Abstract

Stretchable electronics represent an emerging class of devices that can be compressed, twisted and conform to very complicated shapes. The mechanical and electrical compliances of the technology promise to open up applications for healthcare, energy and entertainment purposes. However, advancement in the field has been hindered by material related constraints. Moreover, the current microfabrication facilities are optimized for rigid substrates such as silicon, which have significant different properties compared to elastomers. In this paper, four categories of enabling technologies for stretchable electronics commercialization are critically reviewed, namely: the novel design of stretchable structures, use of non-conventional materials, state-of-art printing techniques and also the patterning of electrodes or metal interconnects via conventional manufacturing techniques.

Similar content being viewed by others

References

Chortos, A. & Bao, Z. Skin-inspired electronic devices. Mater. Today 17, 321–331 (2014).

Kim, D.-H., Ghaffari, R., Lu, N. & Rogers, J. A. Flexible and Stretchable Electronics for Biointegrated Devices. Annu. Rev. Biomed. Eng. 14, 113–128 (2012).

Lacour, S. P. et al. Flexible and stretchable micro-electrodes for in vitro and in vivo neural interfaces. Med Biol Eng Comput 48, 945–54 (2010).

Lee, J. H., Kim, H., Kim, J. H. & Lee, S.-H. Soft implantable microelectrodes for future medicine: prosthetics, neural signal recording and neuromodulation. Lab Chip 16, 959–976 (2016).

Chortos, A., Liu, J. & Bao, Z. Pursuing prosthetic electronic skin. Nat. Mater. 15, 937–950 (2016).

Liu, Y. et al. Epidermal mechano-acoustic sensing electronics for cardiovascular diagnostics and human-machine interfaces. Sci. Adv. 2, 1–12 (2016).

Fan, F. R., Tang, W. & Wang, Z. L. Flexible Nanogenerators for Energy Harvesting and Self-Powered Electronics. Adv. Mater. 28, 4283–4305 (2016).

Kim, C.-C. et al. Highly stretchable, transparent ionic touch panel. Science 353, 682–7 (2016).

Marketsandmarkets.com. Stretchable Electronics Market by Component - 2023. (2015). Available at: http://www.marketsandmarkets.com/Market-Reports/stretchable-electronic-market-181339852.html. (Accessed: 6th December 2016)

Future Markets, inc. Nanotechnology in Smart Textiles and Wearables, Medical and Healthcare. (2016). Available at: http://www.reportlinker.com/p04422604-summary/Nanotechnology-in-Smart-Textiles-and-Wearables.html.(Accessed: 6th December 2016)

Pailler-Mattei, C., Bec, S. & Zahouani, H. In vivo measurements of the elastic mechanical properties of human skin by indentation tests. Med. Eng. Phys. 30, 599–606 (2008).

Kim, D.-H. et al. Materials for multifunctional balloon catheters with capabilities in cardiac electrophysiological mapping and ablation therapy. Nat. Mater. 10, 316–23 (2011).

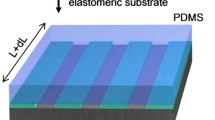

Khang, D.-Y., Jiang, H., Huang, Y. & Rogers, J. A. A Stretchable Form of Single-Crystal Silicon for High-Performance Electronics on Rubber Substrates. Science 311, 208–212 (2006).

Kim, J. et al. Stretchable silicon nanoribbon electronics for skin prosthesis. Nat. Commun. 5, 5747 (2014).

Gao, L. et al. Optics and Nonlinear Buckling Mechanics in Large-Area, Highly Stretchable Arrays of Plasmonic Nanostructures. ACS Nano 9, 5968–5975 (2015).

Liu, Z. F. et al. Hierarchically buckled sheath-core fibers for superelastic electronics, sensors, and muscles. Science. 349, (2015).

Fruett, F. The Piezojunction Effect in Silicon, its Consequences and Applications for Integrated Circuits and Sensors. (Delft University Press, Delft, 2001).

