Abstract

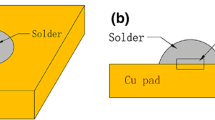

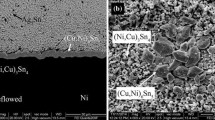

Intermetallic compound (IMC) growth during solid-state aging at 125, 150, and 170 °C up to 1500 h for four solder alloys (eutectic SnPb, Sn–3.5Ag, Sn–3.8Ag–0.7Cu, and Sn–0.7Cu) on Cu under bump metallization was investigated. The samples were reflowed before aging. During the reflow, the solders were in the molten state and the formation of the IMC Cu6Sn5 in the cases of eutectic SnPb and Sn–3.5Ag had a round scallop-type morphology, but in Sn–0.7Cu and Sn–3.8Ag–0.7Cu the scallops of Cu6Sn5 were faceted. In solid-state aging, all these scallops changed to a layered-type morphology. In addition to the layered Cu6Sn5, the IMC Cu3Sn also grew as a layer and was as thick as the Cu6Sn5. The activation energy of intermetallic growth in solid-state aging is 0.94 eV for eutectic SnPb and about 1.05 eV for the Pb-free solders. The rate of intermetallic growth in solid-state aging is about 4 orders of magnitude slower than that during reflow. Ternary phase diagrams of Sn–Pb–Cu and Sn–Ag–Cu are used to discuss the reactions. These diagrams predict the first phase of IMC formation in the wetting reaction and the other phases formed in solid-state aging. Yet, the morphological change and the large difference in growth rates between the wetting reaction and solid-state aging cannot be predicted.

Similar content being viewed by others

References

M. Abtew and G. Selvaduray, Mater. Sci. Eng. 27, 95 (2000).

J. Bath, C. Handwerker, and E. Bradley, Circuits Assem. 11, 30 (2000).

P. Biocca, Surf. Mount Technol. 13, 64 (1999).

K. Snowdon, Proc. Eur. Microelectron. Packag. Conf., 12th 71 (1999).

S.K. Kang and A.K. Sarkhel, J. Electron. Mater. 23, 701 (1994).

M. McCormack and S. Jin, J. Electron. Mater. 23, 715 (1994).

J.W. Morris, J.L.F. Goldstein, and Z. Mei, JOM 45, 25 (1993).

J. Sigelko, S. Choi, K.N. Subramanian, J.P. Lucas, and T.R. Bieler, J. Electron. Mater. 28, 1184 (1999).

S.K. Kang, R.S. Rai, and S. Purushothaman, J. Electron. Mater. 25, 1113 (1996).

C.Y. Liu, C. Chen, A.K. Mai, and K.N. Tu, J. Appl. Phys. 85, 1 (1999).

D.R. Frear and P.T. Vianco, Metall. Mater. Trans. A 25A, 1509 (1994).

C.F. Chan, S.K. Lahiri, P. Yuan, and J.B.H. How, Proc. 2000 Electron. Packag. Technol. Conf. 72 (2000).

J.K. Lin, A. De. Silva, D. Frear, Y. Guo, J.W. Jang, L. Li, D. Mitchell, B. Yeung, and C. Zhang, Proc. Electron. Compon. Technol. Conf., 51st 455 (2001).

D. Frear, J.W. Jang, J.K. Lin, and C. Zhang, JOM 53, 28 (2001).

K.N. Tu, T.Y. Lee, J.W. Jang, L. Li, D.R. Frear, K. Zeng, and J. Kivilahti, J. Appl. Phys. 89, 4843 (2001).

D. Frear, D. Grivas, and J.W. Morris Jr., J. Electron. Mater. 16, 181 (1987).

H.P.R. Frederikse, R.J. Fields, and A. Feldman, J. Appl. Phys. 72, 2879 (1992).

C-S. Oh, J-H. Shim, B-J. Lee, and D.N. Lee, J. Alloys Comp. 238, 155 (1996).

J-H. Shim, C-S. Oh, B-J. Lee, and D.N. Lee, Z. Metallkd. 87, 205 (1996).

F.H. Hayes, H.L. Lukas, G. Effenberg, and G. Petzow, Z. Metallkd. 77, 749 (1986).

L. Kaufinan and H. Bernstein, Computer Calculation of Phase Diagrams (Academic Press, New York, 1970).

W. Peng, K. Zeng, and J.K. Kivilahti, Helsinki University of Technology, Helsinki, Finland (unpublished work, 1999).

C.M. Miller, I.E. Anderson, and J.F. Smith, J. Electron. Mater. 23, 95 (1994).

M.E. Loomans and M.E. Fine, Metall. Mater. Trans. 31A, 1155 (2000).

K-W. Moon, W.J. Boettinger, U.R. Kattner, F.S. Biancaniello, and C.A. Handwerker, J. Electron. Mater. 29, 1122 (2000).

B.E. Dyson, T.R. Anthony, and D. Turnbull, J. Appl. Phys. 38, 3408 (1967).

B.F. Dyson, J. Appl. Phys. 37, 2375 (1966).

H.K. Kim and K.N. Tu, Phys. Rev. B 53, 16027 (1996).

I.V. Belova and G.E. Murch, J. Phys. Chem Solids 59, 1 (1997).

K.N. Tu and R.D. Thompson, Acta Metall. 30, 947 (1982).

C. Goria, Metall. Ital. 148, 358 (1956).

A. Gervais and D. Keller, Physica C 246, 29 (1995).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Lee, T.Y., Choi, W.J., Tu, K.N. et al. Morphology, kinetics, and thermodynamics of solid-state aging of eutectic SnPb and Pb-free solders (Sn–3.5Ag, Sn–3.8Ag–0.7Cu and Sn–0.7Cu) on Cu. Journal of Materials Research 17, 291–301 (2002). https://doi.org/10.1557/JMR.2002.0042

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/JMR.2002.0042