Abstract

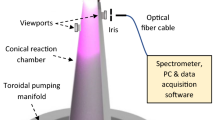

We have investigated how ion irradiation can selectively promote the formation of dense sp3-bonded cubic boron nitride (cBN) over the graphite-like sp2-bonded phases. We have conducted a series of experiments using ion-assisted pulsed laser deposition in which either the ion mass (mion) or ion energy (E) was varied in conjunction with the ratio of ion flux to depositing atom flux (J/a). For a fixed ion energy and mass, there is a critical J/a above which cBN formation is initiated, a window of J/a values in which large cBN percentages are obtained, and a point at which J/a is so large that the resputter and deposition rates balance and there is no net film deposition, in agreement with Kester and Messier. As do Kester and Messier, we find that cBN formation is controlled by a combination of experimental parameters that scale with the momentum of the ions. However, unlike Kester and Messier, we do not find that cBN formation scales with the maximum momentum that can be transferred in a single binary collision, as either incorrectly formulated by Targove and Macleod and used by Kester and Messier, or as correctly formulated. Instead we observe that cBN formation best scales with the total momentum of the incident ions, (mionE)1/2. We also consider the mechanistic origins of this (mionE)1/2 dependence. Computer simulations of the interaction of ions with BN show that cBN formation cannot be simply scaled to parameters such as the number of atomic displacements or the number of vacancies produced by the ion irradiation. A critical examination of the literature shows that none of the proposed models satisfactorily accounts for the observed (mionE)1/2 dependence. We present a quantitative model that describes the generation of stress during ion-assisted film growth. The model invokes a kinetic approach to defect production and loss. We apply a simplified version of the model to cBN synthesis, and find that it predicts an approximate (mionE)1/2 dependence for cBN formation.

Similar content being viewed by others

References

H. Holleck, J. Vac. Sci. Technol. A 4, 2661 (1986).

L. Vel, G. Demazeau, and J. Etourneau, Mater. Sci. Eng. B 10, 149 (1991).

R. C. DeVries, GE CRD Report No. 72CRD178 (1972).

S. P. S. Arya and A. D’Amico, Thin Solid Films 157, 267 (1988).

W. A. Yarbrough, J. Vac. Sci. Technol. A 9, 1145 (1991).

R. H. Wentorf, Jr., J. Chem. Phys. 36, 1990 (1962).

O. Mishima, in Synthesis and Properties of Boron Nitride, edited by J. J. Pouch and S. A. Alterovitz (Trans Tech Publications, Ltd., Brookfield, 1990), Vol. 54–55, p. 313.

M. Murakawa and S. Watanabe, in Applications of Diamond Films and Related Materials, edited by Y. Tzeng, M. Yoshikawa, M. Murakawa, and A. Feldman (Elsevier, The Netherlands, 1991), p. 661.

J. C. Angus, Y. Wang, and M. Sunkara, Annu. Rev. Mater. Sci. 21, 221 (1991).

hBN has been considered to be the thermodynamically stable phase at ambient conditions, but new work suggests that cBN may be the thermodynamically stable phase at ambient condition [see Nakano and Fukunaga, Diamond and Rel. Mater. 2, 1409 (1993), and V. L. Solozhenko, Thermochimican Acta 218, 221 (1993)]. The large activation energy barrier between ABN and cBN is said to account for the difficulty in synthesizing cBN at ambient conditions. Regardless of whether hBN or cBN is the equilibrium phase at ambient conditions, high pressures are required for bulk synthesis.

W. Gissler, J. Haupt, T. A. Crabb, P. N. Gibson, and D. G. Rickerby, Mater. Sci. Eng. A 139, 284 (1991).

T. Wada and N. Yamashita, J. Vac. Sci. Technol. A 10, 515 (1992).

K. Inagawa, K. Watanabe, H. Ohsone, K. Saitoh, and A. Itoh, J. Vac. Sci. Technol. A 5, 2696 (1987).

A. K. Ballal, L. Salamanca-Riba, G. L. Doll, C. A. Taylor II, and R. Clarke, J. Mater. Res. 7, 1618 (1992).

A. K. Ballal, L. Salamanca-Riba, C. A. Taylor II, and G. L. Doll, Thin Solid Films 224, 46 (1993).

T. A. Friedmann, W. M. Clift, H. A. Johnsen, E. J. Klaus, K. F. McCarty, D. L. Medlin, M. J. Mills, and D. K. Ottesen, in Laser Ablation in Materials Processing: Fundamentals and Applications, edited by B. Braren, J. J. Dubowski, and D. P. Norton (Mater. Res. Soc. Symp. Proc. 285, Pittsburgh, PA, 1993), p. 507.

