Abstract

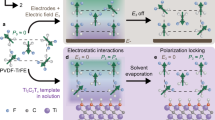

Flexible piezoelectric generators (PEGs) present a unique opportunity for renewable and sustainable energy harvesting. Here, we present a low-temperature and low-energy deposition method using solvent evaporation-assisted three-dimensional printing to deposit electroactive poly (vinylidene fluoride) (PVDF)-trifluoroethylene (TrFE) up to 19 structured layers. Visible-wavelength transmittance was above 92%, while ATR-FTIR spectroscopy showed little change in the electroactive phase fraction between layer depositions. Electroactivity from the fabricated PVDF-TrFE PEGs showed that a single structured layer gave the greatest output at 289.3 mV peak-to-peak voltage. This was proposed to be due to shear-induced polarization affording the alignment of the fluoropolymer dipoles without an electric field or high temperature.

Similar content being viewed by others

References

Z.L. Wang, G. Zhu, Y. Yang, S.H. Wang, and C.F. Pan: Progress in nano-generators for portable electronics. Mater. Today 15, 532 (2012).

C.R. Bowen, J. Taylor, E. LeBoulbar, D. Zabek, A. Chauhan, and R. Vaish: Pyroelectric materials and devices for energy harvesting applications. Energy Environ. Sci. 7, 3836 (2014).

C.R. Bowen, H.A. Kim, P.M. Weaver, and S. Dunn: Piezoelectric and ferroelectric materials and structures for energy harvesting applications. Energy Environ. Sci. 7, 25 (2014).

J. Li, L. Kang, Y.H. Yu, Y. Long, J.J. Jeffery, W.B. Cai, and X.D. Wang: Study of long-term biocompatibility and bio-safety of implantable nano-generators. Nano Energy 51, 728 (2018).

Y.H. Yu, H.Y. Sun, H. Orbay, F. Chen, C.G. England, W.B. Cai, and X.D. Wang: Biocompatibility and in vivo operation of implantable mesopo-rous PVDF-based nanogenerators. Nano Energy 27, 275 (2016).

K.S. Ramadan, D. Sameoto, and S. Evoy: A review of piezoelectric polymers as functional materials for electromechanical transducers. Smart Mater. Struct. 23, 033001 (2014).

P. Martins, A.C. Lopes, and S. Lanceros-Mendez: Electroactive phases of poly(vinylidene fluoride): determination, processing and applications. Prog. Polym.Sci. 39, 683 (2014).

M.Y. Li, I. Katsouras, C. Piliego, G. Glasser, I. Lieberwirth, P.W.M. Blom, and D.M. de Leeuw: Controlling the microstructure of poly(vinylidene-fluoride) (PVDF) thin films for microelectronics. J. Mater. Chem., 2 7695 (2013).

V. Bhavanasi, V. Kumar, K. Parida, J.X. Wang, and P.S. Lee: Enhanced piezoelectric energy harvesting performance of flexible PVDF-TrFE bilayer films with graphene oxide. ACSAppi. Mater. Interfaces 8, 521 (2016).

S. Rajala, M. Schouten, G. Krijnen, and S. Tuukkanen: High bending-mode sensitivity of printed piezoelectric poly(vinylidenefluoride-co-trifluoroethylene) sensors. ACS Omega 3, 8067 (2018).

G. Eberle, H. Schmidt, and W. Eisenmenger: Piezoelectric polymer elec-trets. IEEE Trans. Dielectr. Electr. Insul. 3, 624 (1996).

T. Soulestin, V. Ladmiral, F.D. Dos Santos, and B. Ameduri: Vinylidene fluoride- and trifluoroethylene-containing fluorinated electroactive copolymers. How does chemistry impact properties? Prog. Polym. Sci. 72, 16 (2017).

Y. Ito and K. Uchino: Piezoelectricity. In Encyclopedia of RF and Microwave Engineering, edited by K. Chang (John Wiley & Sons, Inc., Hoboken, New Jersey, 2005), p. 480.

X. Chen, H.O.T. Ware, E. Baker, W. Chu, J. Hu, and C. Sun: The development of an all-polymer-based piezoelectric photocurable resin for additive manufacturing. Procedia CIRP 65, 157 (2017).

M. Fortunato, R.C. Chandraiahgari, G. De Bellis, P. Ballirano, F. Sarto, A. Tamburrano, and S.M. Sarto: Piezoelectric effect and electroactive phase nucleation in self-standing films of unpoled PVDF nanocomposite films. Nanomaterials 8, 743 (2018).

