Abstract

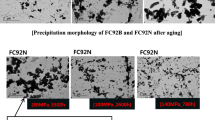

The effect of B and C microadditions on the fracture toughness of IN 718 superalloy was investigated at room temperature (RT) and at 650 °C. At RT, the fracture toughness was observed to increase with increasing B and C concentrations. C had a relatively weak effect on the fracture toughness at 650 °C, but the influence of B was significant. At RT the highest fracture toughness value was obtained for the alloy with 29 ppm B and 225 ppm C at RT, and at 650 °C the alloy with 60 ppm B and 40 ppm C had the highest fracture toughness. An increase in the concentration of B to 100 ppm, however, resulted in a reduction in the fracture toughness at 650 °C. Fractographic observations showed that the formation and coalescence of microvoids was the predominant fracture mechanism at RT. In contrast, at 650 °C, the fracture surface exhibited intergranular cracking in the alloy with lower B concentrations and transgranular cracking coupled with fine dimples in the alloy with higher B concentrations. It is suggested that B impedes intergranular cracking by increasing the cohesion of grain boundaries and improving the grain boundary stabilization. The RT increase in the fracture toughness of the material caused by the addition of C is attributed to the formation of intergranular and intragranular carbides that increased the resistance to the plastic deformation.

Similar content being viewed by others

References

R.T. Holt and W. Wallace, Impurities and Trace Elements in Nickelbase Superalloys, Int. Metals Rev., Vol 21, 1976, p 1–24

T.J. Garosshen, T.D. Tillman, and G.P. McCarthy, Effects of B, C, and Zr on the Structure and Properties of a P/M Nickel Base Superalloy, Metall. Trans. A, Vol. 18, 1987, p 69–77

F.T. Furillo, J.M. Davidson, J.K. Tien, and L.A. Jackman, The Effects of Grain Boundary Carbides on the Creep and Back Stress of a Nickelbase Superalloy, Mater. Sci. Eng., Vol 39, 1979, p 267–273

T.J. Garosshen and G.P. McCarthy, Low Temperature Carbide Precipitation in a Nickel Base Superalloy, Metall. Trans. A, Vol 16A, 1985, p 1213–1223

C.C. Law and M.J. Blackburn, Creep-Rupture in Powder Metallurgical Nickel-Base Superalloys at Intermediate Temperatures, Metall. Trans. A, Vol 11, 1980, p 495–507

M.A. Burke, J. Greggi, Jr., and G.A. Whitlow, The Effect of Boron and Carbon on the Microstructural Chemistries of Two Wrought Nickel Base Superalloys, Scripta Metall., Vol 18, 1984, p 91–94

W.D. Cao and R.L. Kennedy, Effect and Mechanism of Phosphorus and Boron on Creep Deformation of Alloy 718, Proceedings of the Coference on Superalloys 718, 625, 706 and Various Derivatives, E.A. Loria, Ed., TMS, Warrendale, PA, 1997, p 511–520

S. Floreen and J.M. Davidson, The Effects of B and Zr on the Creep and Fatigue Crack Growth Behavior of a Ni-Base Superalloy, Metall. Trans. A, Vol 14, 1983, p 895–901

X. Huang, M.C. Chaturvedi, N.L. Richards, and J. Jackman, The Effect of Grain Boundary Segregation of Boron in Cast Alloy 718 on HAZ Microfissuring—a SIMS Analysis, Acta Mater., Vol 45, 1997, p 3095–3107

W. Chen, M.C. Chaturvedi, N.L. Richards, and G. McMahom, Grain Boundary Segregation of Boron in Inconel 718, Metall. Mater. Trans. A, Vol 29, 1998, p 1947–1954

X. Huang, M.C. Chaturvedi, and N.L. Richards, Effect of Homogenization Heat Treatment on the Microstructure and Heat-Affected Zone Microfissuring in Welded Cast Alloy 718, Metall. Mater. Trans. A, Vol 27, 1996, p 785–790

