Abstract

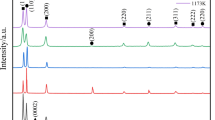

In the present study, hot deformation behavior of a FCC high-entropy alloy CoCuFeMnNi has been investigated to explore the stress—strain response for a wide range of temperatures and strain rates. The deformation response has been examined by plotting a processing map and examining the evolution of microstructure and texture in each of the temperature—strain rate domain. Hot compression tests were carried out in the temperature range 850–1050 °C at strain rates varying from 0.001 s−1 to 10 s−1. Stress—strain curves indicate characteristic softening behavior due to dynamic recrystallization (DRX). DRX has been observed along grain boundaries, shear bands, as well as in the interior of deformed grains. The size of dynamically recrystallized grains shows a strong dependence on deformation temperature and increases with temperature. A high degree of twin formation takes place in the DRX grains evolved inside the shear bands, and the extent of twinning decreases at high temperatures. The optimal processing window has been estimated based on strain rate sensitivity and has been validated with detailed analyses of microstructure and texture. The best region for thermo-mechanical processing has been identified as in the temperature range 850–950 °C at strain rate 10−1 s−1.

Similar content being viewed by others

References

D.B. Miracle, J.D. Miller, O.N. Senkov, C. Woodward, M.D. Uchic, and J. Tiley: Exploration and development of high entropy alloys for structural applications. Entropy 16, 494 (2014).

Y. Deng, C.C. Tasan, K.G. Pradeep, H. Springer, A. Kostka, and D. Raabe: Design of a twinning-induced plasticity high entropy alloy. Acta Mater. 94, 124 (2015).

B. Schuh, F. Mendez-Martin, B. Völker, E.P. George, H. Clemens, R. Pippan, and A. Hohenwarter: Mechanical properties, microstructure and thermal stability of a nanocrystalline CoCrFeMnNi high-entropy alloy after severe plastic deformation. Acta Mater. 96, 258 (2015).

G. Laplanche, A. Kostka, O.M. Horst, G. Eggeler, and E.P. George: Microstructure evolution and critical stress for twinning in the CrMnFeCoNi high-entropy alloy. Acta Mater. 118, 152 (2016).

Y. Zhang, T.T. Zuo, Z. Tang, M.C. Gao, K.A. Dahmen, P.K. Liaw, and Z.P. Lu: Microstructures and properties of high-entropy alloys. Prog. Mater. Sci. 61, 1 (2014).

R. Raghavan, K.C. Hari Kumar, and B.S. Murty: Analysis of phase formation in multi-component alloys. J. Alloys Compd. 544, 152 (2012).

B. Ren, Z.X. Liu, D.M. Li, L. Shi, B. Cai, and M.X. Wang: Effect of elemental interaction on microstructure of CuCrFeNiMn high entropy alloy system. J. Alloys Compd. 493, 148 (2010).

S. Guo, C. Ng, J. Lu, and C.T. Liu: Effect of valence electron concentration on stability of fcc or bcc phase in high entropy alloys. J. Appl. Phys. 109, 103505 (2011).

B. Cantor, I.T.H. Chang, P. Knight, and A.J.B. Vincent: Microstructural development in equiatomic multicomponent alloys. Mater. Sci. Eng., A 375–377, 213 (2004).

L.H. Wen, H.C. Kou, J.S. Li, H. Chang, X.Y. Xue, and L. Zhou: Effect of aging temperature on microstructure and properties of AlCoCrCuFeNi high-entropy alloy. Intermetallics 17, 266 (2009).

Y.Y. Chen, T. Duval, U.T. Hong, J.W. Yeh, H.C. Shih, L.H. Wang, and J.C. Oung: Corrosion properties of a novel bulk Cu0.5NiAlCoCrFeSi glassy alloy in 288 °C high-purity water. Mater. Lett. 61, 2692 (2007).

C.Y. Hsu, T.S. Sheu, J.W. Yeh, and S.K. Chen: Effect of iron content on wear behavior of AlCoCrFexMo0.5Ni high-entropy alloys. Wear 268, 653 (2010).

G.D. Sathiaraj, P.P. Bhattacharjee, C. Tsai, and J. Yeh: Effect of heavy cryo-rolling on the evolution of microstructure and texture during annealing of equiatomic CoCrFeMnNi high entropy alloy. Intermetallics 69, 1 (2016).

F. Otto, Y. Yang, H. Bei, and E.P. George: Relative effects of enthalpy and entropy on the phase stability of equiatomic high-entropy alloys. Acta Mater. 61, 2628 (2013).

Y.F. Ye, Q. Wang, J. Lu, C.T. Liu, and Y. Yang: The generalized thermodynamic rule for phase selection in multicomponent alloys. Intermetallics 59, 75 (2015).

Y. Zhang, T.T. Zuo, Z. Tang, M.C. Gao, K.A. Dahmen, P.K. Liaw, and Z.P. Lu: Microstructures and properties of high-entropy alloys. Prog. Mater. Sci. 61, 1–93 (2014).

K.Y. Tsai, M.H. Tsai, and J.W. Yeh: Sluggish diffusion in Co—Cr—Fe—Mn—Ni high-entropy alloys. Acta Mater. 61, 4887 (2013).

