Abstract

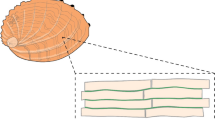

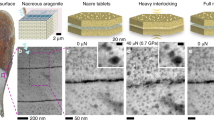

Nacre, the inner iridescent layer of seashells is a model biomimetic system composed of 95% of inorganic (aragonite) phase and 5% of organic phase. Nacre exhibits an interlocked layered “brick and mortar” structure where the bricks are made up of aragonitic calcium carbonate and mortar is an organic phase. Here, we report the role of indentation load and penetration depth on measurement of nanomechanical properties of nacre. A range of loads from 10 μN to 10,000 μN were applied to obtain the response from different depths of nacre. The values of hardness and elastic modulus decrease with increasing load (i.e., increase in penetration depth). The variation in these values is significant at lower loads and decreases with increase in indentation load. From our results, it appears that the nanoindentation tests done at lower loads are highly influenced by micro and nanostructure in nacre. The indentation experiments performed at low loads indicate an elastic modulus of about 15 GPa for the organic phase. The low load, low penetration experiments appear to be better indicators of nanomechanical behavior. Also, we have observed a step-like behavior in the load-displacement curves at high load indentations on nacre. These features are attributed to the organic layer between the aragonite platelets. The indentation tests with penetration depths more than ~250-300 nm often disrupt the organic layer and the behavior is not recovered in the unloading part of the curve. The microarchitecture and the composition of nacre contribute to the decrease in hardness values with increasing depth along with the indentation size effects.

Similar content being viewed by others

References

J.D. Currey: Mechanical properties of mother of pearl in tension. Proc. R. Soc. London, Ser. B Biol. Sci. 196, 443 (1977).

A.P. Jackson, J.F.V. Vincent, R.M. Turner: The mechanical design of nacre. Proc. R. Soc. London, Ser. B Biol. Sci. 234, 415 (1988).

A.P. Jackson, J.F.V. Vincent, R.M. Turner: Comparison of nacre with other ceramic composites. J. Mater. Sci. 25, 3173 (1990).

J.D. Currey In The Mechanical Properties of Biological Materials, edited by J.F.V. Vincent and J.D. Currey (Cambridge University Press, London, 1980) p. 75.

M. Yasrebi, G.M. Kim, K.E. Gunnison, D.L. Milius, M. Sarikaya, I.A. Aksay Bimomimetic processing of ceramics and ceramic-metal composites, in Better Ceramics Through Chemistry IV edited by B.J.J. Zelinski, C.J. Brinker, D.E. Clark, and D.R. Ulrich (Mater. Res. Soc. Symp. Proc. 180, Pittsburgh, PA, 1990), p. 625.

M. Sarikaya, K.E. Gunnison, M. Yasrebi, D.L. Milius, I.A. Aksay Mechanical properties-microstructure relationships in abalone shell, in Materials Synthesis Utilizing Biological Processes edited by P.C. Rieke, P.D. Calvert, and M. Alper (Mater. Res. Soc. Symp. Proc. 174, Pittsburgh, PA, 1999), p. 109.

K.S. Katti, M. Qian, D.W. Frech, M. Sarikaya: Electron energy loss spectroscopy and dielectric functions of geological and biological polymorphs of CaCO3. Microsc Microanal. 5, 358 (1999).

D. Verma, K.S. Katti, and D.R. Katti: Photoacoustic FTIR spectroscopic study of undisturbed nacre from red abalone. Spectrochim. Acta (in press, 2005).

D.R. Katti, K.S. Katti: Modeling microarchitecture and mechanical behavior of nacre using 3D finite element techniques. J. Mater. Sci. 36, 1411 (2001).

K.S. Katti, D.R. Katti, J. Tang, M. Sarikaya: Modeling mechanical responses in a laminated biocomposite. Part II. Nonlinear responses and nuances of nanostructure. J. Mater. Sci. 40, 1749 (2005).

D.R. Katti, K.S. Katti, J.M. Sopp, M. Sarikaya: 3D finite element modeling of mechanical response in nacre-based hybrid nanocomposites. Comput. Theor. Polym. Sci. 11, 2485 (2001).

D.R. Katti, S.M. Pradhan, K.S. Katti: Modeling the organic-inorganic interfacial nanoasperities in a model bio-nanocomposite, nacre. Rev. Adv. Mater. Sci. 6, 162 (2004).

