Abstract

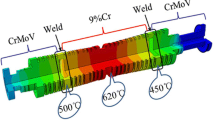

Narrow gap submerged arc welding method accompanied with multilayer and multipass technology was used to manufacture advanced 9Cr and CrMoV dissimilarly welded joint used as a newly developed turbine rotor. The aim of this investigation was to evaluate the high cycle fatigue (HCF) behavior of the welded joint at room temperature. Uniaxial-stress controlled HCF tests at stress ratio R = −1 were performed with specimens chipped from the welded joint of mockup and the S-N curve up to 1.0 × 108 cycle lifetime was obtained. It was found that the fracture location transferred from heat affected zone (HAZ) of CrMoV side to weld metal (WM) with decreasing stress amplitude. The microstructure of the welded joint was characterized and microstructure diversity was found to be responsible for the failure locations both in the CrMoV-HAZ and WM. Fracture morphology of failure samples were also investigated by a scanning electron microscope. It is detected that the stress amplitude required to drive the inclusion to be the crack initiation of the CrMoV-HAZ lies behind the transition. With decreasing stress amplitudes, void in the WM more easily tends to be the initiation of a fatigue crack than inclusion.

Similar content being viewed by others

References

K. Jeongtea and K. Byeongook: Materials technology for PC-TPP in green economic era. Mater. Sci. Forum 654–656, 398 (2010).

K.H. Mayer and F. Masuyama: The development of creep-resistant steels. In Creep-Resistant Steels, F. Abe, T-U. Kern, and R. Viswanathan eds.; Woodhead Publishing: Sawston, UK, 2008; p. 15.

A. Nagesha, M. Valsan, R. Kannan, K.B.S. Rao, and S.L. Mannan: Influence of temperature on the low cycle fatigue behaviour of a modified 9Cr–1Mo ferritic steel. Int. J. Fatigue 24(12), 1285 (2002).

V. Shankar, M. Valsan, K.B.S. Rao, R. Kannan, S.L. Mannan, and S.D. Pathak: Low cycle fatigue behavior and microstructural evolution of modified 9Cr–1Mo ferritic steel. Mater. Sci. Eng., A 437(2), 413 (2006).

I. Le May, H.C. Furtado, and L.H. de Almeida: Precipitation in 9Cr–1Mo steel after creep deformation. Mater. Charact. 58(1), 72 (2007).

V.V. Satyanarayana, G.M. Reddy, and T. Mohandas: Dissimilar metal friction welding of austenitic-ferritic stainless steels. J. Mater. Process Technol. 160(2), 128 (2005).

H. Naffakh, M. Shamanian, and F. Ashrafizadeh: Dissimilar welding of AISI 310 austenitic stainless steel to nickel-based alloy Inconel 657. J. Mater. Process Technol. 209(7), 3628 (2009).

K.R. Kolhe and C. Datta: Prediction of microstructure and mechanical properties of multipass SAW. J. Mater. Process Technol. 197(1–3), 241 (2008).

P. Liu, F. Lu, X. Liu, H. Ji, and Y. Gao: Study on fatigue property and microstructure characteristics of welded nuclear power rotor with heavy section. J. Alloys Compd. 584, 430 (2014).

Q. Wu, F. Lu, H. Cui, X. Liu, P. Wang, and X. Tang: Role of butter layer in low-cycle fatigue behavior of modified 9Cr and CrMoV dissimilar rotor welded joint. Mater. Des. 59, 165 (2014).

Q. Guo, F. Lu, X. Liu, R. Yang, H. Cui, and Y. Gao: Correlation of microstructure and fracture toughness of advanced 9Cr/CrMoV dissimilarly welded joint. Mater. Sci. Eng., A 638, 240 (2015).

D. Meng, F. Lu, H. Cui, Y. Ding, X. Tang, and X. Huo: Investigation on creep behavior of welded joint of advanced 9% Cr steels. J. Mater. Res. 30(2), 197 (2015).

F. Lu, P. Liu, H. Ji, Y. Ding, X. Xu, and Y. Gao: Dramatically enhanced impact toughness in welded 10%Cr rotor steel by high temperature post-weld heat treatment. Mater. Charact. 92, 149 (2014).

W. Liu, X. Liu, F. Lu, X. Tang, H. Cui, and Y. Gao: Creep behavior and microstructure evaluation of welded joint in dissimilar modified 9Cr–1Mo steels. Mater. Sci. Eng., A 644, 337 (2015).

