Abstract

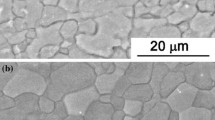

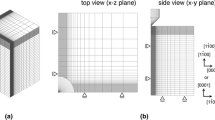

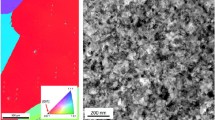

The effects of temperature and alloying elements on deformation in the high-strain-rate regime were investigated by testing fine-grained magnesium alloys with an average grain size of 2 ∼ 3 μm by a nanoindentation technique. The dynamic hardness measurements aligned well with existing quasistatic data, together spanning a wide range of strain rates, 10−3 ∼ 150/s. The high-rate hardness was influenced by various alloying elements (Al, Li, Y and Zn) to different degrees, consistent with expectations based on solid solution strengthening. Transmission electron microscopy observations of the indented region revealed no evidence for deformation twins for any alloying elements, despite the high strain-rate. The activation energy for deformation in the present alloys was found to be 85 ∼ 300 kJ/mol within the temperature range of 298 ∼ 373 K, corresponding to a dominant deformation mechanism of dislocation glide.

Similar content being viewed by others

References

R. Armstrong, I. Codd, R.M. Douthwaite, and N.J. Petch: The plastic deformation of polycrystalline aggregates. Philos. Mag. 7, 45 (1962).

J.A. Chapman and D.V. Wilson: The room-temperature ductility of fine-grain magnesium. J. Inst. Met. 91, 39 (1962–1963).

H. Somekawa and T. Mukai: Effect of grain refinement on fracture toughness in extruded pure-magnesium. Scr. Mater. 53, 1059 (2005).

M.R. Barnett: A rationale for the strong dependence of mechanical twinning on grain size. Scr. Mater. 59, 696 (2008).

S.R. Agnew, M.H. Yoo, and C.N. Tome: Application of texture simulation to understanding mechanical behavior of Mg and solid solution alloys containing Li or Y. Acta Mater. 49, 4277 (2001).

A. Akhtar and E. Teghtsoonian: Substitutional solution hardening of magnesium single crystals. Philos. Mag. 25, 897 (1972).

S. Miura, S. Imagawa, T. Toyoda, K. Ohkubo, and T. Mohri: Effect of rare-earth elements Y and Dy on the deformation behavior of Mg alloy single crystals. Mater. Trans. 49, 952 (2008).

H. Watanabe, A. Owashi, T. Uesugi, Y. Takigawa, and K. Higashi: Grain boundary relaxation in fine-grained magnesium solid solutions. Philos. Mag. 91, 4158 (2011).

Y. Chino, M. Kado, T. Ueda, and M. Mabuchi: Solid solution strengthening for Mg-3%Al and Mg-0.06%Ca alloys. Metall. Mater. Trans. A 42, 1965 (2011).

M.Z. Butt, I.M. Ghauri, R. Qamar, K.M. Hashmi, and P. Feltham: Solid-solution hardening in dilute alloys. Acta Metall. 29, 829 (1981).

H. Somekawa, T. Inoue, A. Singh, and T. Mukai: Deformation mechanism in the crack-tip region of fine-grained magnesium alloy. Metall. Mater. Trans. A 42, 2475 (2011).

ASM Specialty Handbook: Magnesium and Magnesium Alloys ({ASM International, Materials Park, OH, 1999).

J. Koike: Enhanced deformation mechanisms by anisotropic plasticity in polycrystalline Mg alloys at room temperature. Metall. Mater. Trans. A 36, 1689 (2005).

T. Mukai, M. Yamanoi, H. Watanabe, and K. Higashi: Ductility enhancement in AZ31 magnesium alloy by controlling its grain structure. Scr. Mater. 45, 89 (2001).

B. Li, S. Joshi, K. Azevedo, E. Ma, K.T. Ramesh, R.B. Figueiredo, and T.G. Langdon: Dynamic testing at high strain-rates of an ultrafine-grained magnesium alloy processed by ECAP. Mater. Sci. Eng., A 517, 24 (2009).

H. Watanabe and K. Ishikawa: Effect of texture on high temperature deformation behavior at high strain-rates in a Mg-3Al-1Zn alloy. Mater. Sci. Eng., A 523, 304 (2009).

M.T. Sucker, M.F. Horstemeyer, P.M. Gullett, H.E. Kadiri, and W.R. Whittington: Anisotropic effects on the strain-rate dependence of a wrought magnesium alloy. Scr. Mater. 60, 182 (2009).

G. Wan, B.L. Wu, Y.D. Zhang, G.Y. Sha, and C. Esling: Anisotropy of dynamic behavior of extruded AZ31 magnesium alloy. Mater. Sci. Eng., A 527, 2915 (2010).

G. Wan, B.L. Wu, Y.H. Zhao, Y.D. Zhang, and C. Esling: Strain-rate sensitivity of textured AZ31 alloy under impact deformation. Scr. Mater. 65, 461 (2011).

