Abstract

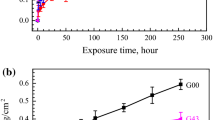

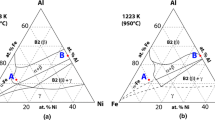

X-ray diffraction and temperature dependent (5 K–380 K) magnetic measurements have been carried out in INCONEL 718 superalloy before and after high temperature aging treatments. (INCONEL is a trademark of the INCO family of companies.) The nominal composition of this alloy is Ni (52.5%), Cr (19.0%), Fe (18.5%), Nb (5.1%), Mo (3.0%), Ti (0.9%), Al (0.5%), Cu (0.15%), and C (0.08%), and it yields an x-ray diffraction pattern consisting of a fcc phase with α = 3.5987 (3) Å and an orthorhombic phase associated with δ-Ni3Nb. It is concluded that the fcc pattern is due to both the γ austenitic phase and γ′ Ni3(Al, Ti) phase of alloy 718. The standard annealing and aging treatment carried out in air at temperatures between 621 and 982 °C produces surface oxides (Cr, Fe)2O3 and FeNbO4 (which are easily removed by etching and polishing) and contracts the lattice. Magnetic measurements show a distinct phase transition at Tc = 14 K, which has been attributed to the γ′-Ni3(Al, Ti) phase by the process of elimination and by observing that it has most of the characteristics of the weak itinerant ferromagnet Ni74.5Al25.5. This transition may have some effects on the cryogenic applications of this alloy.

Similar content being viewed by others

Change history

01 April 2005

An Erratum to this paper has been published: https://doi.org/10.1557/JMR.2005.0112

References

See, e.g., E. A. Loria, J. Metals, 36, July 1988, and references therein.

Superalloys–A Technical Guide, edited by E. F. Bradley (ASM INTERNATIONAL, Metals Park, OH, 1988), pp. 75–87.

M. Sundararaman, P. Mukhopadhyay, and S. Banerjee, Metall. Trans. A 19A, 453 (1988).

C. L. Corey and D. I. Potter, J. Appl. Phys. 38, 3894 (1967).

R. Kozubski and M. C. Cadeville, J. Phys. F: Met. Phys. 18, 2569 (1988).

F. Cardellini, F. Cleri, G. Mazzone, A. Montone, and V. Rosato, J. Mater. Res. 8, 2504 (1993).

T. Fang, S. J. Kennedy, L. Quan, and T. J. Hicks, J. Phys: Condens. Matter 4, 2405 (1992).

See, e.g., T. G. Kollie, Phys. Rev. B 16, 4872 (1977), and references therein.

T. F. Smith, A. B. Kaiser, and G. K. White, Int. J. Thermophys. 12, 627 (1991).

V. Suresh Babu, A. S. Pavlovic, and M. S. Seehra, J. Appl. Phys. (April 1996, in press).

E. F. Wasserman, in Ferromagnetic Materials, edited by K. H. J. Buschow and E. P. Wohlfarth (North-Holland, Amsterdam 1990), Vol. 5, p. 258.

P. C. Ling and T. J. Hicks, J. Phys. F: Metal Phys. 3, 697 (1973); see also N. Buis, J. J. M. Franse, and P. E. Brommer, Physica 106B, 1 (1981).

F. R. de Boer, C. J. Schinkel, J. Biesterbos, and S. Proost, J. Appl. Phys. 40, 1049 (1969).

B. I. Min, A. J. Freeman, and H. J. F. Jansen, Phys. Rev. B 37, 6757 (1988-II); K. Suzuki and Y. Masuda, J. Phys. Soc. Jpn. 54, 326 (1985); T. Moriya, J. Magn. Magn. Mater. 14, 1 (1979).

Author information

Authors and Affiliations

Additional information

INCONEL is a trademark of the INCO family of companies.

Rights and permissions

About this article

Cite this article

Seehra, M.S., Babu, V.S. Low temperature magnetic transition and high temperature oxidation in INCONEL alloy 718. Journal of Materials Research 11, 1133–1136 (1996). https://doi.org/10.1557/JMR.1996.0145

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/JMR.1996.0145