D. J. Kester and R. Messier, J. Appl. Phys. 72, 504 (1992).

J. D. Targove and H. A. Macleod, Appl. Opt. 27, 3779 (1988).

D. R. McKenzie, W. D. McFall, W. G. Sainty, C. A. Davis, and R. E. Collins, Diamond and Rel. Mater. 2, 970 (1993).

N. Tanabe and M. Iwaki, Nucl. Instrum. Meth. B80/81, 1349 (1993).

M. Okamoto, Y. Utsumi, and Y. Osaka, Plasma Sources Sci. Technol. 2, 1 (1993).

H. Windischmann, J. Vac. Sci. Technol. A 9, 2431 (1991).

T. A. Friedmann, P. B. Mirkarimi, D. L. Medlin, K. F. McCarty, E. J. Klaus, D. Boehme, H. A. Johnsen, M. J. Mills, and D. K. Ottesen, J. Appl. Phys. (in press).

Given that the deposition flux is pulsed, the deposition rate, a, is a time averaged value. Since we are depositing only a small fraction of a monolayer (<0.1 Å) per laser pulse, and the ion-solid interactions occur primarily below the surface, the pulsed deposition source is essentially equivalent to a continuous source for the issues addressed here.

D. V. Vechten, G. K. Hubler, and E. P. Donovan, Vacuum 36, 841 (1986).

The ablated material should have energies of a few tens of eV based on a study of pyrolytic BN ablated in vacuum with comparable laser (248 nm) fluences (D. B. Geoghegan, personal communication); this is small compared to the 500–1200 eV ions used in this study. Also, whatever the energy of the ablated material, it is a constant effect independent of variations in ion energy, current, or mass. That is, neglecting the energy/momentum of the ablated species will not affect the differences used to distinguish between the various parametrizations of cBN formation.

O. Burat, D. Bouchier, V. Stambouli, and G. Gautherin, J. Appl. Phys. 68, 2780 (1990).

R. Geick, C. H. Penny, and G. Rupprecht, Phys. Rev. 146, 543 (1966).

P. J. Gielisse, S. S. Mitra, J. N. Plendl, R. D. Griffis, L. C. Mansur, R. Marshall, and E. A. Pascoe, Phys. Rev. 155, 1039 (1967).

D. R. McKenzie, D. Muller, and B. A. Pailthorpe, Phys. Rev. Lett. 67, 773 (1991).

H. Windischmann, J. Appl. Phys. 62, 1800 (1987).

P. Sigmund, in Sputtering by Particle Bombardment, edited by R. Behrisch (Springer, Berlin, 1981), Vol. 1, p. 49.

C. K. Hwangbo, L. Lingg, J. P. Lehan, H. A. Macleod, J. L. Makous, and S. Y. Kim, Appl. Opt. 28, 2769 (1989).

D. Nir, J. Vac. Sci. Technol. A 4, 2954 (1986).

B. Window, J. Vac. Sci. Technol. A 7, 3036 (1989).

C. A. Davis, Thin Solid Films 226, 30 (1993).

H. Windischmann, Crit. Rev. Solid State 17, 547 (1992).

C Weissmantel, J. Vac. Sci. Technol. 18, 179 (1981).

