Abstract

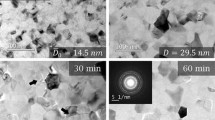

Grain growth in nanocrystalline (nc) Al with a grain size of 26 nm produced by cryogenic mechanical milling was studied through x-ray diffraction, transmission electron microscopy, and differential scanning calorimetry. Grain growth kinetics resembled those of ball-milled nc Fe. For homologous temperatures (T/TM) of 0.51–0.83, the time exponent n from D1/n − D01/n = kt was 0.04–0.28, tending toward 0.5 as T/TM increased. Two grain-growth regimes were distinguished: below T/TM = 0.78 growth ceased at an approximate grain size of 50 nm while at higher temperatures, grain growth proceeded steadily to the submicrometer range. Grain growth over the range of temperatures studied cannot be explained in terms of a single thermally activated rate process. The observed high grain size stability was attributed primarily to impurity pinning drag associated with the grain growth process.

Similar content being viewed by others

References

T.R. Malow and C.C. Koch, Acta Mater. 45, 2177 (1997).

T.R. Malow and C.C. Koch, in Synthesis and Processing of Nanocrystalline Materials, edited by D.L. Bourell (TMS, Warren-dale, PA, 1996), p. 33.

K. Lu, Mater. Sci. Eng. R16, 161 (1996).

J. Weissmuäller, in Synthesis and Processing of Nanocrystalline Materials, edited by D.L. Bourell (TMS, Warrendale, PA, 1996), p. 3.

C. Suryanarayana, Int. Mater. Rev. 40, 41 (1995).

P.G. Shewmon, Transformation in Metals (McGraw-Hill, New York, 1969), p. 300.

R. Birringer, Mater. Sci. Eng. A 117, 33 (1989); V.Y. Gertsman and R. Birringer, Scripta Metall. Mater. 30, 577 (1994).

U. Klement, U. Erb, A. M. El-Sherik, and K.T. Aust, Mater. Sci. Eng. A 203, 177 (1995).

R.W. Siegel, S. Ramasamy, H. Hahn, Z. Li, T. Lu, and R. Gronsky, J. Mater. Res. 3, 1367 (1988).

K. Lu, Z.F. Dong, I. Bakonyi, and A. Cziraki, Acta Metall. Mater. 43, 2641 (1995).

J. Eckert, J.C. Holzer, and W.L. Johnson, J. Appl. Phys. 73, 131 (1993).

C.E. Krill, R. Klein, S. Janes, and R. Birringer, Mater. Sci. Forum 179–181, 443 (1995).

R.J. Perez, H.G. Jiang, C.P. Dogan, and E.J. Lavernia, Metall. Trans. A 29, 2469 (1998).

J. Weissmuäller, Nanostruc. Mater. 3, 261 (1993).

P. Knauth, A. Charai, and P. Gas, Scripta Metall. Mater. 28, 325 (1993).

H.J. Hoäfler and R.S. Averback, Scripta Metall. Mater. 24, 2401 (1990).

K. Boylan, D. Ostrander, U. Erb, G. Palumbo, and K.T. Aust, Scripta Metall. Mater. 25, 2711 (1991).

C. Bansal, Z. Gao, and B. Fultz, Nanostruct. Mater. 5, 327 (1995).

P.A. Beck, J.C. Kremer, L.J. Demer, and M.L. Holzworth, Trans. Am. Inst. Min. Engrs. 175, 372 (1948).

J.E. Burke, Trans. Am. Inst. Min. Engrs. 180, 73 (1949).

H. Hu and B.B. Rath, Metall. Trans. 1, 3181 (1970); R.A. Vandermeer and H. Hu, Acta Metall. Mater. 42, 3071 (1994).

A. Michels, C.E. Krill, H. Ehrhardt, R. Birringer, and D.T. Wu, Acta Mater. 47, 2143 (1999).

M.J. Luton, C.S. Jayanth, M.M. Disko, S. Matras, and J. Vallone, in Multicomponent Ultrafine Microstructures, edited by L.E. McCandish, B.H. Kear, D.E. Polk, and R.W. Siegel (Mater. Res. Soc. Symp. Proc., 132 Pittsburgh, PA, 1989), p. 79.

H.P. Klug and L. Alexander, X-ray Diffraction Procedures for Polycrystalline and Amorphous Materials, 2nd ed. (John Wiley and Sons, New York, 1974), p. 661.

J. Eckert, J.C. Holzer, C.E. Krill III, and W.L. Johnson, J. Mater. Res. 7, 1751 (1992).

D. Oleszak and P.H. Shingu, J. Appl. Phys. 79, 2975 (1996).

C.S. Smith, Trans. AIME 9, 15 (1949).

H.J. Frost and M.F. Ashby, in Deformation-Mechanism Maps: The Plasticity and Creep of Metals and Ceramics (Pergamon Press, Oxford, United Kingdom, 1982), p. 21; Smithells Metals Reference Book, 5th ed. (Butterworths, Oxford, United Kingdom, 1976), p. 860.

S. Dais, R. Messer, and A. Seeger, Mater. Sci. Forum 15–18, 419 (1987).

Y. Yoshizawa, S. Oguma, and K. Yamauchi, J. Appl. Phys. 64, 6044 (1988).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Zhou, F., Lee, J., Dallek, S. et al. High grain size stability of nanocrystalline Al prepared by mechanical attrition. Journal of Materials Research 16, 3451–3458 (2001). https://doi.org/10.1557/JMR.2001.0474

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/JMR.2001.0474