F. Lu, X. Liu, P. Wang, Q. Wu, H. Cui, and X. Huo: Microstructural characterization and wide temperature range mechanical properties of NiCrMoV steel welded joint with heavy section. J. Mater. Res. 30(13), 2108 (2015).

K.D. Ramkumar, A. Choudhary, S. Aggarwal, and A. Srivastava: Characterization of microstructure and mechanical properties of continuous and pulsed current gas tungsten arc welded superaustenitic stainless steel. J. Mater. Res. 30(10), 1727 (2015).

L. Zhao, H. Jing, L. Xu, J. An, G. Xiao, D. Xu, Y. Chen, and Y. Han: Investigation on mechanism of type IV cracking in P92 steel at 650 °C. J. Mater. Res. 26(7), 934 (2011).

J-W. Nah, F. Ren, K-W. Paik, and K.N. Tu: Effect of electromigration on mechanical shear behavior of flip chip solder joints. J. Mater. Res. 21(03), 698 (2006).

V. Muthupandi, P. Bala Srinivasan, S.K. Seshadri, and S. Sundaresan: Effect of weld metal chemistry and heat input on the structure and properties of duplex stainless steel welds. Mater. Sci. Eng., A 358(1–2), 9 (2003).

M-L. Zhu, L-L. Liu, and F-Z. Xuan: Effect of frequency on very high cycle fatigue behavior of a low strength Cr–Ni–Mo–V steel welded joint. Int. J. Fatigue 77, 166 (2015).

N. Farabi, D.L. Chen, J. Li, Y. Zhou, and S.J. Dong: Microstructure and mechanical properties of laser welded DP600 steel joints. Mater. Sci. Eng., A 527(4–5), 1215 (2010).

K. Sugimoto, M. Kobayashi, and S. Yasuki: Cyclic deformation behavior of a transformation-induced plasticity-aided dual-phase steel. Metall. Mater. Trans. A 28(12), 2637 (1997).

Q.J. Wu, F.G. Lu, H.C. Cui, Y.M. Ding, X. Liu, and Y.L. Gao: Microstructure characteristics and temperature-dependent high cycle fatigue behavior of advanced 9% Cr/CrMoV dissimilarly welded joint. Mater. Sci. Eng., A 615, 98 (2014).

ASTM E466-07: Standard Practice for Conducting Force Controlled Constant Amplitude Axial Fatigue Tests of Metallic Materials (ASTM International: Philadelphia, 2007).

Q. Wu, F. Lu, H. Cui, X. Liu, P. Wang, and Y. Gao: Soft zone formation by carbon migration and its effect on the high-cycle fatigue in 9% Cr–CrMoV dissimilar welded joint. Mater. Lett. 141, 242 (2015).

J.A. Francis, W. Mazur, and H.K.D.H. Bhadeshia: Type IV cracking in ferritic power plant steels. Mater. Sci. Technol. 22(12), 1387 (2006).

Y. Murakami, N. Yokoyama, and J. Nagata: Mechanism of fatigue failure in ultralong life regime. Fatigue Fract. Eng. Mater. Struct. 25(8–9), 735 (2002).

T. Sakai: Review and prospects for current studies on very high cycle fatigue of metallic materials for machine structural use. J. Solid Mech. Mater. Eng. 3(3), 425 (2009).

K. Shiozawa, Y. Morii, S. Nishino, and L. Lu: Subsurface crack initiation and propagation mechanism in high-strength steel in a very high cycle fatigue regime. Int. J. Fatigue 28(11), 1521 (2006).

P. Grad, B. Reuscher, A. Brodyanski, M. Kopnarski, and E. Kerscher: Mechanism of fatigue crack initiation and propagation in the very high cycle fatigue regime of high-strength steels. Scr. Mater. 67(10), 838 (2012).

M-L. Zhu, F-Z. Xuan, and J. Chen: Influence of microstructure and microdefects on long-term fatigue behavior of a Cr–Mo–V steel. Mater. Sci. Eng., A 546, 90 (2012).

ACKNOWLEDGMENT

The authors gratefully acknowledge the financial supports by Shanghai Science and Technology Committee (No. 13DZ1101504).

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Shao, C., Lu, F., Li, Z. et al. Role of stress in the high cycle fatigue behavior of advanced 9Cr/CrMoV dissimilarly welded joint. Journal of Materials Research 31, 292–301 (2016). https://doi.org/10.1557/jmr.2015.398

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2015.398