The form of equation 18 is essentially an inverted form of the type of equation 12, since one is not writing the flux in terms of a material gradient but the material gradient in terms of the flux. This is not a problem if one is solving the equations as written; however, many numerical packages require a second-order differential equation (e.g., see equation 14). To do this with the Stefan-Maxwell equations, inversion of them is required. For a two-component system where the pressure-diffusion is negligible, one arrives at equation 12. For higher numbers of components, the inversion becomes cumbersome and analytic expressions are harder to obtain, resulting oftentimes in numerical inversion. In addition, the inversion results in diffusion coefficients which are more composition dependent. For example, Bird et al. show the form for a three-component system.86

Finally, in addition to the above equation set, other models have been proposed including the binary friction model that uses a single equation by combining Darcy's law directly into the Stefan-Maxwell framework.87 Using this model, a governing equation for each species can be used instead of a mixture equation and n−1 species transport equations, thereby enabling the use of individual species viscosity instead of a mixture average viscosity. The combined Fick's and Darcy model, Stefan-Maxwell, and binary-friction models were recently compared.88

Charge transport

The conservation equation for charged species is an extension of the conservation of mass. Taking equation 10 and multiplying by ziF and summing over all species and phases while noting that all reactions are charge balanced yields

![Equation ([19])](https://content.cld.iop.org/journals/1945-7111/161/12/F1254/revision1/jes_161_12_F1254eqn19.jpg)

where the volumetric charge density and areal current density can be defined by

![Equation ([20])](https://content.cld.iop.org/journals/1945-7111/161/12/F1254/revision1/jes_161_12_F1254eqn20.jpg)

and

![Equation ([21])](https://content.cld.iop.org/journals/1945-7111/161/12/F1254/revision1/jes_161_12_F1254eqn21.jpg)

respectively. Because a large electrical force is required to separate charge over an appreciable distance, a volume element in the electrode will, to a good approximation, be electrically neutral; thus one can assume electroneutrality for each phase

![Equation ([22])](https://content.cld.iop.org/journals/1945-7111/161/12/F1254/revision1/jes_161_12_F1254eqn22.jpg)

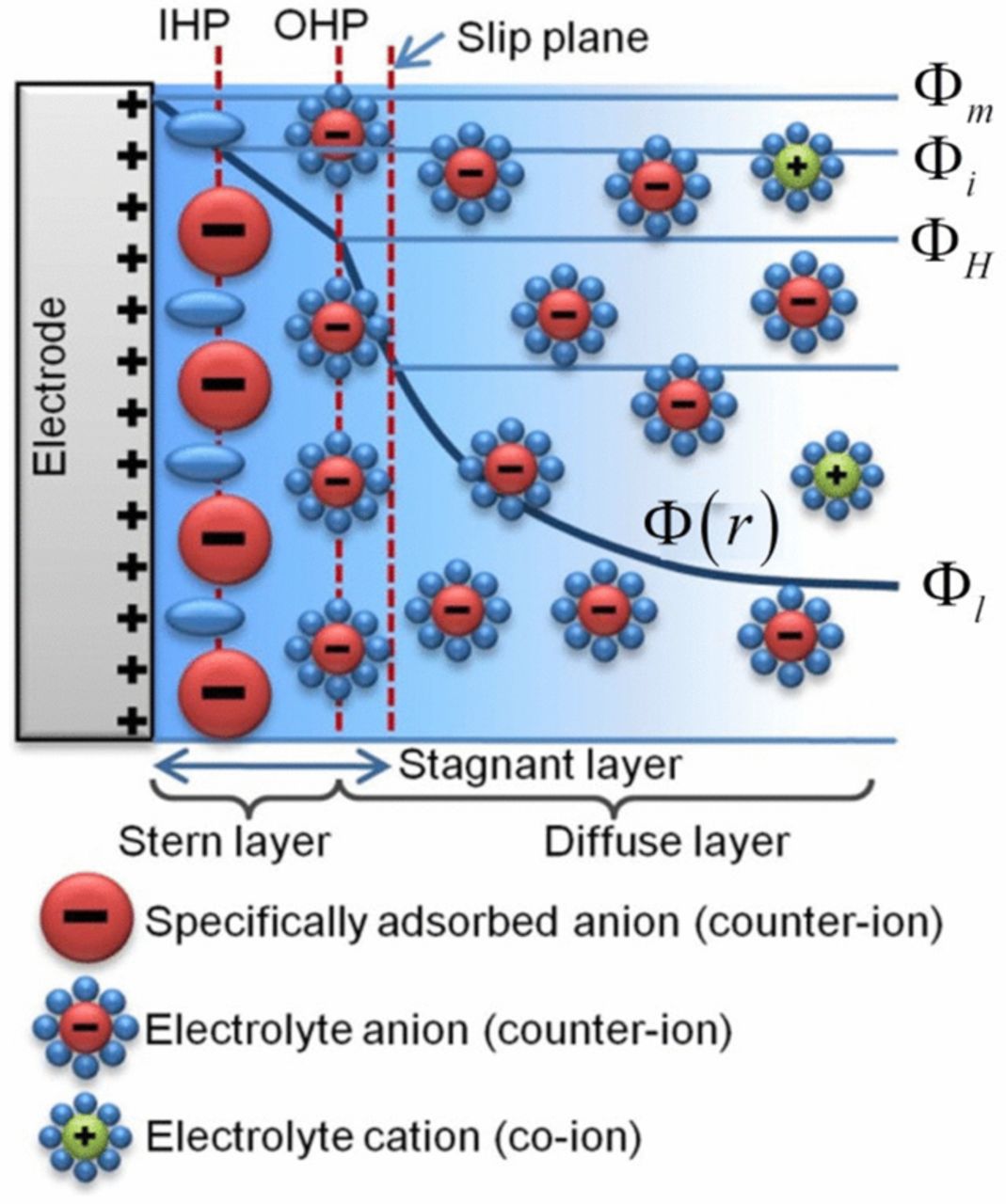

The assumption of electroneutrality implies that the diffuse double layer, where there is significant charge separation, is small compared to the volume of the domain, which is normally (but not necessarily always as discussed later) the case. The general charge balance (equation 19), assuming electroneutrality and the current definition (equation 21) becomes

![Equation ([23])](https://content.cld.iop.org/journals/1945-7111/161/12/F1254/revision1/jes_161_12_F1254eqn23.jpg)

While this relationship applies for almost all of the modeling, there are cases where electroneutrality does not strictly hold, including for some transients and impedance measurements, where there is charging and discharging of the double layer, as well as simulations at length scales within the double layer (typically on the order of nanometers) such as reaction models near the electrode surface. For these cases, the correct governing charge conservation results in Poisson's equation,

![Equation ([24])](https://content.cld.iop.org/journals/1945-7111/161/12/F1254/revision1/jes_161_12_F1254eqn24.jpg)

where ɛ0 is the permittivity of the medium. For the diffuse part of the double layer, often a Boltzmann distribution is used for the concentration of species i

![Equation ([25])](https://content.cld.iop.org/journals/1945-7111/161/12/F1254/revision1/jes_161_12_F1254eqn25.jpg)

where Φ is the potential as referenced to the bulk solution (i.e., having concentration ci, ∞). To charge this double layer, one can derive various expressions for the double-layer capacitance depending on the adsorption type, ionic charges, etc.,89 where the differential double-layer capacitance is defined as

![Equation ([26])](https://content.cld.iop.org/journals/1945-7111/161/12/F1254/revision1/jes_161_12_F1254eqn26.jpg)

where q is the charge in the double layer and the differential is at constant composition and temperature. To charge the double layer, one can write an equation of the form

![Equation ([27])](https://content.cld.iop.org/journals/1945-7111/161/12/F1254/revision1/jes_161_12_F1254eqn27.jpg)

where the charging current will decay with time as the double layer becomes charged.

For the associated transport of charge, models can use either a dilute-solution or concentrated-solution approach. In general, the concentrated-solution approach is more rigorous but requires more knowledge of all of the various interactions (similar to the material-transport-equation discussion above). For the dilute-solution approach, one can use the Nernst-Planck equation,

![Equation ([28])](https://content.cld.iop.org/journals/1945-7111/161/12/F1254/revision1/jes_161_12_F1254eqn28.jpg)

where ui is the mobility of species i in phase k. In the equation, the terms on the right side correspond to migration, diffusion, and convection, respectively. Multiplying equation 28 by ziF and summing over the species i in phase k,

![Equation ([29])](https://content.cld.iop.org/journals/1945-7111/161/12/F1254/revision1/jes_161_12_F1254eqn29.jpg)

and noting that the last term is zero due to electroneutrality (convection of a neutral solution cannot move charge) and using the definition of current density (equation 21), one gets

![Equation ([30])](https://content.cld.iop.org/journals/1945-7111/161/12/F1254/revision1/jes_161_12_F1254eqn30.jpg)

where κk is the conductivity of the solution of phase k

![Equation ([31])](https://content.cld.iop.org/journals/1945-7111/161/12/F1254/revision1/jes_161_12_F1254eqn31.jpg)

When there are no concentration variations in the solution, equation 30 reduces to Ohm's law,

![Equation ([32])](https://content.cld.iop.org/journals/1945-7111/161/12/F1254/revision1/jes_161_12_F1254eqn32.jpg)

This dilute-solution approach does not account for interaction between the solute molecules. Also, this approach will either use too many or too few transport coefficients depending on if the Nernst-Einstein relationship is used to relate mobility and diffusivity,

![Equation ([33])](https://content.cld.iop.org/journals/1945-7111/161/12/F1254/revision1/jes_161_12_F1254eqn33.jpg)

which only rigorously applies at infinite dilution. Thus, concentrated-solution theory is preferred unless there are too many unknown parameters and transport properties.

