Abstract

The critical velocity of copper (Cu) particles for deposition in cold spraying was estimated both experimentally and theoretically. An experimental method is proposed to measure the critical velocity based on the theoretical relationship between deposition efficiency and critical velocity at different spray angles. A numerical simulation of particle impact deformation is used to estmate the critical velocity. The theoretical estimation is based on the critical velocity corresponding to the particle velocity at which impact begins to cause adiabatic shear instability. The experimental deposition was conducted using Cu particles of different particle sizes, velocities, oxygen contents, and temperatures. The dependency of the critical velocity on particle temperature was examined. Results show that the critical velocity can be reasonably measured by the proposed test method, which detects the change of critical velocity with particle temperature and oxygen content. The Cu particles of oxygen content 0.01 wt.% yielded a critical velocity of about 327 m/s. Experiments show that the oxygen content of powder significantly influences the critical velocity. Variations in oxygen content can explain the large discrepancies in critical velocity that have been reported by different investigators. Critical velocity is also found to be influenced by particle temperature as well as types of materials. High particle temperature causes a decrease in critical velocity. This effect is attributed to the thermal softening at elevated temperatures.

Similar content being viewed by others

References

A.P. Alkimov, V.F. Kosarev, and A.N. Papyrin, A Method of Cold Gas Dynamic Deposition. Dokl. Akad. Nauk SSSR, 1990, 318(5), p 1062–1065

R.S. Lima, J. Karthikeyan, C.M. Kay, J. Lindemann, and C.C. Berndt, Microstructural Characteristics of Cold-Sprayed Nanostructured WC-Co Coatings. Thin Solid Films, 2002, 416(1–2), p 129–135.

C.-J. Li, G.-J. Yang, X.-C. Huang, W.-Y. Li, and A. Ohmori, Formation of TiO2 Photocatalyst Through Cold Spraying. Thermal Spray 2004: Advances in Technology and Application, ASM International, May 10–12, 2004. (Osaka, Japan), ASM International, 2004, p 345–349

T.H. Van Steenkiste, J.R. Smith, R.E. Teets, J.J. Moleski, D.W. Gorkiewicz, R.P. Tison, D.R. Marantz, K.A. Kowalsky, W.J. Riggs, P.H. Zajchowski, B. Pilsner, R.C. McCune, and K.J. Barnett, Kinetic Spray Coatings, Surf. Coat. Technol. 1999, 111(1), p 62–71

T. Stoltenhoff, J. Voyer, and H. Kreye, Cold Spraying: State of the Art and Applicability, International Thermal Spray Conference, E. Lugscheider and C.C. Berndt, Ed., March 4–6, 2002 (Essen, Germany), DVS Deutscher Verband für Schweißen, 2002, p 366–374.

D. Zhang, P.H. Shipway, and D.G. McCartney, Particle-Substrate Interactions in Cold Gas Dynamic Spraying, Thermal Spray 2003: Advancing the Science and Applying the Technology, B.R. Marple and C. Moreau, Ed., May 5–8, 2003 (Orlando, FL), ASM International, 2003, Vol. 1, p 45–52.

D.L. Gilmore, R.C. Dykhuizen, R.A. Neiser, T.J. Roemer, and M.F. Smith, Particle Velocity and Deposition Efficiency in the Cold Spray Process. J Thermal Spray Technol, 1999, 8(4), p 576–582

R.C. Dykhuizen and M.F. Smith, Gas Dynamic Principles of Cold Spray, J. Thermal Spray Technol., 1998, 7(2), p 205–212

T.H. Van Steenkiste, J.R. Smith, and R.E. Teets, Aluminum Coatings via Kinetic Spray with Relatively Large Powder Particles. Surf. Coat. Technol., 2002, 154(2–3), p 237–252

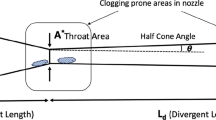

C.-J. Li and W.-Y. Li, Optimization of Spray Conditions in Cold Spraying Based on the Numerical Analysis of Particle Velocity. Trans. Nonferrous Met. Soc. China 14(Special 2), 2004, p 43–48

C.-J. Li and W.-Y. Li, Deposition Characteristics of Titanium Coating in Cold Spraying. Surf. Coat. Technol., 2003, 167(2–3), p 278–283.

C.-J. Li, W.-Y. Li, Y.-Y. Wang, and H. Fukanuma, A Theoretical Model for Prediction of Deposition Efficiency in Cold Spraying. Thin Solid Films, 2005, 485, p 79–85

H. Assadi, F. Gärtner, T. Stoltenhoff, and H. Kreye, Bonding Mechanism in Cold Gas Spraying, Acta Mater., 2003, 51(15), p 4379–4394

W.-Y. Li, C.-J. Li, Y.-Y. Wang, and G.-J. Yang, Effect of Cu Particle Parameters on Its Impacting Behavior in Cold Spraying. Acta Metall. Sin., 2005, 41(3), p 282–286, in Chinese

Fluent Inc., NH, FLUENT Manual, 1999

C.-J. Li and W.-Y. Li, Optimal Design of a Novel Cold Spray Gun Nozzle at a Limited Space. J. Thermal Spray Technol. 2005, 14(3), p 391–396

Livermore Software Technology Corporation, CA, LS-DYNA Theorectical Manual, 1998

G.R. Johnson and W.H. Cook, Fracture Characteristics of Three Metals Subjected to Various Strains, Strain Rates, Temperatures and Pressures, Eng. Fract. Mech., 1985, 21(1), p 31–48

C.-J. Li, W.-Y. Li, and G.-J. Yang, Examination of Impact Fusion Phenomenon During Cold Spraying of Zinc, Thermal Spray 2004; Advances in Technology and Application, ASM International, May 10–12, 2004, (Osaka, Japan), ASM International, 2004, p 335–340

F. Gärtner, T. Stoltenhoff, T. Schmidt, and H. Kreye, The Cold Spray Process and Its Potential for Industrial Applications, Thermal Spray Connects: Explore Its Surface Potential, E. Lugscheider, Ed., May 2–4, 2005, (Basel, Switzerland), DVS, p 158–163

C.-J. Li, W.-Y. Li, and H.-L. Liao, “Significant Influence of Particle Surface Oxidation on the Critical Velocity for Particle Deposition, Interface Microstructure and Adhesive Strength of the Deposited Coatings in Cold Spraying,” Thermal Spray Laboratory Report of Xi'an Jiaotong University, 2005

M. Grujicic, C.L. Zhao, W.S. DeRosset, and D. Helfritch, Adiabatic Shear Instability Based Mechanism for Particle/Substrate Bonding in the Cold-Gas Dynamic-Spray Process, Mater. Des., 2004, 25(8), p 681–688.

Author information

Authors and Affiliations

Additional information

The original version of this paper was published in the CD ROM Thermal Spray Connects: Explore Its Surfacing Potential, International Thermal Spray Conference, sponsored by DVS, ASM International, and HW International Institute of Welding, Basel, Switzerland, May 2–4, 2005, DVS-Verlag GmbH, Düsseldorf, Germany.

Rights and permissions

About this article

Cite this article

Li, CJ., Li, WY. & Liao, H. Examination of the critical velocity for deposition of particles in cold spraying. J Therm Spray Tech 15, 212–222 (2006). https://doi.org/10.1361/105996306X108093

Received:

Revised:

Issue Date:

DOI: https://doi.org/10.1361/105996306X108093