Abstract

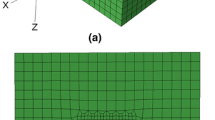

This study reports on the anisotropic indentation response of α-titanium. Coarse-grained titanium was characterized by electron backscatter diffraction. Sphero-conical nanoindentation was performed for a number of different crystallographic orientations. The grain size was much larger than the size of the indents to ensure quasi-single-crystal indentation. The hexagonal c-axis was determined to be the hardest direction. Surface topographies of several indents were measured by atomic force microscopy. Analysis of the indent surfaces, following Zambaldi and Raabe (Acta Mater. 58(9), 3516–3530), revealed the orientation-dependent pileup behavior of α-titanium during axisymmetric indentation. Corresponding crystal plasticity finite element (CPFE) simulations predicted the pileup patterns with good accuracy. The constitutive parameters of the CPFE model were identified by a nonlinear optimization procedure, and reproducibly converged toward easy activation of prismatic glide systems. The calculated critical resolved shear stresses were 150 ± 4, 349 ± 10, and 1107 ± 39 MPa for prismatic and basal 〈a〉-glide and pyramidal〈c + a〉-glide, respectively.

Similar content being viewed by others

References

C. Zambaldi and D. Raabe: Plastic anisotropy of gamma-TiAl revealed by axisymmetric indentation. Acta Mater. 58, 3516 (2010).

G. Lütjering and J.C. Williams: Titanium (Engineering Materials and Processes) (Springer, Berlin, Germany, 2007).

T.R. Bieler, R.M. Trevino, and L. Zeng: Alloys: Titanium, in Encyclopedia of Condensed Matter Physics (Elsevier, Oxford, 2005), pp. 65–76.

F.P.E. Dunne, A. Walker, and D. Rugg: A systematic study of hcp crystal orientation and morphology effects in polycrystal deformation and fatigue. Proc. R. Soc. London, Sect. A 463, 1467 (2007).

X. Wu, S. Kalidindi, C. Necker, and A. Salem: Modeling anisotropic stress-strain response and crystallographic texture evolution in alpha-titanium during large plastic deformation using Taylor-type models: Influence of initial texture and purity. Metall. Mater. Trans. A 39, 3046 (2008).

L. Wang, R. Barabash, Y. Yang, T. Bieler, M. Crimp, P. Eisenlohr, W. Liu, and G. Ice: Experimental characterization and crystal plasticity modeling of heterogeneous deformation in polycrystalline alpha-Ti. Metall. Mater. Trans. A 42, 626 (2011).

W. Hutchinson and M. Barnett: Effective values of critical resolved shear stress for slip in polycrystalline magnesium and other hcp metals. Scr. Mater. 63, 737 (2010).

T. Ungár, G. Ribárik, L. Balogh, A.A. Salem, S.L. Semiatin, and G.B. Vaughan: Burgers vector population, dislocation types and dislocation densities in single grains extracted from a polycrystalline commercial-purity Ti specimen by X-ray line-profile analysis. Scr. Mater. 63, 69 (2010).

C.J. Bettles, P.A. Lynch, A.W. Stevenson, D. Tomus, M.A. Gibson, K. Wallwork, and J. Kimpton: In situ observation of strain evolution in CP-Ti over multiple length scales. Metall. Mater. Trans. A 42, 100 (2010).

T.R. Bieler, P.D. Nicolaou, and S.L. Semiatin: An experimental and theoretical investigation of the effect of local colony orientations and misorientation on cavitation during hot working of Ti-6Al-4V. Metall. Mater. Trans. A 36, 129 (2005).

T.B. Britton, S. Birosca, M. Preuss, and A.J. Wilkinson: Electron backscatter diffraction study of dislocation content of a macrozone in hot-rolled Ti-6Al-4V alloy. Scr. Mater. 62, 639 (2010).

Y. Yang, L. Wang, T. Bieler, P. Eisenlohr, and M.A. Crimp: Quantitative atomic force microscopy characterization and crystal plasticity finite element modeling of heterogeneous deformation in commercial purity titanium. Metall. Mater. Trans. A 42, 636 (2011).

