Abstract

Pharmaceutical industries and drug regulatory agencies are inclining towards continuous manufacturing due to better control over the processing conditions and in view to improve product quality. In the present work, continuous manufacturing of O/W emulgel by melt extrusion process was explored using lidocaine as an active pharmaceutical ingredient. Emulgel was characterized for pH, water activity, globule size distribution, and in vitro release rate. Additionally, effect of temperature (25°C and 60°C) and screw speed (100, 300, and 600 rpm) on the globule size and in vitro release rate was studied. Results indicated that at a given temperature, emulgel prepared under screw speed of 300 rpm resulted in products with smaller globules and faster drug release.

Graphical Abstract

Similar content being viewed by others

References

Christianto W, Ka M Ng. Product‐oriented process synthesis and development: creams and pastes. AIChE J. 47. 2001; 12:2746–2767. https://doi.org/10.1002/aic.690471214

Brown M, Pratt S, Harrison C. QbD Strategies to secure the scale-up of semi-solid topical formulations. Pharm Tech. 2018.

Amit A, Khichariya A, Gupta S, Patel RJ, Giri TK, Tripathi DK. Recent expansions in an emergent novel drug delivery technology: Emulgel. J Control Release. 2013;171:122–32. https://doi.org/10.1016/j.jconrel.2013.06.030.

Muhammad S, Naveed A, Abdul R, Khan HMS, Khan H. An approach to enhanced stability: formulation and characterization of Solanum lycopersicum derived lycopene based topical emulgel. Saudi pharm J. 2018;26:1170–7. https://doi.org/10.1016/j.jsps.2018.07.005.

Yuh-Fun M, Hsu CC. Performance of sonication and microfluidization for liquid–liquid emulsification. Pharm Dev Technol. 1999;4:233–40. https://doi.org/10.1081/PDT-100101357.

Vanhoorne V, Vervaet C. Recent progress in continuous manufacturing of oral solid dosage forms. Int J Pharm. 2020; 579:119194. https://doi.org/10.1016/j.ijpharm.2020.119194.

ICH Q13 guidelines: CM of drug substance and drug products draft version endorsed on 27 July 2021.

Koeberle M, Wolfgang S. QbD: improving pharmaceutical development and manufacturing workflows to deliver better patient outcomes. Suppl. 2017;4:s20–3.

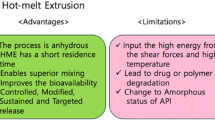

Maniruzzaman M, Nokhodchi A. CM via hot melt extrusion and scale-up: regulatory matters. Drug Discov. 2017;22(2):340–51. https://doi.org/10.1016/j.drudis.2016.11.007.

Ajjarapu S, Rangappa S, Shankar VK, Shettar A, Kumar HN, Kulkarni VI, Repka MA, Murthy SN. A rapid tool to optimize process variables for continuous manufacturing of metronidazole ointment using melt extrusion technique. AAPS PharmSciTech. 2020;21:1–7. https://doi.org/10.1208/s12249-020-01808-8.

Shettar A, Shankar VK, Ajjarapu S, Kulkarni VI, Repka MA, Murthy SN. Development and characterization of Novel topical oil/PEG creams of voriconazole for the treatment of fungal infections. J Drug Deliv Sci Technol. 2021;66: 102928. https://doi.org/10.1016/j.jddst.2021.102928

Brkich LL, Markin PA, Moskaleva NE, Pyatigorskaya NV, Brkich GE, Panov AV, Grin MA. Development and validation of a method for determining lidocaine hydrochloride and miramistin in an innovative wound-healing gel. Pharm Chem J. 2020;54:69–72. https://doi.org/10.1007/s11094-020-02158-2.

Reiser MRL. Effect of continuous phase drug concentration, evaporation and partitioning on transdermal drug permeation kinetics with lipophilic vehicles. PhD diss: University of Basel; 2008.

Fasolo D, Bruna P, Gabriela M, Giovanni Z, Alexandre M, Gilsane von Poser F, Helder FT. Topical delivery of antifungal Brazilian red propolis benzophenones-rich extract by means of cationic lipid nanoemulsions optimized by means of Box-Behnken design. J Drug Deliv Sci Technol. 2020; 56: 101573. https://doi.org/10.1016/j.jddst.2020.101573

Daryab M, Mehrdad F, Arash M, Reza A. Preparation and characterization of lidocaine-loaded, microemulsion-based topical gels. Iran J Pharm Res. 2022;21. https://doi.org/10.5812/ijpr.123787

Dong Y, Leanna H, Deval P, Robert H, Qu H, Stephanie C, Muhammad A, Celia NC, Xiaoming X. A kinetic approach to determining drug distribution in complex biphasic systems. J Pharm Sci. 2019;1(08):2002–11. https://doi.org/10.1016/j.xphs.2019.01.003.

Alshamsan A, Kazi M, Badran MM, Alanazi FK. Role of alternative lipid excipients in the design of self-nanoemulsifying formulations for fenofibrate: characterization, in vitro dispersion, digestion and ex vivo gut permeation studies. Front. Pharmacol. 2018;9,1219. https://doi.org/10.3389/Fphar.2018.01219

Bonacucina G, Marco C, Giovanni FP. Characterization and stability of emulsion gels based on acrylamide/sodium acryloyldimethyl taurate copolymer. AAPS PharmSciTech. 2009;10:368–75. https://doi.org/10.1208/s12249-009-9218-1.

Karoyo AH, Lee DW. A review on the design and hydration properties of natural polymer-based hydrogels. Materials. 2021;14:1095. https://doi.org/10.3390/ma14051095.

Mendonsa NS, Pradhan A, Sharma P, Prado RMB, Murthy SN, Kundu S, Repka MA. A quality by design approach to develop topical creams via hot-melt extrusion technology Eur J Pharm Sci. 2019; 136: 104948. https://doi.org/10.1016/j.ejps.2019.06.002

Simoes MF, Rui MAP, Sérgio S. Hot-melt extrusion in the pharmaceutical industry: toward filing a new drug application. Drug Discov Today. 2019;24:1749–68. https://doi.org/10.1016/j.drudis.2019.05.013.

Acknowledgements

The authors also acknowledge the technical support by STEERLife India Pvt Ltd, Bangalore.

Funding

The present work was partially funded by Pfizer Inc, USA and by Topical Products Testing LLC, Oxford, MS.

Author information

Authors and Affiliations

Contributions

Conceptualization: [S Narasimha Murthy], [Yeoh Thean], [Abu Zayed Badruddoza], [Jaymin Shah]; methodology: [Anusha Echanur V], [Anusha V Matadh], [Pragathi S G], [Sarasija S]; formal analysis and investigation: [Vijay Kulkarni], [H N Shivakumar], [Sarasija S]; writing—original draft preparation: [S Narasimha Murthy], [Anusha V Matadh], [Srinivas Ajjarapu]; writing—review and editing: [Howard Maibach], [S Narasimha Murthy], [Shivakumar H N], [Reena N. M]; supervision and advise: [S Narasimha Murthy], [Sarasija S].

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare no competing interests.

Additional information

Communicated by: Jayachandra Babu Ramapuram and Ashana Puri

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Echanur, V.A., Matadh, A.V., Pragathi, S.G. et al. Continuous Manufacturing of Oil in Water (O/W) Emulgel by Extrusion Process. AAPS PharmSciTech 24, 76 (2023). https://doi.org/10.1208/s12249-023-02530-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1208/s12249-023-02530-x