The concentrated-solution approach for charge utilizes the same underpinnings as that of the Stefan-Maxwell equation, which starts with the original equation of multicomponent transport90

![Equation ([34])](https://content.cld.iop.org/journals/1945-7111/161/12/F1254/revision1/jes_161_12_F1254eqn34.jpg)

where di is the driving force per unit volume acting on species i and can be replaced by a electrochemical-potential gradient of species i, and Ki, j are the frictional interaction parameters between species i and j. The above equation can be analyzed in terms of finding expressions for the Ki,j's, introducing the concentration scale including reference velocities and potential definition, or by inverting the equations and correlating the inverse friction factors to experimentally determined properties. If one uses a diffusion coefficient to replace the drag coefficients,

![Equation ([35])](https://content.cld.iop.org/journals/1945-7111/161/12/F1254/revision1/jes_161_12_F1254eqn35.jpg)

where  is an interaction parameter between species i and j based on a thermodynamic driving force, then the multicomponent equations look very similar to the Stefan-Maxwell ones (equation 18). In addition, using the above definition for Ki,j and assuming that species i is a minor component and that the total concentration, cT, can be replaced by the solvent concentration (species 0), then equation 34 for species i in phase k becomes

is an interaction parameter between species i and j based on a thermodynamic driving force, then the multicomponent equations look very similar to the Stefan-Maxwell ones (equation 18). In addition, using the above definition for Ki,j and assuming that species i is a minor component and that the total concentration, cT, can be replaced by the solvent concentration (species 0), then equation 34 for species i in phase k becomes

![Equation ([36])](https://content.cld.iop.org/journals/1945-7111/161/12/F1254/revision1/jes_161_12_F1254eqn36.jpg)

This equation is very similar to the Nernst-Planck equation 28, except that the driving force is the thermodynamic electrochemical potential, which contains both the migration and diffusive terms.

Transport in the membrane

For the special case of the PEM (subscript 2), concentrated-solution theory can be used to obtain91

![Equation ([37])](https://content.cld.iop.org/journals/1945-7111/161/12/F1254/revision1/jes_161_12_F1254eqn37.jpg)

and

![Equation ([38])](https://content.cld.iop.org/journals/1945-7111/161/12/F1254/revision1/jes_161_12_F1254eqn38.jpg)

where ξ is the electro-osmotic coefficient and is defined as the ratio of flux of water to the flux of protons in the absence of concentration gradients, α is the transport parameter that can be related to a hydraulic pressure or concentration gradient through the chemical-potential driving force,50

![Equation ([39])](https://content.cld.iop.org/journals/1945-7111/161/12/F1254/revision1/jes_161_12_F1254eqn39.jpg)

where aw,  , and p are the activity, molar volume, and hydraulic pressure of water, respectively. As mentioned, there is still a lot of debate over the functional forms of the transport properties of the membrane, as well as the existence of a possible interfacial resistance.51–68,92,93 To account for such an interface, the membrane water-uptake boundary condition is altered to include a mass-transfer coefficient instead of assuming an equilibrium isotherm directly

, and p are the activity, molar volume, and hydraulic pressure of water, respectively. As mentioned, there is still a lot of debate over the functional forms of the transport properties of the membrane, as well as the existence of a possible interfacial resistance.51–68,92,93 To account for such an interface, the membrane water-uptake boundary condition is altered to include a mass-transfer coefficient instead of assuming an equilibrium isotherm directly

![Equation ([40])](https://content.cld.iop.org/journals/1945-7111/161/12/F1254/revision1/jes_161_12_F1254eqn40.jpg)

where in and out refer to the water activities directly inside and outside of the membrane interface (which can be defined from Flory-Rehner equation in the polymer94 and the relative humidity in the gas phase, respectively) and kmt is a mass-transfer coefficient that can be a function of local conditions (e.g., humidity, temperature, gas-velocity, etc.).51,52,54,58,61,62,64–68,92,93 This approach is the same as including a surface reaction (e.g., condensation) at the membrane interface,95–97 and is not as often used in modeling as perhaps it should be. One caveat to the above is that it must be used in such a way that the activity is defined at at least one boundary of the membrane in order to avoid multiple solutions.

Momentum transport

Due to the highly coupled nature of momentum conservation and transport, both are discussed below. Also, the momentum or volume conservation equation is highly coupled to the mass or continuity conservation equation (equation 10). Newton's second law governs the conservation of momentum and can be written in terms of the Navier-Stokes equation83

![Equation ([41])](https://content.cld.iop.org/journals/1945-7111/161/12/F1254/revision1/jes_161_12_F1254eqn41.jpg)

where μk and vk are the viscosity and mass-averaged velocity of phase k (equation 13), respectively. The transient term in the momentum conservation equation represents the accumulation of momentum with time and the second term describes convection of the momentum flux (which is often small for PEFC designs). The first two terms on the right side represent the divergence of the stress tensor and the last term represents other sources of momentum, typically other body forces like gravity or magnetic forces. However for PEFCs, these forces are often ignored and unimportant, i.e. Sm = 0.

It should be noted that for porous materials and multiphase flow, as discussed below, the Navier-Stokes equations are not used and instead one uses the empirical Darcy's law for the transport equation (where gravity has been neglected),98,99

![Equation ([42])](https://content.cld.iop.org/journals/1945-7111/161/12/F1254/revision1/jes_161_12_F1254eqn42.jpg)

where vk is the mass-averaged velocity of phase k

![Equation ([43])](https://content.cld.iop.org/journals/1945-7111/161/12/F1254/revision1/jes_161_12_F1254eqn43.jpg)

This transport equation can be used as a first-order equation or combined with a material balance (equation 10) to yield

![Equation ([44])](https://content.cld.iop.org/journals/1945-7111/161/12/F1254/revision1/jes_161_12_F1254eqn44.jpg)

which is similar to including it as a dominant source term. In the above expression, kk is effective permeability of phase k.

Energy transport

Throughout all layers of the PEFC, the same transport and conservation equations exist for energy with the same general transport properties, and only the source terms vary. The conservation of thermal energy can be written as

![Equation ([45])](https://content.cld.iop.org/journals/1945-7111/161/12/F1254/revision1/jes_161_12_F1254eqn45.jpg)

In the above expression, the first term represents the accumulation and convective transport of enthalpy, where  is the heat capacity of phase k which is a combination of the various components of that phase. The second term is energy due to reversible work. For condensed phases this term is negligible, and an order-of-magnitude analysis for ideal gases with the expected pressure drop in a PEFC demonstrates that this term is negligible compared to the others. The first two terms on the right side of equation 45 represent the net heat input by conduction and interphase transfer. The first is due to heat transfer between two phases

is the heat capacity of phase k which is a combination of the various components of that phase. The second term is energy due to reversible work. For condensed phases this term is negligible, and an order-of-magnitude analysis for ideal gases with the expected pressure drop in a PEFC demonstrates that this term is negligible compared to the others. The first two terms on the right side of equation 45 represent the net heat input by conduction and interphase transfer. The first is due to heat transfer between two phases

![Equation ([46])](https://content.cld.iop.org/journals/1945-7111/161/12/F1254/revision1/jes_161_12_F1254eqn46.jpg)

where hk, p is the heat-transfer coefficient between phases k and p per interfacial area. Most often this term is used as a boundary condition since it occurs only at the edges. However, in some modeling domains it may need to be incorporated as above. The second term is due to the heat flux in phase k

![Equation ([47])](https://content.cld.iop.org/journals/1945-7111/161/12/F1254/revision1/jes_161_12_F1254eqn47.jpg)

where  is the partial molar enthalpy of species i in phase k, Ji, k is the flux density of species i relative to the mass-average velocity of phase k

is the partial molar enthalpy of species i in phase k, Ji, k is the flux density of species i relative to the mass-average velocity of phase k

![Equation ([48])](https://content.cld.iop.org/journals/1945-7111/161/12/F1254/revision1/jes_161_12_F1254eqn48.jpg)

and  is the effective thermal conductivity of phase k, which is averaged over the various phases.1,100–106 The third term on the right side of equation 45 represents viscous dissipation, the heat generated by viscous forces, where τ is the stress tensor. This term is also small, and for most cases can be neglected. The fourth term on the right side comes from enthalpy changes due to diffusion. Finally, the last term represents the change in enthalpy due to reaction

is the effective thermal conductivity of phase k, which is averaged over the various phases.1,100–106 The third term on the right side of equation 45 represents viscous dissipation, the heat generated by viscous forces, where τ is the stress tensor. This term is also small, and for most cases can be neglected. The fourth term on the right side comes from enthalpy changes due to diffusion. Finally, the last term represents the change in enthalpy due to reaction

![Equation ([49])](https://content.cld.iop.org/journals/1945-7111/161/12/F1254/revision1/jes_161_12_F1254eqn49.jpg)

where the expressions can be compared to those in the material conservation equation 10. The above reaction terms include homogeneous reactions, interfacial reactions (e.g., evaporation), and interfacial electron-transfer reactions. The irreversible heat generation is represented by the activation overpotential and the reversible heat generation is represented by the Peltier coefficient, Πh. The Peltier coefficient for charge-transfer reaction h is given by

![Equation ([50])](https://content.cld.iop.org/journals/1945-7111/161/12/F1254/revision1/jes_161_12_F1254eqn50.jpg)

where ΔSh is the entropy of reaction h. The above equation neglects transported entropy (hence the approximate sign), and the summation includes all species that participate in the reaction (e.g., electrons, protons, oxygen, hydrogen, water). While the entropy of the half-reactions that occur at the catalyst layers is not truly obtainable since it involves knowledge of the activity of an uncoupled proton, the Peltier coefficients have been measured experimentally for these reactions, with most of the reversible heat in a PEFC is due to the 4-electron oxygen reduction reaction.107,108

It is often the case that because of the intimate contact between the gas, liquid, and solid phases within the small pores of the various PEFC layers, that equilibrium can be assumed such that all of the phases have the same temperature for a given point in the PEFC (this assumption is discussed more in a later section). Assuming local equilibrium eliminates the phase dependences in the above equations and allows for a single thermal energy equation to be written. Neglecting those phenomena that are minor as mentioned above and summing over the phases, results in

![Equation ([51])](https://content.cld.iop.org/journals/1945-7111/161/12/F1254/revision1/jes_161_12_F1254eqn51.jpg)

where the expression for Joule or ohmic heating has been substituted in for the fourth-term in the right side of equation 45 assuming an effective conductivity

![Equation ([52])](https://content.cld.iop.org/journals/1945-7111/161/12/F1254/revision1/jes_161_12_F1254eqn52.jpg)

In equation 51, the first term on the right side is energy transport due to convection, the second is energy transport due to conduction, the third is the ohmic heating, the fourth is the reaction heats, and the last represents reactions in the bulk which include such things as vaporization/condensation and freezing/melting. Heat lost to the surroundings is only accounted for at the boundaries of the cell. In terms of magnitude, the major heat generation sources are the oxygen reduction reaction and the water phase changes, and the main mode of heat transport is by conduction.

