Abstract

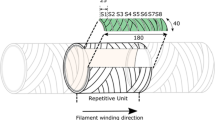

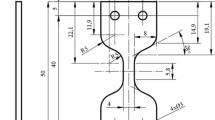

Composite preform fiber architectures range from the very simple to the complex, and the extremes are typified by parallel continuous fibers and complicated three-dimensional woven structures. Subsequent processing of these preforms to produce dense composites may depend critically on the geometry of the interfiber porosity. The goal of this study is to fully characterize the structure of a 0°/90° cloth layup preform using x-ray tomographic microscopy (XTM). This characterization includes the measurement of intercloth channel widths and their variability, the transverse distribution of through-cloth holes, and the distribution of preform porosity. The structure of the intercloth porosity depends critically on the magnitude and direction of the offset between adjacent cloth layers. The structures observed include two-dimensional networks of open pipes linking adjacent holes, arrays of parallel one-dimensional pipes linking holes, and relatively closed channels exhibiting little structure, and these different structures would appear to offer very different resistances to gas flow through the preform. These measurements, and future measurements for different fiber architectures, will yield improved understanding of the role of preform structure on processing.

Similar content being viewed by others

References

S. Musikant, What Every Engineer Should Know About Ceramics (Marcel Dekker, Inc., 1991).

S. Yajima, J. Hayashi, and M. Omori, Chem. Lett. 9, 931–934 (1975).

S. Yajima, J. Hayashi, M. Omori, and K. Okamura, Nature (London) 261, 683–685 (1976).

D. P. Stinton, T. M. Besmann, R. A. Lowden, Am. Ceram. Soc. Bull. 67 (2), 350–355 (1988).

A. J. Caputo, D. P. Stinton, R. A. Lowden, and T. M. Besmann, Am. Ceram. Soc. Bull. 66 (2), 368–372 (1987).

E. Fitzer and R. Gadow, Am. Ceram. Soc. Bull. 65 (2), 326–335 (1986).

J. A. DiCarlo, J. Metals, 44–49 (June 1985).

Y. Chiang, J. Haggerty, R. S. Messner, and C. Demetry, Am. Ceram. Soc. Bull. 68 (2), 420–428 (1989).

D. P. Stinton, A. J. Caputo, and R. A. Lowden, Am. Ceram. Soc. Bull. 65 (2), 347–350 (1986).

T. L. Starr, J. Mater. Res. 10, 2360–2366 (1995).

J. H. Kinney, T. M. Breunig, T. L. Starr, D. Haupt, M. C. Nichols, S. R. Stock, M. D. Butts, and R. A. Saroyan, Science 260, 789–792 (1993).

S. R. Stock, A. Guvenilir, T. M. Breunig, J. H. Kinney, and M. C. Nichols, JOM (J. Metals) 47 (1), 19–23 (1995).

T. M. Breunig, “Nondestructive Evaluation of Damage in SiC/Al Metal/Matrix Composite Using X-ray Tomographic Microscopy,” Ph.D. Thesis, Georgia Institute of Technology (1992).

E. Zywicz, J. H. Kinney, M. L. Sattler, T. M. Breunig, and M. C. Nichols, J. Microscopy 169 (2), 247–253 (1993).

S-B. Lee, “Nondestructive Examination of Chemical Vapor Infiltration of 0°/90° SiC/Nicalon Composites,” Ph.D. Thesis, Georgia Institute of Technology (1993).

Nippon Carbon Co., Tokyo, Japan.

J. Kinney and M. Nichols, Annu. Rev. Mater. Sci. 22, 121–152 (1992).

A. C. Kak and M. Slaney, Principles of Computerized Tomographic Imaging (IEEE Press, New York, 1987).

D. Mckie and C. Mckie, Essentials of Crystallography (Blackwell Scientific Publications, 1986).

Interactive Data Language (IDL), Research Systems Inc., 2995 Wilderness Place, Boulder, CO 80301.

B. W. Sheldon and T. M. Besmann, J. Am. Ceram. Soc. 74 (12), 3046–3053 (1991).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Lee, SB., Stock, S.R., Butts, M.D. et al. Pore geometry in woven fiber structures: 0°/90° plain-weave cloth layup preform. Journal of Materials Research 13, 1209–1217 (1998). https://doi.org/10.1557/JMR.1998.0172

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/JMR.1998.0172