Abstract

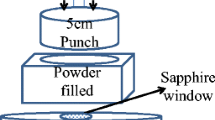

There is an increasing need to provide more detailed insight into the behavior of particulate systems. The current powder characterization tools are developed empirically and in many cases, modification of existing equipment is difficult. More flexible tools are needed to provide understanding of complex powder behavior, such as mixing process and segregation phenomenon. An approach based on the fast prototyping of new powder handling geometries and interfacing solutions for process analytical tools is reported. This study utilized 3D printing for rapid prototyping of customized geometries; overall goal was to assess mixing process of powder blends at small-scale with a combination of spectroscopic and mechanical monitoring. As part of the segregation evaluation studies, the flowability of three different paracetamol/filler-blends at different ratios was investigated, inter alia to define the percolation thresholds. Blends with a paracetamol wt% above the percolation threshold were subsequently investigated in relation to their segregation behavior. Rapid prototyping using 3D printing allowed designing two funnels with tailored flow behavior (funnel flow) of model formulations, which could be monitored with an in-line near-infrared (NIR) spectrometer. Calculating the root mean square (RMS) of the scores of the two first principal components of the NIR spectra visualized spectral variation as a function of process time. In a same setup, mechanical properties (basic flow energy) of the powder blend were monitored during blending. Rapid prototyping allowed for fast modification of powder testing geometries and easy interfacing with process analytical tools, opening new possibilities for more detailed powder characterization.

Similar content being viewed by others

References

Yu LX. Pharmaceutical quality by design: product and process development, understanding, and control. Pharm Res. 2008;25(4):781–91. https://doi.org/10.1007/s11095-007-9511-1.

Rantanen J, Khinast J. The future of pharmaceutical manufacturing sciences. J Pharm Sci. 2015;104(11):3612–38. https://doi.org/10.1002/jps.24594.

Mangal S, Meiser F, Lakio S, Morton D, Larson I. The role of physico-chemical and bulk characteristics of co-spray dried l-leucine and polyvinylpyrrolidone on glidant and binder properties in interactive mixtures. Int J Pharm. 2015;479(2):338–48. https://doi.org/10.1016/j.ijpharm.2015.01.001.

Ph.Eur.8.0_2.9.36. Monograph 2.9.36. Powder flow. In: European Pharmacopeia. In Comissi. Strasbourg: European Directorate for the Quality of Medicine (EDQM); 2015. p. 346–9.

Leturia M, Benali M, Lagarde S, Ronga I, Saleh K. Characterization of flow properties of cohesive powders: a comparative study of traditional and new testing methods. Powder Technol. 2014;253:406–23. https://doi.org/10.1016/j.powtec.2013.11.045.

Schulze D, Wittmaier A. Flow properties of highly dispersed powders at very small consolidation stresses. Chem Eng Technol. 2003;26:133–7. https://doi.org/10.1002/ceat.200390019.

Igne B, De JA, Jaumot J, Lallemand J, Preys S, Drennen JK, et al. Modeling strategies for pharmaceutical blend monitoring and end-point determination by near-infrared spectroscopy. Int J Pharm. 2014;473(1–2):219–31. https://doi.org/10.1016/j.ijpharm.2014.06.061.

Sulub Y, Konigsberger M, Cheney J. Blend uniformity end-point determination using near-infrared spectroscopy and multivariate calibration. J Pharm Biomed Anal. 2011;55(3):429–34. https://doi.org/10.1016/j.jpba.2008.10.001.

Sulub Y, Wabuyele B, Gargiulo P, Pazdan J, Cheney J, Berry J, et al. Real-time on-line blend uniformity monitoring using near-infrared reflectance spectrometry: a noninvasive off-line calibration approach. J Pharm Biomed Anal. 2009;49(1):48–54. https://doi.org/10.1016/j.jpba.2008.10.001.

Martinez L, Peinado A, Liesum L, Betz G. Use of near-infrared spectroscopy to quantify drug content on a continuous blending process: influence of mass flow and rotation speed variations. Eur J Pharm Biopharm. 2013;84(3):606–15. https://doi.org/10.1016/j.ejpb.2013.01.016.

Martinez L, Peinado A, Liesum L. In-line quantification of two active ingredients in a batch blending process by near-infrared spectroscopy: influence of physical presentation of the sample. Int J Pharm. 2013;451(1–2):67–75. https://doi.org/10.1016/j.ijpharm.2013.04.078.

Koller DM, Posch A, Hörl G, Voura C, Radl S, Urbanetz N, et al. Continuous quantitative monitoring of powder mixing dynamics by near-infrared spectroscopy. Powder Technol. 2011;205(1–3):87–96. https://doi.org/10.1016/j.powtec.2010.08.070.

Ely D, Chamarthy S, Carvajal MT. An investigation into low dose blend uniformity and segregation determination using NIR spectroscopy. Colloids Surf A Physicochem Eng Asp. 2006;288(1–3):71–6. https://doi.org/10.1016/j.colsurfa.2006.04.032.

Freeman R. Measuring the flow properties of consolidated, conditioned and aerated powders—a comparative study using a powder rheometer and a rotational shear cell. Powder Technol. 2007;174(1–2):25–33. https://doi.org/10.1016/j.powtec.2006.10.016.

Kinnunen H, Hebbink G, Peters H, Shur J, Price R. An investigation into the effect of fine lactose particles on the fluidization behaviour and aerosolization performance of carrier-based dry powder inhaler formulations. AAPS PharmSciTech. 2014;15(4):898–909. https://doi.org/10.1208/s12249-014-0119-6.