Kinetics

Electrochemical kinetic expressions provide the transfer current in the general material balance (i.e., ih, 1 − k in equation 10). A typical electrochemical reaction can be expressed as

![Equation ([53])](https://content.cld.iop.org/journals/1945-7111/161/12/F1254/revision1/jes_161_12_F1254eqn53.jpg)

where si, k, h is the stoichiometric coefficient of species i residing in phase k and participating in electron-transfer reaction h and Mzii represents the chemical formula of i having valence zi. According to Faraday's law, the flux of species i in phase k and rate of reaction h is related to the current as

![Equation ([54])](https://content.cld.iop.org/journals/1945-7111/161/12/F1254/revision1/jes_161_12_F1254eqn54.jpg)

For modeling purposes, especially with the multi-electron transport of species, it is often easiest to use a semi-empirical equation to describe the reaction rate, namely, the Butler-Volmer equation,89,109

![Equation ([55])](https://content.cld.iop.org/journals/1945-7111/161/12/F1254/revision1/jes_161_12_F1254eqn55.jpg)

where ih is the transfer current between phases k and p due to electron-transfer reaction h, the products are over the anodic and cathodic reaction species, respectively, αa and αc are the anodic and cathodic transfer coefficients, respectively, and  and Urefh are the exchange current density per unit catalyst area and the potential of reaction h evaluated at the reference conditions and the operating temperature, respectively. It should be noted that the choice of reference potential and exchange current density are linked meaning that one can result in value and functional changes of the other.86,103 This is especially true in terms of a Tafel expression since the exchange current density and the reference potential are not able to be separately distinguished.89,109 Also, as shown in the generalized material-balance equation 10, the value of the exchange current density is multiplied by the specific interfacial area, and normally, these are not necessarily known independently so models often will just use an ai0 parameter in their kinetic expression.

and Urefh are the exchange current density per unit catalyst area and the potential of reaction h evaluated at the reference conditions and the operating temperature, respectively. It should be noted that the choice of reference potential and exchange current density are linked meaning that one can result in value and functional changes of the other.86,103 This is especially true in terms of a Tafel expression since the exchange current density and the reference potential are not able to be separately distinguished.89,109 Also, as shown in the generalized material-balance equation 10, the value of the exchange current density is multiplied by the specific interfacial area, and normally, these are not necessarily known independently so models often will just use an ai0 parameter in their kinetic expression.

In the above expression, the composition-dependent part of the exchange current density is explicitly written, with the multiplication over those species participating in the anodic or cathodic direction. The reference potential is determined by thermodynamics as described above (e.g., equation 6), where the same (imaginary) reference electrode should be used for calculation of the electronic and ionic potentials. The term in parentheses in equation 27 can be written in terms of an electrode overpotential

![Equation ([56])](https://content.cld.iop.org/journals/1945-7111/161/12/F1254/revision1/jes_161_12_F1254eqn56.jpg)

If the reference electrode is exposed to the conditions at the reaction site, then a surface or kinetic overpotential can be defined

![Equation ([57])](https://content.cld.iop.org/journals/1945-7111/161/12/F1254/revision1/jes_161_12_F1254eqn57.jpg)

The surface overpotential is the overpotential that directly influences the reaction rate across the interface.

For the HOR occurring at the anode, equation 55 can be written as

![Equation ([58])](https://content.cld.iop.org/journals/1945-7111/161/12/F1254/revision1/jes_161_12_F1254eqn58.jpg)

where the reaction is almost always taken to be first order in hydrogen. Typically, the dependence on the activity of the proton(H)-membrane(M) complex is not shown since the electrolyte is a polymer of defined acid concentration (i.e., cHM = crefHM). However, if one deals with contaminant ions, then equation 58 should be used as written,110–112 and one might also expect that due to temperature, hydration, or other local conditions the activity coefficient for HM may change and thus aHM does not necessary equal arefHM. It has also been shown that the HOR may proceed with a different mechanism at low hydrogen concentrations or under certain conditions113,114; in such cases, the kinetic equation is altered depending on the mechanism89 (e.g., by the use of a surface adsorption term). However, more mechanistic-based equations are typically only used for specific studies and models and are beyond the scope of this review. Due to the choice of reference electrode, the reference potential and reversible potential are both equal to zero.

Unlike the facile HOR, the ORR is slow. Due to its sluggishness, the anodic part of the ORR is considered negligible and is dropped, resulting in the so-called Tafel approximation

![Equation ([59])](https://content.cld.iop.org/journals/1945-7111/161/12/F1254/revision1/jes_161_12_F1254eqn59.jpg)

with an observed kinetic dependence on oxygen partial pressure, m0, of between 0.8 and 1115–118 and an Arrhenius temperature dependence for the exchange current density. For both the HOR and ORR, α is typically taken to be equal to 1,115,116,119–121 however newer models use a value between 0.5 and 1 (with significant cell-performance prediction changes) for the ORR due to Pt-oxide formation as examined in more detail below.122–125 In addition, as mentioned, the choice of the reference potential for the overpotential will directly impact the exchange-current density (since they cannot be separated) and even reaction order.115 Due to the importance of the ORR, more detailed kinetic expressions have been developed as described briefly below. In addition, other reactions such as those involving durability (e.g., carbon corrosion) are discussed in subsequent sections of this review.

Pt-oxide and the double trap model

The underlying assumption of using a Butler-Volmer (or Tafel) equation is that the reaction proceeds through a single rate-determining-step (RDS). However, in electrocatalysis reactions over a wide potential range, the RDS can change, as intermediates form on the surface of the catalyst. These intermediates are due to oxide formation, which forms at the potential range of the ORR (0.6 to 1.0 V) by water or gas-phase oxygen. These oxides can inhibit the ORR by blocking active Pt sites with chemisorbed surface oxygen. Typically, a constant Tafel slope for the ORR kinetics around 60 to 70 mV/decade is assumed over the cathode potential range relevant to PEFC operation. However, it has been suggested by experiments that this approach has to be modified to account for the potential-dependent oxide coverage,122,126–128 especially for low catalyst loadings where poisoning has greater impact due to the low catalyst-site number. To implement this coverage, either a term is added to the ORR kinetic equation 59129 or a more mechanistic model is used.124,130,131 For the first approach, equation 59 becomes

![Equation ([60])](https://content.cld.iop.org/journals/1945-7111/161/12/F1254/revision1/jes_161_12_F1254eqn60.jpg)

where ΘPtO is the coverage of Pt oxide; it should be noted that several oxides can exist and here PtO is taken as an example, and ω is the energy parameter for oxide adsorption. There are various methods to calculate PtO using kinetic equations, such as132,133

![Equation ([61])](https://content.cld.iop.org/journals/1945-7111/161/12/F1254/revision1/jes_161_12_F1254eqn61.jpg)

where

![Equation ([62])](https://content.cld.iop.org/journals/1945-7111/161/12/F1254/revision1/jes_161_12_F1254eqn62.jpg)

and ηPtO and UPtO are the Pt-oxide overpotential and equilibrium potential, respectively. Another approach is to estimate it with experimental correlations.134

While the above approach predicts the doubling of the Tafel slope,135,136 it assumes that the adsorbates are site-blockers and that the first electron transfer step is the RDS. To relax these assumptions, a double-trap kinetic model was developed by Wang et al.130,131 In this model, the kinetics are explained with four elementary reaction steps,

![Equation ([63])](https://content.cld.iop.org/journals/1945-7111/161/12/F1254/revision1/jes_161_12_F1254eqn63.jpg)

![Equation ([64])](https://content.cld.iop.org/journals/1945-7111/161/12/F1254/revision1/jes_161_12_F1254eqn64.jpg)

![Equation ([65])](https://content.cld.iop.org/journals/1945-7111/161/12/F1254/revision1/jes_161_12_F1254eqn65.jpg)

![Equation ([66])](https://content.cld.iop.org/journals/1945-7111/161/12/F1254/revision1/jes_161_12_F1254eqn66.jpg)

any of which can become the RDS depending on the potential. Schematically, these elementary reactions represent two adsorption pathways that proceed through: 1) dissociative adsorption (DA) and 2) reductive adsorption (RA):

![Equation ([67])](https://content.cld.iop.org/journals/1945-7111/161/12/F1254/revision1/jes_161_12_F1254eqn67.jpg)

Using a steady-state approximation (intermediate coverage does not change with time: dθO/dt = dθOH/dt = 0), the total kinetic current can be expressed as a combination of elementary currents

![Equation ([68])](https://content.cld.iop.org/journals/1945-7111/161/12/F1254/revision1/jes_161_12_F1254eqn68.jpg)

The individual currents can be expressed as a difference between the forward and backward reaction currents and in terms of a reference prefactor, j*, activation free energy, and adsorbed species; a detailed derivation is provided elsewhere.131 As an example, the kinetic current for the RD step, which represents the desorption of OH, is

![Equation ([69])](https://content.cld.iop.org/journals/1945-7111/161/12/F1254/revision1/jes_161_12_F1254eqn69.jpg)

where the activation energies are potential dependent.131

In this framework, the adjustable kinetic parameters are four activation and two adsorption free energies, which are fit to kinetic polarization data and cyclic-voltammetry data for surface oxide coverage,137–139 or they can be estimated computationally by ab-initio modeling.124,139,140 A double-trap modeling framework offers a versatile way to model the PEFC's reaction kinetics (provided good data for the fitting parameters is available), and it predicts the observed doubling of the Tafel slope due to reaction-pathway changes and captures the trends of the experimental oxide coverage. It can also has a capability to bridge the more traditional kinetic models with the theoretical results from ab-initio studies. Finally, it can also be extended to capture Pt dissolution and high-oxide-coverage regime (>1 V).

