Abstract

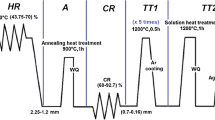

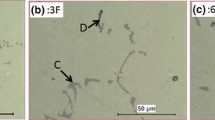

Fe–Al–O ODS alloy prepared via mechanical alloying was subjected to three different heat treatments. Material basic state exhibited a fine-grained (300–500 nm) microstructure with fine dispersion of aluminum oxide particles (60% up to 20 nm). Heat treatment at 1100 °C for 3 h resulted in local grain and particles coarsening. Prolongation of the heat treatment to 24 h resulted in further grain (50 % up to 5 μm) and particle (25 % with size 25–40 nm) coarsening. Annealing at 1200 °C for 24 h led to a bimodal microstructure (35 % of grains with size 100–250 μm and 45 % of particles with size 30–60 nm) and substantial oxide particle coarsening. Microstructural changes resulted in tensile strength decrease and ductility increase. Tensile tests at 800 °C revealed a 90% decrease of tensile strength while ductility increased 4–6 times when compared to the room temperature tests. The hardening ratio was below 10 % for all the alloys and both test temperatures.

Similar content being viewed by others

References

J.H. Lee: Development of oxide dispersion strengthened ferritic steels with and without aluminum. Front. Energy 6, 29–34 (2012).

M. Auger, T. Leguey, A. Munoz, M. Monge, V. de Castro, P. Fernandez, G. Garces, and R. Pareja: Microstructure and mechanical properties of ultrafine-grained Fe-14Cr and ODS Fe-14Cr model alloys. J. Nucl. Mater. 417, 213–216 (2011).

I. Kubena, B. Fournier, and T. Kruml: Effect of microstructure on low cycle fatigue properties of ODS steels. J. Nucl. Mater. 424, 101–108 (2012).

M. Palm: Concepts derived from phase diagram studies for the strengthening of Fe–Al-based alloys. Intermetallics 13, 1286–1295 (2005).

B.A.K.C.P. Sharma: Mechanical Behaviour and Testing of Materials (PHI Learning Private Limited, Delhi, 2011).

C. Zakine, C. Prioul, and D. François: Creep behaviour of ODS steels. Mater. Sci. Eng. A 219, 102–108 (1996).

J. Chao, R. Rementeria, M. Aranda, C. Capdevila, and J.L. Gonzalez-Carrasco: Comparison of ductile-to-brittle transition behavior in two similar ferritic oxide dispersion strengthened alloys. Materials 9, 637 (2016).

O. Khalaj, H. Jirková, T. Janda, L. Kučerová, T. Studecký, and J. Svoboda: Improving the high-temperature properties of a new generation of Fe-Al-O oxide-precipitation-hardened steels. Mater. Technol. 53, 495–504 (2019).

L. Wang, C. Song, F. Sun, L. Li, and Q. Zhai: Microstructure and mechanical properties of 12 wt.% Cr ferritic stainless steel with Ti and Nb dual stabilization. Mater. Des. 30, 49–56 (2009).

F. Siska, L. Stratil, H. Hadraba, S. Fintova, I. Kubena, T. Zalezak, and D. Bartkova: High temperature deformation mechanisms in the 14% Cr ODS alloy. Mater. Sci. Eng. A 689, 34–39 (2017).

L. Stratil, F. Siska, H. Hadraba, D. Bartkova, S. Fintova, and V. Puchy: Fracture behavior of the ODS steels prepared by internal oxidation. Fusion Eng. Des. 124, 1108–1111 (2017).

D. Kumar, U. Prakash, V.V. Dabhade, K. Laha, and T. Sakthivel: Development of oxide dispersion strengthened (ODS) ferritic steel through powder forging. J. Mater. Eng. Perform. 26, 1817–1824 (2017).

B. Mašek, O. Khalaj, Z. Nový, T. Kubina, J. Jirkova, J. Svoboda, and C. Štádler: Behaviour of new ODS alloys under single and multiple deformation. Mater. Technol. 50, 891–898 (2016).

D. Bártková, M. Šmíd, B. Mašek, J. Svoboda, and F. Šiška: Kinetic study of static recrystallization in an Fe–Al–O ultra-fine-grained nanocomposite. Philos. Mag. Lett. 97, 379–385 (2017).

J. Svoboda, V. Horník, L. Stratil, H. Hadraba, B. Mašek, O. Khalaj, and H. Jirková: Microstructure evolution in ODS alloys with a high-volume fraction of nano oxides. Metals 8, 1079 (2018).

A. Kelly and R. Nicholson: Strengthening Methods in Crystals (Elsevier Pub. Co., Amsterdam; New York, 1971).

F. Siska, L. Stratil, H. Hadraba, S. Fintova, I. Kubena, V. Hornik, R. Husak, D. Bartkova, and T. Zalezak: Strengthening mechanisms of different oxide particles in 9Cr ODS steel at high temperatures. Mater. Sci. Eng. A 732, 112–119 (2018).

Acknowledgment

This research has been financially supported by the Ministry of Education, Youth and Sports of the Czech Republic under the project CEITEC 2020 (LQ1601).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Fintová, S., Kuběna, I., Luptáková, N. et al. Development of advanced Fe–Al–O ODS alloy microstructure and properties due to heat treatment. Journal of Materials Research 35, 2789–2797 (2020). https://doi.org/10.1557/jmr.2020.278

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2020.278