Abstract

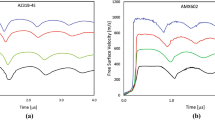

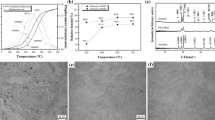

Results are presented on the shock response of a zirconium-based bulk metallic glass (BMG), Zr41.25Ti13.75Ni10Cu12.5Be22.5, subjected to planar impact loading. An 82.5-mm bore single-stage gas-gun facility at Case Western Reserve University, Cleveland, OH, was used to conduct the shock experiments. The particle velocity profiles, measured at the back (free) surface of the target plate by using the velocity interferometer system for any reflector (VISAR), were analyzed to (i) better understand the structure of shock waves in BMG subjected to planar shock compression, (ii) estimate residual spall strength of the BMG after different levels of shock compression, and (iii) obtain the Hugoniot elastic limit (HEL) of the material. The spall strength was found to decrease moderately with increasing levels of the applied normal impact stress. The spall strength at a shock-induced stress of 4.4 GPa was 3.5 GPa while the spall strengths at shock-induced stresses of 5.1, 6.0, and 7.0 GPa were 2.72, 2.35, and 2.33 GPa, respectively. The HEL was estimated to be 6.15 GPa.

Similar content being viewed by others

References

H.A. Bruck, A.J. Rosakis, and W.L. Johnson: The dynamic compressive behavior of beryllium bearing bulk metallic glasses. J. Mater. Res. 11, 503 (1996).

J.J. Lewandowski and P. Lowhaphandu: Effects of hydrostatic pressure on mechanical behavior and deformation processing of materials. Int. Mater. Rev. 43, 145 (1998).

A. Inoue and K. Hashimoto: Amorphous and Nanocrystalline Materials: Preparation, Properties and Applications (Springer-Verlag, Berlin, Germany, 2001).

A. Peker and W.L. Johnson: A highly processable metallic glass—Zr41.2Ti13.8Cu12.5Ni10.0Be22.5. Appl. Phys. Lett. 63, 2342 (1993).

W.L. Johnson: Bulk Metallic Glasses edited by W.L. Johnson, A. Inoue and C.T. Liu (Mater. Res. Soc. Symp. Proc. 554, Warrendale, PA, 1999), pp. 311–339.

J. Lu: Mechanical behavior of a bulk metallic glass and its composites over a wide range of strain rates and temperatures. Ph.D. Dissertation, California Institute of Technology, Pasadena, CA (2002).

T.C. Hufnagel, T. Jiao, Y. Li, L.Q. Xing, and K.T. Ramesh: Deformation and failure of Zr57Ti5Cu20Ni8Al10 bulk metallic glass under quasi-static and dynamic compression. J. Mater. Res. 17, 1441 (2002).

G. Subhash, H. Zhang, and H. Li: Thermodynamic and mechanical behavior of hafnium/zirconium based bulk metallic glasses, in Proceedings of the International Conference of Mechanical Behavior of Materials (ICM-9) (Kenes International, Geneva, Switzerland, 2003), p. 1A5.

G.P. Sunny, J.J. Lewandowski, and V. Prakash: Dynamic compression of amorphous and annealed bulk metallic glass, in Proceedings of the 2006 SEM Annual Conference and Exposition on Experimental and Applied Mechanics St. Louis, MO (Society of Experimental Mechanics, Bethel, CT, 2006), Paper # 349.

G.P. Sunny, V. Prakash, and J.J. Lewandowski: Effects of annealing on dynamic behavior of a bulk metallic glass, in Proceedings of the 2005 International Mechanical Engineering Conference and Exposition, ASME (American Society of Mechanical Engineers, New York, 2005), Paper # IMECE2005-83016.

G.P. Sunny, V. Prakash, and J.J. Lewandowski: Results from a novel insert design for high starin-rate compression of a bulk metallic glass, in Proceedings of the 2006 International Mechanical Engineering Conference and Exposition, ASME (American Society of Mechanical Engineers, New York, 2006), Paper # IMECE2006-15414.

G.P. Sunny, F. Yuan, J.J. Lewandowski, and V. Prakash: Dynamic stress-strain response of a Zr-based bulk metallic glass, in Proceedings of the 2005 SEM Annual Conference and Exposition on Experimental and Applied Mechanics (Society of Experimental Mechanics, Bethel, CT, 2005), Paper # 324.

J. Bach, B. Krueger, and B. Fultz: Shock wave consolidation of a Ni–Cr–Si–B metallic-glass powder. Mater. Lett. 11, 383 (1991).

R.D. Conner, R.B. Dandliker, V. Scruggs, and W.L. Johnson: Dynamic deformation behavior of tungsten-fiber/metallic-glass matrix composites. Int. J. Impact Eng. 24, 435 (2000).

S.M. Zhuang, J. Lu, and G. Ravichandran: Shock wave response of a zirconium-based bulk metallic glass and its composite. Appl. Phys. Lett. 80, 4522 (2002).

