Abstract

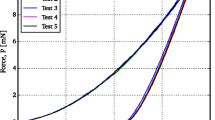

Ultralow load indentation techniques can be used to obtain time-dependent mechanical properties, termed indentation creep, of materials. However, the comparison of indentation creep data to that obtained during conventional creep testing is difficult, mainly due to the determination of the strain rate experienced by the material during indentation. Using the power-law creep equation and the equation for Newtonian viscosity as a function of stress and strain rate, a relationship between indentation strain rate, and the effective strain rate occurring during the indentation creep process is obtained. Indentation creep measurements on amorphous selenium in the Newtonian viscous flow regime above the glass transition temperature were obtained. The data were then used to determine that the coefficient relating indentation strain rate to the effective strain rate is equal to 0.09, or.

Similar content being viewed by others

References

F.R. Brotzen, Int. Mater. Rev. 39 (1), 24 (1994).

W.C. Oliver and G.M. Pharr, J. Mater. Res. 7, 1564 (1992).

M.J. Mayo and W.D. Nix, Acta Metall. 36 (8), 2183 (1988).

V. Raman and R. Berriche, J. Mater. Res. 7, 627 (1992).

Β.Ν. Lucas and W.C. Oliver, in Thin Films: Stresses and Mechanical Properties III, edited by W. D. Nix, J. C. Bravman, E. Arzt, and L. B. Freund (Mater. Res. Soc. Symp. Proc. 239, Pittsburgh, PA, 1992), p. 337.

B. Roebuck and E. A. Almond, J. Mater. Sci. Lett. 1, 519 (1982).

P.M. Sargent and M.F. Ashby, Mater. Sci. Technol. 8, 594 (1993).

S.N.G. Chu and J.C. M. Li, J. Mater. Sci. 12, 2200 (1977).

S.N.G. Chu and J.C. M. Li, Mater. Sci. Eng. 39, 1 (1979).

W-T. Han and M. Tomozawa, J. Am. Ceram. Soc. 73 (12), 3626 (1990).

N.M. Keulen, J. Am. Ceram. Soc. 76 (4), 904 (1993).

D. Tabor, The Hardness of Metals (Clarendon Press, Oxford, 1951).

H. M. Pollock, D. Maugis, and M. Barquins, in Microindentation Techniques in Materials Science and Engineering, ASTM STP 889, edited by P.J. Blau and B.R. Lawn (ASTM, Philadelphia, PA, 1986), p. 47.

A. G. Atkins, A. Silvério, and D. Tabor, J. Inst. Metals 94, 369 (1966).

T.O. Mulhearn and D. Tabor, J. Inst. Metals 89, 7 (1960).

A. De La Torre, P. Adeva, and M. Aballe, J. Mater. Sci. 26, 4351 (1991).

A. Juhasz, P. Tasnadi, and I. Kovacs, J. Mater. Sci. Lett. 5, 35 (1986).

F.O. Muktepavel and I. Manika, J. Mater. Sci. Lett. 8, 4 (1989).

A.L. Yurkov, J. Mater. Sci. Lett. 12, 767 (1993).

W. W. Walker, in The Science of Hardness Testing and its Research Applications, edited by J. H. Westbrook and H. Conrad (American Society for Metals, Metals Park, OH, 1973), p. 258.

M.J. Mayo, R.W. Siegel, A. Narayanasamy, and W.D. Nix, J. Mater. Res. 5, 1073 (1990).

W. B. Li and R. Warren, Acta Metall. et Mater. 41 (10), 3065 (1993).

W. B. Li, J. L. Henshall, R. M. Hooper, and Κ. Ε. Easterling, Acta Metall. et Mater. 39 (12), 3099 (1991).

W. R. LaFontaine, B. Yost, R. D. Black, and C-Y. Li, J. Mater. Res. 5, 2100 (1990).

T.W. Wu, M. Moshref, and P.S. Alexopoulos, Thin Solid Films 187, 295 (1990).

H. J. Frost and M. F. Ashby, Deformation-Mechanism Maps (Pergamon Press, Oxford, 1982).

D.M. Marsh, Proc. R. Soc. London A279, 420 (1964).

K.L. Johnson, J. Mech. Phys. Solids 18, 115 (1970).

M.J. Mayo, R.W. Siegel, Y.X. Liao, and W.D. Nix, J. Mater. Res. 7, 973 (1992).

H. Y. Yu and J.C.M. Li, J. Mater. Sci. 12, 2214 (1977).

R. Hill, Proc. R. Soc. London A436, 617 (1992).

A. F. Bower, N. A. Fleck, A. Needleman, and N. Ogbonna, Proc. R. Soc. London A441, 97 (1993).

B. Storåkers and P. Larsson, J. Mech. Phys. Solids 42 (2), 307 (1994).

J.R. Matthews, Acta Metall. 28, 311 (1980).

S.P. Timoshenko and J.N. Goodier, Theory of Elasticity (McGraw-Hill, New York, 1970).

M. Cukierman and D. R. Uhlmann, J. Non-Cryst. Solids 12, 199 (1973).

A. Eisenberg and A. V. Tobolsky, J. Polymer Sci. 61, 483 (1962).

L.J. Graham and R. Chang, J. Appl. Phys. 36 (10), 2983 (1965).

S.O. Kasap, S. Yannacopoulos, and P. Gundappa, J. Non-Cryst. Solids 111, 82 (1989).

S.O. Kasap, V. Aiyah, and S. Yannacopoulos, J. Phys. D 23, 553 (1990).

R.B. Stephens, J. Appl. Phys. 49 (12), 5855 (1978).

M.C. Coughlin and B. Wunderlich, J. Polymer Sci.: Polymer Phys. 11, 1735 (1973).

V.E. Jenckel, Kolloid-Zeitschrift 84, 266 (1938).

K. Vedam, D. Miller, and R. Roy, J. Appl. Phys. 37 (9), 3432 (1966).

W. C. Oliver, B.N. Lucas, and G. M. Pharr, in Mechanical Properties and Deformation Behavior of Materials Having Ultra-Fine Microstructures, edited by M. Nastasi, D. Parkin, and M. Gleiter (Kluwer Academic, Dordrecht, The Netherlands, 1993), p. 417.

H. Scholze and N. J. Kreidl, in Glass Science and Technology, Volume 3: Viscosity and Relaxation, edited by D. R. Uhlmann and N.J. Kreidl (Academic Press, Orlando, FL, 1986), p. 233.

J.H. Li and D.R. Uhlmann, J. Non-Cryst. Solids 3, 127 (1970).

J.H. Simmons, R. Ochoa, K. D. Simmons, and J.J. Mills, J. Non-Cryst. Solids 105, 313 (1988).

S. S. Chiang, D. B. Marshall, and A. G. Evans, J. Appl. Phys. 53 (1), 298 (1982).

W. Hirst and G. Howse, Proc. R. Soc. London A311, 429 (1969).

A. K. Bhattacharya and W.D. Nix, Int. J. Solids and Structures 27 (8), 1047 (1991).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Poisl, W.H., Oliver, W.C. & Fabes, B.D. The relationship between indentation and uniaxial creep in amorphous selenium. Journal of Materials Research 10, 2024–2032 (1995). https://doi.org/10.1557/JMR.1995.2024

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/JMR.1995.2024