T. Bieler, P. Eisenlohr, F. Roters, D. Kumar, D. Mason, M. Crimp, and D. Raabe: The role of heterogeneous deformation on damage nucleation at grain boundaries in single phase metals. Int. J. Plast. 25, 1655 (2009).

S. Zaefferer: A study of active deformation systems in titanium alloys: Dependence on alloy composition and correlation with deformation texture. Mater. Sci. Eng., A 344, 20 (2003).

P. Franciosi and A. Zaoui: Multislip in f.c.c. crystals a theoretical approach compared with experimental data. Acta Metall. 30, 1627 (1982).

P. Franciosi: The concepts of latent hardening and strain-hardening in metallic single-crystals. Acta Metall. 33, 1601 (1985).

A.T. Churchman: The slip modes of titanium and the effect of purity on their occurrence during tensile deformation of single crystals. Proc. R. Soc. London, Ser. A 226, 216, http://www.jstor.org/stable/99430 (1954).

N.E. Paton and W.A. Backofen: Plastic deformation of titanium at elevated temperatures. Metall. Trans. B 1, 2839 (1970).

T. Sakai and M.E. Fine: Plastic-deformation of Ti-Al single-crystals in prismatic slip. Acta Metall. 22, 1359 (1974).

A. Akhtar: Basal slip and twinning in alpha-titanium single-crystals. Metall. Trans. A 6, 1105 (1975).

M.P. Biget and G. Saada: Low-temperature plasticity of high-purity alpha-titanium single-crystals. Philos. Mag. A 59, 747 (1989).

J.C. Williams, R.G. Baggerly, and N.E. Paton: Deformation behavior of HCPTi-Al alloy single crystals. Metall. Mater. Trans. A 33, 837 (2002).

D. Raabe, D. Ma, and F. Roters: Effects of initial orientation, sample geometry and friction on anisotropy and crystallographic orientation changes in single crystal microcompression deformation: A crystal plasticity finite element study. Acta Mater. 55, 4567 (2007).

L. Wang, P. Eisenlohr, Y. Yang, T. Bieler, and M. Crimp: Nucleation of paired twins at grain boundaries in titanium. Scr. Mater. 63, 827 (2010).

I.J. Beyerlein, L. Capolungo, P.E. Marshall, R.J. McCabe, and C.N. Tome: Statistical analyses of deformation twinning in magnesium. Philos. Mag. 90, 4073 (2010).

F. Roters: Application of crystal plasticity fem from single crystal to bulk polycrystal. Comput. Mater. Sci. 32, 509 (2005).

F. Roters, P. Eisenlohr, L. Hantcherli, D.D. Tjahjanto, T.R. Bieler, and D. Raabe: Overview of constitutive laws, kinematics, homogenization, and multiscale methods in crystal plasticity finite element modeling: Theory, experiments, applications. Acta Mater. 58, 1152 (2010).

S.R. Kalidindi, C.A. Bronkhorst, and L. Anand: Crystallographic texture evolution in bulk deformation processing of fcc metals. J. Mech. Phys. Solids 40, 537 (1992).

E.H. Lee: Elastic-plastic deformation at finite strains. J. Appl. Mech. 36, 1 (1969).

J. Hutchinson: Bounds and self-consistent estimates for creep of polycrystalline materials. Proc. R. Soc. London, Ser. A 348, 101 (1976).

D. Peirce, R.J. Asaro, and A. Needleman: Material rate dependence and localized deformation in crystalline solids. Acta Metall. 31, 1951 (1983).

R.J. Asaro and A. Needleman: Overview 42. Texture development and strain-hardening in rate dependent polycrystals. Acta Metall. 33, 923 (1985).

D. Peirce, R.J. Asaro, and A. Needleman: An analysis of nonuniform and localized deformation in ductile single-crystals. Acta Metall. 30, 1087 (1982).

M.S.C. Software: MARC2010, Volume D—User Subroutines and Special Routines. MSC.Software Corp. (2010).

A.K. Bhattacharya and W.D. Nix: Finite-element simulation of indentation experiments. Int. J. Solids Struct. 24, 881 (1988).