C.C. Hays, C.P. Kim, and W.L. Johnson: Microstructure controlled shear band formation and enhanced plasticity of bulk metallic glasses containing in situ formed ductile phase dendrite dispersions. Phys. Rev. Lett. 84, 2901 (2000).

S.J. Turneaure, J.M. Winey, and Y.M. Gupta: Compressive shock wave response of a Zr-based bulk amorphous alloy. Appl. Phys. Lett. 84, 1692 (2004).

C. Yang, R.P. Liu, B.Q. Zhang, Q. Wang, Z.J. Zhan, L.L. Sun, J. Zhang, and Z.Z. Gong: Void formation and cracking of Zr41Ti14Cu12.5–Ni10Be22.5 bulk metallic glass under planar shock compression. J. Mater. Sci. 40, 3917 (2005).

C. Yang, W.K. Wang, R.P. Liu, X.Y. Zhang, and X. Li: Damage features of Zr41Ti14Cu12.5Ni10Be22.5 bulk metallic glass impacted by hypervelocity projectiles. J. Spacecr. Rockets 43, 565 (2006).

T. Mashimo, H. Togo, Y. Zhang, Y. Uemura, and Y. Kawamura: Shock-compression behavior of Zr-based metallic glass, in 12th International Symposium on Plasticity and its Applications: Anisotropy, Texture, Dislocations and Multiscale Modeling in Finite Plasticity and Viscoplasticity and Metal Forming, edited by A.S. Khan and R. Kazmi (Neat, Inc., Fulton, MD, 2006), pp. 157–159.

P. Lowhaphandu and J.J. Lewandowski: Fracture toughness and notched toughness of bulk amorphous alloy: Zr–Ti–Ni–Cu–Be. Scripta Mater. 38, 1811 (1998).

K.S. Kim, R.J. Clifton, and P. Kumar: A combined normal and transverse displacement interferometer with an application to impact of Y-cut quartz. J. Appl. Phys. 48, 4132 (1977).

L.M. Barker and R.E. Hollenbach: Laser interferometer for measuring high velocities of any reflecting surface. J. Appl. Phys. 43, 4669 (1972).

V. Prakash: A pressure-shear plate impact experiment for investigating transient friction. Exp. Mech. 35, 329 (1995).

D.E. Grady and M.E. Kipp: High-Pressure Shock Compression of Solids (Springer-Verlag, Berlin, Germany, 1993).

T. Mashimo: Effect of shock compression on ceramic materials, in High-Pressure Shock Compression of Solids III, edited by L. Davison and H. Shahinpoor (Springer-Verlag, New York, 1998), pp. 101–146.

G.R. Fowles: Shock wave compression of hardened and annealed 2024 Aluminum. J. Appl. Phys. 32, 1475 (1961).

J.J. Lewandowski and P. Lowhaphandu: Effects of hydrostatic pressure on the flow and fracture of a bulk amorphous metal. Philos. Mag. A82, 3427 (2002).

H.D. Espinosa, Y. Xu, and N.S. Brar: Micromechanics of failure waves in glass: I. Experiments. J. Am. Ceram. Soc. 80, 2061 (1997).

J. Cagnoux and F. Longy: Spallation and shock-wave behavior of some ceramics. J. Phys. Coll. 49, 3 (1988).

M. Shazly: Dynamic deformation and failure of gamma-Met PX at room and elevated temperatures. Ph.D. Dissertation, Case Western Reserve University, Cleveland, OH (2005).

P.T. Bartkowski and D.P. Dandekar: Spall strengths of sintered and hot pressed silicon carbide, in Shock Compression of Condensed Matter—1995, edited by S.C. Schmidt and W.C. Tao (American Institute of Physics, New York, 1996), pp. 535–539.

D.P. Dandekar: Spall strength of silicon carbide under normal and simultaneous compression-shear shock wave loading. Int. J. Appl. Ceram. Technol. 1, 261 (2004).

D.I. Nathenson, V. Prakash, and D.P. Dandekar: Dynamic response of silicon nitride under combined pressure and shear impact, in Proceedings of the 2005 SEM Annual Conference and Exposition on Experimental and Applied Mechanics (Society of Experimental Mechanics, Bethel, CT, 2005), Paper # 315 (s22).

L. Tsai and V. Prakash: Dynamic response and spall strength of S-glass fiber reinforced polymer composites, in Proceedings of the 2005 SEM Annual Conference and Exposition on Experimental and Applied Mechanics (Society of Experimental Mechanics, Bethel, CT, 2005), Paper # 322 (s57).

Author information

Authors and Affiliations

Corresponding author

Additional information

This author was an editor of this focus issue during the review and decision stage. For the JMR policy on review and publication of manuscripts authored by editors, please refer to http://www.mrs.org/jmr_policy.

Rights and permissions

About this article

Cite this article

Yuan, F., Prakash, V. & Lewandowski, J.J. Spall strength and Hugoniot elastic limit of a zirconium-based bulk metallic glass under planar shock compression. Journal of Materials Research 22, 402–411 (2007). https://doi.org/10.1557/jmr.2007.0053

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2007.0053