K.S. Katti, D.R. Katti, S.M. Pradhan, A. Bhosle: Platelet interlocks are the key to toughness and strength in nacre. J. Mater. Res. 20, 1097 (2005).

K.S. Katti, D.R. Katti Why is nacre so strong and tough? Mater. Sci. Eng., C (in press, 2006).

W.C. Oliver, G.M. Pharr: An improved technique for determining hardness and elastic-modulus using load and displacement sensing indentation experiments. J. Mater. Res. 7, 1564 (1992).

A.E. Giannakopoulos, S. Suresh: Determination of elastoplastic properties by instrumented sharp indentation. Script. Mater. 40, 1191 (1999).

T.A. Venkatesh, Van K.J. Vliet, A.E. Giannakopoulos, S. Suresh: Determination of elasto-plastic properties by instrumented sharp indentation: Guidelines for property extraction. Script. Mater. 42, 833 (2000).

X. Li, B. Bhusan: A review of nanoindentation continuous stiffness measurement technique and its applications. Mater. Charact. 48, 11 (2002).

W.C. Oliver, G.M. Pharr: Measurement of hardness and elastic modulus by instrumented indentation: Advances in understanding and refinements to methodology. J. Mater. Res. 19, 3 (2004).

Q. Ma, D.R. Clarke: Size dependent hardness in silver single crystals. J. Mater. Res. 10, 853 (1995).

W.D. Nix, H. Gao: Indentation size effects in crystalline materials: A law for strain gradient plasticity. J. Mech. Phys. Solids 46, 411 (1998).

K.W. McElhaney, J.J. Vlassak, W.D. Nix: Determination of indenter tip geometry and indentation contact area for depth-sensing indentation experiments. J. Mater. Res. 13, 1300 (1998).

N.A. Stelmashenko, M.G. Walls, L.M. Brown, Y.V. Milman: Microindentation on W and Mo oriented single crystals: An STM study. Acta Metall. Mater. 41, 2855 (1993).

T.Y. Zhang, W.H. Xu: Surface effects on nanoindentation. J. Mater. Res. 17, 1715 (2002).

J.G. Swadener, E.P. George, G.M. Pharr: The correlation of the indentation size effect measured with indenters of various shaped. J. Mech. Phys. Solids 50, 681 (2002).

A.J. Bushby, D.J. Dunstan: Plasticity size effects in nanoindentation. J. Mater. Res. 19, 137 (2004).

Y. Wei, X. Wang, M. Zhao: Size effect measurement and characterization in nanoindentation test. J. Mater. Res. 19, 208 (2004).

N.A. Fleck, J.W. Hutchinson: Strain gradient plasticity. Adv. Appl. Mech. 33, 295 (1997).

H. Gao, Y. Huang, W.D. Nix, J.W. Hutchinson: Mechanism-based strain gradient plasticity-I. Theory J. Mech. Phys. Solids 47, 1239 (1999).

Y. Huang, H. Gao, W.D. Nix, J.W. Hutchinson: Mechanism-based strain gradient plasticity-II. Anal. J. Mech. Phys. Solids 48, 99 (2000).

R.O. Ritchie, J.J. Kruzic, C.L. Muhlstein, R.K. Nalla, E.A. Stach: Characteristic dimensions and the micro-mechanisms of fracture and fatigue in “nano” and “bio” materials. Int. J. Fracture 128, 1 (2004).

X. Li, P. Nardi: Micro/nanomechanical characterization of a natural nanocomposite material: The shell of Pectinidae. Nanotechnology 15, 211 (2004).

X. Li, W. Chang, Y.J. Chao, R. Wang, M. Chang: Nanoscale structural and mechanical characterization of a natural nanocomposite material: The shell of red abalone. Nano Lett. 4, 613 (2004).

B.J.F. Bruet, R. Panas, K. Tai, C. Ortiz, H.J. Qi, M.C. Boyce: Nanoscale morphology and indentation of individual nacre tablets from the gastropod mollusk Trochus Niloticus. J. Mater. Res. 20, 2400 (2005).

D.L. Joslin, W.C. Oliver: A new method for analyzing data from continuous depth sensing microindentation test. J. Mater. Res. 5, 123 (1990).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Katti, K.S., Mohanty, B. & Katti, D.R. Nanomechanical properties of nacre. Journal of Materials Research 21, 1237–1242 (2006). https://doi.org/10.1557/jmr.2006.0147

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2006.0147