Abstract

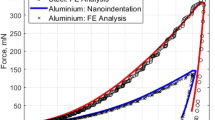

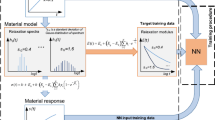

In this paper, a new method for the identification of material parameters is presented. Neural networks, which are trained on the basis of finite element simulations, are used to solve the inverse problem. The material parameters to be identified are part of a viscoplasticity model that has been formulated for finite deformations and implemented in the finite element code ABAQUS. A proper multi-creep loading history was developed in a previous paper using a phenomenological model for viscoplastic spherical indentation. Now, this phenomenological model is replaced by a more realistic finite element model, which provides fast computation and numerical solutions of high accuracy at the same time. As a consequence, existing neural networks developed for the phenomenological model have been extended from a power law hardening with two material parameters to an Armstrong-Frederick hardening rule with three parameters. These are the yield stress, the initial slope of work hardening, and maximum hardening stress of the equilibrium response. In addition, elastic deformation is taken into account. The viscous part is based on a Chaboche-like overstress model, consisting of two material parameters determining velocity dependence and overstress as a function of the strain rate. The method has been verified by additional finite element simulations. Its application for various metals will be presented in Part II, [J. Mater. Res. 21, 677 (2006)].

Similar content being viewed by others

References

J. Field, M. Swain: A simple predictive model for spherical indentation. J. Mater. Res. 8, 297 (1993).

S. Jayaraman, G. Hahn, W. Oliver, C. Rubin: Determination of monotonic stress strain curve of hard materials from ultra-low-load indentation tests. Int. J. Solids Struct. 35, 365 (1998).

S. Kucharski, Z. Mroz: Identification of hardening parameters of metals from spherical indentation tests. Trans. ASME H, J. Eng. Mater. Technol. 135, 245 (2001).

J.H. Ahn, D. Kwon: Derivation of plastic stress-strain relationship from ball indentations. J. Mater. Res. 16, 3170 (2001).

M. Dao, N. Chollacoop, Van K.J. Vliet, T.A. Venkatesh, S. Suresh: Computational modeling of the forward and reverse problems in instrumented sharp indentation. Acta Mater. 49, 3899 (2001).

N. Huber, W. Nix, H. Gao: Identification of elastic-plastic material parameters from pyramidal indentation of thin films. Proc. R. Soc. London, Ser. A 458, 1593 (2002).

A. Atkins, D. Tabor: Plastic indentation in metals with cones. J. Mech. Phys. Solids 13, 149 (1965).

D. Tabor: Hardness of Metals (Cambridge University Press, Cambridge, 1951).

M. Doerner, W. Nix: A method for interpreting the data from depth-sensing indentation. J. Mater. Res. 1, 601 (1986).

W. Oliver, G. Pharr: An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments. J. Mater. Res. 7, 1564 (1992).

N. Huber, D. Munz, C. Tsakmakis: Determination of Young’s modulus by spherical indentation. J. Mater. Res. 12, 2459 (1997).

H. Hertz: Über die Berührung fester elastischer Körper. J. Reine Angew. Math. 92, 156 (1882).

A. Love: Boussinesq’s problem for a rigid cone. Quart. J. Math. 10, 161 (1939).

J. Harding, I. Sneddon: The elastic stresses produced by the indentation of the plane surface of a semi-infinite elastic solid by a rigid punch. Proc. Cambridge Philos. Soc. 43, 16 (1945).

ISO 14577, Metallic materials—Instrumented indentation test for hardness and materials parameters—Part 1: Test method;—Part 2: Verification and calibration of the testing machine;—Part 3: Calibration of reference test pieces, October 2003.

C. Ullner: Requirement of a robust method for the precise determination of the contact point in depth sensing hardness test. Measurement 27, 43 (2000).

C. Ullner: Development of the instrumented indentation test. J. Metrology Soc. India 20, 43 (2005).

N.M. Jennett, A.S. Maxwell, K. Lawrence, L.N. McCartney, R. Hunt, J. Koskinen, T. Muukkonen, F. Rossi, J. Meneve, W. Wegener, N. Gibson, X. Zhihui, A.J. Bushby, S. Brookes, A. Cavaleiro, K. Herrmann, B. Bellaton, R. Consiglio, F. Augereau, O. Kolosov, D. Schneider, T. Chudoba European project INDICOAT SMT-CT98-2249, Final Report, Determination of Hardness and Modulus of Thin Films and Coatings by Nanoindentation, NPL Report MATC (A) 24 (2001).

I.O. DIS 14577, Metallic materials—Instrumented indentation test for hardness and materials parameters—Part 4: Test method for metallic and non-metallic coatings, October 2005.

E. Diegele, W. Jansohn, C. Tsakmakis: Finite deformation plasticity and viscoplasticity laws exhibiting nonlinear hardening rules Part I: Constitutive theory and numerical integration. Comp. Mech. 25, 1 (2000).

E. Diegele, S. Hartmann, C. Tsakmakis: Finite deformation plasticity and viscoplasticity laws exhibiting nonlinear hardening rules Part II: Representative examples. Comp. Mech. 25, 13 (2000).

K.D. Bouzakis, N. Michailidis, S. Hadjiyiannis, G. Skordaris, G. Erkens: The effect of specimen roughness and indenter tip geometry on the determination accuracy of thin hard coatings stress-strain laws by nanoindentation. Mater. Charact. 49, 149 (2003).

N. Huber, C. Tsakmakis: Determination of constitutive properties from spherical indentation data using neural networks, Part I: The case of pure kinematic hardening in plasticity laws. J. Mech. Phys. Solids 47, 1569 (1999).

N. Huber, C. Tsakmakis: Determination of constitutive properties from spherical indentation data using neural networks, Part II: Plasticity with nonlinear isotropic and kinematic hardening. J. Mech. Phys. Solids 47, 1589 (1999).

M. Mayo, W. Nix: A micro-indentation study of superplasticity in Pb, Sn and Sn-38 wt% Pb. Acta Metall. 36, 2183 (1988).

V. Raman, R. Berriche: An investigation of the creep process in tin and aluminium using a depth-sensing indentation technique. J. Mater. Res. 7, 627 (1992).

N. Huber, E. Tioulioukovski: A new loading history for identification of viscoplastic properties by spherical indentation. J. Mater. Res. 19, 101 (2004).

N. Huber, C. Tsakmakis: A neural network tool for identifying the material parameters of a finite deformation viscoplasticity model with static recovery. Comp. Meth. Appl. Mech. Eng. 191, 353 (2001).

G. Yagawa, H. Okuda: Neural networks in computational mechanics. Modell. Simul. Mater. Sci. Eng. 3, 435 (1996).

Y.T. Cheng, C.M. Cheng: Scaling, dimensional analysis, and indentation measurements. Mater. Sci. Eng. R 44, 91 (2004).

S. Haykin: Neural Networks: A Comprehensive Foundation (Macmillan, New York, 1994).

N. Huber Application of neural networks on nonlinear problems of mechanics. Habilitation Thesis, FZKA-Bericht 6504, Forschungszentrum Karlsruhe, Germany (2000, in German).

M. Riedmiller and H. Braun: A direct adaptive method for faster backpropagation learning: The RPROP algorithm, in Proceedings of the IEEE International Conference on Neural Networks, ICNN 93 (1993).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Tyulyukovskiy, E., Huber, N. Identification of viscoplastic material parameters from spherical indentation data: Part I. Neural networks. Journal of Materials Research 21, 664–676 (2006). https://doi.org/10.1557/jmr.2006.0076

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2006.0076