Abstract

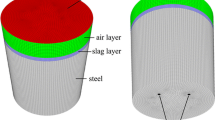

A 1/6th water physical model of a 140 tons gas-stirred steel ladle is used to evaluate mixing times (τm at 95% of chemical uniformity) in a two phase system without slag (air-water) and in a more realistic three phase system (air-water-oil) to simulate the argon-steel-slag system and quantify the effect of the slag layer on the mixing time. Slag layer is kept constant at 0.004 m. Mixing times are estimated through measured changes in pH due to the addition of a tracer (NaOH 1 M). The effect of the following variables on the mixing time is evaluated for a single injector: gas flow rate (7, 17 y 37 l/min) and the injector position (R/r= 0, 1/3, ½, 2/3 and 4/5). Experimental results obtained in this work show good agreement when compared against mixing time correlations reported by Mazumdar for the two phase air-water case (no slag considered). Another comparison is done using the new concept called “effective bath height” proposed by Barati, where the mixing time is a function of the size of the slag layer since this layer dissipates part of the total amount of stirring energy introduced into the ladle by the injection of gas. Agreement is not good in this case. Finally, an estimation of the percentage of the stirring energy dissipated by the slag is computed, including other factors that govern the dissipation of stirring energy. Percentage of energy dissipated by the slag is found to be between 2.7 to 12 % depending on the process conditions.

Similar content being viewed by others

References

D. Mazumdar and R. Guthrie, “The physical and mathematical modelling of gas stirred ladle Systems,” ISIJ int. 35 No.1, 1 (1995).

D. Mazumdar and J. W. Evans: Macroscopic models for gas stirred ladles, ISIJ Int. 44 No.3, 447 (2004).

J. W. Han, S. H. Heo, D. H. Kam, B. D. You J. J. Pak and H. S. Song: Transient fluid flow phenomena in a gas stirred liquid bath with top oil layer-approach by numerical simulation and water model experiments, ISIJ Int., 41 No. 10, 1165 (2001).

K. Krishnapisharody and G. A. Irons, “Modeling of slag eye formation over a metal bath due to gas bubbling,” Metall. Trans., 37B, 763 (2006).

P. Dayal, K. Beskow, J. Björkvall and D. Sichen, “Study of slag/metal interface in ladle treatment,” Ironmaking & Steelmaking, 33, No.6, 454 (2006).

M. Thunman, S. Eckert, O. Hennig, J. Björkvall and D. Sichen, “Study on the formation of open-eye and slag entrainment in gas stirred ladle,” Steel research int. 78 No. 12, 849 (2007).

L. T. Khajavi and M. Barati, “Liquid mixing in thick-slag-covered metallurgical baths-blending of bath,” Metall. Trans., 41B, 86 (2010).

D. Mazumdar and R. I. L. Guthrie, “Modeling Energy Dissipation in slag-covered steel baths in steelmaking ladles,” Metall. Trans., 41B, 976 (2010).

Y. Kishimoto, Y. Sheng, G. A. Irons and Jen-Shih Chang: “Energy dissipation distribution in gas-stirred liquids”, ISIJ Int. 39 No.2, 113 (1999).

A. M. Amaro-Villeda, J. A. González, M. A. Ramírez-Argáez: “Experimental study in gas-stirred ladles with and without the slag phase trough a water physical model,” Mater. Res. Soc. Symp. Proc. Vol. 1373, 155 (2012).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Amaro-Villeda, A.M., Conejo, A. & Ramírez-Argáez, M.A. Effect of Slag on Mixing Time in Gas-Stirred Ladles Assisted with a Physical Model. MRS Online Proceedings Library 1485, 15–20 (2012). https://doi.org/10.1557/opl.2013.256

Published:

Issue Date:

DOI: https://doi.org/10.1557/opl.2013.256