Critical Issues in the Field

As mentioned above, the two critical issues in the field for transport modeling to address are multiphase flow and modeling of catalyst layers, particularly the cathode. Specifically, there is still a need to resolve, understand, and model liquid-water transport and interactions, especially at the GDL / gas-channel interface. In terms of catalyst layers, they are the most complex layer within the PEFC, being composed of all other components and requiring knowledge of a wide variety of physics that interacts on multiple scales. In addition, there is still a lack of experimental data on issues related specifically to the catalyst layer, which makes modeling them challenging. Below, we examine each of these critical areas in sequence. We will discuss the governing equations for these issues, while highlighting those areas that require improvement and understanding. While the discussion will primarily remain focused on the continuum, macroscale phenomena, other lengthscales and approaches will be mentioned, especially in how they might interact with the continuum approaches or provide insight and are areas for future research.

Multiphase Flow

Multiphase flow refers to the simultaneous existence and movement of material in different phases. It is well known that liquid and vapor coexist within PEFCs, especially at lower temperatures (e.g., during start-up) and with humidified conditions wherein the ohmic losses through the membrane are minimized. While multiphase flow in PEFC components and cells has been investigated deeply over the last two decades with substantial progress occurring recently due to advances in diagnostics, microscale models, and visualization techniques as discussed in this review, there are still unresolved issues, especially with the various interfaces and within the PEFC porous media and flowfield channels.