Z. Wang, W. Qiu, Y. Yang, and C.T. Liu: Atomic-size and lattice-distortion effects in newly developed high-entropy alloys with multiple principal elements. Intermetallics 64, 63 (2015).

N.P. Gurao and Biswas Krishanu, In the quest of single phase multi-component multiprincipal high entropy alloys. J. Alloys Compd. 697, 434 (2017).

R. Sonkusare, P. Divya Janani, N.P. Gurao, S. Sarkar, S. Sen, K.G. Pradeep, and K. Biswas: Phase equilibria in equiatomic CoCuFeMnNi high entropy alloy. Mater. Chem. Phys. (2017).

Biswas Krishanu and N. P. Gurao: Deciphering micro-mechanisms of plastic deformation in a novel single phase Fcc-based MnFeCoNiCu high entropy alloy using crystallographic texture. Mater. Sci. Eng. 657, 224 (2016).

S.M. Oh and S.I. Hong: Microstructural evolution and mechanical properties in a Mn1.05Fe1.05CoNiCu0.9 high entropy alloy. Key Eng. Mater. 737, 44 (2017).

Y.V.R.K. Prasad: Processing maps: A status report. J. Mater. Eng. Perform. 12, 638 (2003).

P. Zhang, C. Hu, C.G. Ding, Q. Zhu, and H.Y. Qin: Plastic deformation behavior and processing maps of a Ni-based superalloy. Mater. Des. 65, 575 (2015).

R.S. Kottada: Hot deformation behaviour and processing map of Co—Cu—Fe—Ni—Ti eutectic high entropy alloy. Mater. Sci. Eng., A 664, 227 (2016).

A. Chaudhuri, A. Sarkar, R. Kapoor, R.N. Singh, J.K. Chakravartty, and S. Suwas: Microstructural features of hot deformed Nb–1Zr–0.1C alloy. JOM 66, 1923 (2014).

A. Chaudhuri, A. Sarkar, and S. Suwas: Investigation of stress—strain response, microstructure and texture of hot deformed pure molybdenum. Int. J. Refract. Met. Hard Mater. 73, 168 (2018).

S. Roy and S. Suwas: The influence of temperature and strain rate on the deformation response and microstructural evolution during hot compression of a titanium alloy Ti–6Al–4V–0.1B. J. Alloys Compd. 548, 110 (2013).

R.R. Eleti, T. Bhattacharjee, L. Zhao, P.P. Bhattacharjee, and N. Tsuji: Hot deformation behavior of CoCrFeMnNi FCC high entropy alloy. Mater. Chem. Phys. 210, 176 (2018).

J.Y. He, C. Zhu, D.Q. Zhou, W.H. Liu, T.G. Nieh, and Z.P. Lu: Steady state flow of the FeCoNiCrMn high entropy alloy at elevated temperatures. Intermetallics 55, 9 (2014).

N.D. Stepanov, D.G. Shaysultanov, N.Y. Yurchenko, S.V. Zherebtsov, A.N. Ladygin, G.A. Salishchev, and M.A. Tikhonovsky: High temperature deformation behavior and dynamic recrystallization in CoCrFeNiMn high entropy alloy. Mater. Sci. Eng., A 636, 188 (2015).

K. Huang and R.E. Logé: A review of dynamic recrystallization phenomena in metallic materials. Mater. Des. 111, 548 (2016).

W. Gao, A. Belyakov, H. Miura, and T. Sakai: Dynamic recrystallization of copper polycrystals with different purities. Mater. Sci. Eng., A 265, 233 (1999).

M. Jafari, A. Najafizadeh, and J. Rasti: Dynamic recrystallization by necklace mechanism during hot deformation of 316 stainless steel. Int. J. ISSI 4, 16 (2008).

T. Sakai, A. Belyakov, R. Kaibyshev, H. Miura, and J.J. Jonas: Dynamic and post-dynamic recrystallization under hot, cold and severe plastic deformation conditions. Prog. Mater. Sci. 60, 130 (2014).

Suwas Satyam, and Nilesh P. Gurao, Crystallographic texture in Materials, J. Indian Inst. Sci. 88.2, 151 (2008).

S. Guha, S. Sangal, and S. Basu: A review of higher order strain gradient theories of plasticity: Origins, thermodynamics and connections with dislocation mechanics. Sadhana Acad. Proc. Eng. Sci. 40, 1205 (2015).

T. Abe and Y. Ono: Numerical study of grain rotation in polycrystalline metal during plastic deformation. Met. Mater. 4, 376 (1998).

E. Ghassemali, R. Sonkusare, K. Biswas, and N.P. Gurao: In situ study of crack initiation and propagation in a dual phase AlCoCrFeNi high entropy alloy. J. Alloys Compd. 710, 539–546 (2017).

Acknowledgment

This work was carried out as a part of project funded by Indo-Australian grant (AISRF), Grant No. DST/INT/AUS/P-72/2017. The authors acknowledge Advanced Facility for Microscopy and Microanalysis at the Indian Institute of Science, Bangalore, India, for providing the required research facilities and are also thankful to Mr. S. Sashidhara and Mr. Kantaraj for their assistance in conducting the deformation experiments.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Prasad, N., Bibhanshu, N., Nayan, N. et al. Hot deformation behavior of the high-entropy alloy CoCuFeMnNi. Journal of Materials Research 34, 744–755 (2019). https://doi.org/10.1557/jmr.2018.500

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2018.500