T. Mukai, M. Yamanoi, H. Watanabe, K. Ishikawa, and K. Higashi: Effect of grain refinement on tensile ductility in ZK60 magnesium alloy under dynamic loading. Mater. Trans. 42, 1177 (2001).

K. Ishikawa, H. Watanabe, and T. Mukai: High temperature compressive properties over a wide range of strain-rates in an AZ31 magnesium alloy. J. Mater. Sci. 40, 1577 (2005).

T. Mukai, M. Yamanoi, and K. Higashi: Processing of ductile magnesium alloy under dynamic tensile loading. Mater. Trans. 42, 2652 (2001).

M.A. Meyers, O. Vohringer, and V.A. Lubarda: The onset of twinning in metals; A constitutive description. Acta Mater. 49, 4025 (2001).

D. Lahaie, J.D. Embury, M.M. Chadwick, and G.T. Gray: A note on the deformation of fine-grained magnesium alloys. Scr. Metall. Mater. 27, 139 (1992).

G. Constantinides, C.A. Tweedie, D.M. Holbrook, P. Barragan, J.F. Smith, and K.J. Van Vliet: Quantifying deformation and energy dissipation of polymeric surfaces under localized impact. Mater. Sci. Eng., A 489, 403 (2008).

J.R. Trelewicz and C.A. Schuh: The Hall-Petch breakdown at high strain-rates: Optimizing nanocrystalline grain size for impact applications. Appl. Phys. Lett. 93, 171916 (2008).

Y. Tirupataiah and G. Sundararajan: A dynamic indentation technique for the characterization of the high strain-rate plastic flow behavior of ductile metals and alloys. J. Mech. Phys. Solids 39, 243 (1991).

G. Constantinides, C.A. Tweedie, N. Savva, J.F. Smith, and K.J. Van Vliet: Quantitative impact testing of energy dissipation at surfaces. Exp. Mech. 49, 511 (2009).

Z. Kalcioglu, M. Qu, K.E. Strawhecker, T. Shazly, E. Edelman, M.R. VanLandingham, J.F. Smith, and K.J. Van Vliet: Dynamic impact indentation of hydrated biological tissues and tissue surrogate gels. Philos. Mag. 91, 1339 (2011).

H. Somekawa and C.A. Schuh: Effect of solid solution elements on nanoindentation hardness, rate dependence and incipient plasticity in fine-grained magnesium alloys. Acta Mater. 59, 7554 (2011).

K.L. Johnson: Contact Mechanics (Cambridge University Press, Cambridge, UK, 1984).

C.M. Sellars and W.J. McTegart: On the mechanism of hot deformation. Acta Metall. 14, 1136 (1966).

D.S. Tabor: The Hardness of Metals (Clarendon Press, Oxford, 1951).

H.J. Frost and M.F. Ashby: Deformation Mechanism Map (Pergamon press, Oxford, 1982).

S.X. Song, J.A. Horton, N.J. Kim, and T.G. Nieh: Deformation behavior of a twin-roll-cast Mg-6Zn-0.5Mn-0.3Cu-0.02Zr alloy at intermediate temperature. Scr. Mater. 56, 393 (2007).

C.L. Wang, T. Mukai, and T.G. Nieh: Room temperature creep of fine-grained pure Mg: A direct comparison between nanoindentation and uniaxial tension. J. Mater. Res. 24, 1615 (2009).

H. Somekawa and T. Mukai: Nanoindentation creep behavior of grain boundary in pure magnesium. Philos. Mag. Lett. 90, 883 (2010).

P.G. Oberson and S. Ankem: The effect of time-dependent twinning on low temperature creep of an alpha-titanium alloy. Int. J. Plast. 25, 881 (2009).

M.R. Barnett, Z. Keshavarz, A.G. Beer, and D. Atwell: Influence of grain size on the compressive deformation of wrought Mg-3Al-1Zn. Acta Mater. 52, 5093 (2004).

J.A. Yasi, L.G. Erctor, and D.R. Trinkle: First-principles data for solid solution strengthening of magnesium: From geometry and chemistry to properties. Acta Mater. 58, 5704 (2010).

Acknowledgments

The authors are grateful to Dr. A. F. Schwartzman (Massachusetts Institute of Technology) and Dr. A. Singh (National Institute for Materials Science) for their help with the indentation method and TEM observation, respectively. This work was supported at MIT by the US Army Research Office under grant W911QX-09-P-0009, by the Institute for Soldier Nanotechnologies and by the JSPS Grant-in-Aid for Young Scientists (B) No. 21760564.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Somekawa, H., Schuh, C.A. High-strain-rate nanoindentation behavior of fine-grained magnesium alloys. Journal of Materials Research 27, 1295–1302 (2012). https://doi.org/10.1557/jmr.2012.52

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2012.52