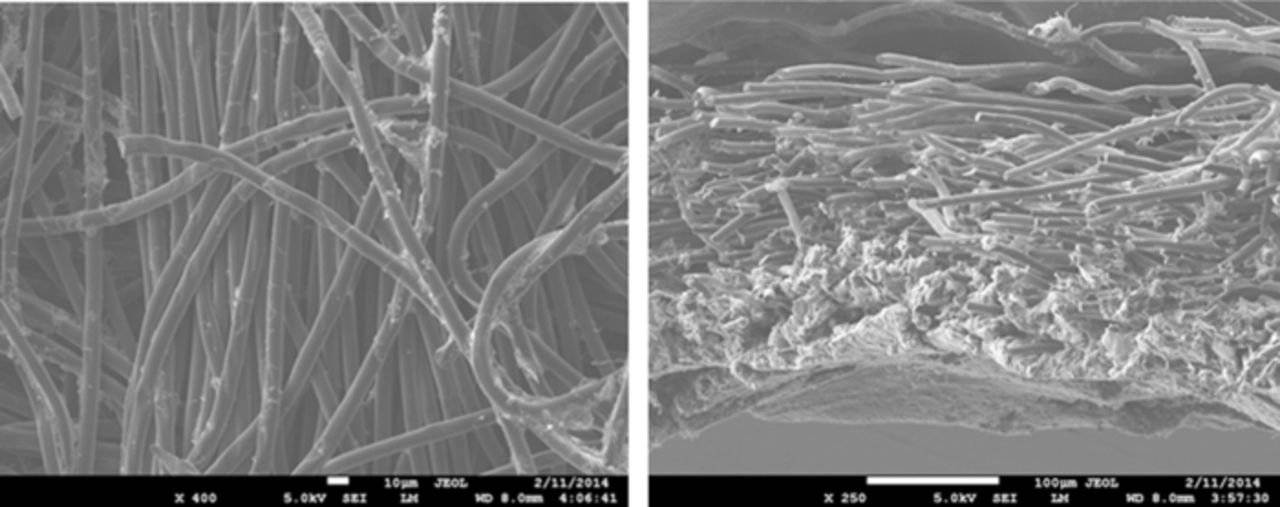

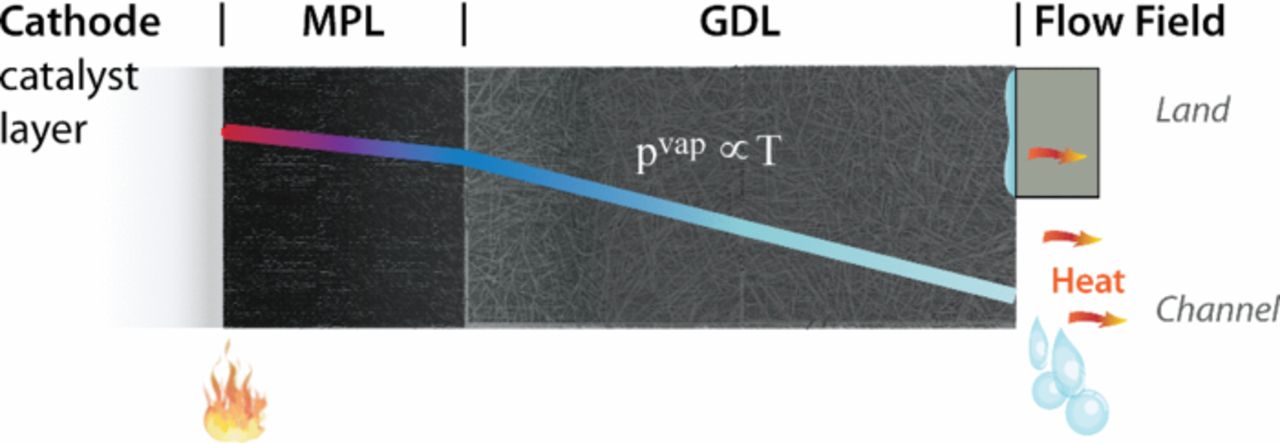

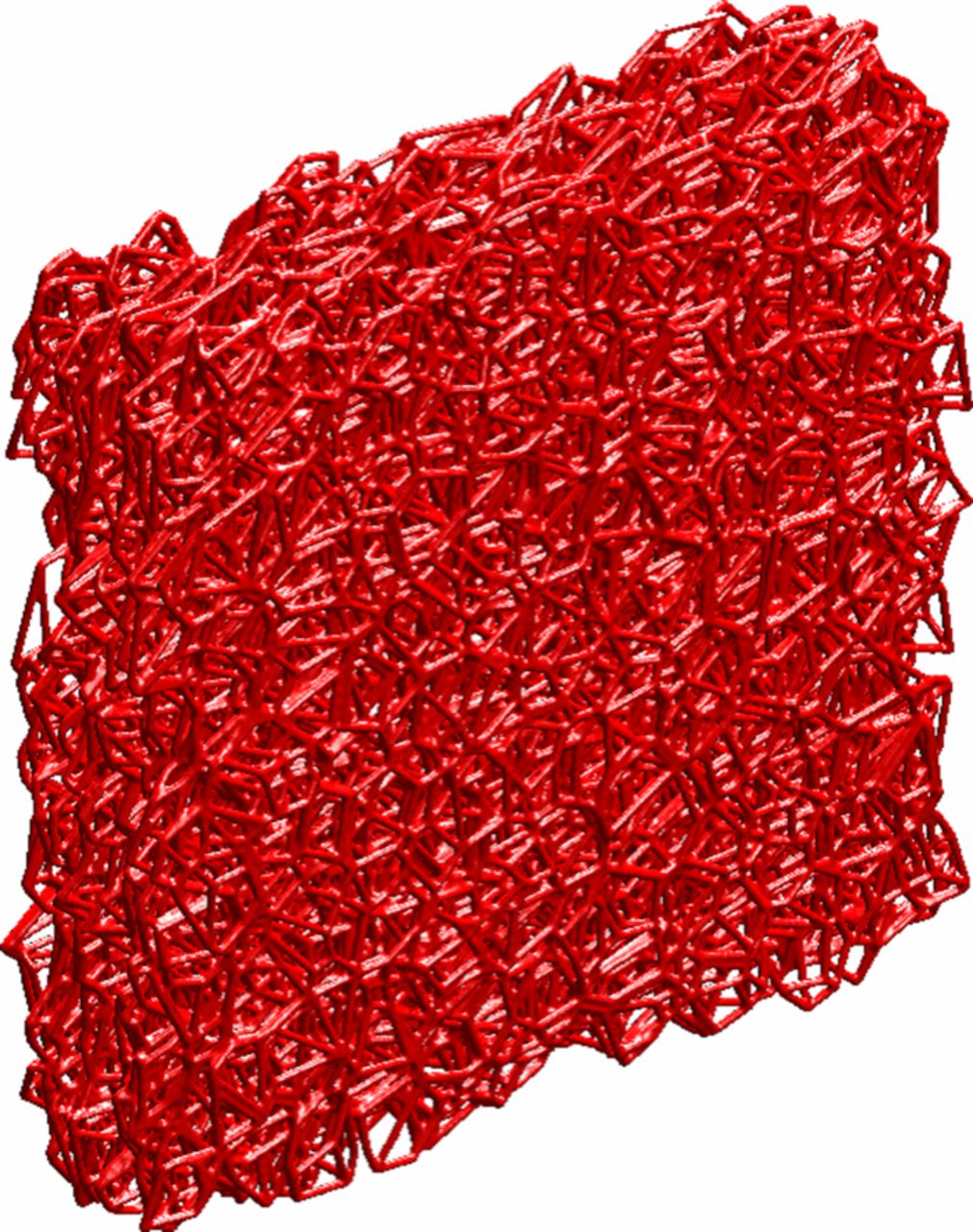

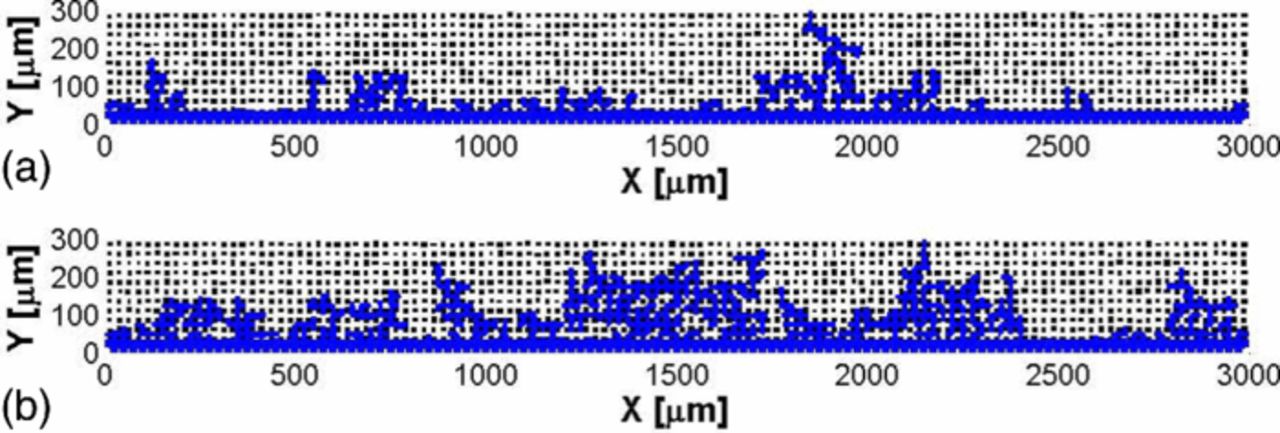

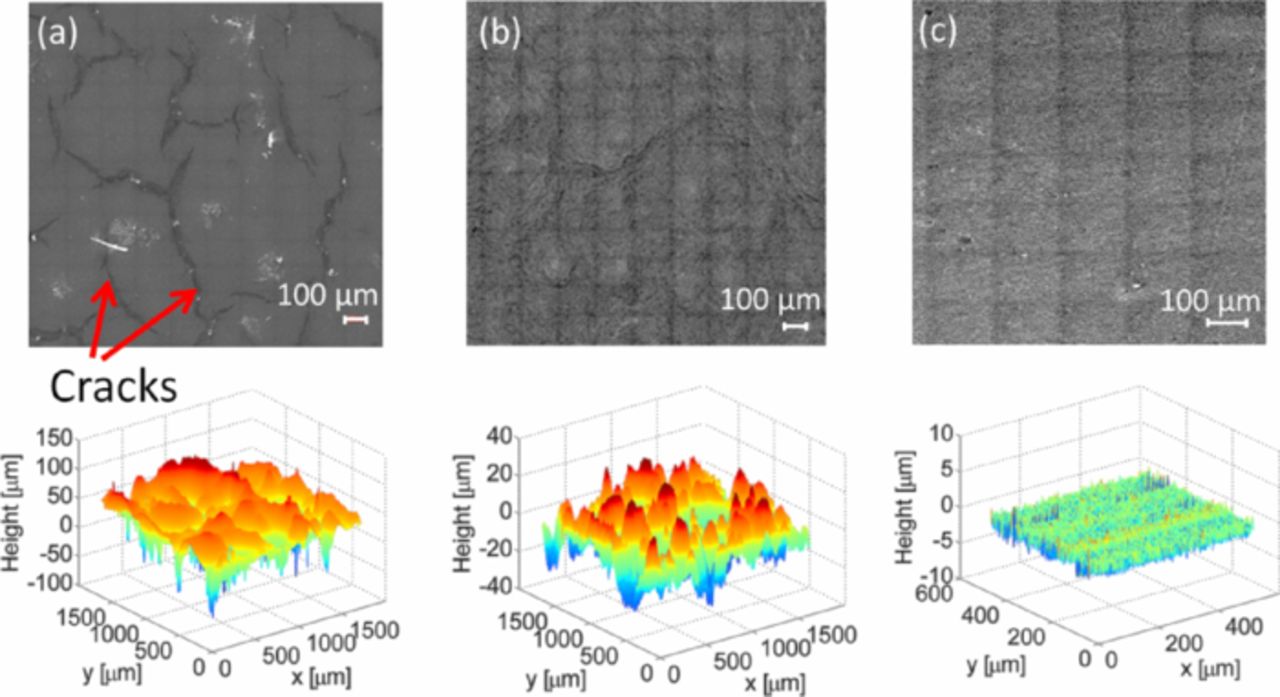

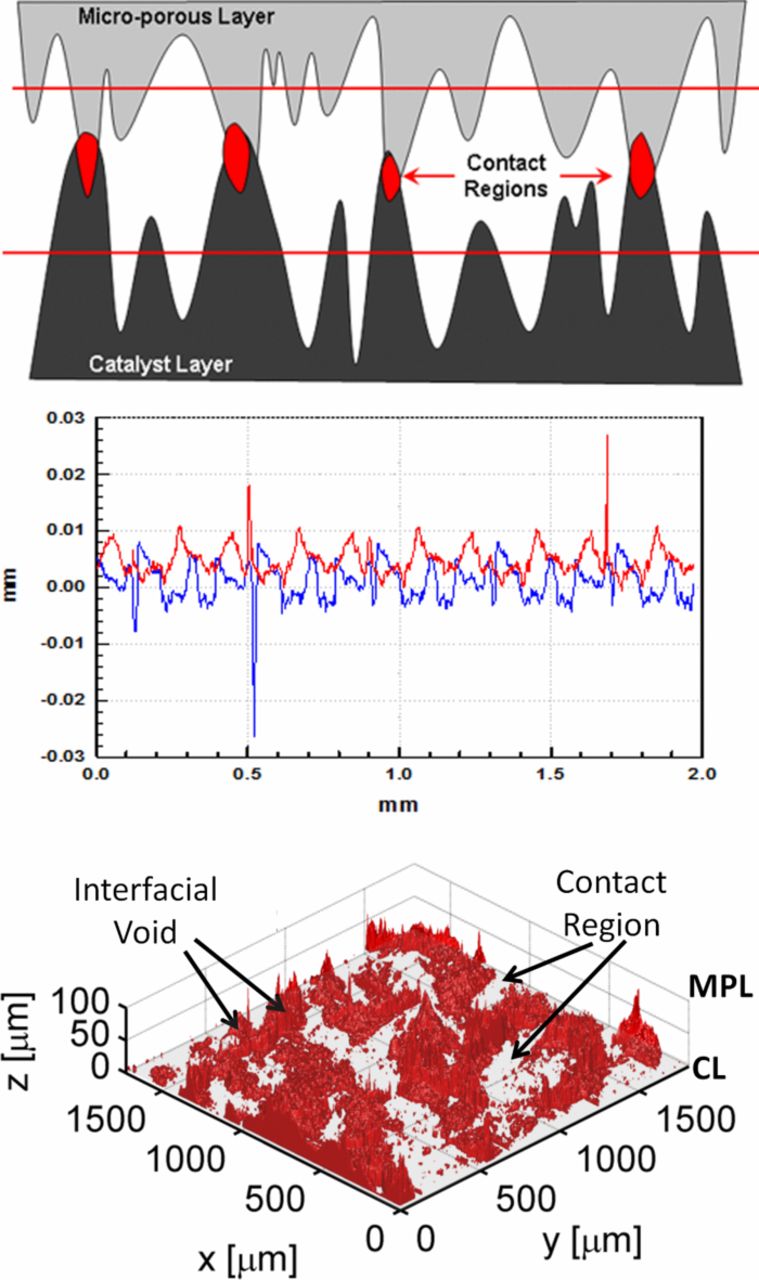

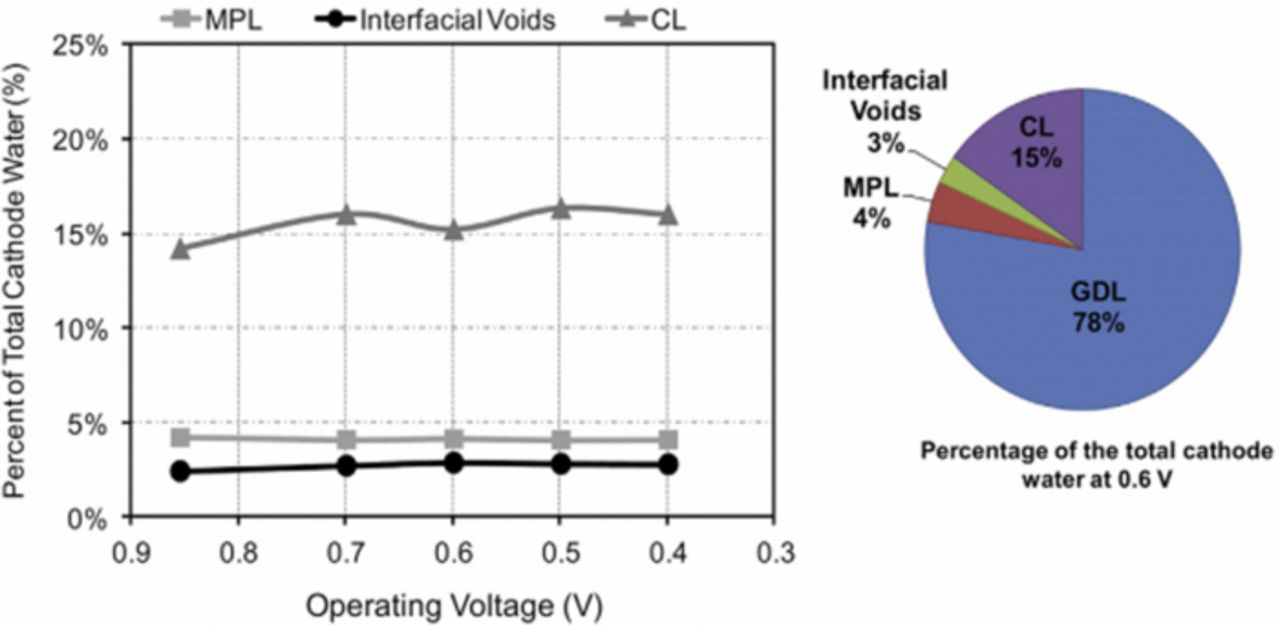

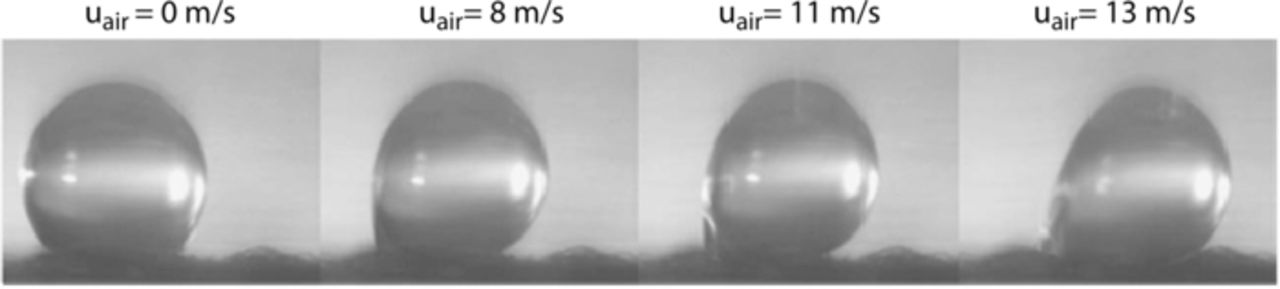

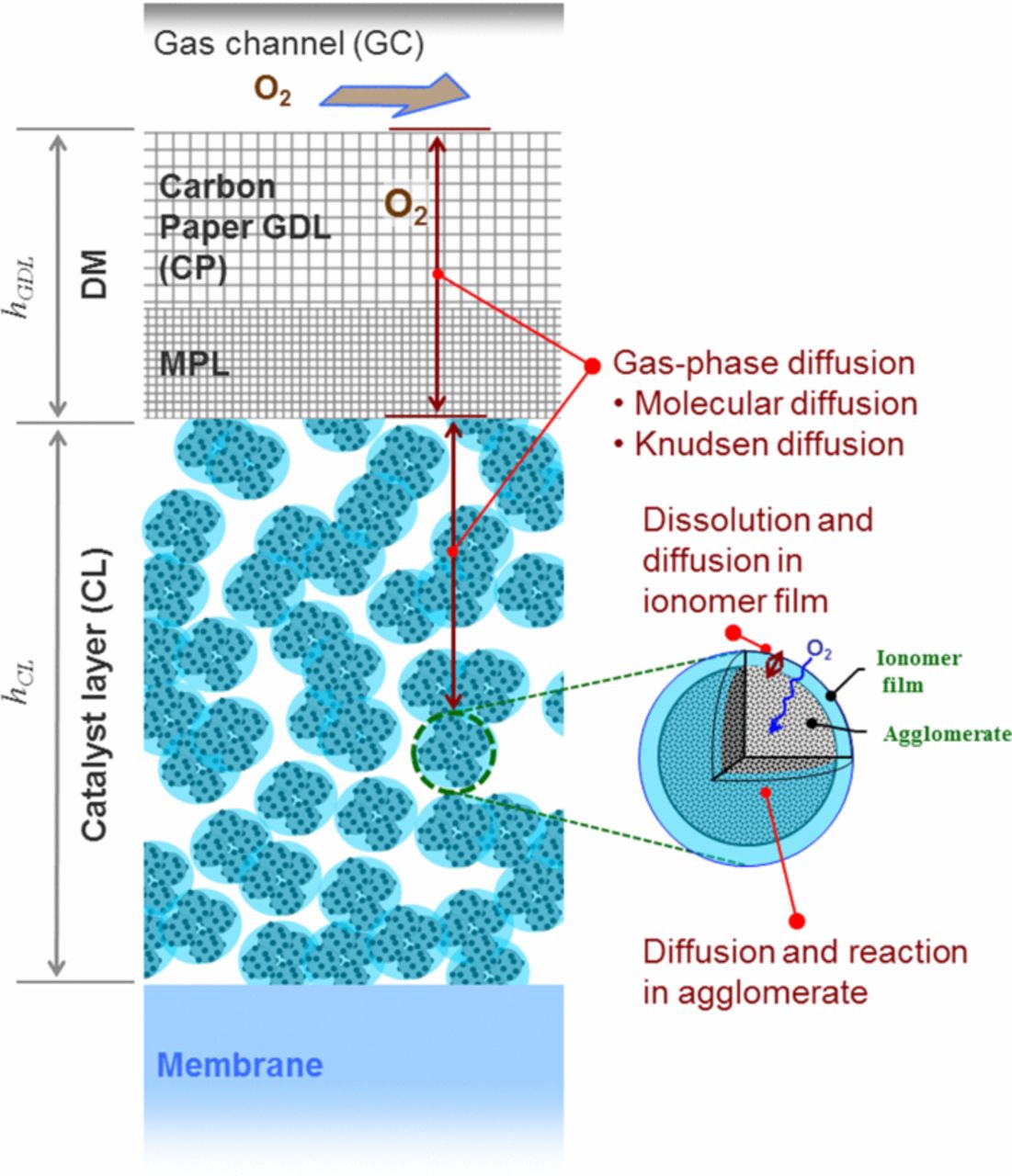

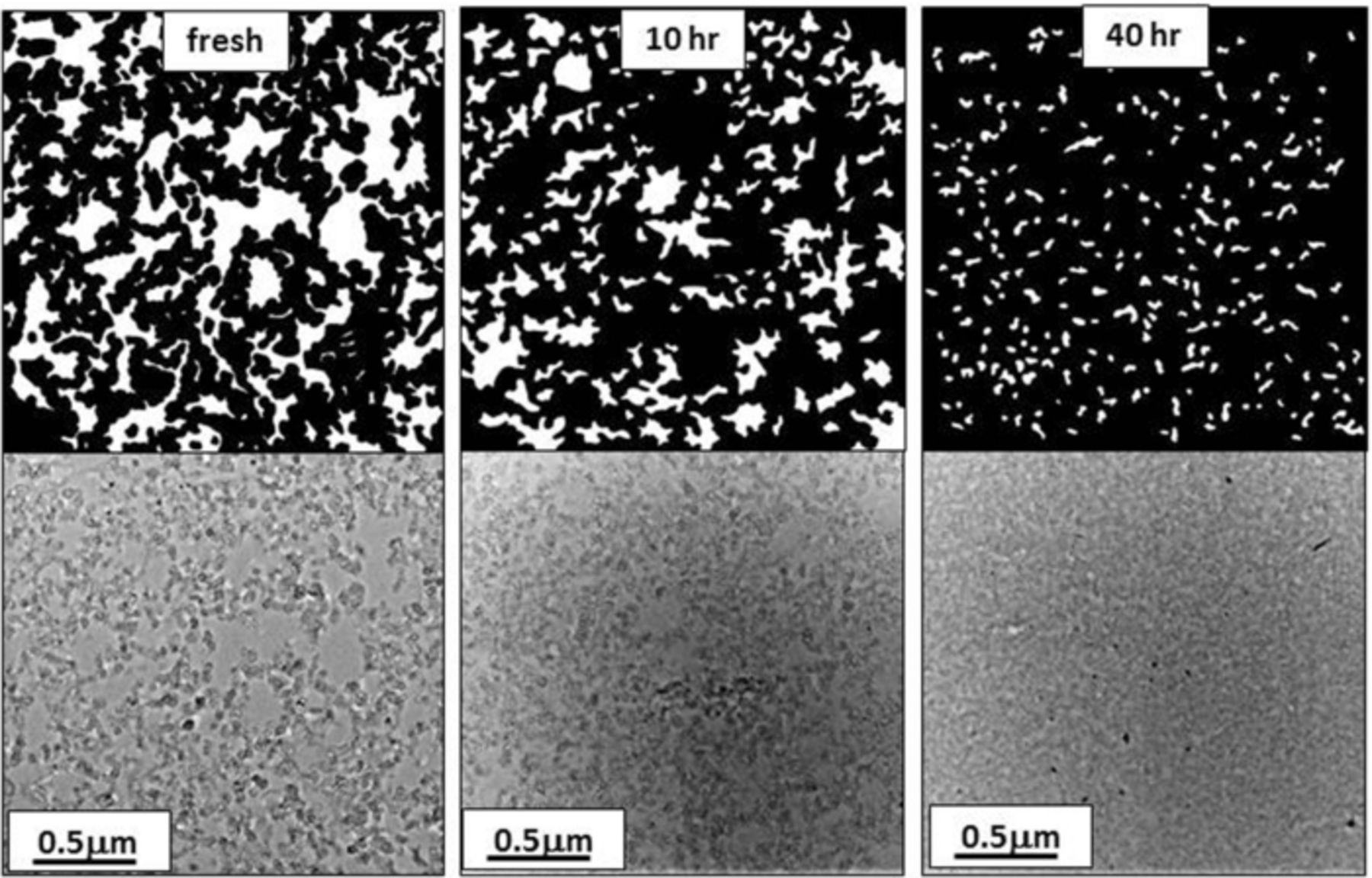

Nowhere is multiphase flow treated by such a variety of methods as in the composite DM (as shown in Figure 3) owing to the importance of these composite layers in water management. They provide pathways to disperse reactant fuel, oxidant, heat, and electrons while removing product water. A DM has to be hydrophilic enough to wick out the water and hydrophobic enough to not fill with liquid water and "flood" and block the reactant gas from reaching the catalyst site as mentioned above. This seemingly competing objective is met by partial treatment of the naturally mixed wettable layers with hydrophobic PTFE. Water produced at the cathode and water transported across the membrane is wicked out of the cell by capillary effects including perhaps transport through cracks and preferential pathways. A MPL serves to protect the membrane from being penetrated by the carbon fibers of the macroporous GDL, as well as provide discrete locations of water injection into the GDL.141–144 This decreases the water accumulation near the cathode and hence decreases oxygen mass-transport resistance.

Figure 3. Scanning electron micrograph of (left) GDL surface and (right) DM cross-section with microporous layer on the bottom and GDL on the top.

