Abstract

The effect of segregation of alloying elements on the phase transformation of ductile iron during austempering was investigated. Four heats, each containing 0.4%Mn, 1% Cu, 1.5% Ni, or 0.4% Mo (wt%) separately, were melted; then three different sizes of casting bars (3,15, and 75 mm diameter) were poured from each heat. The distribution and the degree of segregation of certain elements were quantitatively analyzed using an electron microprobe. A personal computer (PC)-controlled heat treating system was used to measure electrical resistivity, and the information on resistivity variations was used to analyze the effect of segregation on phase transformations during austempering. Also, Charpy impact and Rockwell hardness tests were performed to determine the effect of segregation on properties.

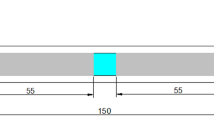

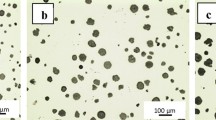

Results of the electron microprobe analysis showed that the degree of segregation of alloy elements increases with an increase in diameter of the casting bars (i.e., an increase of solidification time of castings). The degree of segregation of alloy elements, represented by segregation ratio (SR) (the maximum concentration of element in cell divided by the minimum concentration of element in cell), varied linearly with the casting modulus (M) (volume of casting divided by surface area of casting). Regarding the segregating tendency among alloy elements, positive segregating elements Mn and Mo showed more segregation than the negative segregating elements Si, Cu, and Ni. In addition, segregation of Mo was more significant than Mn, and that for Cu was greater than Ni and Si.

Between the time of finishing the first stage and beginning the second stage of bainite reaction in ductile irons, there is a significant “processing window,” At;, for austempering to obtain optimum mechanical properties. From the electrical resistivity data, it was observed that the austempering temperature plays a major role in the processing window. There was a narrow window at 400 ‡C but a larger one at 350 ‡C. Additionally, the microsegregation of alloying elements led to variation of the time of phase transformation for various regions in the grain cells of ductile iron which caused the processing window to decrease. The span of the processing window decreased with an increase in degree of segregation.

There was no significant difference in the hardness of the alloys in various diameter specimens. However, the impact toughness was significantly affected by the segregation. The impact values in 15 mm specimens with less degree of segregation were greater than those in 75 mm specimens with significant segregation.

The Ni, Cu, and Mn alloys that were austempered to complete the first stage of bainite formation had approximately the same impact values for all diameter samples. The Mo alloy upon austempering produced no bainite, but it had much untransformed retained austenite in the intercellular regions and, therefore, had lower impact values.

Similar content being viewed by others

References

P.A. Blackmore and R.A. Harding, The Effect of Metallurgical Process Variables on the Properties of Austempered Ductile Iron,J. Heat Treating, Vol 3, 1984, p 310–325

J.F. Janowark and R.B. Gundlach, Development of Ductile Iron for Commercial Austempering,AFS Trans., Vol 91, 1983, p 377–388

R.C. Voigt, Microstructural Analysis of Austempered Ductile Cast Iron Using the Scanning Electron Microscope,AFS Trans., Vol 91, 1983, p 377–388

M. Jonansson, Austenitic-Bainitic Ductile Iron,AFS Trans., Vol 95, 1977, p 117–122

DJ. Moore, T.N. Rouns, and K.B. Rundman, The Effect of Heat Treatment, Mechanical Deformation and Alloying Element Additions on the Rate of Bainite Formation in Austempered Ductile Iron,J. Heat Treating, Vol 4, 1985, p 7–24

DJ. Moore, T.N. Rouns, and K.B. Rundman, Structure and Mechanical Properties of Austempered Ductile Iron,AFS Trans., Vol 93, 1985, p 705–718

D.J. Moore, B.S. Shugart, K.L. Hayrynen, and K.B. Rundman, A Microstructure Determination of Isothermal Transformation Diagram in a Low-Alloy Ductile Iron,AFS Trans., Vol 98, 1990, p 519–526