F. Seitz and J. S. Koehler, in Progress in Solid State Physics (Academic Press, New York, 1954), Vol. 2, p. 30.

M. Nastasi and J. W. Mayer, Mater. Sci. Rep. 6, 1 (1991).

Y. Lifshitz, S. R. Kasi, and J. W. Rabalais, Phys. Rev. B 41, 10468 (1990).

J. Robertson, Diamond and Rel. Mater. 2, 984 (1993).

H. J. Steffen, D. Marton, and J. W. Rabalais, Phys. Rev. Lett. 68, 1726 (1992).

J. Koike, D. M. Parkin, and T. E. Mitchell, Appl. Phys. Lett. 60, 1450 (1992).

T. Ikeda, T. Satou, and H. Satoh, Surf. Coatings and Technol. 50, 33 (1991).

D. L. Medlin, T. A. Friedmann, P. B. Mirkarimi, K. F. McCarty, and M. J. Mills, in Phase Transformations in Thin Films— Thermodynamics and Kinetics, edited by M. Atzmon, A. L. Greer, J. M. E. Harper, and M. R. Libera (Mater. Res. Soc. Symp. Proc. 311, Pittsburgh, PA 1993).

D. L. Medlin, T. A. Friedmann, P. B. Mirkarimi, P. Rez, K. F. McCarty, and M. J. Mills, J. Appl. Phys. (in press).

D. R. McKenzie, D. J. H. Cockayne, D. A. Muller, M. Murakawa, S. Miyake, S. Wantanabe, and P. Fallon, J. Appl. Phys. 70, 3007 (1991).

D. J. Kester, K. S. Ailey, R. F. Davis, and K. L. More, J. Mater. Res. 8, 1213 (1993).

S. Shanfield and R. Wolfson, J. Vac. Sci. Technol. A 1, 323 (1983).

J. F. Ziegler, J. P. Biersak, and U. Littmark, The Stopping and Range of Ions in Solids (Pergamon Press, New York, 1985).

N. V. Doan and F. Rossi, Solid State Phenomena 30 & 31, 75 (1993).

G. H. Kinchin and R. S. Pease, Rept. Progr. Phys. 18, 1 (1955).

D. R. McKenzie, D. A. Muller, E. Kravtchinskaia, D. Segal, D. J. H. Cockayne, G. Amaratunga, and R. Silva, Thin Solid Films 206, 198 (1991).

J. Koskinen, J. Appl. Phys. 63, 2094 (1988).

J. Ishikawa, Y. Takeiri, K. Ogawa, and T. Takagi, J. Appl. Phys. 61, 2509 (1987).

C. Weissmantel, Thin Solid Films 92, 55 (1982).

R. C. DeVries, in Diamond and Diamond-Like Films and Coatings, edited by R. E. Clausing (Plenum Press, New York, 1991), p. 151.

R. S. Daley, L. J. Terminello, P. B. Mirkarimi, and K. F. McCarty, unpublished.

While ion energy is also lost to phonons and ionization events, in the context of the model the important pathway for energy loss is to defect production.

See, for example, A. D. Brailsford and R. Bullough, J. Nucl. Mater. 44, 121 (1972).

W. G. Wolfer and A. Si-Ahmed, J. Nucl. Mater. 99, 117 (1981).

In a constrained film, the stress is biaxial. However, in order to potentially compare with a thermodynamic pressure (p), we give the hydrostatic stress σH = 1/3(σ11 + σ22 + σ33) = −p, where σii are the diagonal components of the stress tensor.

W. G. Wolfer, J. Phys. F (Metal Phys.) 12, 425 (1982).

P. Eberhardt, in Conf. on Dimensional Stability and Mechanical Behavior of Irradiated Metals and Alloys in London (British Nucl. Energy Society, 1983).

H. J. Wollenberger, in Vacancies and Interstitials in Metals, edited by A. Seeger, D. Schumacher, W. Schilling, and J. Diehl (North-Holland, Amsterdam, 1970), p. 215.

A. Barbu and G. Martin, Solid State Phenomena 30 & 31, 179 (1993).

P. A. Thrower and R. M. Mayer, Phys. Status Solidi 47, 11 (1978).

D. S. Williams, J. Appl. Phys. 57, 2340 (1985).

W. A. Johnson, J. Vac. Sei. Technol. B 1, 257 (1987).

American Institute of Physics Handbook, edited by D. E. Gray (McGraw-Hill, New’ York, 1982).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Mirkarimi, P.B., McCarty, K.F., Medlin, D.L. et al. On the role of ions in the formation of cubic boron nitride films by ion-assisted deposition. Journal of Materials Research 9, 2925–2938 (1994). https://doi.org/10.1557/JMR.1994.2925

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/JMR.1994.2925