Y. Liu, B. Wang, M. Yoshino, S. Roy, H. Lu, and R. Komanduri: Combined numerical simulation and nanoindentation for determining mechanical properties of single crystal copper at mesoscale. J. Mech. Phys. Solids 53, 2718 (2005).

G. Simmons and H. Wang: Single Crystal Elastic Constants and Calculated Aggregate Properties: A Handbook (MIT Press, Cambridge, MA, 1971).

J. Nelder and R. Mead: A simplex method for function minimization. Comput. J. 7, 308 (1965).

W. Press, S. Teukolsky, W. Vetterling, and B. Flannery: Numerical Recipes C++ (Cambridge University Press, Cambridge, U.K., 2007).

M. Grujicic and S. Batchu: A crystal plasticity materials constitutive model for polysynthetically-twinned gamma-TiAl+alpha(2)-Ti3Al single crystals. J. Mater. Sci. 36, 2851 (2001).

Gwyddion: Free AFM Data Analysis Software. http://gwyddion.net (2004–2009).

G. Viswanathan, E. Lee, D.M. Maher, S. Banerjee, and H.L. Fraser: Direct observations and analyses of dislocation substructures in the alpha-phase of an alpha/beta Ti-alloy formed by nanoindentation. Acta Mater. 53, 5101 (2005).

E. Merson, R. Brydson, and A. Brown: The effect of crystallographic orientation on the mechanical properties of titanium. J. Phys Conf. Ser. 126, 1 (2008).

Y. Lee, J. Hahn, S. Nahm, J. Jang, and D. Kwon: Investigations on indentation size effects using a pile-up corrected hardness. J. Phys. D: Appl. Phys. 41, 074027 (2008).

K. Tsuya: Effect of temperature on hardness anisotropy of beryllium single crystals. J. Nucl. Mater. 22, 148 (1967).

C. Zambaldi: Micromechanical Modeling of γ-TiAl Based Alloys, Dissertation RWTH Aachen (Shaker Verlag, Aachen, Germany, 2010), http://darwin.bth.rwth-aachen.de/opus3/volltexte/2011/3607/.

Y. Gaillard, A.H. Macías, J. Muñoz-Saldaña, M. Anglada, and G. Trápaga: Nanoindentation of BaTiO3: Dislocation nucleation and mechanical twinning. J. Phys. D 42, 085502 (2009).

Q. Yu, Z. Shan, J. Li, X. Huang, L. Xiao, J. Sun, and E. Ma: Strong crystal size effect on deformation twinning. Nature 463, 335 (2010).

Y. Liu, S.V.J. Ma, M.Y.H. Lu, and R. Komanduri: Orientation effects in nanoindentation of single crystal copper. Int. J. Plast. 24, 1990 (2008).

G. Bolzon, G. Maier, and M. Panico: Material model calibration by indentation, imprint mapping and inverse analysis. Int. J. Solids Struct. 41, 2957 (2004).

M. Bocciarelli, G. Bolzon, and G. Maier: Parameter identification in anisotropic elastoplasticity by indentation and imprint mapping. Mech. Mater. 37, 855 (2005).

A. Yonezu, Y. Kuwahara, K. Yoneda, H. Hirakata, and K. Minoshima: Estimation of the anisotropic plastic property using single spherical indentation—An FEM study. Comput. Mater. Sci. 47, 611 (2009).

J. Gong and A.J. Wilkinson: Anisotropy in the plastic flow properties of single-crystal α-titanium determined from micro-cantilever beams. Acta Mater. 57, 5693 (2009).

E. Demir, D. Raabe, N. Zaafarani, and S. Zaefferer: Investigation of the indentation size effect through the measurement of the geometrically necessary dislocations beneath small indents of different depths using EBSD tomography. Acta Mater. 57, 559 (2009).

G. Pharr, E. Herbert, and Y. Gao: The indentation size effect: A critical examination of experimental observations and mechanistic interpretations. Annu. Rev. Mater. Res. 40, 271 (2010).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zambaldi, C., Yang, Y., Bieler, T.R. et al. Orientation informed nanoindentation of α-titanium: Indentation pileup in hexagonal metals deforming by prismatic slip. Journal of Materials Research 27, 356–367 (2012). https://doi.org/10.1557/jmr.2011.334

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2011.334