Abstract

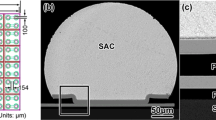

The tensile fracture behavior for solid-state-annealed eutectic SnPb and lead-free solder flip chip bumps was examined. The annealing temperatures were in the range of 125–170 °C for 500 h. Prior to solid state annealing, the eutectic Sn–37Pb (SnPb) and Sn–0.7Cu (SnCu) solders showed fracture through the bulk solder. Brittle interfacial fracture occurred in the Sn–3.5Ag (SnAg) solder. After solid-state annealing, the fracture behavior changed dramatically. For eutectic SnPb solder, the fracture modes gradually changed from cohesive solder failure to interfacial fracture with increasing annealing temperature. The fracture mode of the SnCu solder showed greater change than the SnPb and SnCu solders. After annealing at 125 °C, the SnAg solder had a ductile taffy pull fracture, but an increase in temperature resulted in brittle interfacial fracture again. The SnCu solder maintained the same ductile taffy pull mode up to170 °C annealing, independent of the under bump metallization (UBM) type. Microstructure analysis showed that the interfacial fracture of the SnPb and SnAg solder bumps was ascribed to Pb-rich layer formation and Ag embrittlement at the interface, respectively. The bulk solder fracture of SnAg annealed at 125 °C appeared to be a transient phenomenon due to the abrupt breakdown of the hard lamella structure. The eutectic SnCu solder bumps had no significant change in the interfacial structure, except for interfacial intermetallic growth.

Similar content being viewed by others

References

International Technology Roadmap for Semiconductors (Semiconductor Industry Association, San Jose, CA, 2001).

C.S. Chang, A. Oscilowski, and R. C. Bracken: Future challenges in electronics packaging. IEEE Circuits Device Mag. 14, 45 (1998).

J. Cannis: Green IC packaging. Adv. Packaging 10, 38 (2001).

M. Abtew and G. Selvaduray: Lead-free solders in microelectronics. Mater Sci Eng R 27, 95 (2000).

G.J. Jackson, R. Durairaj, and N.N. Ekere: Characterisation of lead-free solder pastes for low cost flip-chip bumping, in Proc. 27th Annual IEEE/CPMT/SEMI International Electronics Manufacturing Technology Symposium, San Jose, CA, July 2002 (IEEE, Piscataway, NY), pp. 223–228.

J.W. Jang, A.P. De Silva, T.Y. Lee, J.K. Lin, and D.R. Frear: Direct correlation between microstructure and mechanical tensile properties in Pb-free solders and eutectic SnPb solder for flip chip technology. Appl Phys. Lett 79, 482 (2001).

D.R. Frear, J.W. Jang, J.K. Lin, and C. Zhang: Pb-free solders for flip-chip interconnects. JOM 53, 28 (2001).

M. McCormack, S. Jin, and G.W. Kammlott: Suppression of mi-crostructural coarsening and creep deformation in a lead-free solder. Appl. Phys. Lett. 64, 580 (1994).

J.S. Hwang, Z. Guo, and H. Koenigsmann: High-strength and high-fatigue-resistant lead-free solder. Surface Mount Technology 14, 55 (2000).

J.S. Hwang, Modern Solder Technology for Competitive Electronics Manufacturing, (McGraw Hill, New York, 1996), Chap. 3.

W. Yang and R.W. Messler, Jr.: Microstructure evolution of eutectic Sn-Ag solder joints. J. Electron. Mater. 23, 765 (1994).

V.M. López Hirata and K. Hirano: Ostwald ripening of -Fe precipitates in a Cu-1.5 at.% Fe alloy. Scripta Metall. 31, 117 (1994).

D.M. Kim and A.J. Ardell: Coarsening of Ni3Ge in binary Ni–Ge alloys: Microstructures and volume fraction dependence of kinetics. Acta Mater. 51, 4073 (2003).

T.Y. Lee, W.J. Choi, K.N. Tu, J.W. Jang, S.M. Kuo, J.K. Lin, D.R. Frear, K Zeng, and J.K. Kivilahti: Morphology, kinetics, and thermodynamics of solid-state aging of eutectic SnPb and Pb-free solders (Sn-3.5Ag, Sn-3.8Ag-0.7Cu and Sn-0.7Cu) on Cu. J. Mater. Res. 17, 291 (2002).

J.S. Ha, T.S. Oh, and K.N. Tu: Effect of supersaturation of Cu on reaction and intermetallic compound formation between Sn-Cu solder and thin film metallization. J. Mater. Res. 18, 2109 (2003).

P.G Kim, J.W. Jang, T.Y. Lee, and K.N. Tu: Interfacial reaction and wetting behavior in eutectic SnPb solder on Ni/Ti thin films and Ni foils. J. Appl. Phys. 86, 6746 (1999).

T.B. Massalski: Binary Alloy Phase Diagrams (ASM International, Materials Park, OH, 1990), Vol. 3.

J.K. Lin, A. De Silva, D. Frear, Y. Guo, J.W. Jang, L. Li, D. Mitchell, B. Yeung, and C. Zhang: Characterization of lead-free solders and under bump metallurgies for flip-chip package, in Proc. 51st Electronic Components and Technology Conference, Orlando, FL, May 2001 (IEEE, Piscataway, NY), p. 455.

Y. Guo, J.K. Lin, and A. De Silva: Reliability evaluations of chip interconnect in lead-free solder systems, in Proc. 52ndElectronic Components and Technology Conference 2002, San Diego, CA, May 2002 (IEEE, Piscataway, NY), p. 1275.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Jang, JW., De Silva, A.P., Lin, JK. et al. Tensile fracture behaviors of solid-state-annealed eutectic SnPb and lead-free solder flip chip bumps. Journal of Materials Research 19, 1826–1834 (2004). https://doi.org/10.1557/JMR.2004.0235

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/JMR.2004.0235