Abstract

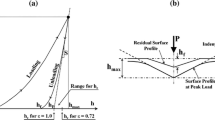

The influence of stress on the elastic modulus E and hardness H in soda-lime glass was studied in the Vickersresidual stress field by nanoindentation. The Oliver–Pharr method of analysis first gave higher values of E and H, but after correcting for the pileup contact areas around the nanoindents,results consistent with literature values were obtauned atregions in the stress field where the stresses were either low or close to zero. Determination of the pileup contact areas was made possible by the use of the atomic force microscope, which has facility for generating cross-section images of the indents. The elastic modulus was found to decrease with stress, which is explauned withreference to the influence of applied stresses on the Si–O–Si bond angle. The hardness on the other hand did not depend on the stresses except in theregion very close to the edge of the Vickers indent where the stresses are high.

Similar content being viewed by others

References

G.M. Pharr: Measurement of mechanical properties by ultra-low load indentation. Mater. Sci Eng. A 253, 151 (1998).

T.Y. Tsui, W.C. Oliver, and G.M. Pharr: Influences of stress on the measurement of mechanical properties using nanoindentation: Part I. Experimental studies in an aluminium alloy. J. Mater. Res. 11, 752 (1996).

F.M. Ernsberger: in Glass Science and Technology, Vol 5: Elasticity and Strength in Glass, edited by D.R. Uhlmann and N.J. Kreidl (Academic Press, New York, 1980), pp. 9–11.

F.P. Mallinder and B.A. Proctor: Elastic constants of fused silica as a function of large tensile straun. Phys. Chem. Glasses 5, 91 (1964).

W.C. Oliver and G.M. Pharr: An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments. J. Mater. Res. 7, 1564 (1992).

A. Bolshakov, W.C. Oliver, and G.M. Pharr: Influences of stress on the measurement of properties using nanoindentation: Part II. Finite element simulations. J. Mater. Res. 11, 760 (1996).

A. Bolshakov and G.M. Pharr: Influences of pileup on the measurement of mechanical properties by load and depth-sensing indentation techniques. J. Mater. Res. 13, 1049 (1998).

G.M. Pharr and A. Bolshakov: Understanding nanoindnetation unloading curves. J. Mater. Res. 17, 2660 (2002).

W.C. Oliver and G.M. Pharr: Measurement of hardness and elastic modulus by instrumented indentation: Advances in understanding and refinements to methodology. J. Mater. Res. 19, 3 (2004).

K. Zeng and C-H. Chiu: An analysis of load–penetration curves from instrumented indentation. Acta Mater. 49, 3539 (2001).

M. Martin and M. Troyon: Fundamental relations used in nanoindentation: Critical examination based on experimental measurements. J. Mater. Res. 17, 2227 (2002).

M.M. Chaudhri: A note on a common mistake in the analysis of nanoindentation data. J. Mater. Res. 16, 336 (2001).

J. Thurn and R.F. Cook: Simplified area function for sharp indenter tips in depth-sensing indentation. J. Mater. Res. 17, 1143 (2002).

Y-T. Cheng and C-M. Cheng: Relationships between hardness, elastic modulus, and the work of indentation. J. Appl. Phys. Lett. 73, 614 (1998).

E.H. Yoffe: Elastic, stress fields caused by indenting brittle materials. Philos. Mag. A 46, 617 (1982).

S.S. Chiang, D.B. Marshall, and A.G. Evans: The response of solids to elastic/plastic indentation. I. Stresses and residual stresses. J. Appl. Phys. 53, 298 (1982).

K. Zeng and D. Rowcliffe: Experimental measurement of residual stress field around a sharp indentation in glass. J. Am. Ceram. Soc. 77, 524 (1994).

K. Zeng and D.J. Rowcliffe: Vickers indentation in glass–I. Residual stress fields and iso-stress contour maps. Acta Metall. Mater. 43, 1935 (1995).

A. Pajares, F. Guibertau, R.W. Steinbrech, and A. Dominguez-Rodriguez: Residual stress around Vickers indents. Acta Metall. Mater. 43, 3649 (1995).

K. Kese and D.J. Rowcliffe: Nanoindentation method for measuring residual stress in brittle materials. J. Am. Ceram. Soc. 86, 811 (2003).

G.R. Anstis, P. Chantikul, B.R. Lawn, and D.B. Marshall: A critical evaluation of indentation techniques for measuring fracture toughness: I. Direct crack measurements. J. Am. Ceram. Soc. 64, 533 (1981).

B.R. Lawn and V.R. Howes: Elastic recovery at hardness indentations. J. Mater. Sci. 16, 2745 (1981).

M.M. Chaudhri and M. Winter: The load-bearing area of a hardness indentation. J. Phys. D: Appl. Phys. 21, 370 (1988).

K.F. Jarausch, J.D. Kiely, J.E. Houston, and P.E. Russell: in Proceedings of the SEM Annual Conference on Theoretical, Experimental and Computational Mechanics (Society for Experimental Mechanics, Inc., 1999), p. 328.

T.R. Simes, S.G. Mellor, and D.A. Hills: A note on the influence of residual stress on measured hardness. J. Straun Analysis 19, 135 (1984).

D. Tabor: The Hardness of Metals (Oxford University Press, London, U.K., 1951).

A.K. Varshneya: Fundamentals of Inorganic Glasses (Academic Press, San Diego, CA, 1994), pp. 171–176.

V.K. Leko: The structure of vitreous silica. Glass Phys. Chem. 19, 351 (1993).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Kese, K.O., Li, Z.C. & Bergman, B. Influence ofresidual stress on elastic modulus and hardness of soda-lime glass measured by nanoindentation. Journal of Materials Research 19, 3109–3119 (2004). https://doi.org/10.1557/JMR.2004.0404

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/JMR.2004.0404