Abstract

The effect of titanium on the structure and properties of a rapidly cooled hypereutectic cast gray iron has been studied on the example of permanent mold (PM) casting. A microstructure study showed that titanium is a relatively strong element in controlling solidification structure by increasing undercooling and thus promoting type D graphite. The effectiveness of titanium additions depends on the base iron carbon equivalent (CE) with more pronounced changes in iron with a lower CE. The undercooling ability of the titanium decreases after exceeding a certain level. Increasing titanium from 0.09–0.12% slightly increases undercooling in iron with lower CE, but this effect was reduced in a more strongly hypereutectic iron. Alloying with titanium generally improves tensile strength, but the effectiveness of titanium additions also depends on the base iron CE range. Scanning electron microscope (SEM) studies revealed that most of the titanium-containing compounds were located in the metallic matrix: titanium carbides have been found in pearlite, while titanium nitrides and carbonitrides were located in ferrite. The presence of large amounts of extremely hard titanium-containing compounds, which often appear with steadite in a relatively high phosphorous content PM gray iron, amplifies the negative effect of titanium on machinability. This study suggests that for optimal combination of tensile strength/microstructure with good machinability, the titanium content in PM gray iron should not exceed 0.075%.

Similar content being viewed by others

References

Y.S. Lerner and G.S. Griffin: “Developments in Continuous Casting of Gray and Ductile Iron,” Modern Casting, 1997, (November), pp. 41–44.

Y.S. Lerner: “Recent Trends and Developments in Permanent Mold Casting of Iron” in Proc. Int. Foundry Congress, Istanbul, Turkey, Oct 1999, pp. 351–60.

Anon: “Continuous Cast Iron,” Wells Dura-Bar, Company Brochure, Woodstock, IL, 1994.

Y.S. Lerner, A. ElSawy, and M. Fahmy: “Gray Iron Chemistry Optimization for Permanent Mold Molding” in Proc. 6th Int. Conf. on Production Engineering, Design and Control, PEDAC ’97, Alexandria, Egypt, Feb 15–17, 1997, pp. 299–310.

G.R. Ruff and J.F. Wallace: “Control of Graphite Structure and Its Effect on Mechanical Properties of Gray Iron,” AFS Trans., 1976, 84, pp. 705–28.

G.F. Ruff and J.F. Wallace: “Effects of Solidification Structures on the Tensile Properties of Gray Iron,” AFS Trans., 1977, 85, pp. 63–86.

P.J. Mikelonis: “The Effects and Use of Ilmenite Ore as a Titanium Source in Cupola Melted Gray Iron,” AFS Trans., 1976, 84, pp. 449–52.

H.D. Merchant: “Effect of Alloy Additions on High Temperature Hardness of Flake Type Cast Iron,” J. Iron Steel Inst., 1972, 210, pp. 442–46.

J.M. Greenhill and N.M. Reynolds: “Nitrogen Defects in Iron Castings,” Foundry Trade J., 1981, 151(3217), pp. 111–22.

G.X. Sua and C.R. Loper, Jr.: “Titanium Carbonitrides in Cast Irons,” AFS Trans., 1983, 9, pp. 639–46.

J.R. Hitchings and J. Klein: “Titanium in Cast Iron: Its Reactions and Effects,” AFS Trans., 1989, 9, pp. 579–86.

B.J. Chapman and G. Mannion: “Titanium Bearing Cast Irons for Automotive Braking Applications,” Foundry Trade J., 1982, 152(3732), pp. 232–46.

A. Prodhan, S. Ghosh, and O. Mohanty: “Effect of Composition and Inoculation on the Characteristics of Cast Irons for Ingot Mold Production,” Indian Foundry J., 1992, 38(7), pp. 41–51.

R.A. Harding and M.L. Wise: “The Effect of Titanium on Machinability of Ductile Iron,” 104th AFS Casting Congress, Pittsburgh, PA, Apr 8–11, 2000.

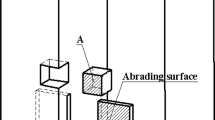

C.E. Bates: “Machinability of Irons,” AFS Research, Des Plaines, IL, 1999.

H. Morrow: “The Metallography of Inclusions in Cast Irons and Pig Irons,” J. Iron Steel Inst., 1961, 1, pp. 207–53.

S. Morito and N. Inoyama: “Behavior of Nitrogen in Cast Iron,” 35th Int. Foundry Congress, Kyoto, Japan, 1968, pp. 41-a to 41-9.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Lerner, Y. Titanium in the rapidly cooled hypereutectic gray iron. J. of Materi Eng and Perform 12, 141–146 (2003). https://doi.org/10.1361/105994903770343277

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1361/105994903770343277