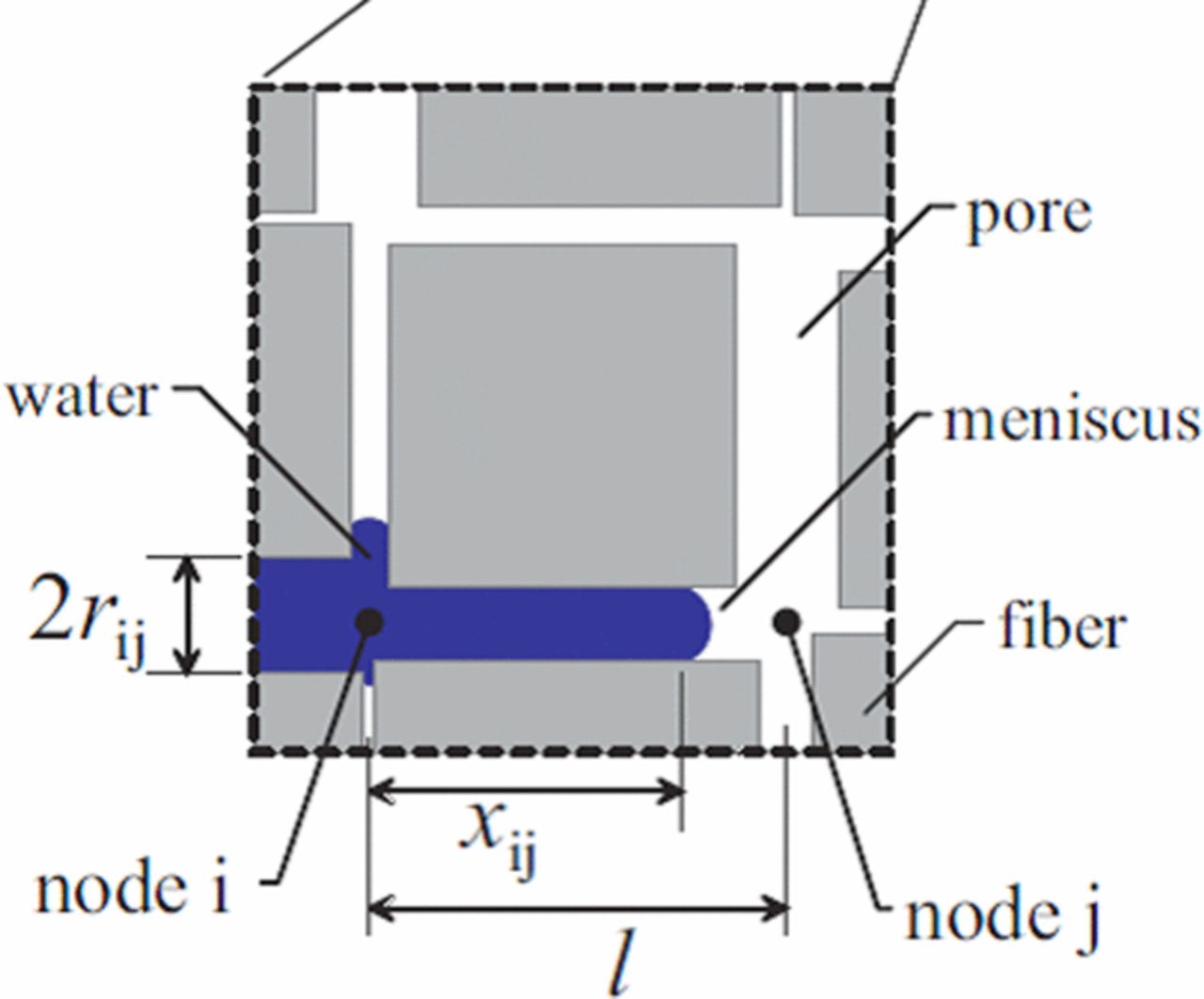

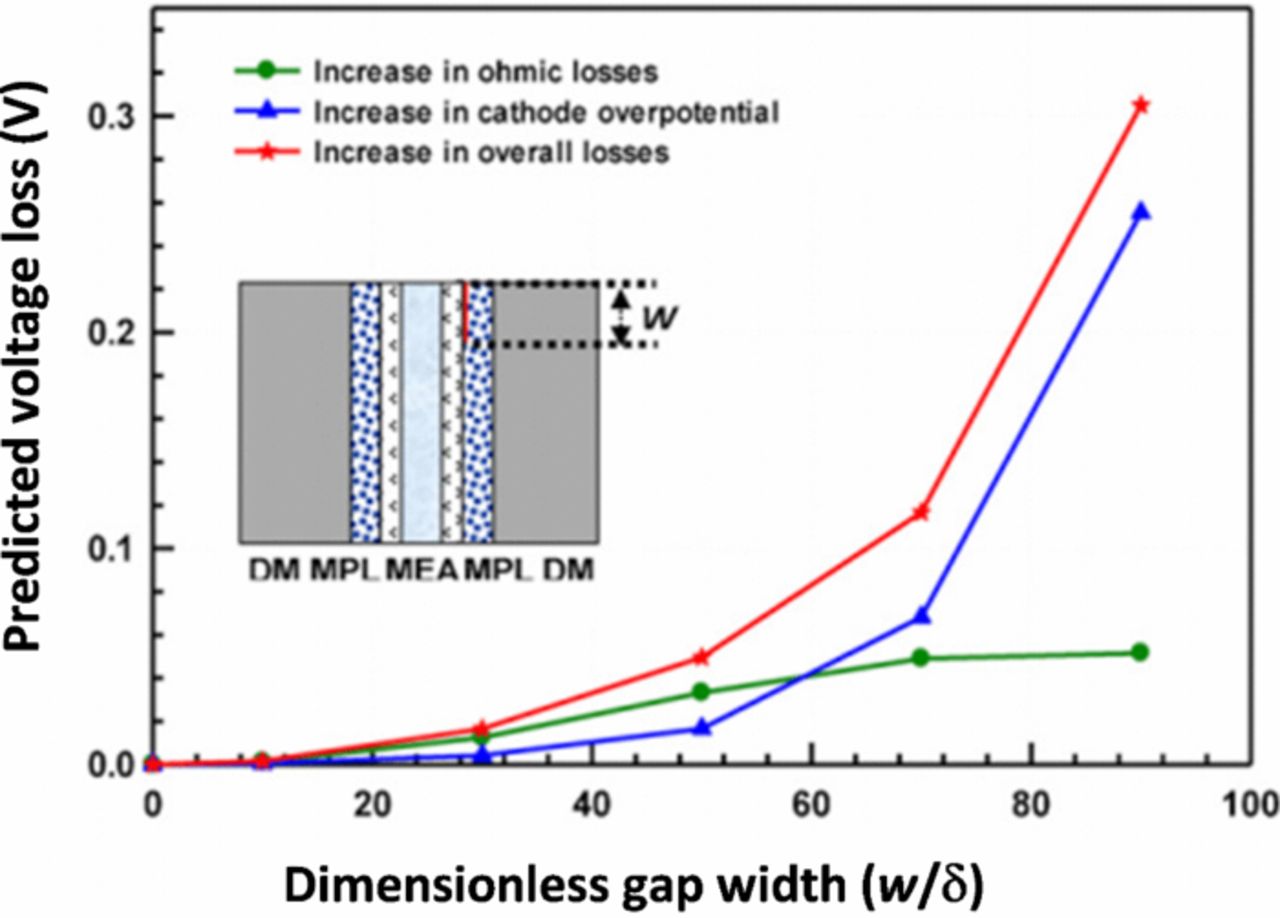

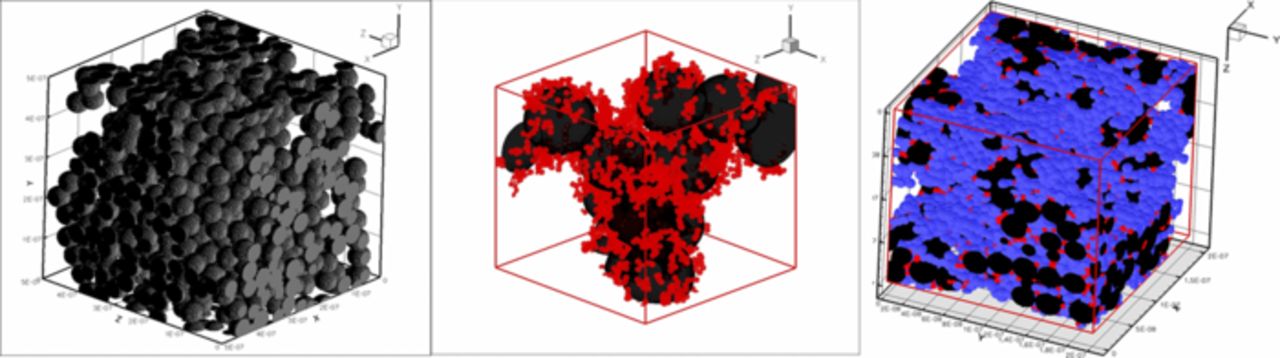

In this section, we discuss the key approaches toward modeling multiphase flow, especially in DM. Of course, there are always caveats and simplifications that must be made to model the macroscale transport. Thus, the specific pore structure is often considered only in a statistical sense, local equilibrium among phases is often assumed, and the effective properties, which are often measured for the entire layer, are applied locally and assumed to remain valid. We will however discuss some more microscopic modeling and how one can reconstruct PEFC porous media computationally. Next, we explore recent work on issues related to specific interfacial phenomena, contact resistances, and correlating the channel conditions to the droplets and water removal. Such effects could dominate the overall response of the cell and serve as boundary conditions or even as discrete interphase regions. Finally, multiphase flow also encompasses water freezing and melting, and the kinetics of such processes are reviewed.

