Abstract

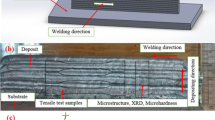

An additive layer manufacturing (ALM) process based on gas tungsten arc welding (GTAW) was used to produce simple 3-dimensional titanium aluminide components, which were successfully in situ alloyed by separately delivering elemental Al and Ti wires to the weld pool. The difference in microstructure, chemical composition, and microhardness of four wall components built with four different wire-feeding conditions has been evaluated. There was no significant change in the microstructure of the four walls. The composition and microhardness values were comparatively homogeneous throughout each wall except the near-substrate zone. However, with increasing the ratio of Al to Ti wire feed rates from 0.80 to 1.30, an increase of Al concentration and γ phases were observed. The situation was reversed for the effect of the Al:Ti ratio on microhardness. Additionally, an unexpected increase in the α2 phase was produced when the ratio was increased to 1.30.

Similar content being viewed by others

References

K.V. Wong and A. Hernandez: A review of additive manufacturing. ISRN Mech. Eng. 2012, 10 (2012).

T.J. Horn and O.L.A. Harrysson: Overview of current additive manufacturing technologies and selected applications. Sci. Prog. 95, 255 (2012).

T. Wohlers: Additive manufacturing advances. Manuf. Eng. 148, 55 (2012).

S. Rawal, J. Brantley, and N. Karabudak: Additive manufacturing of Ti-6Al-4V alloy components for spacecraft applications. In Recent Advances in Space Technologies (RAST), 2013 6th International Conference on IEEE, 2013; p. 5.

S.M. Kelly and S.L. Kampe: Microstructural evolution in laser-deposited multilayer Ti-6Al-4V builds: Part I. Microstructural characterization. Metall. Mater. Trans. A 35, 1861 (2004).

S.M. Kelly and S.L. Kampe: Microstructural evolution in laser-deposited multilayer Ti-6Al-4V builds: Part II. Thermal modeling. Metall. Mater. Trans. A 35, 1869 (2004).

S.H. Mok, G. Bi, J. Folkes, I. Pashby, and J. Segal: Deposition of Ti–6Al–4V using a high power diode laser and wire, Part I: Investigation on the process characteristics. Surf. Coat. Technol. 202, 3933 (2008).

S.H. Mok, G. Bi, J. Folkes, I. Pashby, and J. Segal: Deposition of Ti–6Al–4V using a high power diode laser and wire, Part II: Investigation on the mechanical properties. Surf. Coat. Technol. 202, 4613 (2008).

E. Brandl, V. Michailov, B. Viehweger, and C. Leyens: Deposition of Ti–6Al–4V using laser and wire, part I: Microstructural properties of single beads. Surf. Coat. Technol. 206, 1120 (2011).

E. Brandl, V. Michailov, B. Viehweger, and C. Leyens: Deposition of Ti–6Al–4V using laser and wire, part II: Hardness and dimensions of single beads. Surf. Coat. Technol. 206, 1130 (2011).

F. Martina, J. Mehnen, S.W. Williams, P. Colegrove, and F. Wang: Investigation of the benefits of plasma deposition for the additive layer manufacture of Ti–6Al–4V. J. Mater. Process. Technol. 212, 1377 (2012).

N. Hrabe and T. Quinn: Effects of processing on microstructure and mechanical properties of a titanium alloy (Ti–6Al–4V) fabricated using electron beam melting (EBM), part 1: Distance from build plate and part size. Mater. Sci. Eng., A 573, 264 (2013).

N. Hrabe and T. Quinn: Effects of processing on microstructure and mechanical properties of a titanium alloy (Ti–6Al–4V) fabricated using electron beam melting (EBM), part 2: Energy input, orientation, and location. Mater. Sci. Eng., A 573, 271 (2013).

H.P. Qu and H.M. Wang: Microstructure and mechanical properties of laser melting deposited γ-TiAl intermetallic alloys. Mater. Sci. Eng., A 466, 187 (2007).

L.E. Murr, S.M. Gaytan, A. Ceylan, E. Martinez, J.L. Martinez, D.H. Hernandez, B.I. Machado, D.A. Ramirez, F. Medina, S. Collins, and R.B. Wicker: Characterization of titanium aluminide alloy components fabricated by additive manufacturing using electron beam melting. Acta Mater. 58, 1887 (2010).