S.K. Ghosh and D. Mandal: Synergistically enhanced piezoelectric output in highly aligned 1D polymer nanofibers integrated all-fiber nano-generator for wearable nano-tactile sensor. Nano Energy 53, 245 (2018).

C. Lee and J.A. Tarbutton: Electric poling-assisted additive manufacturing process for PVDF polymer-based piezoelectric device applications. Smart Mater. Struct. 23, 095044 (2014).

H. Kim, F. Torres, Y. Wu, D. Villagran, Y. Lin, and T.-L. Tseng: Integrated 3D printing and corona poling process of PVDF piezoelectric films for pressure sensor application. Smart Mater. Struct. 26, 085027 (2017).

S. Bodkhe, G. Turcot, F.P. Gosselin, and D. Therriault: One-step solvent evaporation-assisted 3D printing of piezoelectric PVDF nanocomposite structures. ACSAppi. Mater. Interfaces 9, 20833 (2017).

G. Postiglione, G. Natale, G. Griffini, M. Levi, and S. Turri: Conductive 3D microstructures by direct 3D printing of polymer/carbon nanotube nano-composites via liquid deposition modeling. Compos. Part A: Appl. Sci. Manuf 76, 110 (2015).

A. Bottino, G. Capannelli, S. Munari, and A. Turturro: Solubility parameters of poly(vinylidene fluoride). J. Polym. Sci., Part B: Polym. Lett. 26, 785 (1988).

L. Yu and P. Cebe: Crystal polymorphism in electrospun composite nanofibers of poly(vinylidene fluoride) with nanoclay. Polymer 50, 2133 (2009).

S.V. Murphy and A. Atala: 3D bioprinting of tissues and organs. Nat. Biotechnol. 32, 773 (2014).

S.C. Ligon, R. Liska, J. Stampfl, M. Gurr, and R. Mülhaupt: Polymers for 3D printing and customized additive manufacturing. Chem. Rev. 117, 10212 (2017).

X.M. Cai, T.P. Lei, D.H. Sun, and L.W. Lin: A critical analysis of the alpha, beta and gamma phases in poly(vinylidene fluoride) using FTIR. RSC Adv. 7, 15382 (2017).

S. Barrau, A. Ferri, A. Da Costa, J. Defebvin, S. Leroy, R. Desfeux, and J.M. Lefebvre: Nanoscale investigations of alpha- and gamma-crystal phases in PVDF-based nanocomposites. ACS Appl. Mater. Interfaces 10, 13092 (2018).

R. Gregorio and M. Cestari: Effect of crystallization temperature on the crystalline phase content and morphology of poly(vinylidene fluoride). J. Polym. Sci., Part B: Polym. Lett. 32, 859 (1994).

J.H. Yang, T. Ryu, Y. Lansac, Y.H. Jang, and B.H. Lee: Shear stress-induced enhancement of the piezoelectric properties of PVDF-TrFE thin films. Org. Electron. 28, 67 (2016).

A. Gebrekrstos, M. Sharma, G. Madras, and S. Bose: Critical insights into the effect of shear, shear history, and the concentration of a diluent on the polymorphism in poly(vinylidene fluoride). Cryst. Growth Des. 17, 1957 (2017).

Acknowledgments

This research was supported by the Australian Government through the Australian Research Council’s Linkage Projects funding scheme (LP160100071) and Future Fellowships funding scheme (FT130100211). This work was performed in part at the Materials Characterisation and Fabrication Platform (MCFP) at the University of Melbourne and the Victorian Node of the Australian National Fabrication Facility (ANFF).

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

43579_2019_9010159_MOESM1_ESM.pdf

3D Printing of Poly(vinylidene fluoride-trifluoroethylene): a Poling-Free Technique to Manufacture Flexible and Transparent Piezoelectric Generators

Supplementary material

Supplementary material

The supplementary material for this article can be found at https://doi.org/10.1557/mrc.2019.19.

Rights and permissions

About this article

Cite this article

Shepelin, N.A., Lussini, V.C., Fox, P.J. et al. 3D printing of poly(vinylidene fluoride-trifluoroethylene): a poling-free technique to manufacture flexible and transparent piezoelectric generators. MRS Communications 9, 159–164 (2019). https://doi.org/10.1557/mrc.2019.19

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/mrc.2019.19