H. Guo, M.C. Chaturvedi, N.L. Richards, and G.S. McMahom, Interdependence of Character of Grain Boundaries, Intergranular Segregation of Boron and Grain Boundary Liquation in Simulated Weld Heat-Affected Zone in Inconel 718, Scripta Mater., Vol 40, 1999, p 383–388

M.G. Stout and W.W. Gerberich, Structure/Property/Continuum Synthesis of Ductile Fracture in Inconel Alloy 718, Metall. Trans. A, Vol 9, 1978, p 649–658

W.J. Mills, The Effect of Heat Treatment on the Room Temperature and Elevated Temperature Fracture Toughness Response of Alloy 718, ASEM J. Eng. Mater. Technol., Vol 102, 1980, p 118–126

M. Clavel and A. Pineau, Fatigue Behaviour of Two Nickel-base Alloys I: Experimental Results on Low Cycle Fatigue, Fatigue Crack Propagation and Substructures, Mater. Sci. Eng., Vol 55, 1982, p 157–171

L.A. James, and W.J. Mills, Effect of Heat-Treatment Upon the Fatigue-Crack Growth Behavior of Alloy 718 Weldments—Part I: Macroscopic Behavior, ASME J. Eng. Mater. Technol., Vol 107, 1985, p 34–40

T.H. Sanders, Jr. R.E. Frishmuth, and G.T. Embley, Temperature Dependent Deformation Mechanisms of Alloy 718 in Low Cycle Fatigue, Metall. Trans. A, Vol 12, 1981, p 1003–1010

H.F. Merrick, The Low Cycle Fatigue of Three Wrought Nickel-Base Alloys, Metall. Trans., Vol 5, 1974, p 891–897

L. Xiao, D.L. Chen, and M.C. Chaturvedi, Effect of Boron on the Low-Cycle Fatigue Behavior and Deformation Structure of Inconel 718 at 650°C, Metall. Mater. Trans. A, Vol 35, 2004, p 3477–3487

L. Xiao, D.L. Chen, and M.C. Chaturvedi, Effect of Boron Concentration on Fatigue Crack Propagation Resistance and Low Cycle Fatigue Properties of Inconel 718, Superalloys 2004, K.A. Green, H. Harada, T.E. Howson, T.M. Pollock, R.C. Reed, J.J. Schirra, and S. Walston, Ed., TMS, Warrendale, PA, 2004, p 275–281

J.D. Landes and J.A. Begley, Test Results from J-Integral Studies: An Attempt to Establish a J IC Testing Procedure, Fracture Analysis, ASTM STP 560, 1974, p 170–186

J.G. Kaufman, Progress in Fracture Testing of Metallic Materials, Review of Developments in Plane Strain Fracture Toughness Testing, W.F. Brown, Jr., Ed., ASTM STP 463, 1970, p 3–21

W.S. Walston, N.R. Moody, I.M. Bernstein, and A.W. Thompson, Comparisons of K JIC and K IC Values from Tests on a Single Crystal Nickel-Bases Superalloy, Scr. Metall. Mater., Vol 25, 1991, p 1333–1337

R.F. Decker and J.W. Freeman, The Mechanism of Beneficial Effects of Boron and Zirconium on Creep Properties of a Complex Heat-Resistant Alloy, Trans AIME, Vol 218, 1960, p 277–284

K.M. Delaryg and G.D.W. Smith, Phase Composition and Phase Stability of a High-Chromium Nickel-Based Superalloy, IN939, Metall. Mater. Trans. A, Vol 14, 1983, p 1771–1783

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Xiao, L., Chaturvedi, M.C. & Chen, D. Effect of boron and carbon on the fracture toughness of IN 718 superalloy at room temperature and 650 °C. J. of Materi Eng and Perform 14, 528–538 (2005). https://doi.org/10.1361/105994905X56106

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1361/105994905X56106