Abstract

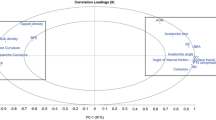

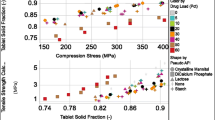

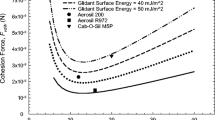

The objective of the present work was to carry out a systematic evaluation of flow of pharmaceutical powders and granules using compendial and non-compendial methods. Angle of repose, bulk density, tapped density, Carr’s compressibility index, and Hausner ratios were evaluated. Additionally, flow was characterized using a powder rheometer in which a sensitive force transducer monitors the forces generated as a result of the sample displacement. The critical attributes such as cohesivity index, caking strength, and flow stability were determined for samples. The samples consisted of different grades of magnesium stearate powder including bovine, vegetable, and food grade, physical mixture powder blend consisting of a model formulation, granules prepared by various methods including slugging, high shear granulator, and fluid bed dryer. Lubricant efficiency was also determined for granules lubricated with various concentrations of magnesium stearate. It was observed that the compendial methods were often non-discriminating for minor variations in powder flow. The additional characterization such as cohesivity, and caking strength were helpful in understanding the flow characteristics of pharmaceutical systems. The flow stability test determined that the powders were not affected by the test conditions on the rheometer. The non-compendial tests were discriminating to even minor variations in powder flow.

Similar content being viewed by others

References

USP. <1174> Powder flow. USP30 NF 25 (2007).

USP. <616> Bulk density and tapped density. USP30 NF 25 (2007).

R. L. Carr. Evaluating flow properties of solids. Chem. Eng. 72:69–72 (1965).

H. H. Hausner. Friction conditions in a mass of metal powder. Int. J. Powder Metall. 3:7–13 (1967).

A. Faqih, B. Chaudhuri, A. W. Alexander, C. Davies, F. J. Muzzio, and T. M. Silvina. An experimental/computational approach for examining unconfined cohesive powder flow. Int. J. Pharm. 324:116–127 (2006).

B. C. Hancock, K. E. Vukovinsky, B. Brolley, I. Grimsey, D. Hedden, A. Olsofsky, and R. A. Doherty. Development of a robust procedure for assessing powder flow using a commercial avalanche testing instrument. J. Pharm. Biomed. Anal. 35:979–990 (2004).

A. W. Jenike. Storage and flow of solids. Utah Eng. Exp. Stn. Bull. 123:1–194 (1964).

H. Ramachandruni, and S. W. Hoag. Design and validation of an annular shear cell for pharmaceutical powder testing. J. Pharm. Sci. 90:531–540 (2001).

T. Dyakowski, S. P. Luke, K. L. Ostrowski, and R. A. Williams. On-line monitoring of dense phase flow using real time dielectric imaging. Powder Technol. 104:287–295 (1999).

M. Weth, M. Hoffman, J. Kuhn, and J. Frick. Measurement of attractive forces between single aerogel powder particles and the correlation with powder flow. J. Non-Cryst. Solids 285:236–243 (2001).

Z. Zatloukal, and Z. Sklubalova. Penetrometry and estimation of the flow rate of powder excipients. Pharmazie. 62:185–189 (2007).

B. H. Kaye, J. Gratton-Limatainen, and J. Lloyd. The effect of flow agents on the rheology of a plastic powder. Part Syst. Charact. 12:194–197 (1995).

N. O. Lindberg, M. Palsson, A. C. Pihl, T. Freeman, H. Zetzener, and G. Enstad. Flowability measurements of pharmaceutical powder mixtures with poor flow using five different techniques. Drug Dev. Ind. Pharm. 30:785–791 (2004).

C. V. Navaneethan, S. Missaghi, and R. Fassihi. Application of powder rheometer to determine powder flow properties and lubrication efficiency of pharmaceutical particulate systems. AAPS PharmSciTech. 6:E398–E404 (2005).

C. M. Iles, I. D. Bateson, and J. A. Walker. Rheometer. US Patent 6,481,267B1. Stable Microsystems Ltd (2002).

T. A. Miller, and P. York. Physical and chemical characteristics of some high purity magnesium sterate and palmitate powders. Int. J. Pharm. 23:55–67 (1985).

Acknowledgements

The authors wish to thank Mazen Hamad, Abhay Gupta, and Christopher Ellison from the division for their assistance.

Author information

Authors and Affiliations

Corresponding author

Additional information

The opinions expressed in this work are only of authors, and do not necessarily reflect the policy and statements of the FDA.

Rights and permissions

About this article

Cite this article

Shah, R.B., Tawakkul, M.A. & Khan, M.A. Comparative Evaluation of Flow for Pharmaceutical Powders and Granules. AAPS PharmSciTech 9, 250–258 (2008). https://doi.org/10.1208/s12249-008-9046-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1208/s12249-008-9046-8