Abstract

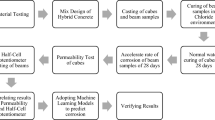

The goal of this study was to determine the effects of model nuclear waste glass composition on the corrosion of Monofrax® K-3 refractory, using machine learning (ML) methods for data investigation and modeling of published borosilicate glass composition data and refractory corrosion performance. First, statistical methods were used for exploration of the data, and the list of features (model terms) was determined. Several model types were explored, and the Bayesian Ridge type was the most promising due to low mean average error and mean standard error as well as high R2 value. Parameters and model results using previously identified model features and those from this study are compared. ML methods appear to give results at least as good as previously available models for describing the effects of glass composition on refractory corrosion.

Graphic Abstract

Similar content being viewed by others

Data availability

Data will be made available on reasonable request.

Notes

Monofrax® is a trademark of the GmbH & Co. KG of Vienna, Austria.

Python™ is a trademark of the Python Software Foundation Montreal, Quebec, Canada.

References

I.S. Muller, K. Gilbo, M. Chaudhuri, I.L. Pegg, I. Joseph, “Final Report: K-3 Refractory Corrosion and Sulfate Solubility Model Enhancement,” Vitreous State Laboratory at the Catholic University of America (US), VSL-18R4360–1, 2018. https://doi.org/10.2172/1513833

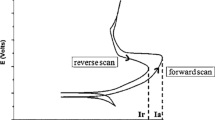

C.M. Jantzen, K.J. Imrich, K.G. Brown, J.B. Pickett, High chrome refractory characterization: part I. Impact of melt reduction/oxidation on the corrosion mechanism. Int. J. Appl. Glass Sci. 6(2), 137–157 (2015). https://doi.org/10.1111/ijag.12105

K. Selkregg, Fusion cast refractories: roles of containment. Am. Ceram. Soc. Bull. 97, 21–28 (2018)

P.A. Bingham, A.J. Connelly, N.C. Hyatt, R.J. Hand, Corrosion of glass contact refractories for the vitrification of radioactive wastes: a review. Int. Mater. Rev. 56(4), 226–242 (2011). https://doi.org/10.1179/1743280410Y.0000000005

M. Hubert, Industrial Glass Processing and Fabrication (Springer International Publishing, Cham, 2019), pp. 1195–1231. https://doi.org/10.1007/978-3-319-93728-1_34

M.E. Smith, “Conceptual Methods for Decontamination and Decommissioning, Size Reduction, and Disposal of the DWPF Melter and Components,” Savannah River Site (US), WSRC-TR-2001–00248, 2001. https://doi.org/10.2172/782041

X.D. Lu, H. Gan, A.C. Buechele, I.L. Pegg, Corrosion of K-3 glass-contact refractory in sodium-rich aluminosilicate melts. MRS Proc. (1999). https://doi.org/10.1557/PROC-556-279

ASTM, Test Method for Isothermal Corrosion Resistance of Refractories to Molten Glass (ASTM International, West Conshohocken, PA, 2018). https://doi.org/10.1520/C0621-09R18

“NumPy—NumPy.” https://numpy.org/.

“SciPy.org—SciPy.org.” https://www.scipy.org/.

“1. Supervised learning—scikit-learn 0.22.1 documentation.” https://scikit-learn.org/stable/supervised_learning.html#supervised-learning.

“pandas—Python Data Analysis Library.” https://pandas.pydata.org/.

J.E. Shelby, Introduction to Glass Science and Technology, 2nd edn. (Royal Society of Chemistry, Cambridge, 2005).

A.K. Varshneya, J.C. Mauro, Fundamentals of Inorganic Glasses (Elsevier, San Diego, 2019).

I.S. Muller, K.S. Matlack, I.L. Pegg, I. Joseph, “Enhanced LAW Glass Correlation—Phase 1,” Vitreous State Laboratory at the Catholic University of America (US), VSL-16R4000-1, 2016. https://doi.org/10.2172/1347604

I.S. Muller, A. Buechele, I.L. Pegg, X. Xie, I. Joseph, “Final Report: Improved High-Alkali Low-Activity Waste Formulations,” Vitreous State Laboratory at the Catholic University of America (US), VSL-15R3290–1, 2015. https://doi.org/10.2172/1529004

I.S. Muller, K.S. Matlack, I.L. Pegg, I. Joseph, “Final Report: Enhanced LAW Glass Correlation - Phase 3,” Vitreous State Laboratory at the Catholic University of America (US), VSL-17R4230–1, 2017. https://doi.org/10.2172/1512925

I.S. Muller et al., “Final Report: Baseline LAW Glass Formulation Testing,” Vitreous State Laboratory at the Catholic University of America (US), VSL-03R3460–1, 2003. https://doi.org/10.2172/1186012

“Standard Scaler Transformation.” https://scikit-learn.org/stable/modules/generated/sklearn.preprocessing.StandardScaler.html.

R.M. Sakia, The box-cox transformation technique: a review. Journal of the Royal Statistical Society Series D (The Statistician) 41(2), 169–178 (1992). https://doi.org/10.2307/2348250

C. Fischer, Comparing the logarithmic transformation and the box-cox transformation for individual tree basal area increment models. For. Sci. 62(3), 297–306 (2016). https://doi.org/10.5849/forsci.15-135

A.S. Hadi, A.H.M.R. Imon, M. Werner, Detection of outliers. WIREs Comput. Stat. 1(1), 57–70 (2009). https://doi.org/10.1002/wics.6

T. Chai, R.R. Draxler, Root mean square error (RMSE) or mean absolute error (MAE)? Arguments against avoiding RMSE in the literature. Geosci. Model Dev. 7(3), 1247–1250 (2014). https://doi.org/10.5194/gmd-7-1247-2014

“Linear Models.” https://scikit-learn.org/stable/modules/linear_model.html#bayesian-ridge-regression.

C.M. Bishop, Pattern Recognition and Machine Learning (Springer, New York, 2006).

“Bayesian Ridge Regression.” https://scikit-learn.org/stable/auto_examples/linear_model/plot_bayesian_ridge.html.

Y. Zhang, C. Ling, A strategy to apply machine learning to small datasets in materials science. npi Comput. Mater. 4(1), 1–8 (2018). https://doi.org/10.1038/s41524-018-0081-z

Acknowledgements

The authors thank Will Eaton, Dong-Sang Kim, and Jorge Perez for useful discussions regarding this work. Comments from an anonymous reviewer greatly improved the manuscript. This research was supported by the Department of Energy Waste Treatment and Immobilization Plant Federal Project Office, contract number 89304017CEM000001, under the direction of Dr. Albert A. Kruger.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

John McCloy was an editor of this journal during the review and decision stage. For the MRS Advances policy on review and publication of manuscripts authored by editors, please refer to mrs.org/editor-manuscripts.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Smith-Gray, N.J., Sargin, I., Beckman, S. et al. Machine learning to predict refractory corrosion during nuclear waste vitrification. MRS Advances 6, 131–137 (2021). https://doi.org/10.1557/s43580-021-00031-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/s43580-021-00031-2