Schwedes J, Schulze D. Measurement of flow properties of bulk solids. Powder Technol. 1990;61:59–68. https://doi.org/10.1016/0032-5910(90)80066-8.

European Federation of Chemical Engineering. Standard shear testing technique for particulate solids using the Jenike shear cell. IChemE. 1989;1–46.

Jenike AW. Storage and flow of solids. Bull 123 Univ Utah. 1964;53 (26).

Jenike AW. A theory of flow of particulate solids in converging and diverging channels based on a conical yield function. Powder Technol. 1987;50(3):229–36. https://doi.org/10.1016/0032-5910(87)80068-2.

Huang Z, Scicolone JV, Han X, Dave RN. Improved blend and tablet properties of fine pharmaceutical powders via dry particle coating. Int J Pharm. 2015;478(2):447–55. https://doi.org/10.1016/j.ijpharm.2014.11.068.

Inghelbrecht S, Remon JP. Roller compaction and tableting of microcrystalline cellulose/drug mixtures. Int J Pharm. 1998;161(2):215–24. https://doi.org/10.1016/S0378-5173(97)00356-6.

Wagner CM, Pein M, Breitkreutz J. Roll compaction of mannitol: compactability study of crystalline and spray-dried grades. Int J Pharm. 2013;453(2):416–22. https://doi.org/10.1016/j.ijpharm.2013.05.024.

Inghelbrecht S, Remon JP. The roller compaction of different types of lactose. Int J Pharm. 1998;166(2):135–44. https://doi.org/10.1016/S0378-5173(98)00022-2.

Abatzoglou N, Castellanos Gil E, Gosselin R. Influence of hopper geometry on radial and axial concentration profiles of segregated and homogenized granular mixture flows. Powder Technol. 2014;262:42–50. https://doi.org/10.1016/j.powtec.2014.04.051.

Castellanos Gil E, Iraizoz Colarte A, Bataille B, Caraballo I. Estimation of the percolation thresholds in lobenzarit disodium native dextran matrix tablets. AAPS PharmSciTech. 2007;8(4):Article 115. https://doi.org/10.1208/pt0804115.

Jenike AW. Quantitative design of mass-flow bins. Powder Technol. 1967;1(4):237–44. https://doi.org/10.1016/0032-5910(67)80042-1.

Schwedes J. Fließverhalten von Schüttgütern in Bunkern. Chem Ing Tech. 1976;48(4):294–300. https://doi.org/10.1002/cite.330480407.

Rantanen J, Wikström H, Turner R, Taylor LS. Use of in-line near-infrared spectroscopy in combination with chemometrics for improved understanding of pharmaceutical processes. Anal Chem. 2005;77(2):556–63. https://doi.org/10.1021/ac048842u.

Nalluri VR, Puchkov M, Kuentz M. Toward better understanding of powder avalanching and shear cell parameters of drug-excipient blends to design minimal weight variability into pharmaceutical capsules. Int J Pharm. 2013;442(1–2):49–56. https://doi.org/10.1016/j.ijpharm.2012.08.010.

Blattner D, Kolb M, Leuenberger H. Percolation theory and compactibility of binary powder systems. Pharm Res. 1990;7:113–7. https://doi.org/10.1023/A:1015864415693.

Rantanen J, Räsänen E, Tenhunen J, Känsäkoski M, Mannermaa JP, Yliruusi J. In-line moisture measurement during granulation with a four-wavelength near infrared sensor: an evaluation of particle size and binder effects. Eur J Pharm Biopharm. 2000;50(2):271–6. https://doi.org/10.1016/S0939-6411(00)00096-5.

Luukkonen P, Rantanen J, Mäkelä K, Räsänen E, Tenhunen J, Yliruusi J. Characterization of wet massing behavior of silicified microcrystalline cellulose and alpha-lactose monohydrate using near-infrared spectroscopy. Pharm Dev Technol. 2001;6(1):1–9. https://doi.org/10.1081/PDT-100000007.

Luukkonen P, Fransson M, Niklasson BI, Hautala J, Lagerholm B, Folestad S. Real-time assessment of granule and tablet properties using in-line data from a high-shear granulation process. J Pharm Sci. 2008;97(2):950–9. https://doi.org/10.1002/jps.20998.

Li W, Johnson MC, Bruce R, Rasmussen H, Worosila GD. The effect of beam size on real-time determination of powder blend homogeneity by an online near infrared sensor. J Pharm Biomed Anal. 2007;43(2):711–7. https://doi.org/10.1016/j.jpba.2006.07.015.

Salguero-Chaparro L, Baeten V, Abbas O, Peña-Rodríguez F. On-line analysis of intact olive fruits by vis-NIR spectroscopy: optimisation of the acquisition parameters. J Food Eng. 2012;112(3):152–7. https://doi.org/10.1016/j.jfoodeng.2012.03.034.

Hamad ML, Bowman K, Smith N, Sheng X, Morris KR. Multi-scale pharmaceutical process understanding: from particle to powder to dosage form. Chem Eng Sci. 2010;65(21):5625–38. https://doi.org/10.1016/j.ces.2010.01.037.

Acknowledgements

The authors acknowledge Holger Grohganz for valuable discussions.

Funding

Miriam Pein-Hackelbusch gratefully acknowledges the financial funding of the “Heinrich-Hertz-Stiftung” and the SEPAWA for financing her endowed chair.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Hirschberg, C., Boetker, J.P., Rantanen, J. et al. Using 3D Printing for Rapid Prototyping of Characterization Tools for Investigating Powder Blend Behavior. AAPS PharmSciTech 19, 941–950 (2018). https://doi.org/10.1208/s12249-017-0904-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1208/s12249-017-0904-0