Abstract

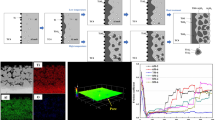

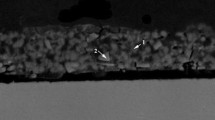

Recent advances in alumina ceramics are focused toward innovative processing routes to improve their mechanical reliability while retaining their superior wear resistance, which might be possible if a thin layer of dense alumina can be formed on a metallic substrate such as Ti–6Al–4V with high mechanical strength. For this purpose, we propose a new two-step process in which a dense layer of Al deposited on the Ti alloy by cold metal transfer method, formed a dense Al3Ti gradient reaction layer at their interface to improve adhesion in a single step. Subsequent micro-arc oxidation treatment transformed Al layer to a graded alumina layer in which γ-alumina decreased and α-alumina increased with increasing depth. Abrasion of outer regions revealed underlying pure α-alumina regions with high Vickers hardness matching with that of sintered alumina. The designed alumina/Ti alloy hybrid can be a potential candidate for wear resistance applications.

Similar content being viewed by others

References

M. Hamadouche, P. Boutin, J. Daussange, M.E. Bolander, and L. Sedel: Alumina-on-alumina total hip arthroplasty—A minimum 18.5-year follow-up study. J. Bone Joint. Surg. Am. 84A(1), 69–77 (2002).

L. Sedel: Clinical Applications of Ceramic–Ceramic Combinations in Joint Replacement, Bioceramics and Their Clinical Applications, T. Kokubo, ed. (Woohhead publishing limited, 2008); pp. 688–698.

I.C. Clarke, M. Manaka, D.D. Green, P. Williams, G. Pezzotti, Y.H. Kim, M. Ries, N. Sugano, L. Sedel, C. Delauney, B. Ben Nissan, T. Donaldson, and G.A. Gustafson: Current status of zirconia used in total hip implants. J. Bone Joint. Surg. Am. 85A, 73–84 (2003).

S. Begand, T. Oberbach, and W. Glien: Investigations of the mechanical properties of an alumina toughened zirconia ceramic for an application in joint prostheses. Key Eng. Mater. 17, 1019–1022 (2005).

W. Burger and H.G. Richter: High strength and toughness alumina matrix composites by transformation toughening and ‘in situ’ platelet reinforcement (ZPTA)—The new generation of bioceramics. Key Eng. Mater. 192–1, 545–548 (2000).

L.W. Hobbs, V.B. Rosen, S.P. Mangin, M. Treska, and G. Hunter: Oxidation microstructures and interfaces in the oxidized zirconium knee. Int. J. Appl. Ceram. Technol. 2(3), 221–246 (2005).

G.T. Evangelista, E. Fulkerson, E. Kummer, and P.E. Di Cesare: Surface damage to an oxinium femoral head prosthesis after dislocation. J. Bone. Joint Surg. Br. 89B(4), 535–537 (2007).

W.L. Jaffe, E.J. Strauss, M. Cardinale, L. Herrera, and F.J. Kummer: Surface oxidized zirconium total hip arthroplasty head damage due to closed reduction. J. Arthroplasty 24(6), 898–902 (2009).

R. Lappalainen, A. Anttila, and H. Heinonen: Diamond coated total hip replacements. Clin. Orthop. Relat. Res. 352, 118–127 (1998).

D. Choudhury, J.M. Lackner, L. Major, T. Morita, Y. Sawae, A. Bin Mamat, I. Stavness, C.K. Roy, and I. Krupka: Improved wear resistance of functional diamond like carbon coated Ti–6Al–4V alloys in an edge loading conditions. J. Mech. Behav. Biomed. Mater. 59, 586–595 (2016).

M.J. Pappas, G. Makris, and F.F. Buechel: Titanium nitride ceramic film against polyethylene—A 48-million cycle wear test. Clin. Orthop. Relat. Res. 317, 64–70 (1995).

R. Hauert, C.V. Falub, G. Thorwarth, K. Thorwarth, C. Affolter, M. Stiefel, L.E. Podleska, and G. Taeger: Retrospective lifetime estimation of failed and explanted diamond-like carbon coated hip joint balls. Acta Biomater. 8(8), 3170–3176 (2012).

M.T. Raimondi and R. Pietrabissa: The in vivo wear performance of prosthetic femoral heads with titanium nitride coating. Biomaterials 21(9), 907–913 (2000).

R. Khanna, T. Kokubo, T. Matsushita, Y. Nomura, N. Nose, Y. Oomori, T. Yoshida, and H. Takadama: Novel artificial hip joint: A layer of alumina on Ti–6Al–4V alloy formed by micro-arc oxidation. Mater. Sci. Eng., C 55, 393–400 (2015).

