Abstract

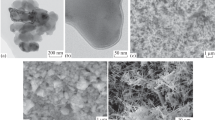

Al2O3 powders with four different particle sizes were densified using a spark plasma sintering (SPS) apparatus under three different sintering conditions: holding time, heating rate, and mechanical pressure. The Al2O3 powder compact sintered at a higher heating rate produced a sample with a higher density and a fine-grained microstructure, while abnormal grain growth and a lower density resulted when a lower heating rate was applied, though the sintering temperature and holding time were the same in both cases. This revealed that rapid sintering by SPS was effective for promoting the densification of the powder. However, the powder with a coarse particle size was hard to sinter at a higher heating rate. Microstructural observation revealed that the edge part was denser than the inside of the sample when the holding time was short. Increasing the holding time made it possible for the inside to be sintered almost as dense as the edge part. Mechanical pressure was found to enhance densification of the Al2O3 powder. On the basis of these results, the SPS process is discussed.

Similar content being viewed by others

References

M. Omori and T. Hirai, New Ceram. 7, 23 (1994).

M. Wada and F. Yamashita, in Proc. Int. Magnetic Conf. (Magnetic Soc. of the Institute of Electrical and Electrons Engineers, Brighton, United Kingdom, 1990), p. 2601.

K. Matsugi, T. Hatayama, and O. Yanagisawa, J. Jpn. Inst. Met. 59, 740 (1995).

S.H. Risbud, C.H. Shan, A.K. Mukherjee, J.S. Bow, and R.A. Holl, J. Mater. Res. 10, 237 (1995).

T. Nishimura, M. Mitomo, H. Hirotsuru, and M. Kawahara, J. Mater. Sci. Lett. 14, 1046 (1995).

S.H. Risbud and C.H. Shan, Mater. Lett. 20, 149 (1994).

C.H. Shan, S.H. Risbud, K. Yamazaki, and K. Shoda, Mater. Sci. Eng. B 26, 55 (1994).

M. Yoshimura, T. Ohji, M. Sando, Y-H. Choa, T. Sekino, and K. Niihara, Mater. Lett. 38, 18 (1999).

L. Gao, H.Z. Wang, J.S. Hong, H. Miyamoto, K. Miyamoto, S.D. De La Torre, and Y. Nishikawa, in Proc. of the 2nd Inter. Symp. On the Science of Engineering Ceramics (EnCera’98), edited by K. Niihara, T. Sekino, E. Yasuda, and T. Sasa (Osaka, Japan, 1998), p. 401.

M. Omori, A. Okubo, K. Gilhwan, and Y. Hirai, J. Mater. Syn. Proc. 5, 279 (1997).

Y.S. Kang, K. Noda, L.D. Chen, S. Moriya, and M. Niino, in Joint ASME, ASCE & SES Summer Meeting (McNU’97) (Northwestern University, Evanston, IL, 1997), p. 414.

M. Omori and Hirai, New Ceram. 7, 27 (1994).

M. Orihashi, Y. Noda, L.D. Chen, Y.S. Kang, A. Moro, and T. Hirai, in Proc. 4th Int. Symp. on Functional Gradient Materials, edited by I. Shiota and Y. Miyamoto (AIST Tsukuba Research Center, Tsukuba, Japan, 1996), p. 569.

Y. Ishiyama, in Proc. of 1993 Powder Metallurgy World Congress, edited by Y. Bando and K. Kosuge (Japan Society of Powder and Powder Metallurgy, Kyoto, Japan, 1993), p. 931.

M. Tokita, J. Soc. Powder Technol. Jpn. 30, 790 (1993).

S.H. Risbud, J.R. Groza, and M.J. Kim, Philos. Mag. B 69, 525 (1994).

M. Omori, J. Jpn. Soc. Powder Powder Metall. 45, 1055 (1998).

Y. Kinemuchi, H. Funakoshi, and K. Ishizaki, J. Ceram. Soc. Jpn. 106, 535 (1998).

H. Tomino, H. Watanabe, and Y. Kondo, J. Jpn. Soc. Powder Powder Metall. 44, 974 (1997).

S. Sumi, Y. Mizutani, and M. Yoneya, J. Jpn. Soc. Powder Powder Metall. 45, 153 (1998).

S.W. Wang, L.D. Chen, Y.S. Kang, M. Niino, and T. Hirai, Mater. Res. Bull. (in press).

W.D. Kingery, H.K, Bowen, and D.R. Uhlmann, Introduction to Ceramics, 2nd ed. (Wiley-Interscience, New York, 1976).

M.P. Harmer and R.J. Brook, J. Br. Ceram. Soc. 80, 147 (1981).

S.W. Wang, L.D. Chen, Y.S. Kang, and T. Hirai, J. Mater. Sci. Lett. 18, 1119 (1999).

D-J. Chen and M.J. Mayo, J. Am. Ceram. Soc. 79, 906 (1996).

Huesup Song and R.L. Coble, J. Am. Ceram. Soc. 73, 2077 (1990).

T. Koyama, A. Nishiyama, and K. Niihara, J. Mater. Sci. 28, 5952 (1993).

S.I. Bae and S. Baik, J. Mater. Sci. 28, 4197 (1993).

Y. Makino, New Ceram. 10, 39 (1997).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Wang, S.W., Chen, L.D. & Hirai, T. Densification of Al2O3 powder using spark plasma sintering. Journal of Materials Research 15, 982–987 (2000). https://doi.org/10.1557/JMR.2000.0140

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/JMR.2000.0140