DJ. Moore, G.P. Faubert, E.D. McCarty, DJ. Ellerbrock, and K.B. Rundman, Isothermal Transformation Diagram in a Heavy-Section, High-Alloy Ductile Cast Iron,AFS Trans., Vol 98, 1990, p 49–457

K. Yasue, T. Nisio, Y. Yamada, and Y. Obata, Effects of Alloying Elements and Austenitizing Conditions on the Isothermal Transformation Diagram of Ductile Cast Iron,Imono, Vol 63, 1991, p 595–600

J.P. Chobaut, P. Brenot, and J. M. Schissler, Secondary Martensite Formation During the Tempering of Bainite S. G. Cast Iron.,AFS Trans., Vol 96, 1988, p 475–480

K.B. Rundman and R.C. Klug, An X-ray and Metallographic Study of an Austempered Ductile Iron,AFS Trans., Vol 90, 1982, p 499–508

B.Y. Lin, A Study on Austemperability of Ductile Iron, Master Thesis, 1987,NTIT, R.O.C.

YJ. Park, R.B. Gundlach, and J.F. Janowark, Monitoring the Bainite Reaction during Austempering of Ductile Steel by Resistivity Measurement,AFS Trans., Vol 95, 1987, p 411–416

B.Y. Lin, E.T. Chen, and T.S. Lei, The Use of Electrical Conductivity on the Study of the Austemperability of Ductile Irons, NSC 80-0405-E011-08, R.O.C.

D.J. Moore, T.N. Rouns, and K.B. Rundman, Effect of Manganese on Structure and Properties of Austempered Ductile Iron: A Processing Window Concept,AFS Trans., Vol 94, 1986, p 255–264

N. Darwish and R. Elliott, Austempering of Low Manganese Ductile Irons—Part 1: Processing Window,Materials Science and Technology, Vol 9, 1993, p 572–585

R.C. Voigt and C.R. Loper, Jr., Austempered Ductile Iron—Process Control and Quality Assurance,J. Heat Treating, Vol 3, 1984, p 291–309

B.V. Kovacs, Austempered Ductile Iron: Fact and Fiction,Modern Casting, March 1990, p 38–41

G. Jolley, Segregation During Solidification of Nodular Cast Iron,The Solidification of Metals, London, Iron and Steel Inst., Vol 110, 1968, p 242–250

N.K. Datta and N.N. Engel, Electron Microprobe Study of the Distribution of Si, Cu, Ni, Mn, Mo, and Cr in Ductile Iron,AFS Trans., Vol 84, 1976, p 431–436

P.C. Liu and C.R. Loper, Jr., Electron Microprobe Study of the Intercellular Compounds in Heavy Section Ductile Iron,AFS Trans., Vol 89, 1981, p 131–140

R. Boeri and F. Weinberg, Microsegregation in Ductile Iron,AFS Trans., Vol 97, 1989, p 179–184

J.M. Schissler and J. Saverna, The Effect of Segregation on the Formation of Austempered Ductile Iron,J. Heat Treating, Vol 4, 1985, p 167–176

K.L. Hayrynen, G.P Faubert, D.J. Moore, and K.B. Rundman, Heavy Section ADI: Microsegregation, Microstructure, and Tensile Properties,AFS Trans., Vol 97, 1989, p 747–756

G.P Faubert, D.J. Moore, and K.B. Rundman, Heavy Section ADI: Tensile Properties in the As-Cast and Austempered Condition,AFS Trans., Vol 99, 1991, p 551–561

M.C. Flemings, Solidification Processing, McGraw-Hill, New York, 1974, p 11

B.Y. Lin, The Effect of Alloy Elements on the Austemper-Transformation of Ductile Irons, Ph.D. Thesis, 1995,NTIT, R.O.C.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Lin, B.Y., Chen, E.T. & Lei, T.S. The effect of segregation on the austemper transformation and toughness of ductile irons. J. of Materi Eng and Perform 7, 407–419 (1998). https://doi.org/10.1361/105994998770347864

Received:

Revised:

Issue Date:

DOI: https://doi.org/10.1361/105994998770347864