Incorporation of multiphase phenomena

Modeling the PEFC porous media requires descriptions of the fluxes in the gas and liquid phases, interrelationships among those phases, as well as electron and heat transport. Traditional equations including Stefan-Maxwell diffusion (equation 18), Darcy's law for momentum (equation 42), and Ohm's law for electron conduction (equation 32) are typically used, where most of the effective transport properties of the various layers have been measured experimentally,37 or perhaps modeled by microscopic methods. Effective properties are required to account for the microscopic heterogeneity of the porous structures. This is accomplished by volume averaging all the relevant properties and system variables for transport within the porous domain,

![Equation ([70])](https://content.cld.iop.org/journals/1945-7111/161/12/F1254/revision1/jes_161_12_F1254eqn70.jpg)

where ψk represents any property in the phase k and εk and τk are the porosity and tortuosity of phase k, respectively. As an example, the effective gas-phase diffusivities are both a function of the bulk porosity, εo, and the saturation, S, or the liquid volume fraction of the pore space,

![Equation ([71])](https://content.cld.iop.org/journals/1945-7111/161/12/F1254/revision1/jes_161_12_F1254eqn71.jpg)

The power-law exponents have been shown to have values of around 3 for typical fibrous GDLs,41,42,44,145

![Equation ([72])](https://content.cld.iop.org/journals/1945-7111/161/12/F1254/revision1/jes_161_12_F1254eqn72.jpg)

and are anisotropic with the in-plane value being several times larger than the through-plane one, which also agrees with microscopic modeling results.146,147

For the bulk movement and convection of the gas phase, Darcy's law and the mass-averaged velocity (equations 42 and 13, respectively) are used with an effective permeability that is comprised of the absolute (measured) permeability and a relative permeability owing to the impact of liquid

![Equation ([73])](https://content.cld.iop.org/journals/1945-7111/161/12/F1254/revision1/jes_161_12_F1254eqn73.jpg)

where kr,k is the relative permeability for phase k and is often given by a power-law dependence on the saturation.42,148 The above equations are used along with the mass balance (equation 10) to describe the gas-phase transport.

While one can treat the liquid water as a mist or fog flow (i.e., it has a defined volume fraction but moves with the same superficial velocity of the gas), it is more appropriate to use separate equations for the liquid. This treatment is often of the form of Darcy's law (equation 42), which, in flux form is

![Equation ([74])](https://content.cld.iop.org/journals/1945-7111/161/12/F1254/revision1/jes_161_12_F1254eqn74.jpg)

where  is the molar volume of water. One can also add a second derivative to the above equation such that a no-slip condition can be met at the pore surfaces (i.e., Brinkman equation).149

is the molar volume of water. One can also add a second derivative to the above equation such that a no-slip condition can be met at the pore surfaces (i.e., Brinkman equation).149

In terms of heat transport, for DM, the thermal balance turns mainly into heat conduction due to the high thermal conductivity compared to convective fluxes. Although no electrochemical reactions are occurring within the DM, there are still phase-change reactions that can consume/generate a considerable amount of heat, e.g.,

![Equation ([75])](https://content.cld.iop.org/journals/1945-7111/161/12/F1254/revision1/jes_161_12_F1254eqn75.jpg)

where kevap is the reaction rate constant. In typical PEFC porous media, the area between the phases (aG,L) and the reaction rate constant are normally assumed sufficiently high that one can use equilibrium between the liquid and vapor phases. The reaction source terms must be included in the overall heat balance (equation 51), and it should be noted that effective properties are again required to be used in the governing equation, where recent studies have shown the dependence of the anisotropic effective thermal conductivity on water saturation.349,350,105 One must also be aware of contact resistances and interfacial issues to determine the boundary conditions as discussed in the next section.

Finally, there are also modeling methodologies that assume equilibrium among the gas and liquid phases and try to recast the transport equations in order to be computationally more efficient or to converge easier; a prime example is the multiphase mixture model.150,151 In this analysis, although both liquid and vapor phases move simultaneously, they move at different velocities. This difference leads to a drag on either phase. The liquid-phase velocity can be calculated using

![Equation ([76])](https://content.cld.iop.org/journals/1945-7111/161/12/F1254/revision1/jes_161_12_F1254eqn76.jpg)

where the subscript m stands for the mixture, ρk and νk are the density and kinematic viscosity of phase k, respectively, and λL is the relative mobility of the liquid phase which is defined as,

![Equation ([77])](https://content.cld.iop.org/journals/1945-7111/161/12/F1254/revision1/jes_161_12_F1254eqn77.jpg)

A similar equation can be derived for the gas-phase velocity, which is then used to calculate the pressure drop in the gas phase while the Stefan-Maxwell equations 18 govern the diffusive transport of the gas species. In equation 76, the first term represents a convection term, and the second comes from a mass flux of water that can be broken down as flow due to capillary phenomena and flow due to interfacial drag between the phases. The velocity of the mixture is basically determined from Darcy's law using the properties of the mixture. While the use of the multiphase-mixture model does speed computational time and decreases computational cost, problems can arise if the equations are not averaged correctly. In addition, it does not track interfaces rigorously and is typically not seen as a net benefit for most PEFC models since they are not limited computationally, with an exception perhaps being 3-D models.

Liquid/vapor/heat interactions

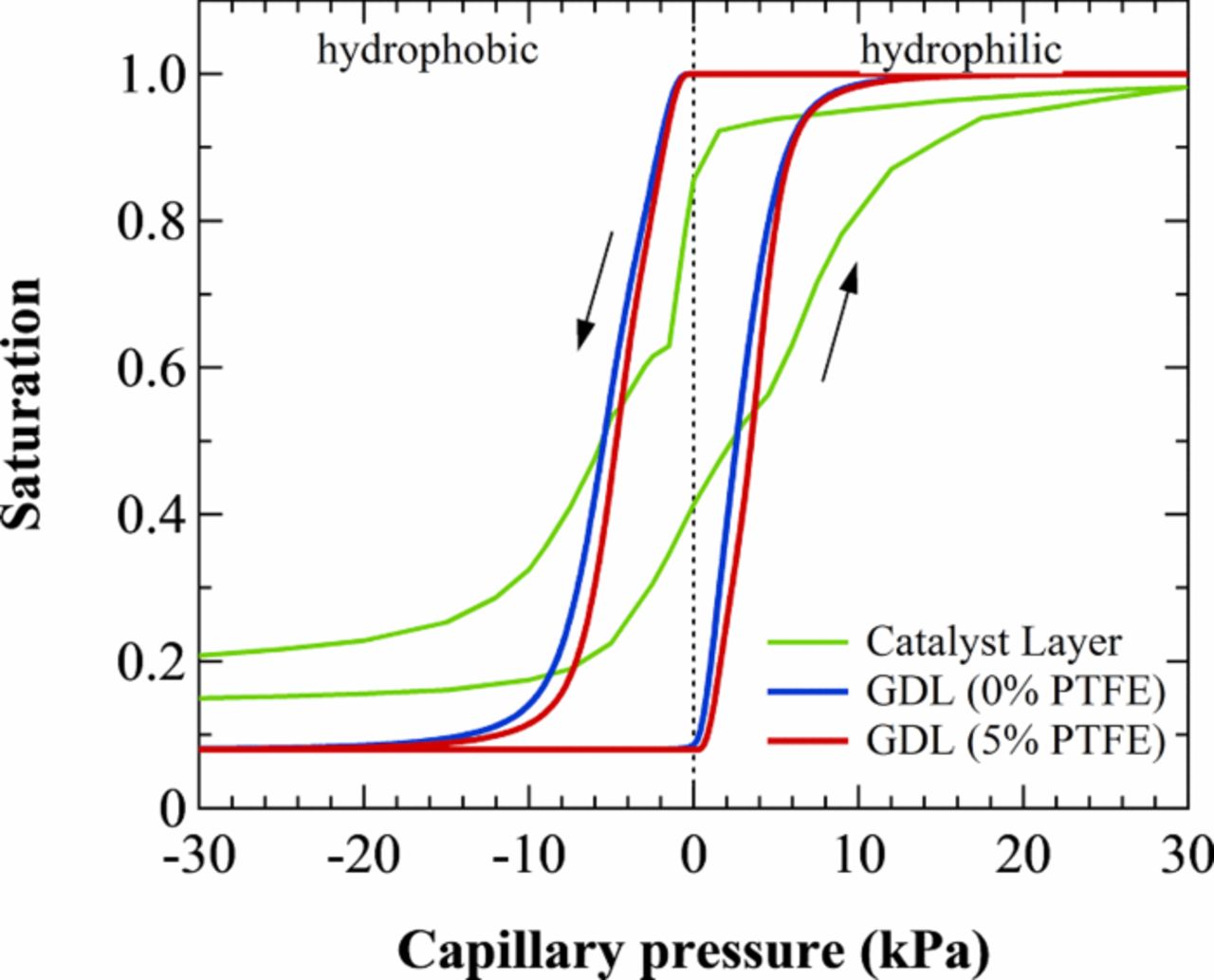

Equations 74, 71, and 73 clearly show that there is an impact of the liquid- and gas-phase volume fractions on the transport of each other through the various effective transport properties. The key in calculating these relationships is determining an expression for the way in which the saturation varies with the independent driving force, namely pressure. From a continuum perspective, in a capillary-dominated system, these are related through the capillary pressure,98,99,152,153

![Equation ([78])](https://content.cld.iop.org/journals/1945-7111/161/12/F1254/revision1/jes_161_12_F1254eqn78.jpg)

where γ is the surface tension of water, r is the pore radius, and θ is the internal contact angle that a drop of water forms with a solid. This definition is based on how liquid water wets the material; hence, for a hydrophilic pore, the contact angle is 0° ⩽ θ < 90°, and, for a hydrophobic one, it is 90° < θ ⩽ 180°. The capillary pressure can also impact the saturation vapor pressure, which should be corrected for pore effects by the Kelvin equation,

![Equation ([79])](https://content.cld.iop.org/journals/1945-7111/161/12/F1254/revision1/jes_161_12_F1254eqn79.jpg)

where pvap0, o is the uncorrected (planar) vapor pressure of water and is a function of temperature