Lacour, S. P., Jones, J., Wagner, S., Li, T. & Suo, Z. Stretchable Interconnects for Elastic Electronic Surfaces. Proceedings of the IEEE 93, 1459–1466 (2005).

Kim, D.-H. et al. Materials and noncoplanar mesh designs for integrated circuits with linear elastic responses to extreme mechanical deformations. Proc. Natl. Acad. Sci. U. S. A. 105, 18675–80 (2008).

Vanfleteren, J. et al. Printed circuit board technology inspired stretchable circuits. MRS Bull. 37, 254–260 (2012).

Fan, J. A. et al. Fractal design concepts for stretchable electronics. Nat. Commun. 5, 3266 (2014).

T. Someya, editor, Stretchable Electronics (WILEY-VCH Verlag GmbH & Co. KGaA,Weinheim, 2013).

Young Oh, J. et al. Intrinsically stretchable and healable semiconducting polymer for organic transistors. Nat. Publ. Gr. 539, (2016).

Benight, S. J., Wang, C., Tok, J. B. H. & Bao, Z. Stretchable and self-healing polymers and devices for electronic skin. Progress in Polymer Science 38, 1961–1977 (2013).

Mohammed, A. & Pecht, M. A stretchable and screen-printable conductive ink for stretchable electronics. Appl. Phys. Lett. 109, 184101 (2016).

Matsuhisa, N. et al. Printable elastic conductors with a high conductivity for electronic textile applications. Nat. Commun. 6, 7461 (2015).

Jin, S. W., Park, J., Hong, S. Y., Park, H. & Jeong, Y. R. Stretchable Loudspeaker using Liquid Metal Microchannel. Nat. Publ. G r. 5, 1–13 (2000).

Li, G., Wu, X. & Lee, D.-W. A galinstan-based inkjet printing system for highly stretchable electronics with self-healing capability. Lab Chip 16, 1366–1373 (2016).

Gao, Y., Shi, W., Wang, W., Leng, Y. & Zhao, Y. Inkjet Printing Patterns of Highly Conductive Pristine Graphene on Flexible Substrates. Ind. Eng. Chem. Res. 53, 16777–16784 (2014).

Chun, K.-Y. et al. Highly conductive, printable and stretchable composite films of carbon nanotubes and silver. Nat. Nanotechnol. 5, 853–857 (2010).

Sekiguchi, A. et al. Robust and Soft Elastomeric Electronics Tolerant to Our Daily Lives. Nano Lett. 15, 5716–5723 (2015).

Seifert, T. et al. Additive Manufacturing Technologies Compared: Morphology of Deposits of Silver Ink Using Inkjet and Aerosol Jet Printing. Ind. Eng. Chem. Res. 54, 769–779 (2015).

Krebs, F. C. Fabrication and processing of polymer solar cells: A review of printing and coating techniques. Solar Energy Materials and Solar Cells 93, 394–412 (2009).

Tekin, E., Smith, P. J. & Schubert, U. S. Inkjet printing as a deposition and patterning tool for polymers and inorganic particles. Soft Matter 4, 703–713 (2008).

Castrejón-Pita, J. R. et al. Future, opportunities and challenges of inkjet technologies. At. Sprays 23, 541–565 (2013).

Kim, J. et al. Highly Transparent and Stretchable Field-Effect Transistor Sensors Using Graphene-Nanowire Hybrid Nanostructures. Adv. Mater. 27, 3292–3297 (2015).

Kaltenbrunner, M. et al. An ultra-lightweight design for imperceptible plastic electronics. Nature 499, 458–463 (2013).

Optomec. Aerosol Jet 300 Series Systems - Datasheet. (2015). Available at: http://www.optomec.com/wp-content/uploads/2014/04/AJ-300-Datasheet_Web.pdf. (Accessed: 4th August 2016)

Cho, J. H. et al. Printable ion-gel gate dielectrics for low-voltage polymer thin-film transistors on plastic. Nat. Mater. 7, 900–906 (2008).