S. Biamino, A. Penna, U. Ackelid, S. Sabbadini, O. Tassa, P. Fino, M. Pavese, P. Gennaro, and C. Badini: Electron beam melting of Ti-48Al-2Cr-2Nb alloy: Microstructure and mechanical properties investigation. Intermetallics 19, 776 (2011).

L.E. Murr, S.M. Gaytan, D.A. Ramirez, E. Martinez, J. Hernandez, K.N. Amato, P.W. Shindo, F.R. Medina, and R.B. Wicker: Metal fabrication by additive manufacturing using laser and electron beam melting technologies. J. Mater. Process. Technol. 28, 1 (2012).

D.D. Gu, W. Meiners, K. Wissenbach, and R. Poprawe: Laser additive manufacturing of metallic components: Materials, processes and mechanisms. Int. Mater. Rev. 57, 133 (2012).

F. Wang, S. Williams, and M. Rush: Morphology investigation on direct current pulsed gas tungsten arc welded additive layer manufactured Ti6Al4V alloy. Int. J. Adv. Manuf. Technol. 57, 597 (2011).

F. Wang: Mechanical property study on rapid additive layer manufacture Hastelloy® X alloy by selective laser melting technology. Int. J. Adv. Manuf. Technol. 58, 545 (2012).

C.M. Liu, X.J. Tian, H.B. Tang, and H.M. Wang: Microstructural characterization of laser melting deposited Ti–5Al-5Mo–5V–1Cr–1Fe near β titanium alloy. J. Alloys Compd. 572, 17 (2013).

Q. Jia and D. Gu: Selective laser melting additive manufacturing of Inconel 718 superalloy parts: Densification, microstructure and properties. J. Alloys Compd. 585, 713 (2014).

E. Brandl, C. Leyens, and F. Palm: Mechanical properties of additive manufactured Ti-6Al-4V using wire and powder based processes. IOP Conf. Ser.: Mater. Sci. Eng. 26, 012004 (2011) IOP Publishing.

B. Baufeld, O. Van der Biest, and R. Gault: Additive manufacturing of Ti-6Al-4V components by shaped metal deposition: Microstructure and mechanical properties. Mater. Des. 31, S106 (2010).

E. Brandl, A. Schoberth, and C. Leyens: Morphology, microstructure, and hardness of titanium (Ti-6Al-4V) blocks deposited by wire-feed additive layer manufacturing (ALM). Mater. Sci. Eng., A 532, 295 (2012).

P. Kazanas, P. Deherkar, P. Almeida, H. Lockett, and S. Williams: Fabrication of geometrical features using wire and arc additive manufacture. Proc. Inst. Mech. Eng. Part B: J. Eng. Manuf. 226, 1042 (2012).

F. Wang, S. Williams, P. Colegrove, and A.A. Antonysamy: Microstructure and mechanical properties of wire and arc additive manufactured Ti-6Al-4V. Metall. Mater. Trans. A 44, 968 (2013).

V. Witusiewicz, A. Bondar, U. Hecht, S. Rex, and T.Y. Velikanova: The Al–B–Nb–Ti system: III. Thermodynamic re-evaluation of the constituent binary system Al–Ti. J. Alloys Compd. 465, 64 (2008).

B.W. Choi, Y.G. Deng, C. McCullough, B. Paden, and R. Mehrabian: Densification of rapidly solidified titanium aluminide powders—I. Comparison of experiments to hiping models. Acta Metall. Mater. 38, 2225 (1990).

M.F. Arenas and V.L. Acoff: Analysis of gamma titanium aluminide welds produced by gas tungsten arc welding. Weld. J. 5, 110 (2003).

M. Oehring, V. Küstner, F. Appel, and U. Lorenz: Analysis of the solidification microstructure of multi-component γ-TiAl alloys. Mater. Sci. Forum: THERMEC 2006 539–543, 1475 (2007).

M. Göken, M. Kempf, and W.D. Nix: Hardness and modulus of the lamellar microstructure in PST-TiAl studied by nanoindentations and AFM. Acta Mater. 49, 903 (2001).

ACKNOWLEDGMENT

The authors acknowledge financial support from the China Scholarship Council (CSC), the University of Wollongong, and the Welding Technology Institute of Australia (WTIA), and use of the facilities within the UOW Electron Microscopy Centre.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ma, Y., Cuiuri, D., Hoye, N. et al. Effects of wire feed conditions on in situ alloying and additive layer manufacturing of titanium aluminides using gas tungsten arc welding. Journal of Materials Research 29, 2066–2071 (2014). https://doi.org/10.1557/jmr.2014.203

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2014.203