Abstract

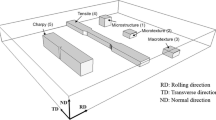

The effect of austenitizing conditions on the microstructure and impact properties of an austempered ductile iron (ADI) containing 1.6% Cu and 1.6% Ni as the main alloying elements was investigated. Impact tests were carried out on samples of initially ferritic matrix structure and which had been first austenitized at 850,900, 950, and 1000°C for 15 to 360 min and austempered at 360°C for 180 min.

Results showed that the austenitizing temperature, Tγ, and time, tγ, have a significant effect on the impact properties of the alloy. This has been attributed to the influence of these variables on the carbon kinetics.

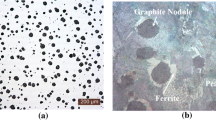

The impact energy is generally high after short tγ, and it falls with further soaking. In samples austenitized at 850 and 900°C, these trends correspond to the gradual disappearance of the pro-eutectoid ferrite and the attainment of fully developed ausferritic structures. In initially ferritic structures, the carbon diffusion distances involved during austenitization are large compared to those in pearlitic structures. This explains the relatively long soaking periods required to attain fully ausferritic structures, which in spite of the lower impact energy values, have a better combination of mechanical properties.

Microstructures of samples austenitized at 950 and 1000°C contain no pro-eutectoid ferrite. The impact properties of the former structures are independent of tγ, while those solution treated at 1000°C are generally low and show wide variation over the range of soaking time investigated.

For fully ausferritic structures, impact properties fall with an increase in Tγ. This is particularly evident at 1000°C. As the Tγ increases, the amount of carbon dissolved in the original austenite increases. This slows down the rate of austenite transformation and results in coarser structures with lower mechanical properties. Optimum impact properties are obtained following austenitizing between 900 and 950°C for 120 to 180 min.

Similar content being viewed by others

References

M. Grech, An Update on Austempered Ductile Iron,International Conference on Mechanical Behaviour of Ductile Cast Iron and Other Cast Metals, Kitakyushu, Japan, Aug 1993, p 18–25

P.A. Blackmore and R.A. Harding, The Effects of Metallurgical Process Variables on The Properties of Austempered Ductile Irons,Proc. 1st Int. Conf. on ADI, 1984, p 117–134

D.J. Moore, T.N. Rouns, and K.B. Rundman, The Relationship Between Microstructure and Tensile Properties in ADI,AFS Trans., 1987, p 765–774

J. Aranzabal, I. Gutierrez, J.M. Rodriguez-Ibabe, and J.J. Urcola, Influence of Heat Treatments on Microstructure and Toughness of Austempered Ductile Iron,Mater. Sci. Technol., Vol 8 (No. 11), 1992, p 263–273

E. Dorazil, B. Barta, E. Munsterova, L. Stransky, and A. Huvar, High-Strength Bainitic Ductile Cast Iron,Cast Metals, AFS Int., 1982, p 52–62

R.B. Gundlach and J.F. Janowak, Austempered Ductile Iron Combines Strength With Toughness and Ductility,Met. Prog., 1988, p 19–26

B. Kovacs, Austempered Ductile Iron-Fact and Fiction,Mod. Cast., 1990, p 38–41

M. Grech, “Structure and Mechanical Properties of an ADI Alloyed With Copper-Nickel”, Ph.D. thesis, Birmingham University, U.K., 1989

M. Delia, M. Alaalam, and M. Grech, Effect of Austenitizing Conditions on The Impact Properties of an Alloyed Austempered Ductile Iron of Initially Pearlitic Matrix Structure,Int. J. Cast Met. Research, Vol 9 (No. 6), 1997, p 345–351

B.V. Kovacs, A Simple Technique to Identify Various Phases in ADI,Mod. Cast., 1987, p 35

T. Skaland and D. Grog, Nodule Distribution in Ductile Cast Iron,AFS Trans., Vol 56, 1991, p 153–157

T.N. Rouns, K.B. Rundman, and D.M. Moore, On The Structure and Properties of Austempered Ductile Cast Iron,AFS Trans., Vol 121, 1984, p 815–840

B.T.S. Shih, C.H. Change, and Z.D. Ou, Mechanical Properties and Microstructure of Copper Alloyed ADI,AFS Trans., Vol 71, 1993, p 857–872

B. Kovacs, On The Terminology and Structure of ADI,AFS Trans., Vol 83, 1994, p 417–420

C.H. Hughes, Austempered Ductile Irons Their Properties and Significance,Mater. Des., Vol 8 (No. 3), 1985, p 124–126

H. Bayati and R. Elliott, Relationship Between Structure and Mechanical Properties in High Manganese Alloyed Ductile Iron,Mater. Sci. Technol, Vol 11, 1995, p 284–293

M.M. Shea and E.F. Ryntz, Austempering Nodular Iron for Optimum Toughness,AFS Trans., Vol 125, 1986, p 683–688

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Delia, M., Alaalam, M. & Grech, M. Effect of austenitizing conditions on the impact properties of an alloyed austempered ductile iron of initially ferritic matrix structure. J. of Materi Eng and Perform 7, 265–272 (1998). https://doi.org/10.1361/105994998770348007

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1361/105994998770348007