R. Khanna, T. Kokubo, T. Matsushita, and H. Takadama: Fabrication of dense α-alumina layer on Ti–6Al–4V alloy hybrid for bearing surfaces of artificial hip joint. Mater. Sci. Eng., C 69, 1229–1239 (2016).

M.A. Trunov, M. Schoenitz, X.Y. Zhu, and E.L. Dreizin: Effect of polymorphic phase transformations in Al2O3 film on oxidation kinetics of aluminum powders. Combust. Flame 140(4), 310–318 (2005).

S.L. Semiatin, V. Seetharaman, and I. Weiss: The thermomechanical processing of alpha/beta titanium alloys. J. Met. 49(6), 33 (1997).

L. Xu, Y.Y. Cui, Y.L. Hao, and R. Yang: Growth of intermetallic layer in multi-laminated Ti/Al diffusion couples. Mater. Sci. Eng., A 435, 638–647 (2006).

H.T. Zhang, J.C. Feng, P. He, B.B. Zhang, J.M. Chen, and L. Wang: The arc characteristics and metal transfer behaviour of cold metal transfer and its use in joining aluminium to zinc-coated steel. Mater. Sci. Eng., A 499, 111–113 (2009).

R. Cao, J.H. Sun, and J.H. Chen: Mechanisms of joining aluminium A6061-T6 and titanium Ti–6Al–4V alloys by cold metal transfer technology. Sci. Technol. Weld. Joining 18(5), 425–433 (2013).

Z.P. Cai, B.Q. Ai, R. Cao, Q. Lin, and J.H. Chen: Microstructure and properties of aluminum AA6061-T6 to copper (Cu)-T2 joints by cold metal transfer joining technology. J. Mater. Res. 31(18), 2876–2887 (2016).

R. Cao, Z. Feng, and J.H. Chen: Microstructures and properties of titanium-copper lap welded joints by cold metal transfer technology. Mater. Des. 53, 192–201 (2014).

G.P. Rajeev, M. Kamaraj, and S.R. Bakshi: Al–Si–Mn alloy coating on aluminum substrate using cold metal transfer (CMT) welding technique. JOM 66, 1061–1067 (2014).

L.R. Krishna, K.R.C. Somaraju, and G. Sundararajan: The tribological performance of ultra-hard ceramic composite coatings obtained through microarc oxidation. Surf. Coat. Technol. 163, 484–490 (2003).

G. Sundararajan and L.R. Krishna: Mechanisms underlying the formation of thick alumina coatings through the MAO coating technology. Surf. Coat. Technol. 167(2–3), 269–277 (2003).

A.L. Yerokhin, A. Shatrov, V. Samsonov, P. Shashkov, A. Pilkington, A. Leyland, and A. Matthews: Oxide ceramic coatings on aluminium alloys produced by a pulsed bipolar plasma electrolytic oxidation process. Surf. Coat. Technol. 199(2–3), 150–157 (2005).

L.R. Krishna, P. Gupta, and G. Sundararajan: The influence of phase gradient within the micro arc oxidation (MAO) coatings on mechanical and tribological behaviors. Surf. Coat. Technol. 269, 54–63 (2015).

M. Matsushima, M. Noda, T. Yoshida, H. Kato, G. Kalita, T. Kizuki, H. Uchida, M. Umeno, and K. Wakita: Formation of graphene nano-particle by means of pulsed discharge to ethanol. J. Appl. Phys. 113(11), 114304 (2013).

W.E. Borbidge, R.V. Allen, and P.T. Whelan: A review of the reaction bonding technique for joining ceramics to metals. J. Phys. 47(C-1), 131–137 (1986).

R. Khanna, T. Matsushita, T. Kokubo, and H. Takadama: formation of alumina layer on Ti alloy for artificial hip joint. Key Eng. Mater. 614, 200 (2014).

H. Pinto, A. Pyzalla, H. Hackl, and J. Bruckner: A comparative study of microstructure and residual stresses of CMT-, MIG- and laser-hybrid welds. Mater. Sci. Forum 524, 627–632 (2006).

ACKNOWLEDGMENTS

We would like to acknowledge the funding support from the Japan Society for the Promotion of Science (2412028). Author RK gratefully acknowledge assistance of colleagues from Indian Institute of Technology Madras, for carrying out the deposition of Al coatings on Ti alloys by CMT method and Takuya Yoshida for providing the bipolar power supply facility to conduct MAO experiments.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Khanna, R., Rajeev, G.P., Takadama, H. et al. Fabrication of dense alumina layer on Ti alloy hybrid by cold metal transfer and micro-arc oxidation methods. Journal of Materials Research 32, 3415–3424 (2017). https://doi.org/10.1557/jmr.2017.105

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2017.105