Grunwald, I. et al. Surface biofunctionalization and production of miniaturized sensor structures using aerosol printing technologies. Biofabrication 2, 014106 (2010).

Ha, M. et al. Aerosol jet printed, low voltage, electrolyte gated carbon nanotube ring oscillators with sub-5 μs stage delays. Nano Lett. 13, 954–960 (2013).

Tait, J. G. et al. Uniform Aerosol Jet printed polymer lines with 30 μm width for 140 ppi resolution RGB organic light emitting diodes. Org. Electron. physics, Mater. Appl. 22, 40–43 (2015).

Wang, K., Chang, Y. H., Zhang, C. & Wang, B. Conductive-on-demand: Tailorable polyimide/carbon nanotube nanocomposite thin film by dual-material aerosol jet printing. Carbon N. Y. 98, 397–403 (2016).

Liu, R. et al. Fabrication of platinum-decorated single-walled carbon nanotube based hydrogen sensors by aerosol jet printing. Nanotechnology 23, 505301 (2012).

Guo, L. & Deweerth, S. P. An effective lift-off method for patterning high-density gold interconnects on an elastomeric substrate. Small 6, 2847–2852 (2010).

Adrega, T. & Lacour, S. P. Stretchable gold conductors embedded in PDMS and patterned by photolithography: fabrication and electromechanical characterization. J. Micromechanics Microengineering 20, 055025 (2010).

Chou, N. et al. Crack-free and reliable lithographical patterning methods on PDMS substrate. J. Micromechanics Microengineering 23, 125035 (2013).

Lee, J. N., Park, C. & Whitesides, G. M. Solvent Compatibility of Poly(dimethylsiloxane)-Based Microfluidic Devices. Anal. Chem. 75, 6544–6554 (2003).

Patel, J. N., Kaminska, B., Gray, B. L. & Gates, B. D. A sacrificial SU-8 mask for direct metallization on PDMS. J. Micromechanics Microengineering 19, 115014 (2009).

Jeong, D.-W., Jang, N.-S., Kim, K.-H. & Kim, J.-M. A stretchable sensor platform based on simple and scalable lift-off micropatterning of metal nanowire network. RSC Adv. 6, 74418– 74425 (2016).

Meacham, K. W., Giuly, R. J., Guo, L., Hochman, S. & DeWeerth, S. P. A lithographically-patterned, elastic multi-electrode array for surface stimulation of the spinal cord. Biomed. Microdevices 10, 259–269 (2008).

Franssila, S. Introduction to Microfabrication Introduction to Microfabrication Second Edition. (John Wiley & Sons, Ltd, Chichester, 2010).

Minev, I. R. et al. Electronic dura mater for long-term multimodal neural interfaces. Science. 347, (2015).

Gong, S. et al. A wearable and highly sensitive pressure sensor with ultrathin gold nanowires. Nat. Commun. 5, 838–843 (2014).

Viventi, J. et al. Flexible, foldable, actively multiplexed, high-density electrode array for mapping brain activity in vivo. Nat. Neurosci. 14, 1599–605 (2011).

Song, Y. M. et al. Digital cameras with designs inspired by the arthropod eye. Nature 497, 95– 99 (2013).

Byun, I., Coleman, A. W. & Kim, B. Transfer of thin Au films to polydimethylsiloxane (PDMS) with reliable bonding using (3-mercaptopropyl)trimethoxysilane (MPTMS) as a molecular adhesive. J. Micromech. Microeng 23, 85016–10 (2013).

Deng, W. et al. A High-yield Two-step Transfer Printing Method for Large-scale Fabrication of Organic Single-crystal Devices on Arbitrary Substrates. Sci. Rep. 4, 4772–4776 (2014).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Tan, E., Jing, Q., Smith, M. et al. Needs and Enabling Technologies for Stretchable Electronics Commercialization. MRS Advances 2, 1721–1729 (2017). https://doi.org/10.1557/adv.2017.2

Published:

Issue Date:

DOI: https://doi.org/10.1557/adv.2017.2